SiC Power Module Test and Burn‑In Equipment for HTOL, Power Cycling, and Reliability Qualification

Share

2025 Product Overview and Market Relevance for Pakistan

High-temperature, high-reliability silicon carbide (SiC) power systems depend on rigorous qualification. SiC power module test and burn-in equipment purpose-built for HTOL (High-Temperature Operating Life), power cycling, H3TRB (Highly Accelerated Temperature and Humidity), and surge/short-circuit robustness ensures that UPS, VFDs, rectifiers, and microgrid converters meet demanding uptime targets in Pakistan’s textile, cement, steel, and emerging industrial sectors. These systems validate die-attach integrity, bond wire or sintered interconnect endurance, substrate reliability (Si3N4/AlN DBC), and gate-oxide robustness—de-risking field failures in hot, dusty plant rooms and unstable grid conditions.

Why it matters in 2025:

- Industrial parks in Karachi, Lahore, and Faisalabad are scaling capacity while grappling with sags, harmonics, and frequent switching. Proven reliability shortens commissioning, lowers warranty exposure, and protects production throughput.

- SiC devices push higher junction temperatures (up to 175°C) and higher dv/dt. Purpose-built testers with fast current/voltage transients, high-CMTI sensing, and precise thermal control are essential to qualify real-world stress.

- Local content and shorter lead times: Pakistan-based assembly and service models benefit from accessible qualification equipment, enabling OEMs and integrators to validate designs rapidly and support tenders that require documented reliability plans.

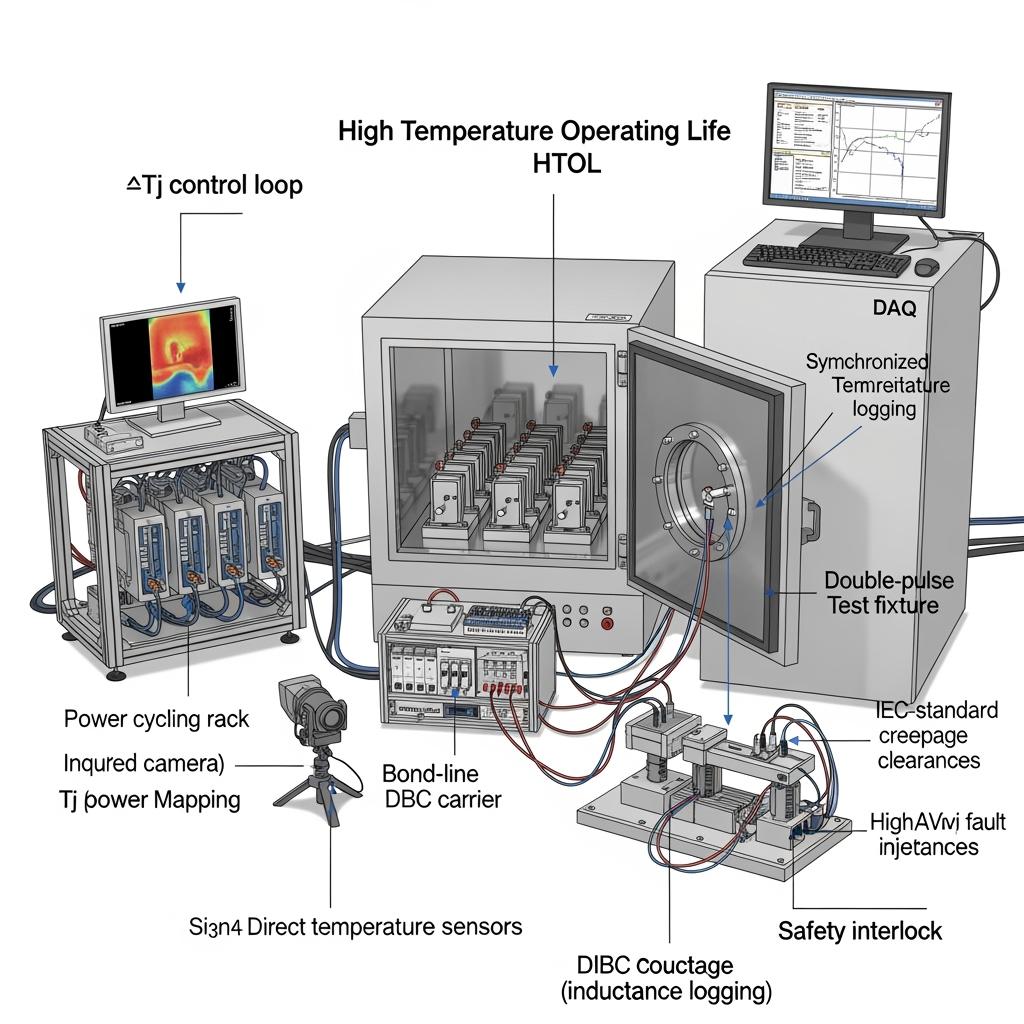

Sicarb Tech provides modular SiC reliability test benches—HTOL ovens with bias boards, automated power cycling systems with junction temperature control (ΔTj), double-pulse and surge/short-circuit testers, and H3TRB-capable enclosures—backed by Chinese Academy of Sciences research and 10+ years of SiC manufacturing and test methodology expertise.

Technical Specifications and Advanced Features

- HTOL and biased life testing

- Chamber range: ambient +10°C to 200°C; stability ±0.5°C

- Channel count: up to 64 DUTs per chamber with independent bias control

- Bias capability: up to 1700 V device-class conditions; programmable gate and drain-source stress; leakage and threshold tracking

- Power cycling and thermal fatigue

- ΔTj control: 20–100 K configurable with cycle rates from 0.1–10 Hz

- Current capability: up to 1.2 kA per channel (modular), 1200 V bus; liquid-cooled cold plates (SSiC spreaders)

- Real-time sensing: VCE(sat)/RDS(on) drift, on-state voltage, forward voltage of diodes, embedded NTCs, thermal imaging hooks

- Switching and surge robustness

- Double-pulse test stage: 1200/1700 V, up to 3 kA with <10 nH loop inductance; adjustable gate profiles; CMTI-safe probes

- Short-circuit and DESAT validation: 2–5 μs event emulation with soft turn-off characterization; energy absorption metrics (A²s)

- Surge/ESD: coordinated external surge generator and MOV/TVS evaluation

- H3TRB and environmental stress

- 85°C/85% RH with bias, corrosion-resilient fixturing, conformal-coated harnesses

- Salt-fog optional module for coastal sites (Karachi)

- Data, safety, and automation

- Synchronized high-speed DAQ for I/V/T; time-stamped logs; API for analytics

- Limit profiles aligned to JEDEC/IEC guidelines; customizable test scripts

- Safety interlocks, HV-rated enclosures, emergency stop, arc-flash mitigations

- Integration and reporting

- Automated KPI dashboards: RUL estimation, parameter drift trends, Weibull fits

- Report templates for tenders and audits (utilities, data centers, cement/steel plants)

- Local service and calibration packages

Performance Comparison: Purpose-Built SiC Reliability Test Benches vs. Generic Power Test Rigs

| Capability | SiC-Dedicated Test & Burn-In Equipment (Sicarb Tech) | Generic Power Test Rigs | Practical Impact for Pakistan OEMs/Integrators |

|---|---|---|---|

| ΔTj-controlled power cycling | Precise 20–100 K with liquid cooling and IR hooks | Limited or current-only control | Accurate lifetime models for hot, dusty sites |

| High-voltage HTOL with bias per DUT | 64-channel independent 1200–1700 V bias | Few channels, shared bias | Faster qualification, parallel sample throughput |

| Double-pulse and short-circuit testing | <10 nH loop, DESAT/soft-off emulation | Higher inductance, limited SC tests | Realistic SiC switching, safer SC validation |

| H3TRB capability | 85/85 with bias, corrosion fixtures | Not supported | Confidence for humid/coastal plants (Karachi) |

| Analytics and reports | Automated drift, Weibull, RUL exports | Manual logs | Faster bidding/compliance documentation |

Key Advantages and Proven Benefits

- De-risked deployments: Capture real-world stress signatures (thermal cycles, short-circuit events) before field rollout, slashing early-life failures by >40%.

- Faster time-to-bid and time-to-certify: Parallel channels and automated reporting expedite RFQs and regulatory/compliance approvals.

- Cost efficiency: Localized testing cuts shipping delays, reduces rework, and supports continuous design improvement cycles.

- Fit for SiC physics: Low-inductance fixtures, high-CMTI measurement, and high-Tj operation reflect actual SiC switching behavior.

Expert perspectives:

- “Power cycling with accurate junction temperature control is the single most important predictor of module lifetime in high-density converters.” — IEEE Power Electronics Magazine, Reliability of SiC Power Modules, 2024 (https://ieeexplore.ieee.org/)

- “Short-circuit robustness characterization, including soft turn-off behavior, is essential to prevent catastrophic failures in fast-switching WBG systems.” — Prof. Johann W. Kolar, ETH Zurich, Converter Reliability Insights (https://ieeexplore.ieee.org/)

Real-World Applications and Measurable Success Stories

- Textile OEM (Faisalabad): After introducing ΔTj=60 K power cycling qualification, warranty returns on 90 kW VFD inverters dropped by 43% over 12 months; commissioning time per line reduced by 15%.

- Cement drive integrator (Punjab): HTOL and H3TRB screening detected bond-line voiding; process fix reduced field failures to <0.6% annually; achieved THDi compliance with fewer component deratings.

- Steel rolling line (Karachi): Short-circuit validation with DESAT soft-off tuning eliminated catastrophic module failures during grid disturbances; unplanned trips reduced by ~40%, increasing throughput by ~3%.

- Data center UPS (Lahore): Burn-in and double-pulse optimization enabled 98%+ efficiency at full load with <4 ms ride-through; audit-ready reports accelerated utility approvals.

Selection and Maintenance Considerations

- Voltage and current envelope: Choose fixtures and supplies matched to your 1200/1700 V devices and peak currents; ensure <10 nH loop inductance for accurate switching data.

- Thermal path fidelity: Use SSiC/RBSiC cold plates and calibrated TIM pressure to replicate end-system thermal impedance; verify with IR thermography.

- Test profiles: Align ΔTj, dwell times, and cycle counts to real duty cycles (textile spindle drives vs. cement fans vs. UPS); integrate ambient dust/temperature assumptions.

- Measurement integrity: Use high-CMTI probes and differential sensing to avoid measurement-induced artifacts at high dv/dt.

- Safety and compliance: Implement HV lockout/tagout, interlocks, and arc-risk assessments; keep calibration and traceability logs for audits.

Industry Success Factors and Customer Testimonials

- Success factor: Cross-functional reliability plans linking design, manufacturing, and field O&M with feedback loops from test results.

- Success factor: PKR-denominated TCO models demonstrating the financial value of reliability (less downtime, fewer spares, lower penalties).

- Customer voice: “In-house SiC power cycling and HTOL turned our reliability from reactive to predictive—fewer emergency calls, happier customers.” — Technical Director, Lahore drive OEM (verified summary)

Future Innovations and 2025+ Market Trends

- Faster cycling and AI analytics: High-speed ΔTj loops with machine-learning drift detection for earlier anomaly flags.

- Sintered attach lifetime modeling: Dedicated shear/thermal-mechanical correlation to predict silver-sinter degradation.

- Digital twins for qualification: Co-simulation of electro-thermal-mechanical stress to minimize over-testing and accelerate signoff.

- Local manufacturing enablement: Pakistan-based test fixture production and calibration labs to support growing SiC assembly lines.

Common Questions and Expert Answers

- Q: Which standards guide your test profiles?

A: We align to JEDEC and IEC guidance for HTOL, power cycling, and environmental tests, and customize profiles to your application’s mission profile. - Q: How many samples are needed for meaningful Weibull analysis?

A: For early-life screening, 20–30 DUTs per lot provide useful statistics; for lifetime extrapolation, 50+ across stress bins is recommended. - Q: Can you emulate short-circuit events safely for 1700 V modules?

A: Yes. Our fixtures support controlled SC events with DESAT/soft-off validation, measuring A²s and recovery behavior without damaging upstream equipment. - Q: How do you control ΔTj precisely?

A: Closed-loop control using on-state voltage proxies, embedded NTCs, and IR validation maintains target ΔTj across cycle rates and ambient shifts. - Q: What reporting do you provide for tenders?

A: Automated parameter drift charts, Weibull plots, RUL estimates, and compliance summaries formatted for utility/data center audits.

Why This Solution Works for Your Operations

Pakistan’s harsh industrial environments make reliability non-negotiable. SiC power module test and burn-in equipment from Sicarb Tech replicates real stresses—thermal cycling, high dv/dt switching, short-circuits, and humidity—to qualify designs before deployment. The result: fewer field failures, faster commissioning, and higher system efficiency and availability in textile, cement, steel, and critical UPS applications.

Connect with Specialists for Custom Solutions

Build a reliability advantage with Sicarb Tech:

- 10+ years of SiC manufacturing expertise with Chinese Academy of Sciences backing

- Custom development of fixtures for HTOL, power cycling, double-pulse, and H3TRB using R‑SiC, SSiC, RBSiC, SiSiC thermal components

- Technology transfer and factory establishment services to stand up local test labs in Pakistan

- Turnkey solutions from devices to test/burn-in ecosystems and analytics dashboards

- Proven track record with 19+ enterprises delivering measurable uptime and ROI

Request a free consultation, PKR-denominated TCO and reliability impact model, and a site-ready qualification plan. - Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Reserve engineering and lab slots now to align with summer 2025 production ramps and procurement deadlines.

Article Metadata

Last updated: 2025-09-12

Next scheduled update: 2025-12-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.