Mastering Homogeneity: A Deep Dive into SiC Powder Mixing Equipment for Advanced Industrial Applications

Share

The journey from raw silicon carbide (SiC) powder to high-performance ceramic components is a meticulous process, demanding precision at every stage. Among these crucial steps, the effective and uniform mixing of SiC powders, often with various binders and sintering aids, stands as a cornerstone for achieving desired material properties and final product quality. For engineers, procurement managers, and technical buyers in sectors like semiconductors, high-temperature processing, aerospace, energy, and industrial manufacturing, understanding the nuances of SiC powder mixing equipment is paramount. This blog post delves into the critical aspects of this equipment, exploring its significance, types, advantages, and considerations for selecting the right technology and supplier to ensure the production of superior custom silicon carbide products and technical ceramics.

The consistency and performance of the final SiC component, be it a seal, bearing, nozzle, or a sophisticated semiconductor wafer processing part, are intrinsically linked to the homogeneity of the initial powder blend. Inadequate mixing can lead to a host of problems, including density variations, inconsistent microstructures, reduced mechanical strength, and unpredictable thermal or electrical properties. As industries increasingly demand SiC components with tighter tolerances and enhanced performance characteristics, the role of advanced SiC powder mixing equipment becomes even more critical. This equipment is designed to ensure that each particle of SiC and any additives are evenly distributed, creating a uniform feedstock essential for subsequent forming and sintering processes. The goal is to produce a homogeneous powder mix that translates into reliable and high-quality advanced ceramic components.

At Sicarb Tech , we’ve been at the forefront of SiC production technology since 2015, deeply involved in the evolution of China’s SiC customizable parts manufacturing hub in Weifang City. This region, now home to over 40 SiC production enterprises, accounts for more than 80% of the nation’s total SiC output. Our journey has allowed us to witness and contribute to the technological advancements in product processes, including the vital stage of powder preparation. We understand that the foundation of a superior SiC product lies in the quality of its initial mix.

Introduction to SiC Powder Mixing and its Industrial Significance

Silicon carbide (SiC) is renowned for its exceptional properties: high hardness, excellent thermal conductivity, low thermal expansion, superior wear resistance, and chemical inertness at elevated temperatures. These characteristics make it an indispensable material for demanding applications. However, to fully harness these properties in a finished technical ceramic component, the manufacturing process must begin with a perfectly prepared SiC powder blend. SiC powder mixing, also known as ceramic powder blending, is the process of combining SiC powder (often of varying particle sizes) with other powders, such as sintering aids (e.g., boron, carbon, alumina, yttria), binders (e.g., PVA, PEG), lubricants, and other property-modifying additives.

The industrial significance of precise SiC powder mixing cannot be overstated. It directly impacts:

- Product Uniformity: Ensures consistent density and microstructure throughout the component, eliminating weak spots or areas of differing performance. This is crucial for high-performance ceramic components that must withstand extreme conditions.

- Mechanical Properties: Homogeneous distribution of sintering aids facilitates uniform grain growth and densification during sintering, leading to enhanced strength, toughness, and hardness.

- Thermal and Electrical Properties: Consistent distribution of SiC particles and any conductive or insulating additives ensures predictable thermal shock resistance, thermal conductivity, and electrical behavior.

- Dimensional Stability: Uniform shrinkage during drying and sintering, resulting from a homogeneous mix, leads to better dimensional control and tighter tolerances in the final custom SiC parts.

- Production Efficiency: Reduces rejects and rework, leading to lower manufacturing costs and improved yield. High-quality SiC raw material processing at the mixing stage pays dividends later.

Types of SiC Powder Mixing Equipment and Their Mechanisms

Selecting the appropriate SiC powder mixing equipment depends on various factors, including the scale of production, the characteristics of the powders being mixed (particle size, density, flowability), the desired level of homogeneity, and whether the process is wet or dry. Different mixers employ distinct mechanisms to achieve particle intermingling.

Here’s an overview of common types of industrial powder mixers suitable for ceramic powder blending, particularly for SiC:

| Mixer Type | Mixing Mechanism | Typical Batch Size | Wet/Dry Mixing | Key Advantages | Considerations |

|---|---|---|---|---|---|

| V-Blenders | Tumbling, Splitting & Combining | Small to Large | Dry | Gentle mixing, easy to clean, good for free-flowing powders. | Can have dead spots, less effective for cohesive powders or large particle size differences. |

| Double Cone Blenders | Tumbling | Small to Large | Dry | Gentle, low shear, suitable for delicate materials, good discharge. | Similar limitations to V-blenders for cohesive powders. |

| Ribbon Blenders | Convective (Ribbons move material in multiple directions) | Medium to Large | Dry & Wet | Good for cohesive powders, can handle large volumes, relatively short mixing times. | Higher shear than tumblers, can generate heat, more complex to clean. |

| Paddle Blenders | Convective (Paddles lift and fold material) | Medium to Large | Dry & Wet | Similar to ribbon blenders, can be more aggressive, effective for pastes. | Higher shear, cleaning can be challenging. |

| Planetary Mixers | Agitators rotate on their own axes while orbiting a central axis | Small to Medium | Wet & Dry | High shear, excellent for dispersing agglomerates, good for viscous slurries. | More complex, higher cost, batch operation primarily. |

| Attritor Mills | Agitation of grinding media | Small to Medium | Wet | Very fine dispersion, deagglomeration, can achieve nanoscale mixing. | High energy consumption, media wear can introduce contamination, typically for wet milling/mixing. |

| Ball Mills | Cascading and Cataracting action of grinding media | Small to Large | Wet & Dry | Simple, effective for grinding and mixing, can handle hard materials. | Long mixing times, potential for media contamination, batch process. |

| High-Shear Mixers (Rotor-Stator) | High-speed rotor draws material into a stator, creating intense shear | Small to Medium | Wet | Rapid mixing, excellent for emulsions and dispersions, deagglomeration. | High energy input, can generate heat, primarily for liquid-based systems. |

The mechanism of mixing is crucial.

- Diffusion Mixing (Tumbling): Occurs when particles roll over each other in a rotating vessel (e.g., V-blenders, Double Cone Blenders). It’s gentle and suitable for free-flowing powders where particle segregation isn’t a major concern.

- Convection Mixing: Involves the bulk movement of groups of particles from one location to another within the mixer, often using blades, ribbons, or paddles (e.g., Ribbon Blenders, Paddle Blenders). This is more effective for cohesive powders or mixtures with disparate particle sizes.

- Shear Mixing: Occurs when forces are applied that cause layers of material to slide relative to each other. High-shear mixers (e.g., Planetary Mixers, High-Shear Rotor-Stator Mixers, Attritors) are excellent for breaking down agglomerates and achieving fine dispersions, especially in SiC slurry preparation.

For SiC powders, which can be abrasive, the material of construction for the mixer and any internal components is also a vital consideration to prevent wear and contamination. Stainless steel is common, but for ultra-high purity applications or highly abrasive scenarios, ceramic linings or components might be necessary. Sicarb Tech supports local enterprises with such advanced process technologies, ensuring that the equipment and methods used are optimized for the specific SiC grades and applications.

Key Advantages of Advanced SiC Powder Mixing Technologies

Investing in advanced SiC powder mixing technologies offers significant advantages that translate directly to improved product quality, operational efficiency, and ultimately, a stronger competitive edge in the technical ceramics manufacturing landscape. These technologies go beyond simple blending; they aim for microscopic homogeneity and process control, which are essential for today’s demanding SiC applications.

Key advantages include:

- Enhanced Homogeneity and Dispersion:

- Modern mixers, especially those employing high shear or complex convective patterns, ensure a more uniform distribution of SiC particles and additives. This is critical when dealing with small percentages of sintering aids or binders, where even minor non-uniformity can drastically affect the final sintered properties.

- Effective deagglomeration of fine SiC powders, which tend to clump together, leads to a more reactive surface area for sintering and more uniform densification.

- Improved Product Consistency and Reliability:

- Consistent batch-to-batch mixing ensures that every SiC component produced meets the specified performance criteria. This reduces variability in mechanical strength, thermal conductivity, and electrical resistivity.

- Reliable custom SiC parts are a direct outcome of predictable material behavior, which starts with a consistent powder mix.

- Greater Control Over Particle Characteristics:

- Some advanced mixing systems, like attritors or specialized wet milling equipment, can simultaneously mix and modify particle size distribution. This allows for finer control over the powder characteristics before forming.

- Maintaining the integrity of delicate additives or avoiding excessive particle comminution (breakdown) can be achieved through precise control of mixing energy and duration.

- Increased Efficiency and Reduced Processing Time:

- Optimized mixing cycles can reduce the time required to achieve the desired level of homogeneity, boosting throughput.

- Efficient mixing can also lead to better flowability of the powder, which can improve the efficiency of downstream processes like die filling in pressing operations or slurry stability in casting.

- Scalability and Process Automation:

- Many advanced mixing systems are designed for scalability, allowing manufacturers to transition from laboratory-scale development to full-scale production with consistent results.

- Integration with process analytical technology (PAT) and automation features allows for real-time monitoring and control of mixing parameters, ensuring quality and reducing operator dependency.

- Reduced Material Waste and Contamination:

- Well-designed mixers minimize dead spots where material can stagnate, ensuring complete incorporation of all ingredients and reducing waste.

- Selection of appropriate construction materials and sealed designs minimizes the risk of external contamination or cross-contamination between batches, crucial for high-purity SiC applications like those in the semiconductor industry.

Sicarb Tech champions the adoption of such advanced technologies. Our deep understanding of the entire SiC production chain, from material science to final component testing, allows us to guide our partners in selecting and implementing mixing solutions that deliver tangible benefits. We believe that superior SiC production technology starts with meticulous control at the powder stage.

Critical Parameters in SiC Powder Mixing for Optimal Results

Achieving an optimal, homogeneous SiC powder mix is not merely about choosing the right equipment; it’s about understanding and controlling the critical parameters that govern the mixing process. These parameters interact in complex ways, and their precise management is key to unlocking the full potential of the SiC material and ensuring the success of subsequent manufacturing steps. For technical procurement professionals and engineers, specifying these parameters or understanding their impact is crucial when sourcing ceramic processing machinery or developing a SiC raw material processing strategy.

The most critical parameters include:

- Powder Characteristics:

- Particle Size and Distribution (PSD): SiC powders can range from sub-micron to several tens of microns. Mixing powders with significantly different PSDs can be challenging and may lead to segregation. A narrower PSD or a well-defined multimodal distribution is often preferred for dense packing and uniform sintering.

- Particle Shape: Irregular or angular SiC particles may interlock better but can also impede flowability. Spherical powders tend to flow better but might offer less green strength.

- Density: Differences in density between SiC and additives can lead to segregation, especially in less energetic mixing systems.

- Flowability and Cohesiveness: Fine powders often exhibit poor flowability and high cohesiveness due to van der Waals forces, making them difficult to mix uniformly. Surface treatments or the use of flow aids might be necessary.

- Hygroscopicity: Some SiC powders or additives can absorb moisture, affecting flow and mixing behavior. Controlled environments may be required.

- Mixer Operational Parameters:

- Mixing Time: Insufficient time leads to an inhomogeneous mix, while excessive mixing can sometimes lead to particle segregation (especially with widely different particle sizes/densities), unnecessary energy consumption, or even particle degradation. Optimization is key.

- Mixing Speed/Intensity (RPM, Shear Rate): Higher speeds or shear generally improve dispersion but can also generate heat, which might be detrimental to organic binders. The optimal speed depends on the mixer type and the nature of the powders.

- Fill Volume: Overfilling or underfilling a mixer can significantly reduce its efficiency. Manufacturers typically specify an optimal fill range (e.g., 40-70% of total volume for V-blenders).

- Sequence of Addition: The order in which materials (SiC powder, binders, lubricants, sintering aids) are added to the mixer can impact the final homogeneity, especially for minor ingredients. Often, a pre-blending of minor components is performed.

- Temperature Control: For processes involving binders that melt or become tacky, or for slurries where viscosity is temperature-dependent, temperature control during mixing is vital.

- Binder and Additive Properties (for wet and dry mixing with binders):

- Binder Type and Amount: The binder’s viscosity, melting point (if applicable), and interaction with the SiC powder are crucial. The amount must be sufficient for green strength but not excessive to cause issues during binder burnout.

- Solvent (for wet mixing/slurry preparation): The choice of solvent (e.g., water, alcohol) and its purity affects dispersion, drying, and potential reactions. The solid loading in SiC slurry preparation is a critical parameter for slip casting or spray drying.

- Dispersants/Surfactants: For wet mixing, these help to deagglomerate particles and maintain a stable suspension by modifying surface charges.

- Environmental Conditions:

- Humidity and Temperature: As mentioned, these can affect powder flow and binder behavior.

- Atmosphere: For highly reactive powders or to prevent oxidation, mixing under an inert atmosphere (e.g., nitrogen, argon) might be necessary.

Mastering these parameters requires a combination of material science knowledge, engineering expertise, and empirical testing. Sicarb Tech , with its robust scientific backing from the Chinese Academy of Sciences and practical experience supporting over 10 local SiC enterprises, offers unparalleled insights into optimizing these mixing parameters for various SiC grades and applications. We provide not just components but also technology transfer for professional silicon carbide production, empowering our clients with the knowledge to control these critical variables effectively.

Below is a table summarizing key considerations for SiC powder characteristics in mixing:

| Powder Characteristic | Impact on Mixing | Mitigation Strategy / Consideration |

|---|---|---|

| Particle Size Mismatch | Risk of segregation; smaller particles may sift through larger ones. | Use appropriate mixer type (e.g., convective), optimize mixing time, consider staged additions. |

| High Cohesiveness | Poor flow, agglomeration, difficult to achieve uniform additive distribution. | Use higher shear mixers, introduce flow aids, granulation, or consider wet mixing with dispersants. |

| Abrasiveness | Wear on mixer components, potential contamination. | Select abrasion-resistant materials for mixer construction (e.g., hardened steel, ceramic linings). |

| Density Differences | Heavier particles may settle, lighter ones may float, leading to stratification. | Increase mixing energy, use mixers with good vertical intermixing, optimize fill level. |

| Electrostatic Charges | Can cause particles to repel or attract, leading to non-uniformity. | Ground equipment, control humidity, use anti-static agents if compatible. |

By carefully controlling these parameters, manufacturers can ensure a homogeneous powder mix, which is the foundation for producing high-quality, reliable custom silicon carbide products.

Applications of Homogeneous SiC Powder Mixes in Manufacturing

The meticulous preparation of homogeneous SiC powder mixes via advanced SiC powder mixing equipment is not an academic exercise; it is a fundamental requirement for manufacturing a vast array of high-performance components across numerous demanding industries. The quality of the initial blend directly dictates the final properties and reliability of these technical ceramic parts. When procurement managers and OEMs source custom SiC parts or consider SiC production technology, understanding the link between powder mixing and application performance is crucial.

Here are some key industrial applications where homogeneous SiC powder mixes are essential:

- Semiconductor Manufacturing:

- Applications: Wafer chucks (electrostatic and vacuum), showerheads for CVD/PVD chambers, focus rings, edge rings, CMP (Chemical Mechanical Planarization) conditioner discs, and structural components for processing equipment.

- Importance of Homogeneity: Ultra-high purity and uniform electrical and thermal properties are critical. Any non-uniformity can lead to wafer damage, inconsistent film deposition, or premature component failure. Homogeneous distribution of sintering aids and the SiC matrix itself ensures predictable thermal expansion and stability during rapid thermal cycling. For parts like CMP conditioners, a uniform distribution of diamond abrasives within the SiC matrix (if used) is vital for consistent polishing.

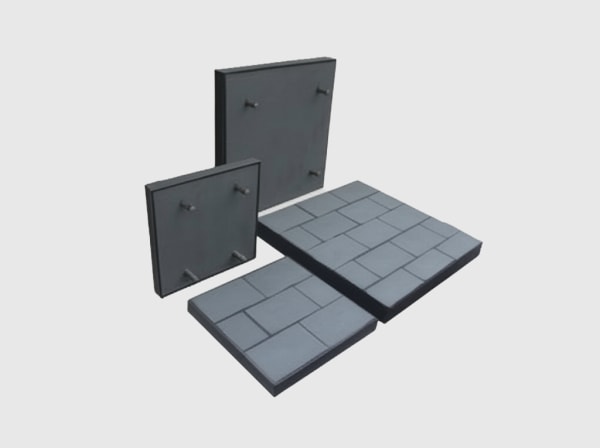

- High-Temperature Furnaces and Kiln Furniture:

- Applications: Beams, rollers, supports, setters, plates, tubes, and burner nozzles used in industrial furnaces operating at extreme temperatures.

- Importance of Homogeneity: Ensures consistent high-temperature strength, creep resistance, and thermal shock resistance. Uniform porosity and density, derived from a well-mixed powder, prevent localized weaknesses that could lead to failure under thermal stress or load. This is critical for the longevity and reliability of industrial furnace components.

- Aerospace and Defense:

- Applications: Turbine components (shrouds, vanes), rocket nozzles, lightweight armor, mirror substrates for optical systems, and high-temperature heat exchangers.

- Importance of Homogeneity: Critical for achieving maximum strength-to-weight ratios, thermal stability, and resistance to erosion and oxidation in extreme environments. For armor applications, a uniform microstructure is essential for consistent ballistic performance. Mirror substrates demand exceptional dimensional stability, which starts with a homogeneous raw material blend.

- Energy Sector:

- Applications: Components for heat exchangers in power generation, fuel cells, nuclear applications (e.g., fuel cladding, control rods – depending on grade), and wear parts in oil and gas extraction.

- Importance of Homogeneity: Ensures reliable thermal performance, corrosion resistance, and wear resistance in harsh operating conditions. For nuclear applications, material consistency is paramount for safety and predictable neutron absorption/transmission.

- Industrial Manufacturing and Wear Parts:

- Applications: Mechanical seals, bearings, pump components (shafts, sleeves), nozzles for abrasive blasting or fluid handling, cyclone liners, and cutting tools.

- Importance of Homogeneity: Delivers consistent hardness, wear resistance, and chemical inertness. In mechanical seals, for instance, uniform lapped surfaces with minimal porosity are crucial for sealing performance, directly stemming from a quality powder mix. Advanced ceramic components for wear applications rely on this uniformity for extended service life.

- Automotive Industry:

- Applications: Diesel particulate filters (DPF), brake discs, components for electric vehicle power electronics (e.g., heat sinks).

- Importance of Homogeneity: For DPFs, controlled porosity and thermal properties are essential for efficient filtration and regeneration. For brake discs, uniform friction and wear characteristics are vital for safety and performance.

The table below highlights specific SiC properties critical for various applications and how powder mixing impacts them:

| Industry Application Example | Critical SiC Property | Impact of Homogeneous Mixing |

|---|---|---|

| Semiconductor Wafer Chucks | Thermal Uniformity, Purity | Ensures even temperature distribution across the wafer; prevents contamination. |

| Kiln Beams & Rollers | High-Temp Strength, Creep Resistance | Provides consistent load-bearing capacity and resistance to deformation at high temperatures. |

| Aerospace Rocket Nozzles | Thermal Shock Resistance, Erosion Resistance | Guarantees structural integrity during rapid temperature changes and exposure to hot gases. |

| Mechanical Seals | Wear Resistance, Low Friction | Ensures long life and effective sealing through uniform surface properties and hardness. |

| Diesel Particulate Filters (DPF) | Controlled Porosity, Thermal Stability | Optimizes filtration efficiency and durability during soot regeneration cycles. |

Sicarb Tech , rooted in Weifang, the hub of China’s silicon carbide customizable parts factories, has been instrumental in advancing the production technologies that cater to these diverse and demanding applications. Our experience since 2015 in assisting local enterprises achieve large-scale production and technological breakthroughs means we deeply appreciate how foundational processes like SiC powder mixing influence the end-product quality. We are committed to providing higher-quality, cost-competitive customized silicon carbide components where the benefits of superior mixing are clearly evident.

Challenges in SiC Powder Mixing and Solutions by Sicarb Tech

While the goal of achieving a perfectly homogeneous SiC powder mix is clear, several challenges can arise during the process. These challenges stem from the inherent properties of SiC powders, the complexities of additive incorporation, and the limitations of certain mixing technologies. Addressing these issues effectively is crucial for manufacturers seeking to produce high-quality technical ceramics and custom SiC parts.

Common challenges in SiC powder mixing include:

- Agglomeration: Fine SiC powders, especially those in the sub-micron range, have a strong tendency to form agglomerates due to van der Waals forces. These agglomerates are difficult to break down and can lead to pores, defects, and non-uniform shrinkage in the sintered part.

- Segregation: When mixing powders with significantly different particle sizes, densities, or shapes, segregation can occur. Heavier or larger particles may settle, while finer particles may float or sift through, leading to an inhomogeneous mixture even after initial blending. This is a concern for bulk powder handling systems feeding the forming processes.

- Binder Distribution: Achieving uniform distribution of small quantities of organic binders or sintering aids throughout a large volume of SiC powder can be difficult. Non-uniform binder distribution leads to inconsistent green strength and can cause defects during binder burnout or sintering.

- Contamination: SiC is a very hard and abrasive material. Mixing equipment can wear, leading to contamination of the powder mix with metallic or other particles. This is particularly critical for high-purity applications like those in the semiconductor industry. Cross-contamination between different batches or material grades is also a risk.

- Heat Generation: High-energy mixing or prolonged mixing times can generate significant heat. This can be detrimental to temperature-sensitive binders, leading to premature melting, degradation, or volatilization, thereby affecting the rheology of the mix or the green body properties.

- Dusting and Material Handling: Fine SiC powders can be prone to dusting, posing health and safety risks and leading to material loss. Proper containment and handling are essential.

- Scaling Up: A mixing process developed at the lab scale may not directly translate to pilot or production scale. Issues like dead zones in larger mixers, changes in heat dissipation, and longer required mixing times can emerge.

Solutions and Approaches by Sicarb Tech :

At Sicarb Tech , we leverage our deep expertise and the technological backing of the Chinese Academy of Sciences to help our partners overcome these challenges. Our approach is holistic, encompassing material understanding, process optimization, and equipment selection/design.

- Addressing Agglomeration:

- We recommend and can help implement high-shear mixing techniques (e.g., using planetary mixers, attritors, or specialized rotor-stator systems for slurries) to effectively deagglomerate fine powders.

- For wet mixing (SiC slurry preparation), we advise on the optimal use of dispersants and surfactants to stabilize particles and prevent reagglomeration.

- Pre-treatment of powders, such as spray drying of slurries to produce free-flowing granules with uniformly distributed binders, is another strategy we can support.

- Mitigating Segregation:

- Our team assists in selecting mixer types with mechanisms that minimize segregation (e.g., convective mixers with appropriate agitator design).

- We emphasize optimizing fill levels and mixing times, as over-mixing can sometimes induce segregation.

- Guidance on matching particle size distributions of different components as closely as possible, or using multi-stage mixing, can be provided.

- Ensuring Uniform Binder Distribution:

- We support techniques like masterbatching (pre-mixing binders with a small portion of SiC powder) or dissolving/emulsifying binders in a solvent for wet mixing to ensure even coating of particles.

- Our process expertise extends to optimizing the temperature and shear conditions to facilitate uniform binder incorporation without degradation.

- Preventing Contamination:

- Sicarb Tech stresses the importance of selecting mixer materials of construction appropriate for SiC’s abrasiveness (e.g., alumina or SiC linings, tungsten carbide components for critical areas).

- We advise on stringent cleaning protocols and, where necessary, dedicated equipment for different material grades or purity levels. Our involvement in the Weifang SiC hub, which produces over 80% of China’s SiC, gives us broad experience with diverse purity requirements.

- Managing Heat Generation:

- We assist in selecting mixers with cooling jackets or implementing process controls to manage temperature during mixing.

- Optimizing mixing parameters (speed, time) to achieve homogeneity with minimal energy input is a key focus.

- Improving Material Handling and Safety:

- We advocate for enclosed mixing systems and proper dust collection equipment.

- Our technology transfer services can include designs for safe and efficient bulk powder handling systems.

- Facilitating Scale-Up:

- With our integrated process knowledge from materials to products, we can help predict and address scale-up challenges. This includes advising on geometric similarity, power input per unit volume, and mixing dynamics.

- Sicarb Tech is committed to assisting clients in establishing specialized factories, offering turnkey project support that includes process validation at scale.

Choosing the Right SiC Powder Mixing Equipment Supplier: A Buyer’s Guide

Selecting the right supplier for SiC powder mixing equipment is a critical decision that can significantly impact your manufacturing efficiency, product quality, and overall operational costs. This choice goes beyond just the initial purchase price; it involves evaluating a vendor’s technical capabilities, after-sales support, understanding of technical ceramics processing, and their ability to cater to your specific custom SiC parts production needs. For procurement managers and OEMs, a strategic approach to supplier selection is essential.

Here are key factors to consider when choosing a SiC powder mixing equipment supplier:

- Technical Expertise and Experience in Ceramics:

- Look for suppliers with demonstrated experience in handling abrasive and fine powders like silicon carbide. Their understanding of ceramic powder blending challenges (agglomeration, contamination, wear) is crucial.

- Do they offer process development support or testing facilities to help you optimize your mixing process with their equipment?

- Suppliers who specialize in or have a strong portfolio in advanced materials processing equipment are often a better choice than general-purpose mixer manufacturers.

- Equipment Range and Customization Capabilities:

- Does the supplier offer a variety of mixer types (e.g., V-blenders, ribbon blenders, planetary mixers, attritors) to suit different scales and mixing intensities?

- Can they customize the equipment? This includes options for materials of construction (e.g., specific stainless steel grades, ceramic linings, tungsten carbide parts) to minimize wear and contamination, a critical factor for SiC raw material processing.

- Are features like vacuum operation, temperature control (heating/cooling jackets), inert atmosphere compatibility, and CIP (Clean-In-Place) systems available?

- Quality of Construction and Durability:

- Given SiC’s abrasiveness, the robustness and build quality of the mixer are paramount. Inspect weld quality, surface finishes, and the quality of components like seals and bearings.

- Inquire about design features that reduce wear or allow for easy replacement of wear parts.

- Process Control and Automation:

- Modern industrial powder mixers should offer good control over mixing parameters (speed, time, temperature).

- Evaluate the level of automation available, from basic controls to PLC-based systems with recipe management and data logging, which can improve consistency and traceability for high-performance ceramic components.

- After-Sales Support and Service:

- What is the supplier’s reputation for after-sales support, including installation, training, spare parts availability, and technical assistance?

- Consider their geographical presence or service network, especially for critical production equipment.

- Cost-Effectiveness (Total Cost of Ownership):

- Don’t solely focus on the initial purchase price. Consider the Total Cost of Ownership (TCO), which includes energy consumption, maintenance costs, expected lifespan, and the potential impact on product quality and yield.

- A slightly more expensive but highly efficient and durable mixer might be more cost-effective in the long run.

- Supplier Reputation and References:

- Seek references from other companies in the technical ceramics industry or those processing similar materials.

- Industry reputation and longevity can be indicators of reliability and product quality.

Why Sicarb Tech is Your Trusted Partner:

While Sicarb Tech is primarily known for its expertise in customized silicon carbide components and SiC production technology transfer, our deep understanding of the entire manufacturing process, including powder preparation, positions us uniquely to guide you. We may not manufacture the mixers ourselves, but we partner with and can recommend the best equipment providers based on your specific needs.

- Unbiased Expertise: Our recommendations are driven by what’s best for your application and product quality, not by allegiance to a specific equipment brand. We leverage our experience, having assisted numerous local enterprises in Weifang—the heart of China’s SiC industry—to optimize their processes.

- Integrated Process Knowledge: We understand how mixing performance impacts downstream processes (forming, sintering) and final product properties. This holistic view is invaluable when selecting equipment.

- Focus on Customization and Quality: Our core business is custom SiC parts. We know what it takes to achieve high quality, and that starts with superior powder mixing. We can help you specify equipment that meets the stringent demands of industries like semiconductors and aerospace.

- Technology Transfer and Turnkey Solutions: If you are looking to establish or upgrade your SiC production capabilities, Sicarb Tech offers comprehensive technology transfer for professional silicon carbide production. This includes advising on and sourcing the most suitable equipment, including mixers, as part of a turnkey project. We can assist with factory design, procurement, installation, commissioning, and trial production, ensuring a more effective investment and reliable technology transformation.

Choosing a supplier is about forging a partnership. With Sicarb Tech , you gain a partner with profound material and process knowledge, committed to ensuring you have the right tools and technologies, including SiC powder mixing equipment, to succeed. We help you source higher-quality, cost-competitive customized silicon carbide components and technologies within China.

A comparative look at supplier evaluation criteria:

| Evaluation Criterion | Key Questions to Ask | Importance for SiC Mixing |

|---|---|---|

| Technical Expertise | Do they understand ceramic powder behavior? Can they advise on process optimization? | Very High |

| Equipment Customization | Can materials be upgraded for wear resistance? Are specific features (vacuum, temp control) available? | Very High |

| Build Quality/Durability | How robust is the construction? What are the wear characteristics with abrasive powders? | Very High |

| After-Sales Service | What is their response time for support? Are spare parts readily available? | High |

| Process Control | How accurately can mixing parameters be controlled? Is automation/data logging available? | High |

| References/Reputation | Who else in the SiC or advanced ceramics industry uses their equipment? What is their feedback? | Medium to High |

| Total Cost of Ownership | What are the long-term operational costs (energy, maintenance) in addition to the upfront price? | High |

By systematically evaluating potential suppliers against these criteria, you can make an informed decision that supports your long-term production goals for high-quality silicon carbide products.

Frequently Asked Questions (FAQ)

Q1: What is the most critical factor when selecting SiC powder mixing equipment for high-purity semiconductor applications?

A1: For high-purity semiconductor applications, the most critical factors are the prevention of contamination and ensuring ultra-high homogeneity. This means selecting equipment constructed from non-contaminating, highly wear-resistant materials (e.g., high-purity alumina or SiC linings, or PFA coatings for certain components where applicable, instead of standard stainless steel which might shed metallic particles). The mixer design should also facilitate easy and thorough cleaning to prevent cross-contamination between batches. High-shear capability might be needed for deagglomeration of fine, pure SiC powders to achieve the required micro-homogeneity for consistent electrical and thermal properties in the final components like wafer chucks or focus rings. Sicarb Tech emphasizes these aspects when advising on equipment for such demanding custom SiC parts.

Q2: How does the particle size of SiC powder affect the choice of mixing equipment?

A2: Particle size significantly influences equipment choice.

- Fine/Ultrafine Powders (sub-micron to few microns): These powders tend to be cohesive and prone to agglomeration. They require mixers with higher shear energy to break down agglomerates and ensure good dispersion, such as planetary mixers, attritors, or high-shear dispersers (often in wet mixing). Gentle tumbling mixers (V-blenders, cone blenders) may not be effective on their own unless the powders are exceptionally free-flowing or granulated.

- Coarser Powders (tens of microns and above): These are generally more free-flowing. Tumbling blenders can be effective, provided particle size differences within the mix are not too large to cause segregation. Ribbon or paddle blenders (convective mixers) are also suitable and can handle larger volumes.

- Mixtures of Different Sizes: If mixing powders with a wide particle size distribution, segregation can be a major issue. Convective mixers or those that impart a more complex motion are generally preferred over simple tumblers. The mixing time also needs careful optimization.

Q3: Can Sicarb Tech assist in developing a complete SiC component manufacturing line, including powder mixing?

A3: Yes, absolutely. Sicarb Tech , leveraging its foundation within the Chinese Academy of Sciences (Weifang) Innovation Park and the national technology transfer center of the Chinese Academy of Sciences, offers comprehensive services beyond just supplying customized SiC components. We specialize in technology transfer for professional silicon carbide production. This includes providing a full range of services for establishing a specialized factory (a turnkey project), which encompasses factory design, procurement of specialized equipment (including optimal SiC powder mixing equipment tailored to your needs), installation and commissioning, and trial production. Our domestic top-tier professional team possesses a wide array of technologies—material, process, design, measurement & evaluation—enabling us to assist you in building a professional SiC products manufacturing plant with reliable technology transformation and a guaranteed input-output ratio. We help ensure you achieve higher-quality, cost-competitive production.

Conclusion: The Foundational Role of Mixing in Superior SiC Products

The journey to producing high-performance custom silicon carbide products is paved with precision, and it unequivocally begins with the meticulous preparation of the raw SiC powder. As we’ve explored, SiC powder mixing equipment is not merely an ancillary piece of machinery; it is a critical asset that directly influences the homogeneity, and therefore the ultimate quality, reliability, and performance of technical ceramics across a spectrum of demanding industrial applications – from semiconductors and aerospace to energy and high-temperature furnaces.

Achieving a truly homogeneous powder mix addresses fundamental challenges such as agglomeration, segregation, and inconsistent additive distribution. The choice of mixing technology, careful control over operational parameters, and selection of the right equipment supplier are paramount for any manufacturer aiming to excel in the competitive advanced ceramics market. The dividends of investing in optimal mixing are clear: enhanced product consistency, improved mechanical and thermal properties, reduced defects, and greater production efficiency.

Sicarb Tech stands as a knowledgeable partner in this intricate landscape. Located in Weifang City, the epicenter of China’s SiC customizable parts manufacturing, and backed by the formidable scientific prowess of the Chinese Academy of Sciences, we offer more than just components. We provide deep process expertise, from material selection through to final product realization. Whether you are seeking higher-quality, cost-competitive customized silicon carbide components, or aiming to establish your own state-of-the-art SiC production technology through our turnkey project and technology transfer services, we are committed to ensuring your success. We understand that the pursuit of excellence in advanced materials like silicon carbide starts with getting the blend right, every single time. Trust Sicarb Tech to be your guide and partner in navigating the complexities of SiC manufacturing and achieving superior outcomes.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.