SiC in Battery Manufacturing: Next-Level Power Solutions

Share

SiC in Battery Manufacturing: Next-Level Power Solutions

Introduction: The Imperative for Advanced Materials in Battery Technology

The global push towards electrification, from electric vehicles (EVs) to grid-scale energy storage and portable electronics, has put immense pressure on battery technology to deliver higher energy densities, faster charging times, longer lifespans, and enhanced safety. While lithium-ion batteries have been the dominant force, their performance is increasingly hitting material limits. This is where advanced materials like silicon carbide (SiC) step in, offering transformative potential. Custom silicon carbide products are not just incremental improvements; they are enabling entirely new performance paradigms in battery manufacturing, addressing critical challenges that conventional materials cannot. For engineers, procurement managers, and technical buyers in industries reliant on cutting-edge battery solutions, understanding the role of SiC is becoming essential.

The demand for superior thermal management, higher voltage capabilities, and robust mechanical stability within battery packs is driving innovation in material science. Silicon carbide components, known for their exceptional thermal conductivity, high breakdown electric field, and excellent wear resistance, are uniquely positioned to meet these demanding requirements. As we delve deeper, this post will explore how custom SiC solutions are revolutionizing battery design and manufacturing, paving the way for next-generation power solutions across diverse sectors including automotive, aerospace, and renewable energy.

The Pivotal Role of SiC in Modern Battery Designs

Silicon Carbide’s unique combination of properties makes it a critical enabler for overcoming some of the most significant hurdles in modern battery design, particularly for high-power and high-density applications. Its influence spans several key areas:

- Thermal Management: Heat generation is a major limiting factor in battery performance and safety. Excessive heat can degrade battery components, reduce lifespan, and in worst-case scenarios, lead to thermal runaway. SiC’s high thermal conductivity (significantly better than traditional ceramics or even some metals) allows it to be used in thermal management systems as heat spreaders, cooling channel components, or integrated within battery module casings. This efficient heat dissipation allows batteries to operate at higher C-rates (charging/discharging rates) without overheating.

- Enhanced Safety: By improving thermal stability and preventing localized hotspots, SiC contributes directly to safer battery operation. Its ability to withstand high temperatures without degradation also provides an additional safety margin. Furthermore, its mechanical robustness can protect battery cells from physical damage.

- Increased Power Density and Efficiency: In power electronics associated with battery systems (e.g., inverters, converters within EV drivetrains or charging infrastructure), SiC-based semiconductors are already well-established. Their higher switching frequencies, lower switching losses, and higher operating temperatures compared to silicon (Si) counterparts lead to more compact, lighter, and more efficient power conversion systems. This indirectly benefits the battery by reducing the overall system size and energy wasted as heat, allowing for more space for active battery material or more efficient energy utilization.

- Component Longevity and Durability: SiC’s exceptional wear resistance and chemical inertness make it suitable for components that might be exposed to corrosive environments within a battery system or require long operational lifetimes under mechanical stress. This ensures that parts made from SiC maintain their integrity and performance characteristics over the battery’s lifespan.

- High Voltage Applications: As battery pack voltages increase (e.g., 800V systems in newer EVs and beyond) to improve charging speeds and reduce resistive losses, the demands on insulating materials become more stringent. SiC possesses excellent dielectric strength and electrical insulation properties, making it suitable for insulators, spacers, and structural components in high-voltage battery architectures.

The integration of custom SiC parts allows designers to tailor these benefits to specific battery chemistries, form factors, and operational demands, moving beyond off-the-shelf solutions to achieve optimal performance.

Why Custom Silicon Carbide is a Game-Changer for Batteries

While standard SiC components offer inherent advantages, custom silicon carbide fabrication elevates the potential of this material in battery manufacturing significantly. “Custom” means designing and producing SiC parts tailored to the precise requirements of a specific battery application, rather than trying to fit a standard component into a complex system. This bespoke approach unlocks several key benefits:

- Optimized Thermal Pathways: Battery packs often have complex geometries and varying thermal loads. Custom SiC heat spreaders, coolers, or substrates can be designed to perfectly match these unique thermal landscapes, ensuring efficient heat extraction from critical areas like cell tabs or inter-cell spaces. This level of optimization is rarely achievable with standard parts.

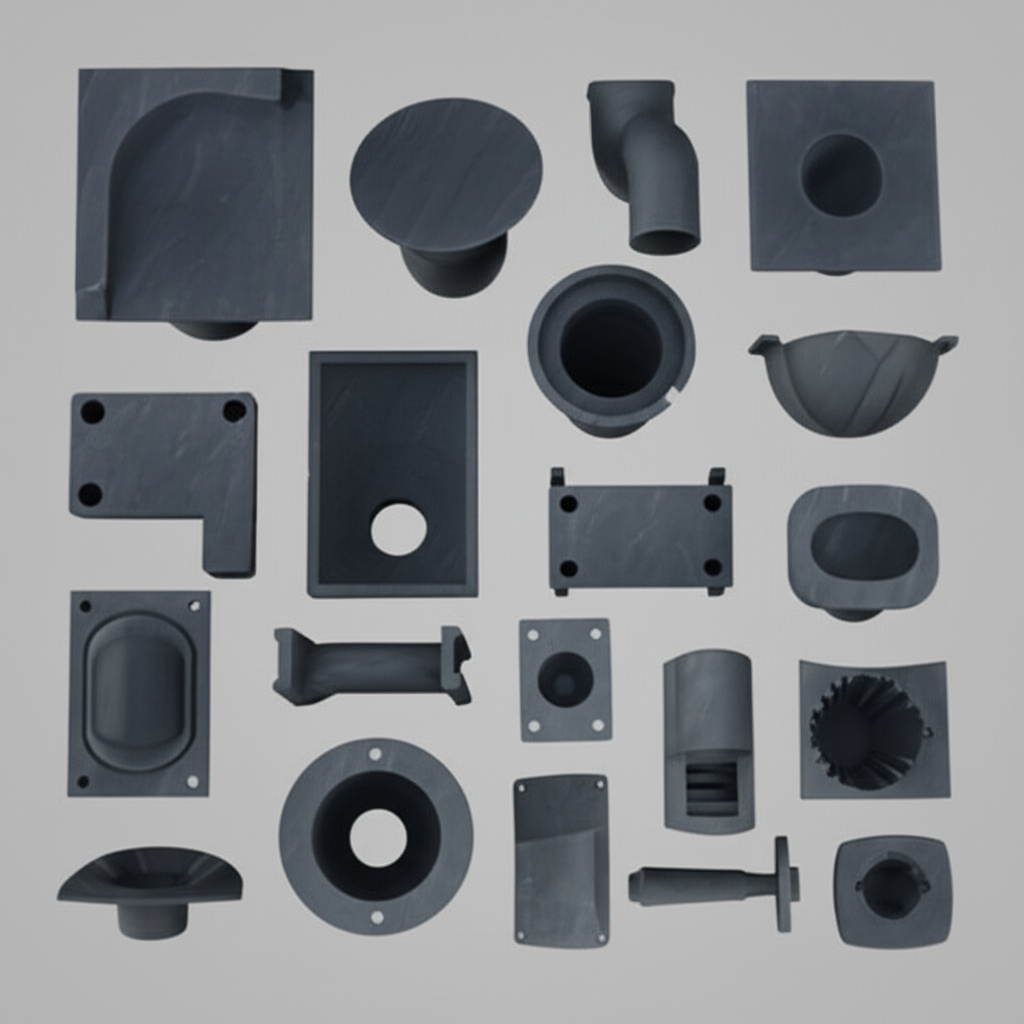

- Precision Fit and Integration: Customization allows for SiC components to be manufactured with precise dimensions, complex shapes, and integrated features (e.g., channels, mounting points) that facilitate seamless assembly within the battery module or pack. This can reduce assembly time, improve reliability, and minimize wasted space.

- Tailored Electrical Properties: While SiC is generally an excellent insulator, its electrical properties can be influenced by its microstructure and purity. Custom manufacturing processes can fine-tune these aspects to meet specific insulation requirements or, in some advanced applications, create SiC components with controlled semiconducting properties if needed for sensors or integrated electronics.

- Enhanced Mechanical Integrity: Battery components, especially in mobile applications like EVs or aerospace, are subject to vibrations, shocks, and mechanical stresses. Custom SiC structural elements can be designed with specific reinforcement features or optimized geometries to maximize strength-to-weight ratio, contributing to the overall robustness of the battery pack.

- Material Grade Selection for Specific Needs: Different battery applications may prioritize different SiC properties. For example, one application might need maximum thermal conductivity, while another might prioritize extreme chemical resistance. Customization allows for the selection of the most appropriate SiC grade (e.g., Sintered SiC for purity and thermal performance, Reaction-Bonded SiC for complex shapes and cost-effectiveness) to meet the primary performance drivers.

- Prototyping and Iterative Design: Reputable suppliers of custom SiC often work closely with clients from the design phase, offering rapid prototyping and iterative improvements. This collaborative approach is crucial in the fast-evolving field of battery technology, allowing for quick adaptation to new cell chemistries or pack designs. You can explore some successful implementations by reviewing our case studies.

In essence, custom SiC solutions bridge the gap between the raw potential of silicon carbide and the specific, often demanding, realities of advanced battery applications. This tailored approach is key to maximizing performance, safety, and longevity, making it a true game-changer for industries pushing the boundaries of energy storage.

Key SiC Grades and Compositions for Battery Applications

Choosing the right type of silicon carbide is crucial for optimizing performance and cost in battery applications. Several grades of SiC are commercially available, each with distinct properties derived from its manufacturing process and microstructure. Below is an overview of common SiC grades relevant to battery components:

| SiC Grade | Key Characteristics | Potential Battery Applications | Considerations |

|---|---|---|---|

| Sintered Silicon Carbide (SSiC) | High purity (>98-99%), excellent thermal conductivity, high strength, excellent corrosion and wear resistance, good electrical insulation. | Heat sinks, substrates for power electronics, high-performance insulators, structural components requiring maximum durability. | Typically higher cost, can be more challenging to produce very complex shapes compared to RBSC. |

| Reaction-Bonded Silicon Carbide (RBSC or SiSiC) | Contains free silicon (typically 8-15%), good thermal conductivity, good wear resistance, relatively easy to form complex shapes, cost-effective. | Thermal management components (e.g., cooling plates), structural supports, protective casings. | Presence of free silicon limits maximum operating temperature (typically ~1350°C) and can affect chemical resistance in certain harsh environments. Electrical resistivity is lower than SSiC. |

| Nitride-Bonded Silicon Carbide (NBSC) | SiC grains bonded by silicon nitride, good thermal shock resistance, good mechanical strength, good resistance to molten metals. | Less common for direct battery internals, but could be used in manufacturing equipment for battery materials or specific high-temperature interface components. | Thermal conductivity generally lower than SSiC or RBSC. |

| Liquid Phase Sintered SiC (LPS-SiC) | Sintered with additives (e.g., yttria, alumina) that form a liquid phase during sintering, allowing for lower sintering temperatures and potentially finer microstructures or near-net shaping. | Components requiring high density and good mechanical properties, potentially intricate thermal management parts. | Properties can vary based on additives used. May offer a balance of performance and manufacturability. |

| CVD Silicon Carbide (Chemical Vapor Deposition) | Extremely high purity SiC, often used as a coating or for producing thin, dense components. Excellent chemical resistance and thermal stability. | Protective coatings on battery components, thin insulating layers, high-purity substrates for sensitive electronics. | Higher cost, typically limited to coatings or smaller/thinner components. |

The selection process involves a careful trade-off analysis considering:

- Operating Temperature Range: While internal battery temperatures are ideally controlled, fault conditions or specific applications might expose components to higher temperatures.

- Thermal Conductivity Requirements: Critical for heat dissipation components.

- Electrical Insulation Needs: Voltage levels and safety standards dictate the required dielectric strength.

- Mechanical Loads: Structural components must withstand vibration, shock, and assembly stresses.

- Chemical Environment: Exposure to electrolyte or other potentially corrosive substances.

- Complexity of Shape and Size: Some SiC grades are more amenable to producing intricate geometries.

- Cost Targets: Material and manufacturing costs vary significantly between grades.

A knowledgeable custom SiC supplier can provide invaluable assistance in selecting the optimal grade and tailoring the manufacturing process to meet the specific demands of your battery application.

Designing Custom SiC Components for Optimal Battery Performance

The design phase is critical when developing custom silicon carbide components for battery applications. Simply substituting an existing part material with SiC without considering the unique properties of this technical ceramic may not yield optimal results. Effective design involves a collaborative approach between battery engineers and SiC manufacturing experts. Key considerations include:

- Manufacturability:

- Geometry Limits: While SiC can be formed into complex shapes, especially grades like RBSC, there are limits. Extremely sharp internal corners, very thin walls relative to overall size, or features that are difficult to mold or machine can increase cost and lead times, or even be unfeasible. Early consultation with the SiC producer is vital.

- Wall Thickness: Minimum achievable wall thickness depends on the SiC grade and manufacturing process (e.g., slip casting, pressing, green machining). Designers should aim for uniform wall thicknesses where possible to minimize stress concentrations and distortion during sintering.

- Draft Angles: For molded parts, appropriate draft angles are necessary for easy removal from the mold.

- Thermal Design:

- Maximizing Surface Area: For heat dissipation components, features like fins or complex channels can increase surface area, but these must be balanced with manufacturability.

- Thermal Interfaces: The design must consider how the SiC component will interface with other materials (e.g., battery cells, cooling fluids). Surface flatness and finish are crucial for minimizing thermal resistance at these interfaces.

- Integration with Cooling Systems: If the SiC part is part of a liquid or air cooling system, flow paths and pressure drop considerations are important.

- Mechanical Design:

- Stress Points: SiC is a brittle material. Designs should avoid sharp corners and stress concentrators. Radii should be incorporated wherever possible. Finite Element Analysis (FEA) is often recommended to identify and mitigate high-stress areas.

- Loading Conditions: Understand the types of loads the component will experience (compressive, tensile, bending, vibrational) and design accordingly. SiC is much stronger in compression than in tension.

- Mounting and Assembly: Consider how the SiC part will be mounted and integrated into the larger battery assembly. Avoid point loads; aim for distributed loads. Consider differential thermal expansion if SiC is joined to materials with different coefficients of thermal expansion.

- Electrical Design (if applicable):

- Creepage and Clearance Distances: For insulating components in high-voltage systems, adequate creepage and clearance distances must be designed to prevent arcing or tracking.

- Dielectric Strength: The thickness of the SiC material will influence its overall breakdown voltage.

Working with a supplier that offers robust customizing support, including design assistance and FEA capabilities, can significantly streamline the development process and lead to more robust and effective SiC components for your battery systems. Iterative prototyping is often a part of this process to validate design choices before committing to large-scale production.

Achievable Tolerances, Surface Finish, and Dimensional Accuracy in SiC Battery Parts

The precision of silicon carbide components is paramount in battery manufacturing, where tight fits, optimal thermal interfaces, and reliable electrical insulation are critical. The achievable tolerances, surface finish, and dimensional accuracy for SiC parts depend on several factors, including the chosen SiC grade, the initial forming method (e.g., pressing, slip casting, extrusion), and the extent of post-sintering machining (grinding, lapping, polishing).

Tolerances:

- As-Sintered Tolerances: Components that are used “as-sintered” (without significant post-machining) typically have wider dimensional tolerances. This is due to shrinkage variations during the high-temperature sintering process. Typical as-sintered tolerances might range from ±0.5% to ±2% of the dimension, depending on the size and complexity of the part and the specific SiC grade.

- Machined Tolerances: For applications requiring higher precision, SiC parts are machined in their sintered state using diamond grinding tools. This allows for much tighter tolerances.

- General Machining: Tolerances of ±0.025 mm to ±0.1 mm (±0.001″ to ±0.004″) are commonly achievable.

- Precision Machining: For critical features, tolerances as tight as ±0.005 mm to ±0.01 mm (±0.0002″ to ±0.0004″) can be achieved with advanced grinding and lapping processes.

Surface Finish:

- As-Sintered Finish: The surface finish of as-sintered parts is characteristic of the forming process and grain size of the SiC. It might be relatively rough, suitable for applications where surface smoothness is not critical. Ra (average roughness) values can be in the range of 1-5 µm.

- Ground Finish: Grinding significantly improves surface finish. Ra values of 0.4 µm to 0.8 µm are typical after standard grinding.

- Lapped/Polished Finish: For applications requiring exceptionally smooth surfaces (e.g., for direct bonding, optimal thermal contact, or specific optical properties if relevant), lapping and polishing can achieve Ra values down to 0.02 µm or even better. This is crucial for SiC components acting as thermal interface materials or precision insulators.

Dimensional Accuracy & Stability:

- Silicon carbide exhibits excellent dimensional stability over a wide range of temperatures and does not suffer from creep at typical battery operating temperatures. Once manufactured to specification, SiC parts maintain their dimensions.

- Achieving high dimensional accuracy across complex geometries requires careful control of each manufacturing step, from powder preparation to final inspection. Advanced metrology equipment is essential for verifying dimensions and tolerances.

Key Considerations for Procurement Professionals and Engineers:

- Communicate Requirements Clearly: Specify critical dimensions, tolerances, and surface finish requirements on engineering drawings. Distinguish between critical and non-critical features to manage costs, as tighter tolerances invariably increase manufacturing effort and expense.

- Understand Cost Implications: Extremely tight tolerances and ultra-fine surface finishes can significantly increase the cost of SiC components due to the extensive machining required. Balance the need for precision with the cost budget.

- Supplier Capability: Ensure your chosen SiC manufacturer has the necessary equipment (precision grinding machines, lapping/polishing capabilities, advanced metrology) and expertise to meet your specifications.

Ultimately, the ability to achieve precise tolerances and desired surface finishes makes custom SiC components highly reliable and effective for demanding battery applications, ensuring consistent performance and facilitating automated assembly processes.

Essential Post-Processing for SiC Battery Components

After the initial forming and sintering stages, many custom silicon carbide components for battery applications undergo various post-processing steps to meet final design specifications, enhance performance, or improve durability. These processes are critical for achieving the tight tolerances, specific surface characteristics, and functional features required in advanced battery systems.

Common post-processing techniques include:

- Grinding: This is the most common post-sintering machining process for SiC. Due to silicon carbide’s extreme hardness (second only to diamond), diamond grinding wheels are essential. Grinding is used to:

- Achieve precise dimensional tolerances.

- Create flat and parallel surfaces.

- Shape complex contours that cannot be formed during the initial pressing or casting.

- Improve surface finish.

- Lapping and Polishing: For applications demanding ultra-smooth surfaces and extremely tight flatness or parallelism (e.g., thermal interface materials, sealing surfaces, substrates for sensitive electronics), lapping and polishing are employed. These processes use progressively finer diamond abrasives to achieve mirror-like finishes and Ra values well below 0.1 µm.

- Cutting and Dicing: Large sintered SiC blocks or plates may need to be cut or diced into smaller, precise components. Diamond saws or laser cutting (for specific SiC types or thinner sections) can be used.

- Drilling and Hole Making: Creating holes in sintered SiC requires specialized techniques like diamond core drilling, ultrasonic machining, or laser drilling. The method chosen depends on the hole diameter, depth, tolerance, and aspect ratio.

- Cleaning: After machining, components must be thoroughly cleaned to remove any residual abrasive particles, machining fluids, or other contaminants that could interfere with battery performance or assembly.

- Edge Chamfering/Radiusing: To reduce the risk of chipping on sharp edges and improve handling safety, edges are often chamfered or radiused. This can also help mitigate stress concentrations.

- Metallization: For some battery applications, SiC components may need to be joined to metallic parts (e.g., electrical contacts, heat sink attachments). Metallization involves depositing a metallic layer (e.g., molybdenum-manganese followed by nickel plating) onto the SiC surface to make it solderable or brazeable. This is common for SiC substrates in power modules.

- Coatings: While SiC itself is highly resistant, specialized coatings (e.g., dielectric coatings for enhanced insulation, or protective layers for extremely aggressive chemical environments beyond SiC’s standard capabilities) can sometimes be applied, although less common for bulk SiC parts in batteries which already leverage SiC’s inherent properties.

- Annealing: In some cases, a post-machining annealing step might be used to relieve any stresses induced during aggressive grinding, though this is carefully considered as it can also affect microstructure.

- Inspection and Quality Control: Though not a modification process, rigorous inspection (dimensional checks, surface roughness measurement, crack detection using NDT methods like dye penetrant or X-ray) is a critical post-processing step to ensure components meet all specifications.

The extent and type of post-processing depend heavily on the specific application and the initial manufacturing route of the SiC ceramic. Working with a supplier who has comprehensive in-house post-processing capabilities ensures better control over quality, lead times, and cost.

Overcoming Challenges in SiC Integration for Battery Manufacturing

While silicon carbide offers significant advantages for battery technology, its integration into manufacturing workflows is not without challenges. Addressing these proactively is key to successfully leveraging SiC’s potential.

- Brittleness and Machining Complexity:

- Challenge: SiC is a very hard but also brittle ceramic. This makes it susceptible to chipping or fracture during machining or handling if not done correctly. Machining requires specialized diamond tooling and techniques, which can be slower and more costly than machining metals.

- Mitigation:

- Design optimization to minimize stress concentrations (e.g., using fillets and radii instead of sharp corners).

- Employing experienced SiC machining specialists who understand the material’s behavior.

- Using advanced machining techniques like ultrasonic-assisted grinding or laser machining for intricate features.

- Careful handling protocols throughout the manufacturing and assembly process.

- Near-net-shape forming techniques to minimize the amount of post-sintering machining required.

- Cost:

- Challenge: High-purity SiC raw materials and the energy-intensive sintering and machining processes can make SiC components more expensive upfront compared to traditional materials like aluminum or some other ceramics.

- Mitigation:

- Focus on the total cost of ownership (TCO). The extended lifespan, improved performance, and enhanced safety offered by SiC can lead to lower TCO over the battery system’s life.

- Value engineering: Optimize component design for manufacturability and material usage. Not all surfaces may need ultra-tight tolerances or finishes.

- Select the appropriate SiC grade. For instance, RBSC is often more cost-effective than SSiC for complex shapes if its properties meet the application requirements.

- Volume production can help reduce per-unit costs.

- Working with suppliers like Sicarb Tech, who leverage extensive local production capabilities and technological expertise, can provide access to cost-competitive custom SiC components.

- Joining SiC to Other Materials:

- Challenge: Efficiently joining SiC to other materials (metals for electrical connections, polymers for sealing) can be difficult due to differences in coefficients of thermal expansion (CTE) and chemical compatibility.

- Mitigation:

- Specialized joining techniques such as active metal brazing, diffusion bonding, or specialized adhesives.

- Designing mechanical clamping or interface layers to accommodate CTE mismatch.

- Metallization of SiC surfaces to make them solderable or brazeable.

- Thermal Shock Resistance:

- Challenge: While generally good, some SiC grades can be susceptible to thermal shock if subjected to extremely rapid temperature changes, especially if there are pre-existing flaws.

- Mitigation:

- Selecting SiC grades with higher thermal shock resistance (e.g., some formulations of RBSC or NBSC).

- Designing for gradual temperature transitions where possible.

- Ensuring high-quality manufacturing to minimize internal flaws that can act as crack initiation sites.

- Supplier Expertise and Scalability:

- Challenge: Finding suppliers with deep expertise in custom SiC fabrication and the capacity to scale production for demanding industries like automotive can be a hurdle.

- Mitigation: Thoroughly vet potential suppliers for their technical capabilities, material knowledge, quality control systems, and track record in similar applications. Look for partners who offer design support and can grow with your production needs.

By understanding these challenges and working with experienced silicon carbide specialists, manufacturers can effectively integrate SiC components and unlock significant performance improvements in their battery systems.

Selecting the Right SiC Supplier for Your Battery Technology

Choosing the right supplier for custom silicon carbide components is as critical as selecting the right material grade. A capable and reliable supplier becomes a partner in innovation, helping you navigate design complexities, optimize for cost, and ensure consistent quality for your demanding battery applications. Here are key factors to consider when evaluating potential SiC suppliers:

- Technical Expertise and Material Knowledge:

- Does the supplier have a deep understanding of various SiC grades (RBSC, SSiC, etc.) and their suitability for specific battery-related stresses (thermal, electrical, mechanical)?

- Can they provide expert advice on material selection and design for manufacturability?

- Do they have R&D capabilities or access to material science expertise?

- Customization Capabilities:

- Are they truly capable of producing custom SiC pa

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.