SiC Heat Exchangers for Superior Thermal Management

Share

SiC Heat Exchangers for Superior Thermal Management

Introduction: Revolutionizing Thermal Management with SiC Heat Exchangers

In today’s demanding industrial landscape, efficient thermal management is not just a preference—it’s a critical necessity. For industries ranging from

Silicon Carbide, an advanced technical ceramic, possesses an extraordinary combination of properties: exceptional thermal conductivity, outstanding high-temperature strength, superior chemical inertness, and remarkable wear and corrosion resistance. These characteristics make

This blog post will delve into the world of

Unlocking Efficiency: Key Industrial Applications of SiC Heat Exchangers

The exceptional properties of

- Semiconductor Manufacturing: In processes like wafer fabrication and chemical vapor deposition (CVD), precise temperature control and ultra-high purity are essential.

SiC heat exchangers are used for cooling processing chambers and gas streams, ensuring minimal contamination and optimal thermal uniformity. Their resistance to corrosive gases used in etching and cleaning is a significant advantage. - Chemical Processing: The chemical industry frequently deals with highly corrosive acids, bases, and solvents, often at elevated temperatures.

SiC tube heat exchangers andSiC plate heat exchangers offer unmatched corrosion resistance, making them perfect for heating, cooling, condensing, and evaporating aggressive media. This leads to longer equipment life and reduced maintenance compared to exotic metal alloys. - Power Electronics and Energy Storage: High-power density in converters, inverters, and battery systems generates significant heat.

SiC heat exchangers provide efficient cooling solutions, ensuring the reliability and longevity of these critical components, particularly inrenewable energy systems (solar, wind) and electric vehicles. - Metallurgy and High-Temperature Furnaces: In metallurgical operations, including heat treatment, sintering, and smelting,

SiC heat exchangers can recover waste heat from flue gases at very high temperatures (often exceeding 1000°C). This significantly improves energy efficiency. Their resistance to thermal shock is critical in these cyclical high-temperature environments. - Aerospace and Defense: Lightweight, high-strength, and high-temperature capable materials are vital.

Custom SiC heat exchangers find applications in thermal management systems for avionics, engine components, and directed energy systems where performance and reliability in extreme conditions are non-negotiable. - Pharmaceutical and Fine Chemicals: Maintaining product purity is paramount. The inertness of SiC prevents leaching of contaminants into sensitive chemical or pharmaceutical products, making

SiC heat exchangers a preferred choice for processes requiring stringent purity controls. - Oil and Gas: Downstream processing in refineries and petrochemical plants often involves corrosive substances and high temperatures.

SiC heat exchangers can handle sour gas, acidic crudes, and other aggressive media, offering a robust alternative to specialized alloys that may have longer lead times or higher costs. - LED Manufacturing: Similar to semiconductor fabrication, LED production involves processes that benefit from SiC’s thermal properties and chemical resistance, ensuring consistent quality and yield.

- Industrial Machinery: For specialized industrial equipment requiring rapid heating or cooling cycles with aggressive media,

custom SiC heat exchangers provide a compact and durable solution.

The versatility of

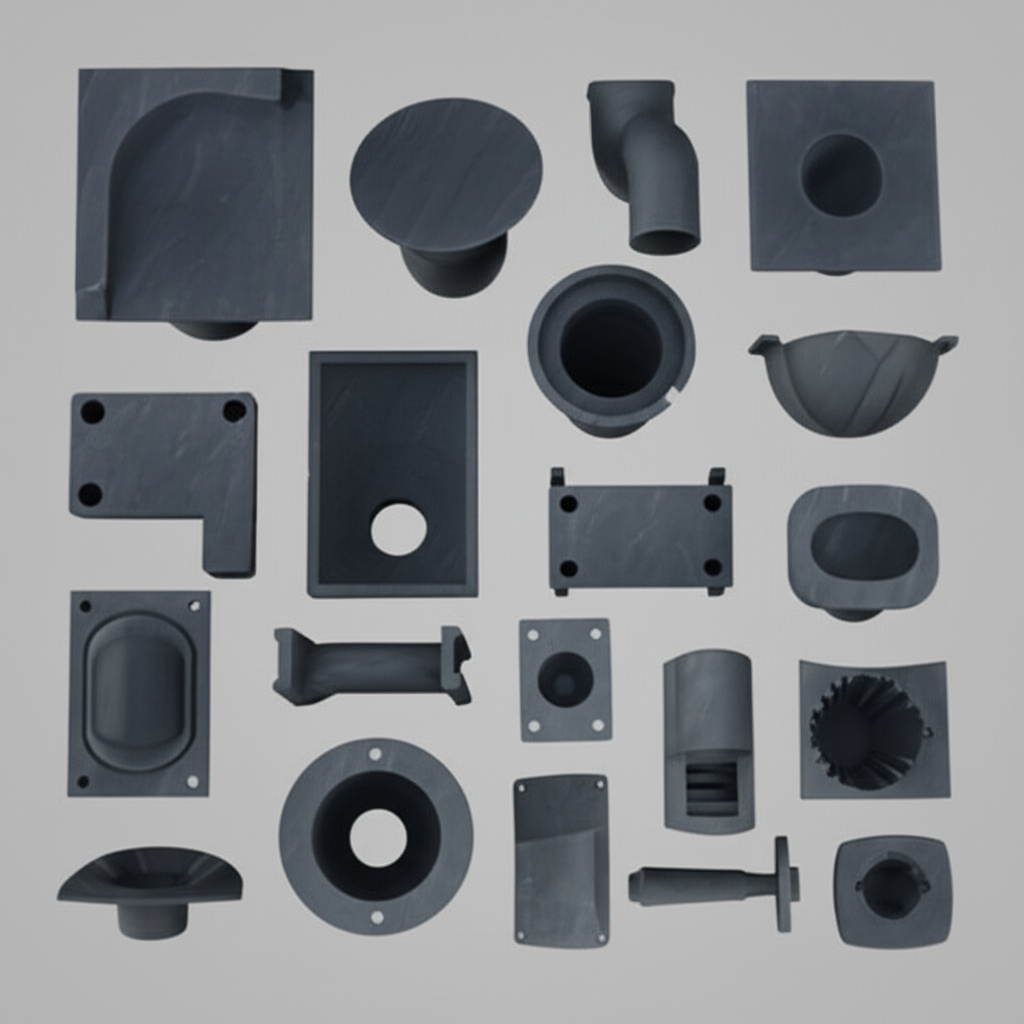

The Custom Advantage: Why Opt for Custom Silicon Carbide Heat Exchangers?

While standard heat exchanger designs serve many purposes, a growing number of advanced industrial processes demand thermal solutions tailored to specific, often extreme, operational parameters. Opting for

- Optimized Thermal Performance: Custom designs allow engineers to precisely match the heat exchanger’s capacity and geometry to the application’s specific heat load, flow rates, and temperature differentials. This ensures maximum thermal efficiency and energy savings. Factors like tube diameter, length, pitch, and overall configuration can be fine-tuned.

- Perfect Fit and Integration:

Custom SiC components , including heat exchangers, can be designed to fit into existing space envelopes or integrated seamlessly into new equipment designs. This is particularly crucial in complex machinery or retrofitting projects where space is at a premium. - Enhanced Material Selection: While SiC is the base material, customization can involve selecting specific grades of SiC (e.g., Reaction-Bonded SiC, Sintered SiC) best suited for the thermal, mechanical, and chemical stresses of the application. Surface finishes and specialized coatings can also be incorporated for enhanced performance in unique environments.

- Superior Durability in Extreme Conditions:

- Extreme Temperature Resistance: SiC maintains its mechanical strength and thermal properties at temperatures exceeding 1400°C, far beyond the capabilities of most metals. Custom designs can account for thermal expansion and stress distribution specific to the operating cycle.

- Unmatched Chemical Inertness: Custom SiC heat exchangers can be designed to handle highly corrosive fluids, such as strong acids (sulfuric, nitric, hydrofluoric), bases, and organic solvents, without degradation. This is vital in chemical, petrochemical, and pharmaceutical industries.

- Exceptional Wear and Abrasion Resistance: In applications involving slurries or particulate-laden fluids, the hardness of SiC minimizes erosion, extending the service life of the heat exchanger.

- Application-Specific Geometries: Customization allows for unique heat exchanger configurations beyond standard shell-and-tube or plate designs. This could include microchannel designs for compact applications, complex manifolding for specific flow distribution, or integrated sensor ports.

- Reduced System Complexity: A custom-designed heat exchanger can sometimes consolidate the functions of multiple components, simplifying the overall system, reducing potential leak points, and lowering maintenance requirements.

- Support for Innovative Processes: Many cutting-edge industrial processes, particularly in

semiconductors ,aerospace , andrenewable energy , have unique thermal challenges.Custom SiC heat exchangers empower engineers to develop and implement these novel processes by providing tailored thermal management solutions.

Investing in

Material Focus: Selecting the Right SiC Grade for Your Heat Exchanger

Silicon Carbide (SiC) is not a monolithic material; various manufacturing processes result in different grades of SiC, each with a unique set of properties. Selecting the appropriate SiC grade is critical for ensuring the optimal performance, longevity, and cost-effectiveness of your

Reaction-Bonded Silicon Carbide (RBSiC / SiSiC)

RBSiC, also known as Siliconized Silicon Carbide (SiSiC), is produced by infiltrating a porous SiC and carbon preform with molten silicon. The silicon reacts with the carbon to form additional SiC, which bonds the original SiC grains. The resulting material typically contains 8-15% free silicon.

- Advantages:

- Relatively lower manufacturing cost compared to SSiC.

- Good thermal conductivity.

- Excellent wear and abrasion resistance.

- High strength and stiffness.

- Ability to produce large and complex shapes with tight tolerances.

- Good thermal shock resistance.

- Limitations:

- The presence of free silicon limits its use in extremely corrosive environments, particularly with strong alkalis or hydrofluoric acid at high temperatures, as silicon is less resistant than pure SiC.

- Maximum service temperature is typically around 1350-1380°C, limited by the melting point of silicon (1414°C).

- Common Applications: Widely used for heat exchanger tubes, plates, and other components in applications like industrial waste heat recovery, radiant tubes, kiln furniture, and components for handling abrasive slurries.

Sintered Silicon Carbide (SSiC)

SSiC is produced by sintering fine SiC powder at very high temperatures (typically >2000°C) with non-oxide sintering aids (like boron and carbon). This process results in a dense, single-phase SiC material with minimal or no free silicon.

- Advantages:

- Superior chemical resistance across a broad pH range, including strong acids and alkalis, even at high temperatures. This makes it the preferred choice for the most aggressive chemical environments.

- Higher maximum service temperature (up to 1600°C or higher in controlled atmospheres).

- Excellent thermal shock resistance.

- Very high hardness and good wear resistance.

- High thermal conductivity (though sometimes slightly lower than the best RBSiC grades).

- Limitations:

- Generally more expensive to manufacture than RBSiC.

- Manufacturing very large or highly complex shapes can be more challenging and costly.

- Common Applications: Ideal for demanding heat exchanger applications in the fine chemical, pharmaceutical, and petrochemical industries where extreme corrosion resistance is paramount. Also used in semiconductor processing equipment and high-temperature energy systems.

Other SiC Variants (Less Common for Bulk Heat Exchangers)

- Nitride-Bonded Silicon Carbide (NBSiC): Offers good thermal shock resistance and strength, often used in refractory applications. Less common for primary heat exchange surfaces due to typically lower thermal conductivity compared to RBSiC or SSiC.

- Chemical Vapor Deposited SiC (CVD-SiC): Produces ultra-high purity SiC, often as coatings. While exceptional, it’s typically too expensive for entire heat exchanger structures but can be used for critical surfaces.

Comparison Table: RBSiC vs. SSiC for Heat Exchangers

| Property | Reaction-Bonded SiC (RBSiC) | Sintered SiC (SSiC) |

|---|---|---|

| Composition | SiC with 8-15% free Silicon | Predominantly pure SiC (>98%) |

| Max. Service Temperature | ~1350-1380°C | ~1600°C (or higher) |

| Thermal Conductivity (W/mK at RT) | 100 – 150 | 80 – 120 (can vary) |

| Corrosion Resistance (Acids) | Good to Excellent (HF can be an issue) | Excellent (including HF) |

| Corrosion Resistance (Alkalis) | Moderate to Good | Excellent |

| Flexural Strength (MPa at RT) | 250 – 550 | 400 – 600 |

| Hardness (Knoop) | ~2500 | ~2800 |

| Manufacturability of Complex Shapes | Good, more cost-effective for large parts | More challenging and costly for very large/complex parts |

| Relative Cost | Lower | Higher |

Choosing between

Engineering Excellence: Critical Design Considerations for SiC Heat Exchangers

Designing

1. Managing Brittleness and Mechanical Stress:

- Stress Concentrations: Avoid sharp internal corners, sudden changes in cross-section, and small radii, which can act as stress concentrators. Generous fillets and rounded edges are crucial.

- Mechanical Loads: Design to minimize tensile and bending stresses. SiC is much stronger in compression. Consider how external loads (piping, vibration, mounting) will be supported.

- Impact Resistance: While hard, SiC can be susceptible to impact damage. Designs should incorporate protective measures if impacts are possible during installation, operation, or maintenance.

2. Thermal Stress Management:

- Thermal Expansion Mismatch: SiC has a relatively low coefficient of thermal expansion (CTE). When interfacing with metallic components (e.g., shells, flanges), differential expansion must be accommodated through flexible joints, bellows, or specialized sealing systems.

- Thermal Gradients and Shock: While SiC generally has good thermal shock resistance (especially SSiC), extreme and rapid temperature changes can induce stress. Designs should aim for uniform heating/cooling where possible. For applications with severe thermal cycling, finite element analysis (FEA) is recommended to predict stress distributions.

- Steady-State vs. Transient Operations: Analyze thermal stresses during both steady-state operation and transient phases (startup, shutdown, process upsets).

3. Fluid Dynamics and Flow Path Design:

- Flow Distribution: Ensure even flow distribution across all tubes or channels to maximize heat transfer efficiency and prevent hot spots or localized corrosion/erosion. Manifold and header design is critical.

- Pressure Drop: Optimize tube/channel diameter, length, and quantity to achieve the desired heat transfer with an acceptable pressure drop for the process fluids.

- Velocity Limits: While SiC is erosion-resistant, extremely high fluid velocities, especially with abrasive particles, can still cause wear over time. Consider velocity limits in the design.

- Preventing Fouling: Design for ease of cleaning if process fluids are prone to fouling. Smooth surfaces and appropriate flow velocities can minimize deposit buildup.

4. Sealing and Joining:

- High-Temperature Sealing: Achieving reliable, leak-tight seals between SiC components (e.g., tube-to-tubesheet joints) and between SiC and metallic parts is a major design challenge, especially at high temperatures.

- Common Sealing Methods:

- Mechanical compression seals using graphite, ceramic fibers, or specialized elastomers (for lower temperatures).

- O-ring seals (often with perfluoroelastomers for chemical resistance).

- Brazing or glass-ceramic sealing for permanent, high-integrity joints (more complex and application-specific).

- Interference fits or shrink fits for certain designs.

- Joint Design: The design of the joint must accommodate thermal expansion differences and maintain sealing integrity under all operating conditions.

5. Manufacturability and Cost:

- Geometric Complexity: While SiC can be formed into complex shapes, overly intricate designs can significantly increase manufacturing costs and lead times. Simplify geometry where possible without compromising performance.

- Tolerances: Specify only the necessary tolerances. Overly tight tolerances add cost. Understand the manufacturing capabilities for the chosen SiC grade.

- Wall Thickness: Balance the need for mechanical strength with thermal performance. Thicker walls increase strength but also thermal resistance. Minimum practical wall thicknesses depend on the manufacturing process and SiC grade.

6. Material Grade Selection:

As discussed earlier, choosing between

7. Integration with Overall System:

- Mounting and Support: Provide adequate support structures to handle the weight of the heat exchanger and any connected piping, without imposing undue stress on the SiC components.

- Instrumentation: Incorporate ports for temperature and pressure sensors as needed for process control and monitoring.

- Maintenance Access: Consider accessibility for inspection, cleaning, or potential repairs, if applicable.

Successful

Precision Matters: Tolerances, Surface Finish, and Dimensional Control in SiC Heat Exchanger Manufacturing

The performance and reliability of

Dimensional Accuracy and Tolerances:

Achieving tight dimensional control with hard, brittle ceramics like SiC is more challenging than with metals. The manufacturing process (e.g., slip casting, extrusion, pressing for RBSiC; die compaction, isostatic pressing for SSiC) followed by sintering or reaction bonding, and potentially diamond grinding, all influence the final dimensions and achievable tolerances.

- As-Fired Tolerances: Components produced without post-sintering machining typically have wider tolerances. For RBSiC, this might be in the range of ±0.5% to ±1.5% of the dimension. SSiC shrinkage during sintering is higher and can be less predictable, sometimes requiring grinding for tighter control.

- Machined Tolerances: For critical dimensions, such as sealing surfaces, tube diameters, or tube-to-tubesheet fits, post-sintering diamond grinding is often necessary. This allows for much tighter tolerances, often in the range of ±0.01 mm to ±0.1 mm, depending on the size and complexity of the feature. However, extensive grinding significantly increases cost.

- Impact of Tolerances:

- Sealing: Tight tolerances on sealing surfaces are crucial for achieving leak-proof joints, especially in high-pressure or vacuum applications.

- Assembly: Precise dimensions ensure proper fit-up of components, such as tubes into tubesheets, reducing assembly stresses and ensuring design integrity.

- Flow Characteristics: Consistent tube diameters and channel dimensions ensure predictable fluid flow and heat transfer performance.

- Geometric Dimensioning and Tolerancing (GD&T): For complex parts, applying GD&T principles helps to clearly define functional requirements for flatness, parallelism, concentricity, etc., ensuring components meet their intended purpose.

Surface Finish:

The surface finish (roughness) of SiC components can impact several performance aspects:

- Fluid Flow and Fouling: Smoother surfaces generally lead to lower frictional pressure drop and can reduce the tendency for fouling or deposit buildup in certain applications. Typical as-fired surfaces might have a roughness (Ra) of 1-5 µm.

- Sealing: Smoother, flatter surfaces are essential for effective gasket sealing. Lapping or polishing can achieve surface finishes down to Ra < 0.1 µm on critical sealing faces.

- Strength: Surface flaws can act as initiation sites for fractures in ceramics. A finer surface finish, achieved through grinding or polishing, can sometimes improve the effective strength of a component by removing microscopic cracks or defects.

- Cleaning: Smoother surfaces are generally easier to clean, which is an important consideration in pharmaceutical, food, or semiconductor applications.

Manufacturers typically offer different levels of surface finish:

- As-fired/As-sintered: The natural surface after the primary forming and firing process. Most economical.

- Ground: Achieved using diamond grinding wheels. Provides better dimensional control and a smoother finish than as-fired.

- Lapped/Polished: Utilizes fine abrasive slurries to produce very smooth, flat, and often reflective surfaces. Reserved for critical areas due to cost.

Dimensional Control Strategies:

Reputable

- Process Control: Strict control over raw material quality, forming processes, sintering/reaction parameters, and machining conditions.

- Mold/Tooling Design: Accurate mold design that accounts for material shrinkage during firing is crucial.

- Advanced Machining: Utilizing precision diamond grinding machines, CNC machining centers adapted for ceramics, and techniques like Electrical Discharge Machining (EDM) for certain SiC grades or features.

- Metrology: Employing sophisticated measurement equipment, including Coordinate Measuring Machines (CMMs), optical profilometers, and laser scanners, to verify dimensions and surface characteristics.

When specifying

Beyond Fabrication: Post-Processing for Enhanced SiC Heat Exchanger Performance

While the primary fabrication of

1. Precision Grinding and Lapping:

As mentioned previously, diamond grinding is often essential for achieving tight dimensional tolerances and specific surface finishes. Lapping takes this a step further:

- Grinding: Used to shape components, achieve precise diameters for tubes, flatness for plates or tubesheets, and prepare surfaces for sealing. It removes larger amounts of material compared to lapping.

- Lapping: An abrasive machining process that uses a loose abrasive slurry between the workpiece and a lap plate. It produces extremely flat, smooth surfaces with very fine finishes (Ra often < 0.2 µm). This is critical for:

- High-performance sealing surfaces where gasket conformity is paramount.

- Applications requiring minimal surface defects for improved mechanical strength or optical properties (less common for heat exchangers but relevant for other SiC components).

2. Polishing:

Polishing is an even finer finishing process than lapping, often using diamond pastes or slurries with progressively smaller particle sizes. It can achieve mirror-like finishes (Ra < 0.05 µm). For

- Ultra-high purity applications where minimizing surface area and potential entrapment sites for contaminan

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.