SiC: A Pillar of Strength for the Chemical Industry

Share

SiC: A Pillar of Strength for the Chemical Industry

Introduction: The Unyielding Material for Extreme Chemical Environments

In the relentless landscape of the chemical industry, where corrosive agents, extreme temperatures, and high pressures are the norm, material selection is paramount. Standard materials often falter, leading to costly downtime, safety hazards, and compromised product purity. Enter Silicon Carbide (SiC), an advanced ceramic material renowned for its exceptional hardness, outstanding thermal conductivity, and superior resistance to chemical attack. Custom silicon carbide products are not just components; they are critical enablers of innovation and reliability in high-performance industrial applications. For chemical processing, SiC offers a lifeline, providing unmatched durability and performance where other materials reach their limits. Its unique combination of properties makes it an indispensable asset for engineers and procurement managers striving for operational excellence and extended equipment lifespan in sectors ranging from bulk chemical production to specialized pharmaceutical synthesis. The ability to engineer SiC into complex geometries further enhances its utility, allowing for bespoke solutions that precisely match demanding application requirements. As we delve deeper, we will explore how this remarkable material is revolutionizing chemical processing equipment and why its adoption is becoming a strategic imperative for forward-thinking organizations.

The demand for high-purity chemicals and more efficient processing methods continues to grow, pushing the boundaries of material science. Silicon carbide stands ready to meet these challenges, offering a robust and reliable solution. Its inherent stability ensures that it does not contaminate processes, a crucial factor in industries where even trace impurities can have significant consequences. From reactor vessels to minute pump components, SiC’s versatility is a game-changer.

The Chemical Industry’s Demanding Environment: A Material Challenge

The chemical processing industry (CPI) is characterized by some of the most aggressive operational conditions found in any manufacturing sector. Materials used in this environment must withstand a barrage of challenges, often simultaneously:

- Corrosive Chemicals: A vast array of acids (e.g., sulfuric, nitric, hydrochloric, hydrofluoric), bases, solvents, and oxidizing agents are handled daily. These substances can rapidly degrade metals, polymers, and even some conventional ceramics. Key B2B search terms like “SiC chemical resistance” and “corrosion-resistant ceramic components” highlight this critical need.

- High Temperatures: Many chemical reactions and processes require elevated temperatures, sometimes exceeding 1000°C (1832°F). Materials must maintain their structural integrity and chemical stability under such thermal loads. “High-temperature SiC parts” and “thermal management ceramics” are frequently sought after.

- Extreme Pressures: Processes often operate under significant pressure or vacuum conditions, demanding materials that can resist deformation and catastrophic failure.

- Abrasive Media: Slurries, catalysts, and particulate-laden fluids can cause severe wear and erosion in components like pipes, valves, and pump internals. “Wear-resistant SiC components” and “abrasion-resistant ceramics” are vital for these applications.

- Thermal Cycling: Rapid temperature changes can induce thermal shock, leading to cracking and failure in susceptible materials. Components must be able to withstand these fluctuations without compromising performance.

- Purity Requirements: In many chemical processes, particularly in pharmaceuticals and electronics manufacturing, maintaining product purity is paramount. Materials must be inert and non-leaching to prevent contamination.

Traditional materials like stainless steel, specialty alloys, and various plastics often fall short when faced with the full spectrum of these challenges, especially in combination. This is where advanced technical ceramics, particularly silicon carbide, demonstrate their profound advantages, offering a longer service life and more reliable performance, ultimately leading to reduced maintenance costs and improved plant safety. The selection of appropriate materials is a critical design consideration for any chemical engineer or plant manager looking to optimize their processes.

Why SiC is a Pillar of Strength: Key Benefits Unveiled

Silicon carbide’s preeminence in harsh chemical environments stems from a unique combination of inherent material properties. These attributes make it a “pillar of strength” for critical applications, offering significant advantages over traditional materials and even other ceramics.

- Exceptional Chemical Inertness: SiC exhibits remarkable resistance to a wide range of corrosive chemicals, including strong acids, alkalis, and oxidizing agents, even at elevated temperatures. This inertness prevents material degradation and ensures product purity, which is crucial for “SiC for acid environments” and “alkali-resistant SiC parts.”

- Outstanding Thermal Stability and Conductivity: Silicon carbide maintains its mechanical strength and structural integrity at very high temperatures (up to 1650°C or higher for some grades in non-oxidizing atmospheres). Its high thermal conductivity allows for efficient heat dissipation or transfer, making it ideal for “SiC heat exchanger tubes” and “high-temperature furnace components.” This property also contributes to excellent thermal shock resistance.

- Superior Wear and Abrasion Resistance: With a Mohs hardness second only to diamond, SiC is extremely resistant to wear from abrasive slurries, particles, and high-velocity flows. This translates to longer component life for “SiC pump seals,” “nozzles,” and “cyclone liners.”

- High Mechanical Strength and Hardness: SiC components possess high compressive and flexural strength, allowing them to withstand significant mechanical loads and pressures. This is critical for structural components in reactors and high-pressure systems.

- Low Thermal Expansion: SiC has a relatively low coefficient of thermal expansion, which, combined with its high thermal conductivity, gives it excellent resistance to thermal shock. This allows SiC components to endure rapid temperature changes without cracking.

- Lightweight: Compared to many metals with high-temperature capabilities (like superalloys), SiC is relatively lightweight, which can be an advantage in certain dynamic applications or where overall system weight is a concern.

- Dimensional Stability: Once fabricated and sintered, SiC parts exhibit excellent dimensional stability over time, even under fluctuating thermal and mechanical loads.

These properties collectively contribute to extended service life, reduced maintenance intervals, improved process efficiency, and enhanced safety in chemical plants. The ability to customize SiC components allows engineers to leverage these benefits in highly specific and demanding applications.

Key Applications of SiC in Chemical Processing Equipment

The outstanding properties of silicon carbide make it suitable for a diverse range of demanding applications within the chemical processing industry. Custom SiC components are frequently specified for areas where longevity, reliability, and resistance to harsh conditions are paramount.

| Component Type | Specific SiC Application | Key Benefits Provided by SiC | Relevant B2B Keywords |

|---|---|---|---|

| Heat Exchangers | Tubes, plates, and shells for corrosive fluid heating/cooling | High thermal conductivity, excellent corrosion resistance, resistance to fouling | “SiC heat exchanger tubes,” “ceramic heat exchangers,” “corrosion-proof heat transfer” |

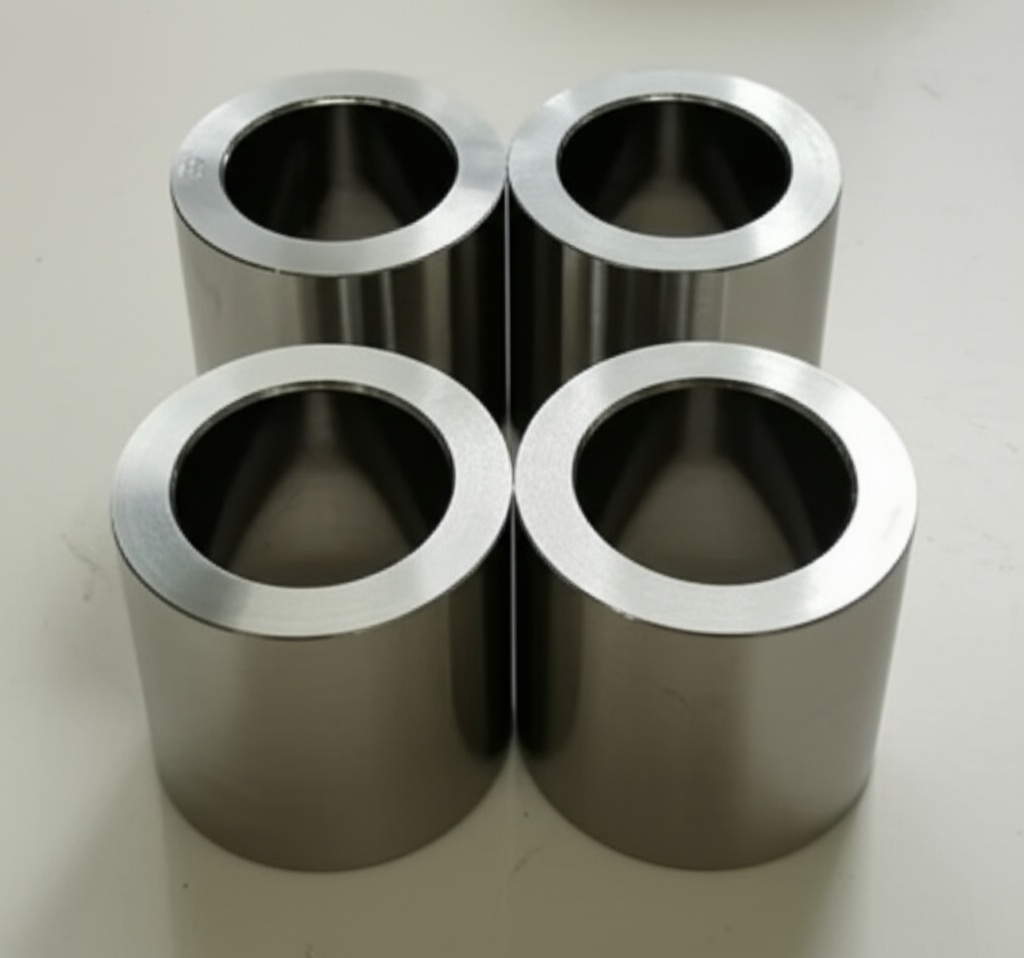

| Pump Components | Mechanical seals, bearings, shafts, impellers, sleeves | Extreme wear resistance, chemical inertness, dry-run capability (for seals) | “SiC mechanical seals,” “silicon carbide pump bearings,” “chemical pump components” |

| Valves and Flow Control | Valve seats, balls, trim, liners, nozzles, orifices | Abrasion and erosion resistance, precise flow control, chemical stability | “SiC valve components,” “ceramic control valves,” “wear-resistant nozzles” |

| Reactor Components | Linings, thermowells, agitator parts, catalyst carriers, crucibles | High-temperature strength, chemical inertness, thermal shock resistance | “SiC reactor linings,” “ceramic thermowells,” “high-temperature crucibles” |

| Piping and Liners | Pipes for abrasive slurries, lined pipes for highly corrosive fluids | Exceptional abrasion resistance, superior corrosion protection | “SiC lined pipes,” “abrasion-resistant piping,” “ceramic pipe spools” |

| Mixing and Dispersion | Mixer blades, dispersion discs, milling media | Wear resistance, chemical inertness, preventing product contamination | “SiC mixer components,” “ceramic milling media” |

| Burner Nozzles & Combustion Components | Burner nozzles, flame holders, recuperator tubes | High-temperature stability, oxidation resistance, thermal shock resistance | “SiC burner nozzles,” “industrial combustion ceramics” |

| Scrubber and Gas Cleaning Systems | Nozzles, venturi scrubbers, packing materials | Corrosion and erosion resistance in aggressive gas environments | “SiC scrubber nozzles,” “ceramic tower packing” |

The versatility of SiC allows for its use in both large-scale structural components and small, intricate precision parts. This adaptability, coupled with its robust performance characteristics, solidifies silicon carbide’s role as a critical material in advancing the efficiency and reliability of modern chemical processing operations.

Advantages of Custom Silicon Carbide Solutions for Chemical Plants

While standard SiC components offer substantial benefits, custom silicon carbide solutions provide an elevated level of performance and integration specifically tailored to the unique challenges of individual chemical plant applications. Opting for custom-designed SiC parts means moving beyond off-the-shelf limitations and embracing components engineered for optimal functionality within a specific operational context.

- Optimized Design for Specific Applications: Customization allows engineers to design SiC components that precisely fit their equipment and process parameters. This includes complex geometries, specific interface requirements, and optimized flow paths, leading to improved efficiency and reduced stress concentrations.

- Enhanced Performance and Efficiency: Tailored designs can maximize the inherent benefits of SiC. For example, a custom-designed SiC heat exchanger tube bundle can offer superior thermal performance compared to a standard design by optimizing tube spacing and surface area for a particular fluid and flow rate.

- Increased Equipment Lifespan: Components designed for the exact wear patterns, chemical exposures, and thermal stresses of an application will inevitably last longer. This reduces replacement frequency, minimizes downtime, and lowers total cost of ownership. Keywords like “long-life SiC parts” and “durable ceramic components” reflect this demand.

- Improved System Integration: Custom SiC parts can be designed for seamless integration with existing metallic or polymeric components, addressing challenges like differential thermal expansion and sealing. This facilitates easier retrofitting and system upgrades.

- Solution for Unique Challenges: Many chemical processes involve unique or extreme conditions for which standard components are simply inadequate. Custom SiC fabrication provides a pathway to develop novel solutions for these niche but critical applications.

- Material Grade Selection: Customization often extends to selecting or even fine-tuning the specific grade of SiC (e.g., SSiC, RBSiC) to perfectly match the chemical and thermal environment, ensuring optimal resistance and performance.

For companies seeking such specialized solutions, partnering with an experienced provider is crucial. This is where organizations like Sicarb Tech excel. Leveraging deep expertise in silicon carbide technology, we specialize in customizing SiC components to meet the rigorous demands of the chemical industry. Our approach involves understanding your specific process challenges and engineering a SiC solution that delivers tangible improvements in performance and reliability.

Recommended SiC Grades for Diverse Chemical Applications

Silicon carbide is not a monolithic material; various manufacturing processes result in different grades of SiC, each with a unique set of properties. Selecting the appropriate grade is critical for optimizing performance and cost-effectiveness in specific chemical applications. The primary grades relevant to the chemical industry include Sintered Silicon Carbide (SSiC), Reaction-Bonded Silicon Carbide (RBSiC), and to a lesser extent, Nitride-Bonded Silicon Carbide (NBSiC) and Recrystallized SiC (ReSiC).

| SiC Grade | Key Characteristics | Typical Chemical Applications | Advantages in Chemical Environments | Limitations |

|---|---|---|---|---|

| Sintered Silicon Carbide (SSiC) / Pressureless Sintered SiC (PSSiC) | Fine-grained, high purity (typically >98% SiC), excellent corrosion resistance, high strength and hardness, good thermal shock resistance. Formed by sintering SiC powder at high temperatures (2000-2200°C). | Mechanical seals, bearings, valve components, nozzles, pump parts in highly corrosive media (strong acids, caustics). Semiconductor processing equipment. | Superior chemical inertness across a very wide pH range. Excellent wear resistance. Maintains properties at high temperatures. | Generally higher cost than RBSiC. Can be more challenging to produce very large or complex shapes. |

| Reaction-Bonded Silicon Carbide (RBSiC) / Siliconized Silicon Carbide (SiSiC) | Composite material containing SiC grains and a silicon metal matrix (typically 8-15% free silicon). Good wear resistance, high thermal conductivity, good thermal shock resistance, easily forms complex shapes. Produced by infiltrating a porous SiC preform with molten silicon. | Heat exchanger tubes, burner nozzles, kiln furniture, wear liners, larger structural components, pump volutes. | Cost-effective for larger components. Excellent thermal conductivity and shock resistance. Good general-purpose corrosion resistance. | Free silicon phase can be attacked by strong alkalis, hydrofluoric acid, and certain molten metals above 1350°C. Lower ultimate temperature limit than SSiC in oxidizing atmospheres. |

| Nitride-Bonded Silicon Carbide (NBSiC) | SiC grains bonded by a silicon nitride (Si3N4) phase. Good strength, moderate thermal shock resistance, good wear resistance. | Kiln furniture, components for metal melting and handling (e.g., aluminum). Some specialized chemical applications. | Good resistance to wetting by molten non-ferrous metals. Decent strength at moderate temperatures. | Lower corrosion resistance compared to SSiC, especially in aggressive acids and bases. Silicon nitride binder can oxidize. |

| Recrystallized Silicon Carbide (ReSiC) | High purity SiC (often >99%) formed by sublimating and re-condensing SiC at very high temperatures (around 2500°C). Porous structure unless densified. | High-temperature furnace components, kiln furniture, setters, supports where extreme temperature resistance is needed. | Highest temperature capability among common SiC grades. Excellent thermal shock resistance due to interconnected porosity (if not densified). | Typically porous, leading to lower mechanical strength and potential permeability unless specifically densified or coated. Can be expensive. |

The choice of SiC grade should be a collaborative decision between the end-user and an experienced SiC supplier. Factors like the specific chemical environment (type of chemical, concentration, temperature, pressure), mechanical stresses, thermal cycling conditions, and component geometry all play a role in determining the optimal grade. “Selecting SiC grades,” “SSiC vs RBSiC,” and “high-purity SiC” are important considerations for procurement professionals.

Design and Engineering Considerations for SiC Components in Chemical Processes

Successfully implementing silicon carbide components in chemical processing requires careful design and engineering considerations that account for SiC’s unique material properties. While incredibly robust, SiC is a brittle ceramic, and this characteristic must be managed throughout the design phase to ensure longevity and reliability.

- Managing Brittleness:

- Avoid sharp internal corners and stress concentrators; use generous radii instead.

- Design for compressive loads where possible, as ceramics are much stronger in compression than in tension.

- Ensure uniform load distribution to prevent localized stress peaks.

- Consider impact protection if the component is in an area prone to accidental collisions.

- Geometric Complexity and Manufacturability:

- While complex shapes are achievable (especially with RBSiC), simpler designs are generally more cost-effective and easier to manufacture with tight tolerances. “Complex SiC shapes” are possible but require expert manufacturing.

- Wall thickness should be sufficient for structural integrity but not excessively thick, as this can increase thermal stress gradients. Minimum wall thicknesses depend on the manufacturing method and size of the part.

- Consider draft angles for parts made using molding techniques.

- Joining and Assembly:

- Joining SiC to other SiC parts or to different materials (like metals) requires specialized techniques such as brazing, shrink-fitting, adhesive bonding, or mechanical clamping.

- Differential thermal expansion between SiC and metallic components must be accommodated in the design to prevent stress buildup during thermal cycling. Flexible interlayers or specific joint designs can help.

- Thermal Management:

- SiC’s high thermal conductivity is often an advantage (e.g., in heat exchangers), but rapid, uneven heating or cooling can still lead to thermal shock if not managed. Design for uniform temperature gradients where possible.

- The excellent thermal shock resistance of many SiC grades mitigates this, but extreme cases still need consideration.

- Sealing Surfaces:

- For applications like mechanical seals or valve seats, the design must allow for achieving very flat and smooth surfaces. Specify appropriate surface finish and flatness tolerances.

- Load Conditions:

- Thoroughly analyze all potential load conditions, including static, dynamic, thermal, and pressure-induced stresses. Finite Element Analysis (FEA) is often recommended for complex or critical SiC components.

- Prototyping and Testing:

- For novel applications or complex designs, prototyping and testing under simulated or actual service conditions are highly advisable to validate the design before full-scale production.

Collaborating with a SiC manufacturer experienced in “design for manufacturability” (DFM) for ceramics is crucial. They can provide valuable input on optimizing the design for both performance and cost-effective production. This early collaboration can prevent costly redesigns and ensure the final component meets all operational requirements.

Precision Machining: Tolerances, Surface Finish, and Dimensional Accuracy for SiC Parts

Achieving the required dimensional accuracy, tight tolerances, and specific surface finishes is critical for the functionality of many silicon carbide components in the chemical industry, especially for dynamic applications like seals, bearings, and valve parts. Due to SiC’s extreme hardness, machining it post-sintering is a challenging and specialized process, typically involving diamond grinding, lapping, and polishing.

- Achievable Tolerances:

- As-Sintered Tolerances: Depending on the SiC grade and manufacturing process (e.g., pressing, slip casting, extrusion), as-sintered parts will have certain dimensional variations. These are typically in the range of ±0.5% to ±2% of the dimension. For applications where this is acceptable, no further machining is needed, reducing cost.

- Ground Tolerances: Diamond grinding can achieve much tighter tolerances, often down to ±0.005 mm (±0.0002 inches) or even better for critical dimensions. This is essential for “precision SiC components” and “tight tolerance ceramic parts.”

- Flatness and Parallelism: For sealing faces, flatness values in the order of a few helium light bands (HLB), equivalent to sub-micron levels (e.g., 0.3-0.9 µm), can be achieved through lapping and polishing. Parallelism can also be tightly controlled.

- Surface Finish Options:

- As-Fired Finish: The surface of an as-sintered part will depend on the forming method and kiln conditions. It might be relatively smooth or have a slight texture.

- Ground Finish: Diamond grinding typically produces a surface roughness (Ra) in the range of 0.2 µm to 0.8 µm (8 to 32 µinches).

- Lapped/Polished Finish: For applications requiring exceptionally smooth surfaces, such as mechanical seals or high-performance bearings, lapping and polishing can achieve Ra values below 0.05 µm (2 µinches), sometimes down to optical quality finishes. “SiC mirror finish” is a relevant term for such requirements.

- Dimensional Accuracy and Stability:

- Silicon carbide is known for its excellent dimensional stability over time and under varying temperatures, ensuring that precision components maintain their accuracy throughout their service life.

- The manufacturing process, from powder preparation to final sintering, is carefully controlled to minimize warpage and ensure consistent shrinkage, contributing to better final accuracy.

- Cost Implications:

- The tighter the tolerance and the finer the surface finish required, the more extensive (and expensive) the post-sintering machining operations will be. It’s crucial to specify only the level of precision truly needed for the application to manage costs effectively.

- Engineers should clearly communicate critical dimensions and surface requirements to the SiC manufacturer.

The capability to machine SiC to such high precision allows for its use in applications demanding minimal leakage, low friction, and consistent performance. This underscores the importance of selecting a supplier with advanced machining capabilities and robust quality control processes to ensure that every component meets the specified dimensional and surface finish requirements.

Overcoming Common Challenges in SiC Implementation in Chemical Applications

While silicon carbide offers a multitude of advantages for the chemical industry, successful implementation requires addressing certain inherent challenges associated with advanced ceramics. Understanding these potential hurdles and knowing how to mitigate them is key to maximizing the benefits of SiC components.

- Brittleness and Fracture Toughness:

- Challenge: SiC, like most ceramics, is brittle and has lower fracture toughness compared to metals. This means it can be susceptible to catastrophic failure from impact or high tensile stress concentrations.

- Mitigation:

- Proper component design: Avoid sharp corners, use fillets, design for compressive stress.

- Careful handling and installation procedures.

- Protective enclosures or mountings in impact-prone areas.

- Selecting grades with enhanced toughness if available and suitable (though this is often a trade-off with other properties).

- Consider composite structures or armoring for very demanding applications.

- Machining Complexity and Cost:

- Challenge: The extreme hardness of SiC makes machining (grinding, lapping, polishing) time-consuming and expensive, requiring specialized diamond tooling and equipment.

- Mitigation:

- Design for “near-net-shape” manufacturing to minimize post-sintering machining.

- Specify tolerances and surface finishes only as tight as absolutely necessary for the application.

- Work with experienced SiC manufacturers who have optimized machining processes.

- Thermal Shock Management:

- Challenge: Although SiC generally has excellent thermal shock resistance (especially RBSiC and some porous grades of ReSiC), very rapid and non-uniform temperature changes can still induce stress and potential cracking, particularly in thick sections or constrained designs.

- Mitigation:

- Select appropriate SiC grades with high thermal conductivity and low thermal expansion.

- Design components to allow for more uniform heating/cooling.

- Implement controlled heat-up and cool-down rates in processes where feasible.

- Finite Element Analysis (FEA) can predict thermal stress distribution and guide design improvements.

- Joining SiC to Other Materials:

- Challenge: Efficiently and reliably joining SiC to metals or other ceramics can be complex due to differences in thermal expansion coefficients, wetting behavior, and mechanical properties.

- Mitigation:

- Utilize specialized joining techniques like active metal brazing, diffusion bonding, shrink fitting, or advanced adhesive bonding.

- Design joints to accommodate thermal expansion mismatches (e.g., using graded interlayers, flexible connectors).

- Consult with experts in ceramic-to-metal joining.

- Sealing Complexities:

- Challenge: Achieving and maintaining effective seals with SiC components, especially in high-pressure or high-temperature dynamic applications, can be demanding.

- Mitigation:

- Ensure extremely precise surface finishes and flatness on sealing faces.

- Select appropriate gasket or seal materials compatible with both SiC and the process

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.