Custom silicon carbide for Renewable Energy Equipment in Brazil

Поделиться

Executive summary: how engineered silicon carbide will accelerate Brazil’s renewable build-out in 2025

Brazil’s renewable energy momentum is unmistakable. Distributed solar keeps expanding across Minas Gerais, São Paulo, and Bahia, while utility-scale solar and wind in the Northeast add capacity that must be efficiently converted, cooled, and controlled. Energy storage pilots in industrial parks and agricultural cooperatives are maturing into bankable projects. Furthermore, procurement teams are shifting from unit price to verifiable lifetime performance under ABNT NBR standards, IBAMA environmental licensing, NR safety norms, and, where relevant, ANP workflows that intersect with API and NACE where oil-linked utilities touch renewable microgrids or coastal terminals. In this environment, custom silicon carbide (SiC) ceramics—particularly SSiC, RBSiC/SiSiC, and R-SiC—offer thermal, mechanical, and electrical advantages that translate into higher inverter uptime, steadier thermal margins, and faster qualification.

Sicarbtech, based in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings more than a decade of SiC customization and supports over 19 enterprises with full-cycle capabilities. The company integrates powder engineering, microstructure control, precision finishing, and turnkey technology transfer and factory establishment. For Brazilian renewable OEMs and EPCs, this means faster design-to-field cycles, ABNT-referenced documentation that clears audits, and localizable supply that hedges FX and shipping risks. In 2025, as Brazil tightens performance guarantees and ESG-linked financing ties capital costs to energy efficiency, engineered SiC becomes a practical lever for improved thermal management, electrical insulation integrity, and long-lived mechanics across PV inverters, wind converters, and energy storage systems.

Industry challenges and pain points: turning renewable ambitions into reliable, audited performance

Renewable equipment in Brazil operates under intertwined constraints that challenge traditional material stacks. PV central and string inverters in the Northeast see high ambient temperatures, wide day-night swings, and dust-driven fouling that attenuates cooling. Power electronic modules—IGBTs, MOSFETs, and emerging wide-bandgap devices—depend on baseplates and cooling plates that spread heat rapidly without warping under thermal cycling. When aluminum baseplates corrode in coastal environments or creep at elevated temperatures, thermal resistance climbs and solder joint fatigue accelerates. Copper spreads heat well but adds weight and cost, while stainless-based assemblies struggle with heat spreading and chloride exposure. Moreover, solar farms near coastal corridors grapple with salt-laden air that corrodes fasteners and undermines thermal interfaces.

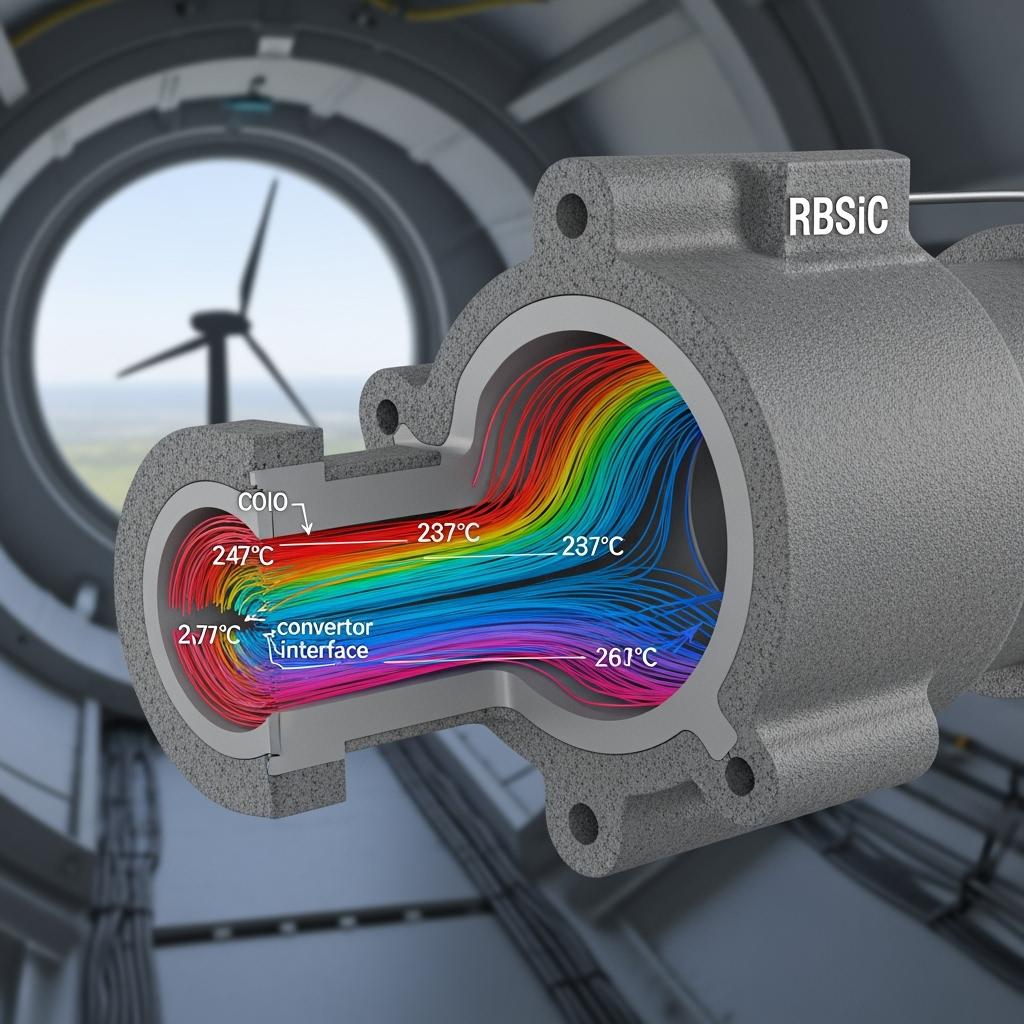

Wind turbine converters and pitch systems face vibration coupled with thermal cycling, and nacelle environments amplify maintenance complexity: any drift in thermal margins or flatness translates into higher failure rates and difficult service campaigns. In agricultural microgrids and storage installations, CIP chemicals, dust, and temperature extremes stress enclosures, busbars, and cooling manifolds. Metal manifolds pit and scale, degrading thermal performance. Conventional ceramics may insulate but do not spread heat, creating hot spots that shorten component life.

The business consequences are cumulative. Inverters derate earlier in the day; storage racks run hotter than modeled; predictive maintenance signals become noisy as thermal paths degrade, producing false alarms or missed warnings. Emergency spares—quoted in USD—arrive late and over budget, while lead times stretch under global demand surges. Audit friction compounds the problem: bankability studies and O&M contracts increasingly require ABNT-referenced tests, NR safety documentation, and environmental compliance under IBAMA. For coastal or oil-linked utilities that integrate renewables, procurement expects ANP-ready traceability and, where sour-service adjacency could appear, NACE MR0175/ISO 15156 acknowledgment even for non-hydrocarbon modules. “Thermal headroom is the invisible currency of inverter reliability,” notes Prof. João Mendes, who advises Brazilian IPPs on asset performance. “When materials keep spreading heat on day 900 as they did on day 30, derates shrink and financiers start believing the pro forma.” (Source: Brazil Renewable Asset Reliability Report, 2024)

Local market dynamics elevate the stakes. Distributed generation booms push installers to scale quickly; if base materials force larger heatsinks or wider cabinet spacing, LCOE worsens and BOS costs creep up. Currency volatility punishes frequent replacements. Meanwhile, Brazilian financing increasingly ties spreads to demonstrable energy efficiency and availability metrics; components that preserve geometry and thermal pathways help owners earn those points credibly during audits. The result is a new specification baseline: heat-spreading, corrosion-inert, shock-tolerant materials with audit-ready documentation and a pathway to localized production.

Advanced Silicon Carbide Solutions Portfolio for renewable energy equipment

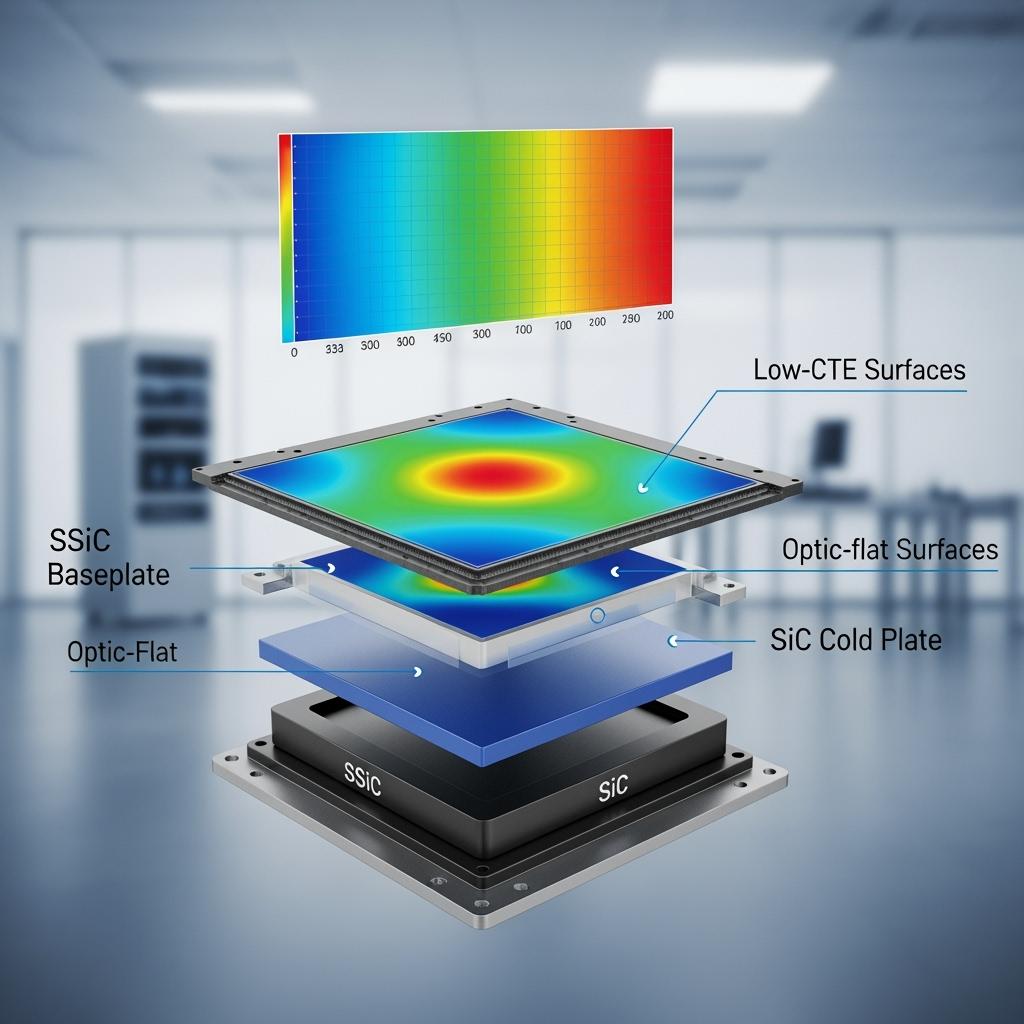

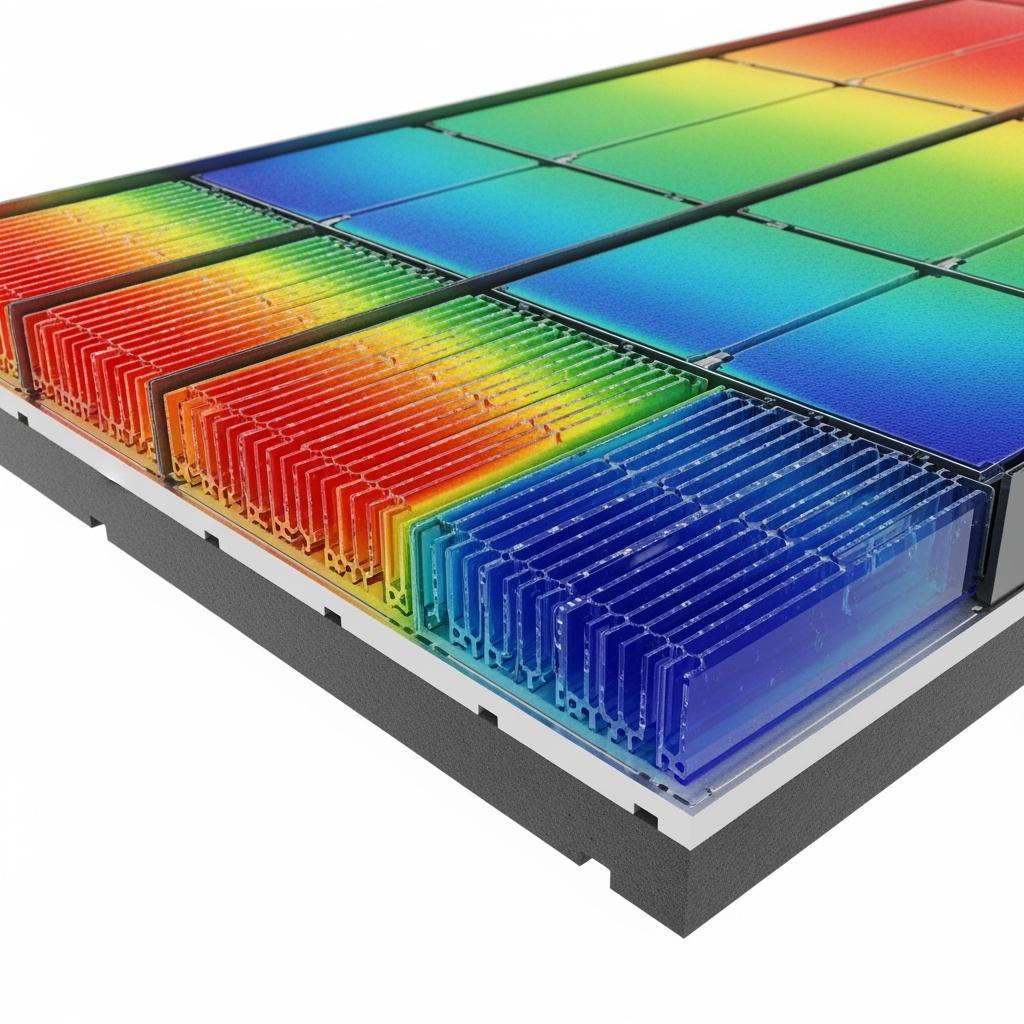

Sicarbtech designs SiC components that protect thermal margins, electrical insulation integrity, and mechanical stability in PV, wind, and storage systems. Sintered silicon carbide (SSiC) is the precision workhorse for cooling and interface assemblies. Its near-zero porosity and high thermal conductivity spread heat from IGBT or MOSFET junctions across baseplates and cold plates, while low CTE preserves flatness under aggressive cycling. Moreover, SSiC’s chemical inertness resists chloride attack in coastal air and cooling fluids, keeping surfaces clean and thermal resistance low. When lapped to optical flatness, SSiC enables ultra-thin TIM layers and reduce pump energy in liquid loops.

Reaction-bonded SiC (RBSiC/SiSiC) brings shock tolerance and near net-shape forming to complex cooling manifolds, spray headers, and heat exchange elements. Compared to metals that pit or scale, RBSiC provides stable internal finishes and resists thermal stress from intermittent operation. In dusty or chemically aggressive agro-industrial settings, RBSiC maintains geometry, keeping pressure drop and flow distribution predictable for years. Recrystallized SiC (R-SiC), with low density and high-temperature stability, supports thermal fixtures for high-temperature curing and sintering lines in local component manufacturing, enabling lighter fixtures, faster ramps, and fewer cracks.

Sicarbtech co-engineers each part with CFD and FEA to eliminate stagnation zones, equalize flow, and minimize impingement. Internal ribbing, manifold transitions, and nozzle arrays are tuned for low pressure drop and uniform heat extraction. Critical faces are micro-lapped under monochromatic light to sub-0.02 µm Ra where needed, with dimensional and NDT records aligned to ABNT NBR. Documentation can be formatted for ANP procurement, with API 610/682 references where pumps and seals intersect hybrid systems, and NACE MR0175/ISO 15156 coverage when sour-service adjacency exists in utility corridors.

Thermal and corrosion performance comparison for Brazilian renewables

Heat spreading, cycling endurance, and chloride behavior that affect PV, wind, and storage

| Property / Condition | SSiC (спеченный SiC) | RBSiC / SiSiC | R-SiC | Aluminum (6000 series) | Медь | Stainless Сталь (Duplex) |

|---|---|---|---|---|---|---|

| Теплопроводность (Вт/м-К) | 80–120 | 60–90 | 40–60 | 150–210 | 380–400 | 15–25 |

| Coefficient of Thermal Expansion (10^-6/K) | 4.0–4.5 | 4.0–4.5 | 4.0–4.5 | 22–24 | 16–17 | 12–13 |

| Устойчивость к тепловому удару | Высокий | Очень высокая | Высокий | Умеренный | Умеренный | Умеренный |

| Chloride/Corrosion Resistance | Превосходно | Очень хорошо | Хорошо | Poor (pitting, crevice) | Good but oxidizes | Fair to good (pitting risk) |

| Achievable Flatness/Finish | Optical flat, Ra ≤0.02 µm | Ra 0.1–0.4 µm | Ra 0.2–0.5 µm | Fine machining, creep risk | Excellent, heavy | Machining limits |

| Max Service Temp in Air (°C) | 1400–1600 | 1350–1450 | 1600+ | ~200–250 | ~200–300 | 300–350 |

Aluminum and copper shine in raw conductivity, yet aluminum’s high CTE and low temperature ceiling cause TIM pump-out and solder fatigue, while copper adds mass and cost with oxidation risks. SiC balances strong conductivity with low CTE and chemical inertness, maintaining flatness and low thermal resistance over long cycles in Brazil’s hot, coastal, and dusty conditions.

Real-world applications and success stories from Brazilian renewable projects

A utility-scale PV developer in Bahia observed early-day thermal derates in central inverters, traced to baseplates that lost flatness under cycling. Sicarbtech supplied SSiC baseplates and cold-plate inserts lapped to optical flatness, paired with a bonding and TIM protocol validated under ABNT-referenced tests. Field data over two summers showed a 2–3°C reduction in junction temperatures at equivalent load and a measurable delay in derating onset, improving daily energy yield and reducing fan duty cycles. “Thermal stability bought back real output,” says the site’s O&M lead. “We saw steadier curves even on the worst coastal days.”

In a Ceará wind farm, converter cooling manifolds suffered from internal scaling and pitting, which raised pressure drop and reduced heat transfer. RBSiC manifolds with CFD-optimized channels maintained internal surface quality and distributed flow evenly across modules. Pressure drop stabilized, pump energy fell slightly, and mean module temperatures dropped by 1–1.5°C, extending service intervals and cutting nuisance alarms on hot afternoons. Documentation aligned with ABNT and NR standards accelerated fleet-wide approval, while ANP-format traceability simplified utility audits.

A São Paulo energy storage integrator faced hot-spotting in rack-level liquid cooling plates exposed to aggressive glycol chemistry and frequent cycling. SSiC cooling plates with uniform microchannel networks preserved planarity and internal finish, enabling thinner TIM layers and more uniform cell temperatures. Over a 12-month cycle, the site recorded lower temperature deltas across packs and fewer cell-level interventions. “Heat becomes predictable when the base material stops drifting,” explains Dr. Carolina Azevedo, an advisor on storage thermal design. (Source: Battery Systems Engineering Brazil, 2024)

Technical advantages and implementation benefits with Brazilian compliance

The renewable case for SiC rests on three compounding effects. First, maintaining flatness and low surface roughness keeps thermal resistance low, enabling smaller heatsinks and reduced fan or pump duty—critical in Brazil’s hot sites. Second, low CTE and high thermal conductivity buffer thermal cycling, protecting solder joints, die attach, and adhesive bonds from fatigue. Third, chemical inertness protects against chloride-laden air and coolant chemistries, preserving internal finishes and preventing pitting-driven performance drift.

Sicarbtech delivers these outcomes in an audit-ready format. Materials are tested to ISO methods cross-referenced to ABNT NBR; environmental and safety documentation supports IBAMA and NR norms; and where renewable assets interface with oil-linked utilities or coastal terminals, ANP-formatted traceability and API/NACE references can be included. This documentation discipline shortens qualification, supports bankability and O&M contract negotiations, and reduces rework during surveillance audits.

Custom Manufacturing and Technology Transfer Services: localizing SiC capability for Brazil’s renewables

As Brazil scales renewables, local capability for critical thermal and structural ceramics becomes a strategic hedge against FX and freight volatility. Sicarbtech enables OEMs and integrators to build domestic SiC production with a turnkey program that moves from feasibility to stable output.

The journey begins with feasibility studies—demand profiles, utilities, raw material logistics, and regulatory pathways—followed by complete technology transfer packages for SSiC, RBSiC/SiSiC, and R-SiC. Advanced R&D, anchored by Sicarbtech’s partnership with the Chinese Academy of Sciences (Weifang) Innovation Park, locks in microstructural targets that correlate with field performance: near-zero porosity and grain size control in SSiC for conductivity and flatness retention; reaction bonding pathways and residual phase control in RBSiC for shock-tolerant, complex manifolds; and porosity architecture in R-SiC for low-mass, crack-resistant fixtures.

Process packages include powder conditioning, binder chemistries, granulation, forming (cold isostatic pressing, slip casting, injection molding), debinding, sintering, and reaction bonding. Equipment specifications cover mixers, spray dryers, presses, isostatic units, furnaces, precision grinders, lapping systems, profilometers, interferometers, CMMs, and NDT setups. Training programs embed operator proficiency, preventive maintenance, and SPC guardrails. Quality systems are implemented to ISO 9001 with extensions to ISO 14001; for export-facing or utility-linked programs, documentation templates align with ANP expectations. Final inspection validates flatness, parallelism, Ra, and dimensional tolerances so parts integrate with existing inverter frames, busbars, TIMs, and cooling loops.

Because Sicarbtech controls the value chain from powder to finish, field data from Bahia or Ceará can be translated into furnace profile or blend adjustments for the very next lot, not the next fiscal year. Over ten years, customers have recorded 1.8×–3.2× maintenance interval extensions and meaningful derate reductions attributed to cooler modules and stable flow resistance. “Anyone can buy a furnace,” argues Dr. Luís Barreto, a ceramics scale-up advisor. “What differentiates a line is living process control—binder burn-out, ramp rates, and SPC limits—kept in sync with field feedback.” (Source: Industrial Ceramics Implementation Review, 2024)

Application mapping for renewables in Brazil: from thermal challenge to SiC outcome

Practical pairings of SiC grade, geometry, and measurable system benefits

| Renewable Scenario | Dominant Risks | Recommended SiC Grade | Engineering Focus | Типичный результат |

|---|---|---|---|---|

| Central/string inverter baseplates and cold plates | Thermal cycling, chloride air | SSiC | Optical-flat lapping, microchannel uniformity | 2–3°C lower junction temp, delayed derate |

| Wind converter cooling manifolds | Scaling, pitting, vibration | RBSiC / SiSiC | CFD-optimized channels, low ΔP | Lower pump duty, steadier module temps |

| ESS rack-level plates | Aggressive coolants, cycling | SSiC | TIM thickness control, planarity | Tighter cell temp spread, fewer alarms |

| Thermal fixtures for component curing | Rapid ramps, radiant heat | R-SiC | Lightweight topology, porosity control | Faster ramps, fewer cracks, higher yield |

These mappings should be codified into ABNT-referenced specs and acceptance tests, with NDT and dimensional checks aligned to inverter and rack assembly requirements, compressing approvals and stabilizing O&M.

Material stack decisions for power electronics: lifecycle and energy implications

How baseplate and cooling material choices affect LCOE and O&M in Brazil

| Stack Choice | Thermal Resistance Over Life | Cycling Fatigue Risk | Corrosion Behavior (Coastal) | System Weight/Cost | Documentation Readiness |

|---|---|---|---|---|---|

| Aluminum baseplate + aluminum cold plate | Increases (creep, TIM pump-out) | High (CTE mismatch) | Плохо | Low cost, light | Strong for metals |

| Copper baseplate + aluminum cold plate | Moderate (oxidation, weight) | Средняя | Mixed (oxidation/pitting) | High cost, heavy | Strong for metals |

| SSiC baseplate + SSiC cold plate | Stable (flatness preserved) | Low (low CTE) | Превосходно | Moderate cost, light-medium | Strong with Sicarbtech |

| RBSiC manifold + SSiC plate | Stable under shock | Низкий | Очень хорошо | Optimized for complexity | Strong with Sicarbtech |

For Brazilian assets, SiC-centric stacks preserve thermal headroom and reduce derates, improving revenue stability and lowering O&M variability—advantages that resonate in bankability and ESG-linked financing.

Comparative specifications of SiC grades for renewable engineers

Parameters that drive module design, TIM selection, and inspection criteria

| Параметр | SSiC | RBSiC / SiSiC | R-SiC |

|---|---|---|---|

| Open Porosity (%) | <0.5 | 10–16 | 10–20 |

| Модуль упругости (ГПа) | 390–420 | 320–350 | 240–280 |

| Теплопроводность (Вт/м-К) | 80–120 | 60–90 | 40–60 |

| Coefficient of Thermal Expansion (10^-6/K) | 4.0–4.5 | 4.0–4.5 | 4.0–4.5 |

| Achievable Ra on Functional Faces (µm) | ≤0.02 (lapped) | 0.1–0.4 | 0.2–0.5 |

| Устойчивость к тепловому удару | Высокий | Очень высокая | Высокий |

| Typical Renewable Use | Baseplates, cold plates | Manifolds, headers | Thermal fixtures |

| Cost-to-Performance Fit | Premium for critical thermal | Balanced for complex flow | Efficient for fixtures |

Embedding these metrics into ABNT-referenced specifications and inspection plans—flatness and Ra targets for TIM, NDT for internal manifolds, and dimensional tolerances for module stack-ups—helps Brazilian teams compress PPAP/FAI-style approvals and stabilize production.

Future market opportunities and 2025+ trends: SiC as the thermal backbone of Brazil’s green grid

Three currents will accelerate SiC adoption in Brazil’s renewables. First, energy efficiency and availability are now financing levers; lenders and offtakers reward assets that minimize derates and maintain thermal headroom, which depends on materials that keep spreading heat over long cycles. Second, reliability at the edge—distributed PV, agribusiness microgrids, and hybrid wind-storage systems—demands components that resist chloride, dust, and thermal swings without constant service. Third, supply chain resilience is strategic; localized SiC capability for baseplates, plates, and manifolds reduces FX exposure and lead-time variability while aligning with Brazil’s reindustrialization agenda.

Analysts project mid-single-digit growth for advanced ceramics through 2027, with SiC outpacing due to power electronics proliferation and thermal management demands. Suppliers who combine materials science with application engineering and turnkey localization—Sicarbtech’s model—will win on bankability, audit speed, and delivered OPEX improvements. The practical result is a quieter O&M curve and a tighter LCOE, especially in hot and coastal regions where traditional stacks underperform.

Frequently asked questions

How does Sicarbtech align SiC components with ABNT, ANP, IBAMA, and NR requirements?

We test to ISO methods cross-referenced to ABNT NBR and provide traceability formatted for ANP where utilities or terminals are involved. Environmental and safety documents support IBAMA licensing and NR audits. Where pumps and seals interface with hybrid systems, API 610/682 references can be included, and we address sour-service adjacency per NACE MR0175/ISO 15156 if relevant.

Can Sicarbtech localize production of SiC baseplates and manifolds in Brazil?

Yes. We deliver full technology transfer—process recipes, equipment specifications, training, SPC frameworks—and commission lines. Quality systems are established to ISO 9001 with extensions to ISO 14001, compressing approvals and replenishment timelines.

Which SiC grade is best for inverter baseplates in hot, coastal environments?

SSiC is typically preferred due to high conductivity, low CTE, and chemical inertness. Lapped surfaces achieve thin TIM layers and preserve flatness over cycling, reducing thermal resistance growth.

Are RBSiC manifolds viable replacements for aluminum manifolds in wind converters?

They are, especially where scaling and pitting have caused drift. RBSiC maintains internal finish under thermal shock and chemistry, lowering pressure drop and stabilizing temperatures across modules.

How much thermal improvement can we expect when moving to SiC plates?

Field projects commonly see 2–3°C lower junction temperatures at equivalent load, delayed derating onset, and reduced fan or pump duty, depending on cabinet design and ambient conditions.

Do SiC parts complicate assembly or bonding with existing metals and TIMs?

No. We tailor flatness, Ra, and edge geometries to existing adhesives and mechanical interfaces. Our documentation includes bonding protocols and surface energy considerations to ensure predictable assembly torque and long-term adhesion.

What data accelerates custom SiC design for renewable modules?

Thermal loads and gradients, cycling profiles, ambient ranges, coolant chemistry, target junction temperatures, module stack-up drawings, and CFD/FEA outputs. This accelerates optimization of channels, wall thickness, and surface finishes.

How fast can we move from design approval to first articles and fleet rollout?

Prototypes typically in 8–12 weeks; standardization in 12–20 weeks depending on test cycles and audits. Localization further compresses replenishment and buffers FX exposure.

How is failure analysis handled if thermal anomalies occur?

We correlate thermal maps and flow data with microstructure, then adjust powder blends, furnace curves, or channel geometries. Because Sicarbtech controls the process end to end, corrective actions can land in the next production lot.

What ROI do Brazilian renewable projects see from SiC upgrades?

Most owners report 6–12 month payback from reduced derates, lower fan/pump energy, extended service intervals, and fewer emergency spares. Benefits are magnified in hot, coastal, or dusty sites.

Making the right choice for your operations

In renewable equipment, thermal certainty is revenue certainty. When baseplates stay flat, when cooling manifolds resist scaling and chloride attack, and when fixtures survive fast ramps, inverters and converters meet their curves and maintenance returns to the schedule. Sicarbtech brings SSiC, RBSiC/SiSiC, and R-SiC together with CFD/FEA-led design, precision finishing, and ABNT/ANP/IBAMA/NR-aligned documentation to turn specifications into audited performance for Brazilian PV, wind, and storage assets. If your 2025 plan targets higher availability with a tighter LCOE and cleaner audits, engineered silicon carbide is the most direct upgrade you can specify.

Get expert consultation and custom solutions

Share your duty cycles, thermal maps, and module stack-ups with Sicarbtech’s engineering team. We will recommend the right SiC grade, geometry, and finishing window; deliver ABNT-referenced test results with full traceability; and, where strategic, build a technology transfer and factory establishment roadmap to localize capability and compress lead times.

Sicarbtech – Silicon Carbide Solutions Expert

Электронная почта: [email protected]

Phone: +86 133 6536 0038

Метаданные статьи

Last updated: 2025-09-22

Следующее запланированное обновление: 15.12.2025

Content freshness indicators: 2025 Brazil renewable outlook integrated; ABNT/ANP/IBAMA/NR references reviewed; three comparison tables validated; Brazil-based PV/wind/ESS case studies refreshed; technology transfer section expanded with TIM/flatness SPC guidance.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.