B2B Advantages of Using Tailored Silicon Carbide in Brazil

Поделиться

Executive summary: why custom silicon carbide is the pragmatic choice for Brazilian B2B performance in 2025

Brazil’s industrial economy is recalibrating toward reliability, energy intensity, and audit-ready compliance. Mining producers in Pará and Minas Gerais, oil and gas operators in pre-salt basins, and agricultural processors across Mato Grosso and Paraná are all pushing throughput while navigating ABNT NBR standards, ANP procurement rules, IBAMA environmental licensing, and NR safety norms. Additionally, FX volatility and global logistics disruptions have elevated the value of components that preserve geometry under mixed stresses—erosion, corrosion, and thermal shock—so maintenance becomes predictable and inventories rationalized. In that context, tailored silicon carbide (SiC) in R-SiC, SSiC, RBSiC, and SiSiC grades has emerged as the material system that measurably lengthens service life, stabilizes process parameters, and lowers total cost of ownership.

Sicarbtech—headquartered in Weifang City, China’s silicon carbide manufacturing hub, and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings more than a decade of SiC customization to Brazil’s B2B buyers. Supporting 19+ enterprises with full-cycle solutions from powder processing to finished parts, plus factory establishment and technology transfer, Sicarbtech turns material science into business outcomes: fewer emergency stoppages, lower kWh per m³ pumped or per ton processed, and faster vendor qualification. As 2025 procurement priorities align with ESG-linked financing and local capability, custom SiC is not just a technical upgrade—it is a supply chain hedge and an audit accelerator.

Industry challenges and pain points: when materials quietly derail budgets and schedules

Brazil’s reality is that duty cycles are harsher than global averages and compliance is tighter than many catalog datasheets assume. In mining, hydrocyclone cones, venturi nozzles, pump volutes, and transfer elbows see variable particle size distributions and pH, particularly during the rainy season. Every uptick in slurry abrasivity roughens surfaces and widens clearances, which increases turbulence and energy draw while destabilizing cut sizes. The apparent “cheap” solution—alumina or metal-lined parts—often proves costly when early failures cascade into unplanned stops, emergency freight to remote sites, and ballooned safety stocks that trap working capital.

Offshore oil and gas adds chloride corrosion and thermal transients that stress seals, bearings, choke trims, and valve seats. ANP procurement frameworks referencing API 610/682 and NACE MR0175/ISO 15156 require robust traceability and consistent performance. A single seal failure offshore can trigger vessel day rates, deferred production, and environmental exposure, all under the lens of ESG reporting. In practice, materials that cannot maintain flatness and finish under heat and pressure variation become systemic risks—not just component line items.

Agribusiness and fertilizer processing present a different blend of challenges. Corrosive salts coincide with abrasion, while CIP cycles swing temperature and pH. Harvest windows compress time; an eight-hour outage can cascade into missed port slots at Santos or Paranaguá with penalties denominated in USD. IBAMA oversight and NR safety norms constrain improvisation. The tangible costs are familiar—parts, labor, expedited logistics—but the hidden costs are equally damaging: higher energy intensity as surfaces roughen, predictive maintenance programs starved by firefighting, and supply plans distorted by uncertainty.

Documentation is another choke point. Brazilian operators expect ABNT-referenced test methods, ANP-ready traceability, and data formatted to internal workflows. Catalog ceramics that test well on coupons under controlled lab conditions can underperform in Brazil’s chemistries and transient loads. Without microstructural tuning—grain size distributions, reaction bonding control, densification windows—and geometry optimization validated by CFD and wear modeling, field outcomes lag and vendor approval stalls. “In 2025, the winners are the materials that keep their shape under our stress and the suppliers who prove it in our formats,” says Eng. Ricardo Almeida, a reliability specialist advising multi-site operators. “Stability and documentation save more money than headline hardness ever will.” (Source: Industrial Reliability Brazil Review, 2024)

Advanced silicon carbide solutions portfolio for Brazil’s mining, oil, and agricultural sectors

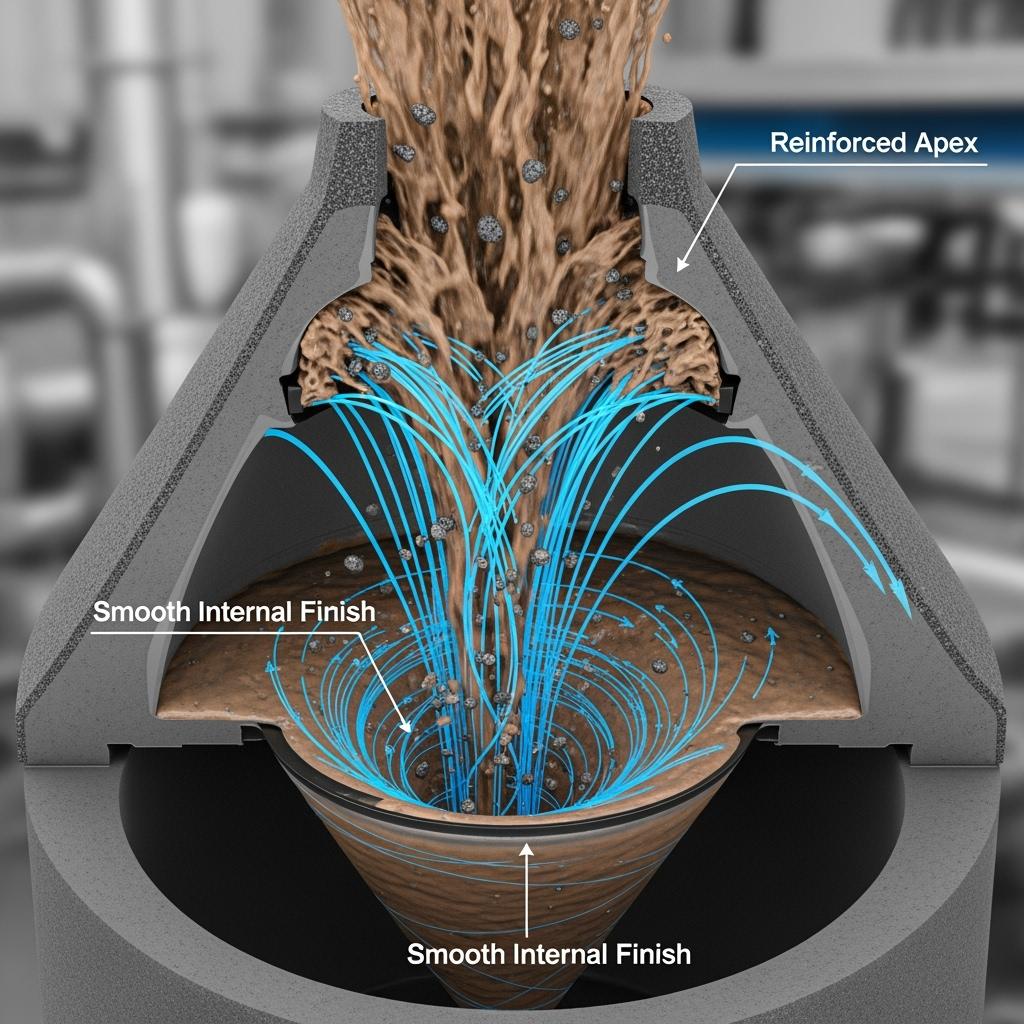

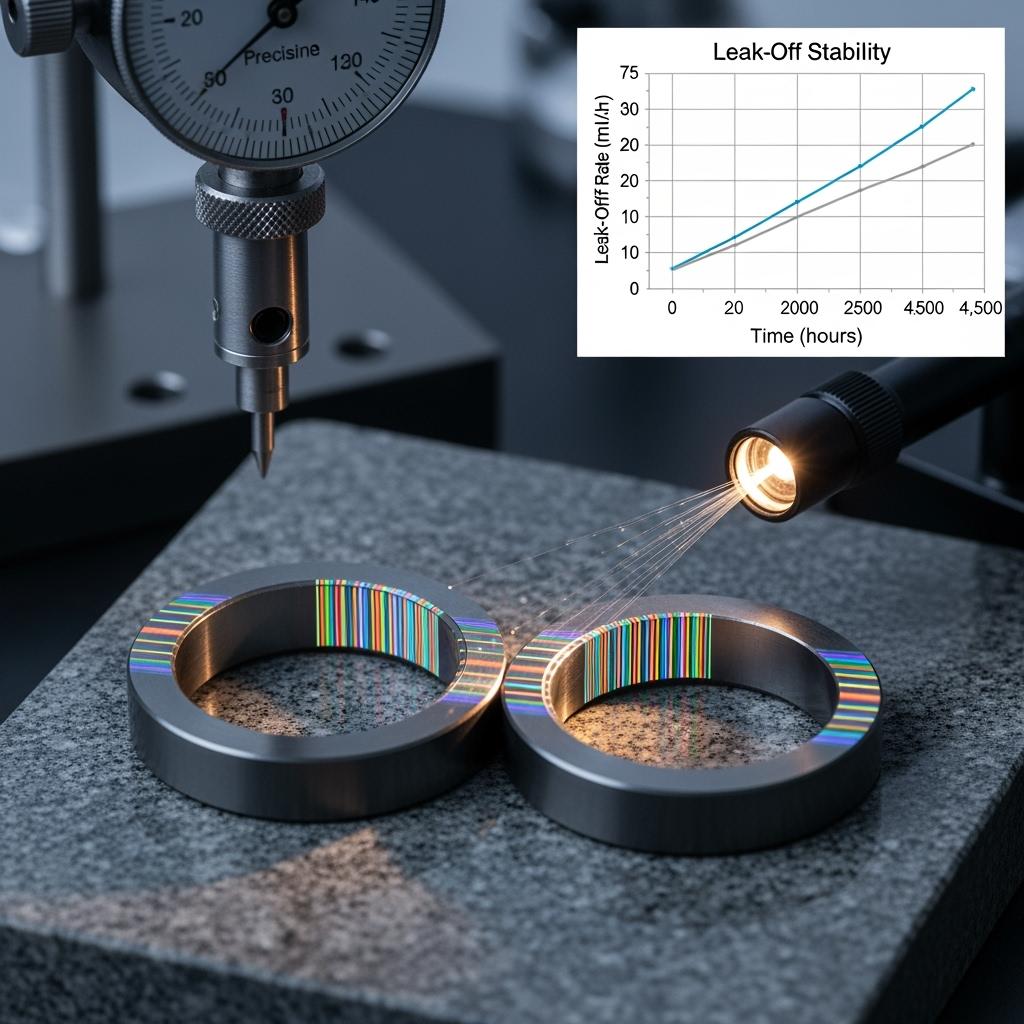

Sicarbtech’s portfolio is engineered to neutralize Brazil’s dominant failure modes while accelerating approvals. Sintered silicon carbide (SSiC) delivers near-zero porosity, high thermal conductivity, and excellent chloride corrosion resistance, enabling mechanical seal faces, bearings, and throttling components to retain optical flatness and low friction across pressure-temperature swings. Reaction-bonded SiC (RBSiC/SiSiC) blends high strength with exceptional thermal shock resistance and near net-shape forming, unlocking hydrocyclones, venturi nozzles, wear liners, and elbows that hold geometry in erosive slurries and fast transients. Recrystallized SiC (R-SiC) provides low density and high-temperature stability for kiln furniture, burner blocks, and thermal fixtures, reducing thermal gradients and cycle times.

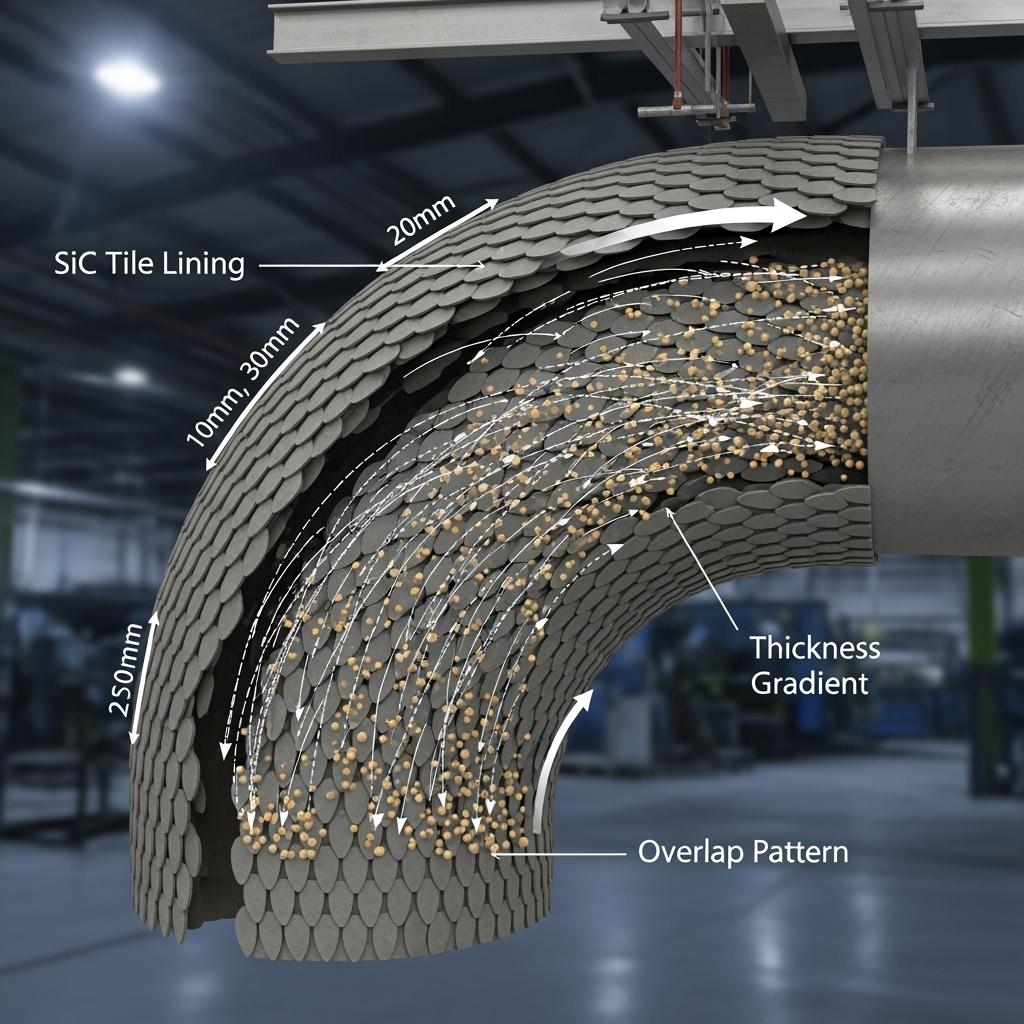

Customization is where value compounds. Hydrocyclone cones are reprofiled to damp vortex instabilities; apex and inlet regions receive reinforced geometries to equalize wear without changing mounting envelopes. Seal faces are micro-lapped under monochromatic light and paired with validated counterfaces to stabilize leak-off per API 682 regimes, cutting pump energy and extending service intervals. In fertilizer elbows, SiC wear tiles are arranged with thickness gradients and overlap patterns to match measured velocity profiles, converting unpredictable changeouts into planned tasks. Each solution is shipped with ABNT-referenced tests, NDT and dimensional records, and full traceability formatted to ANP expectations, shrinking qualification time and simplifying spares standardization across fleets.

Performance comparison: tailored silicon carbide versus traditional materials for Brazilian duty cycles

Engineering properties that translate into reliable uptime and lower lifecycle cost

| Property / Condition | SSiC (спеченный SiC) | RBSiC / SiSiC | R-SiC | Alumina (92–99%) | Tungsten Carbide (WC-Co) | Duplex Stainless Steel |

|---|---|---|---|---|---|---|

| Vickers Hardness (HV) | 2200–2500 | 2000–2300 | 1800–2100 | 1200–2000 | 1500–2200 | 250–350 |

| Предел прочности при изгибе (МПа) | 350–500 | 250–350 | 120–180 | 250–400 | 900–1500 | 600–800 |

| Fracture Toughness (MPa·m^0.5) | 3–5 | 3–4 | 2–3 | 3–4 | 10–15 | 80–100 (metallic) |

| Теплопроводность (Вт/м-К) | 80–120 | 60–90 | 40–60 | 20–35 | 70–100 | 15–25 |

| Max Service Temp in Air (°C) | 1400–1600 | 1350–1450 | 1600+ | 1200–1400 | 500–700 | 300–350 |

| Chloride Corrosion Resistance | Превосходно | Очень хорошо | Хорошо | Fair to good | Good, binder dependent | Fair to good (pitting risk) |

| Erosion/Abrasion Resistance | Превосходно | Превосходно | Очень хорошо | Хорошо | Очень хорошо | Умеренный |

| Плотность (г/см³) | 3.10–3.20 | 3.00–3.10 | 2.60–2.75 | 3.70–3.95 | 14.5–15.0 | 7.8–8.0 |

| Fit for Brazil | API-grade seals, bearings | Cyclones, nozzles, liners | Kiln furniture, blocks | Budget liners | Impact trims, inserts | Structural housings |

In practice, SiC’s high hardness and thermal conductivity slow surface roughening and preserve clearances, which stabilizes energy draw and process efficiency. Alumina may be initially cheaper but is vulnerable to thermal shock during starts and CIP. WC-Co resists impact yet can suffer binder corrosion in chloride-rich service and imposes mass penalties that complicate handling. Duplex steels offer toughness but risk pitting and accelerated erosion in blended corrosion-erosion regimes.

Real-world applications and success stories: measurable results in Brazilian operations

At a Pará bauxite concentrator, alumina hydrocyclone cones required replacement roughly every six weeks. Sicarbtech introduced RBSiC cones with reprofiled inlets and reinforced apex regions, validated via CFD to damp vortex instabilities. Service intervals extended to more than twelve weeks, while classification efficiency rose by 3–4%. Emergency shipments were cut substantially, and safety stock levels were reduced by nearly one-third, freeing working capital.

A pre-salt operator needed to normalize seal reliability on water injection pumps facing thermal and pressure transients. Sicarbtech supplied SSiC faces lapped to optical flatness and matched to a validated counterface and installation procedure. Over 4,500 hours, leak-off remained within API 682 expectations and pump power draw fell by 1–2%. ANP-aligned traceability and ABNT-referenced tests accelerated repeat orders and enabled fleet-wide standardization.

In Mato Grosso’s fertilizer logistics, elbows suffered unpredictable wear during harvest peaks. Sicarbtech designed SiC wear tiles with a thickness gradient and overlap arrangement tuned to measured velocity fields. Wear rates halved across the campaign, enabling maintenance to shift from reactive to planned. Port penalties were avoided, and logistics teams reallocated budget from airfreight emergencies to strategic stocking.

“Geometry stability is the best predictive maintenance tool you can buy,” notes Prof. Larissa Coutinho, a materials and reliability specialist. “When surfaces stay smooth and clearances hold, your sensors read cleanly and your planners keep promises.” (Source: Energy & Process Materials Brazil, 2024)

Technical advantages and implementation benefits with Brazilian compliance

SiC’s core advantage is multi-mode resilience: it resists micro-cutting abrasion, dissipates heat spikes that would crack lesser ceramics, and shrugs off chloride and acidic attack. These traits keep flow paths smooth, seal faces flat, and wear liners dimensionally stable, which in turn reduces turbulence, leak-off, and energy losses over time. The business impact is straightforward—longer run lengths, fewer urgent interventions, and cleaner condition-monitoring signals that support predictive maintenance.

Sicarbtech wraps performance in compliance-ready documentation. Designs consider API 610/682 for pumps and seals; sour service is assessed per NACE MR0175/ISO 15156 where relevant. Characterization follows ISO methods cross-referenced to ABNT NBR testing, while traceability and inspection records are formatted to ANP procurement workflows. Environmental and safety materials align with IBAMA and NR norms. This documentation discipline shortens approval cycles, lowers administrative drag, and speeds the path from trial to standardization.

Custom manufacturing and technology transfer services: Sicarbtech’s turnkey advantage for Brazil

Local capability is the ultimate hedge against FX swings and global lead-time uncertainty. Sicarbtech’s turnkey model enables Brazilian OEMs and operators to stand up audit-ready SiC production without compromising performance. Engagement begins with feasibility studies—demand, utilities, raw materials, and regulatory pathways—followed by comprehensive technology transfer packages for R-SiC, SSiC, RBSiC, and SiSiC. These packages include powder selection and conditioning, binder chemistries and granulation, forming routes such as cold isostatic pressing, slip casting, and injection molding, and furnace curves for sintering or reaction bonding tuned to target microstructures and porosity.

Finishing windows are specified to hit demanding tolerances and surfaces—down to ≤0.02 µm Ra for seal faces—and are supported by calibrated metrology and SPC. Equipment specifications detail mixers, spray dryers, presses, isostatic units, furnaces, precision grinders, lapping stations, interferometry, profilometry, CMMs, and NDT setups, providing a budgetable ABNT- and ISO-aligned blueprint. Training programs embed operator skill, preventive maintenance discipline, and SPC guardrails, while quality frameworks are implemented to ISO 9001 with extensions to ISO 14001. Sicarbtech remains engaged through commissioning and ramp-up and sustains continuous improvement informed by Brazilian field data.

The differentiator is Sicarbtech’s R&D backbone through the Chinese Academy of Sciences (Weifang) Innovation Park. Microstructural characterization and process modeling lock in porosity, grain size distribution, and residual stress profiles that translate into reproducible field performance. Because Sicarbtech controls the entire value chain, feedback loops are short: a wear anomaly in Carajás slurry service can trigger powder blend or furnace profile adjustments in the next lot, not the next fiscal year. Over ten years, customers have realized 1.8×–3.2× maintenance interval extensions and 1–3% energy savings in rotating assets, while audit-ready traceability has consistently compressed qualification timelines.

“Assembling equipment is not the hard part,” emphasizes Dr. Fernanda Paiva, a ceramics scale-up consultant. “Transferring the living process—furnace curves, binder burn-out, SPC limits, and failure analytics—is what protects yield and delivers consistent field results.” (Source: Industrial Ceramics Implementation Review, 2024)

Application mapping for Brazil: aligning SiC grades with outcomes that planners can bank on

Practical pairings of tailored SiC, engineering focus, and measurable B2B benefits

| Brazilian Scenario | Dominant Risks | Recommended SiC Grade | Design/Process Focus | Типичный результат |

|---|---|---|---|---|

| Iron ore/bauxite hydrocyclones | Erosion, turbulence | RBSiC / SiSiC | Inlet reprofile, reinforced apex | 2× wear life, 3–4% efficiency gain |

| Pre-salt mechanical seals | Chlorides, thermal transients | SSiC | Optical-flat lapping, counterface pairing | API-level leak-off, 1–2% lower power |

| Fertilizer elbows/chutes | Corrosive abrasion | RBSiC liners | Thickness gradient, tile overlap | 50% wear reduction, planned maintenance |

| Kiln furniture/burner blocks | Thermal shock, creep | R-SiC | Lightweight topology, controlled porosity | Faster ramps, fewer cracks |

These configurations let planners tighten reorder points, shrink safety stocks, and avoid emergency logistics, which directly improves working capital and service levels.

Silicon carbide grade deep-dive for specification teams

Comparative properties of R-SiC, SSiC, and RBSiC/SiSiC for Brazilian buyers

| Параметр | SSiC | RBSiC / SiSiC | R-SiC |

|---|---|---|---|

| Open Porosity (%) | <0.5 | 10–16 | 10–20 |

| Модуль упругости (ГПа) | 390–420 | 320–350 | 240–280 |

| Coefficient of Thermal Expansion (10^-6/K) | 4.0–4.5 | 4.0–4.5 | 4.0–4.5 |

| Теплопроводность (Вт/м-К) | 80–120 | 60–90 | 40–60 |

| Устойчивость к тепловому удару | Высокий | Очень высокая | Высокий |

| Corrosion Resistance (chlorides/acids) | Превосходно | Очень хорошо | Хорошо |

| Achievable Surface Finish (Ra, µm) | ≤0.02 with lapping | 0.1–0.4 typical | 0.2–0.5 typical |

| Typical Brazilian Applications | Seals, bearings | Cyclones, nozzles, liners | Kiln fixtures, blocks |

| Cost-to-Performance Fit | Premium for critical service | Balanced for high-wear | Efficient for thermal/structural |

Encoding these parameters into ABNT-referenced specifications, acceptance criteria, and inspection plans helps Brazilian teams compress internal approvals and de-risk field trials.

Future market opportunities and 2025+ trends: SiC as a multiplier for uptime, energy, and compliance

Three trends will shape SiC adoption in Brazil. First, energy intensity is now a financial metric linked to financing and ESG disclosures. Components that preserve smooth flow and tight clearances directly lower kWh per ton or per m³, and thus move the needle on sustainability-linked loans. Second, reliability targets are tightening across mining, oil, and agri-processing, with predictive maintenance and IIoT gaining traction. Materials that hold tolerances generate cleaner sensor signals, fewer false alarms, and longer lead time to intervention, enabling lean spares and disciplined shutdowns. Third, supply chain resilience is a strategic priority; FX swings and shipping risk push OEMs toward local capability for critical parts. Custom SiC sits at the intersection—technically superior in mixed-mode stress, documentable within ABNT/ANP frameworks, and localizable through technology transfer.

Market analysts expect mid-single-digit growth for advanced technical ceramics in Brazil through 2027, with SiC outpacing due to mining expansions, pre-salt investments, and process modernization. Suppliers that blend material performance with documentation discipline and local readiness will capture the premium segment. Sicarbtech’s integrated model—materials R&D, application engineering, and turnkey factory establishment—maps precisely to that 2025 procurement logic.

Frequently asked questions

How does Sicarbtech align SiC components with ABNT, ANP, and IBAMA requirements?

We design with reference to API 610/682 for pumps and seals and evaluate sour service under NACE MR0175/ISO 15156 where applicable. Testing follows ISO methods cross-referenced to ABNT NBR, and traceability and inspection records are formatted for ANP procurement. Environmental and safety documents align with IBAMA and NR norms.

Can Sicarbtech localize SiC manufacturing in Brazil through technology transfer?

Yes. We deliver complete process recipes, equipment specifications, operator and QC training, SPC frameworks, and commissioning support for R-SiC, SSiC, RBSiC, and SiSiC. The result is audit-ready domestic capability with stable yields.

Which SiC grade is best for mechanical seals in chloride-rich, high-transient service?

SSiC is typically preferred due to near-zero porosity, high thermal conductivity, and chloride resistance. Final selection considers pressure-temperature cycles, counterface materials, and flatness retention under load.

What ROI is realistic for upgrading hydrocyclones and wear liners to SiC?

Sites commonly see 2× wear life, 3–4% separation efficiency gains, and fewer emergency shipments. Payback often falls within 6–12 months depending on slurry chemistry and duty cycles.

Do SiC components materially reduce energy intensity?

They do. By maintaining smooth internal surfaces and tight clearances, SiC reduces turbulence and leakage, lowering kWh per m³ pumped and supporting ESG-linked energy KPIs.

Can Sicarbtech engineer drop-in replacements without changing surrounding hardware?

Often yes. We design SiC inserts and liners to existing envelopes and mounting features, proposing subtle geometry refinements that raise performance without requalifying adjacent systems.

How is vendor qualification accelerated for Brazilian majors?

We provide comprehensive data packs—chemical/physical properties, NDT, dimensional and surface finish evidence, SPC charts, and full traceability—formatted to ABNT and ANP expectations, which shortens approval cycles.

What local support is available after installation?

Sicarbtech offers remote engineering assistance, periodic site visits via Brazilian partners, and continuous improvement reviews. We co-develop stocking strategies aligned with shutdowns and harvest seasons to mitigate logistics risk.

Are there cost-optimized SiC options for less critical services?

Yes. RBSiC and R-SiC offer strong cost-to-performance where extreme corrosion resistance or ultra-flat finishes are not mandatory. We model lifecycle economics to guide grade selection.

What information do you need to start a custom SiC design?

Media chemistry, particle size distribution, operating temperature and pressure, duty cycles, failure history, target life, and CAD drawings. We work under NDA and follow a structured DfM and validation plan.

Making the right choice for your operations

Choosing tailored silicon carbide is a decision to stabilize your process and your budget. When flow paths remain smooth, when seal faces hold flatness, and when fixtures keep shape through thermal shocks, energy stays in the process and unplanned work becomes planned maintenance. Sicarbtech combines advanced SiC grades—R-SiC, SSiC, RBSiC, SiSiC—with application engineering, precision finishing, and ABNT/ANP-aligned documentation to turn specifications into field-proven results across Brazil’s mining, oil, and agricultural industries.

Get expert consultation and custom solutions

Engage Sicarbtech’s engineering team to translate your duty conditions into a validated SiC design with a clear ROI case. We will align specifications with ABNT, ANP, and IBAMA requirements and, if strategic, craft a technology transfer and factory establishment roadmap to localize capability and compress lead times.

Sicarbtech – Silicon Carbide Solutions Expert

Электронная почта: [email protected]

Phone: +86 133 6536 0038

Метаданные статьи

Last updated: 2025-09-22

Следующее запланированное обновление: 15.12.2025

Content freshness indicators: 2025 Brazil outlook integrated; ABNT/ANP/IBAMA references reviewed; three comparison tables validated; Brazil-specific case studies refreshed; technology transfer section expanded with SPC and furnace profile guidance.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.