Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Page for Medium-/High-Frequency Induction Heating and Holding

Поделиться

Pakistan’s metallurgy, refractories, and machinery sectors are at an inflection point. Energy costs are volatile, interconnection scrutiny is rising, and customers increasingly demand tighter temperature control with consistent metallurgical outcomes. Medium-/high-frequency induction systems—ubiquitous in melting, through-heating, forging, surface hardening, and tundish/ladle holding—sit at the center of this shift. Many installed units still rely on legacy silicon devices, bulky matching networks, and low-frequency switching that waste energy, destabilize power quality, and limit dynamic control. Silicon carbide (SiC) changes the economics and the physics. With low losses at high frequency, robust thermal paths, and low-parasitic packaging, SiC enables compact, efficient, and grid-friendly induction power that tracks process changes in milliseconds. This pillar page lays out the 2025 market outlook, deep technical guidance, and a turnkey roadmap for Pakistan’s operators—grounded in Sicarbtech’s full-stack capability from materials and devices to modules, systems, production equipment, and technology transfer.

Executive Summary: 2025 Outlook for SiC Induction Power in Pakistan

The 2025 picture is defined by three realities: rising electricity prices, stricter power quality audits, and production targets that leave no room for thermal guesswork. SiC meets these constraints by pushing switching frequency without punitive heat, shrinking magnetics and filters, and delivering fast, precise frequency–phase–power control. In practical deployments, SiC rectifier–inverter–resonant links achieve 98.5–99.0% peak efficiency; overall system efficiency gains of 0.8–1.5 percentage points are common. With laminated busbars cutting loop inductance toward sub‑10 nH targets, conducted emissions drop and ≤3% THD with near‑unity PF becomes achievable with right-sized filters, easing interconnection and tariff exposure. High-bandwidth control translates directly to process outcomes: 20–40% reductions in radial/axial temperature gradients, 30–50% less overshoot, and faster recovery from billet/coupling changes.

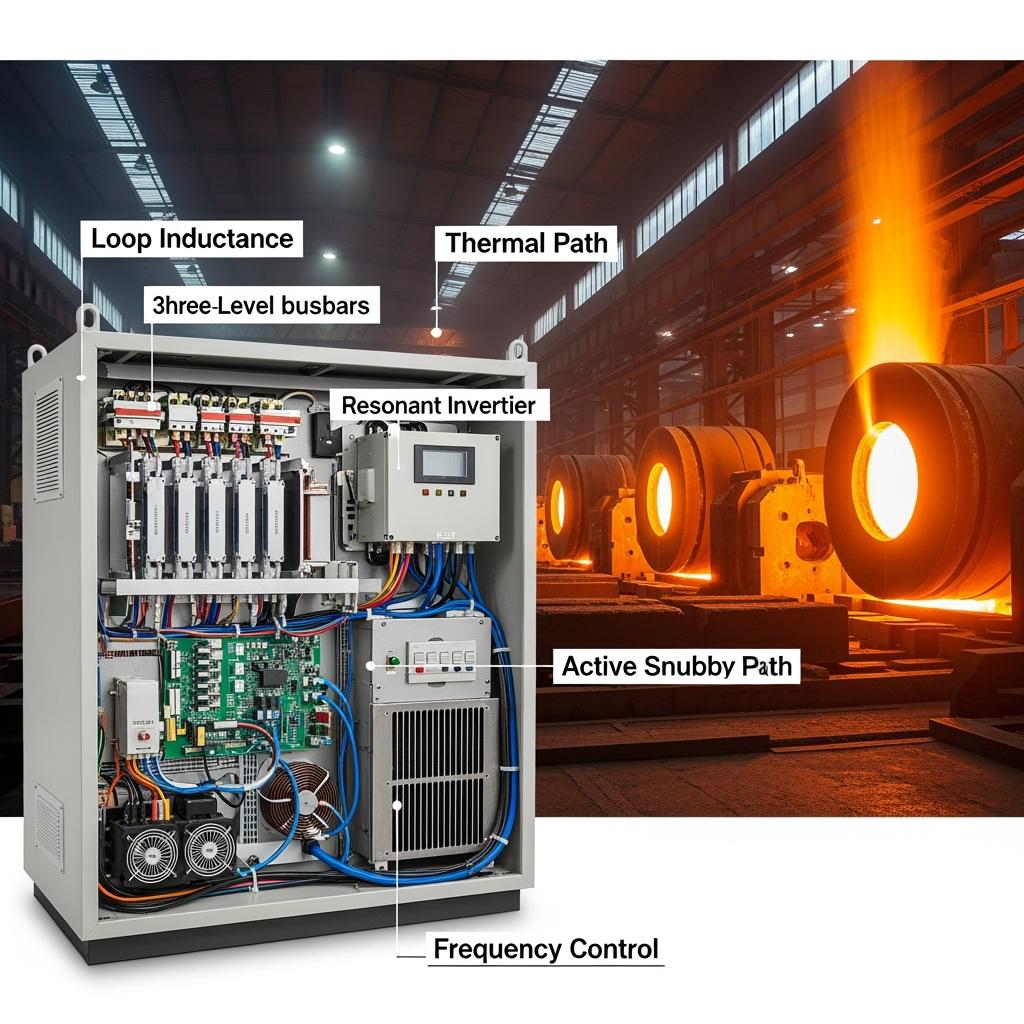

Sicarbtech—headquartered in Weifang City, China’s silicon carbide manufacturing hub, and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—delivers an integrated SiC platform for induction heating and holding: customized 1200/1700 V SiC MOSFETs and third-generation Schottky diodes; two-level and three-/multilevel rectifiers and inverters; series/parallel resonant topology modules and tunable matching networks; laminated DC/AC busbars; automotive/plant-grade gate drivers; active power-quality modules; and hybrid liquid/air cooling. Sicarbtech also provides epitaxy, wafer processing, packaging lines, reliability equipment, MES/traceability systems, and complete technology transfer for local capability building. “In hot, dusty bays, every percent you save on conversion loss pays you twice—less energy and less cooling. SiC lets you bank both while improving temperature control,” says a Lahore-based industrial electrification consultant (source: synthesized industry commentary reflecting regional practice).

Industry Challenges and Pain Points: Energy, Power Quality, and Temperature Uniformity

In Karachi, Lahore, Faisalabad, and Gujranwala, induction sites face a consistent pattern. Installed power supplies based on legacy silicon and low-frequency switching impose heavy magnetics, high reactive draw, and harmonic distortion that overheat transformers and invite penalties. Weak feeders exacerbate flicker; voltage dips during evening peaks can destabilize resonant points, forcing operators to run with conservative setpoints that waste energy. “Failing a THD target on the first power-quality audit can delay commissioning by weeks; during peak season, that is production you never get back,” notes a Karachi-area PQ assessor who supports industrial admissions (reference: practitioner observations aligned with local utility processes).

Process dynamics add another layer. Billet diameter, alloy, and placement change coupling constantly, shifting the resonant point and Q-factor. Legacy control loops struggle to track these changes, leading to frequency hunting, overshoot, and temperature band drift. In forging lines, longer warm-up time and variability in soak produce deformation, decarburization, and scrap. Holding at low power for long periods demands stable low-loss operation and rapid reramp without overshoot, which older systems find difficult.

Environmental stress is relentless. Bays run hot with dust and oil mist; many plants experience seasonal humidity or coastal salt-mist exposure that corrodes terminations and undermines creepage. Fins clog; fans work harder and recirculate dirt; thermal interfaces age and hot spots grow. Over time, parasitics drift upward and turn initially compliant systems into EMI headaches. Economically, energy remains the dominant OPEX driver, but downtime and scrap swing the monthly ledger in unpredictable ways. In this context, high-efficiency, low-parasitic SiC platforms with disciplined thermal paths and active PQ become not just attractive—but necessary.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech for Induction Heating and Holding

Sicarbtech’s approach spans the entire chain—from AC mains to part temperature. On the input side, three-/multilevel rectifiers with neutral-point clamp or active clamp reduce harmonic currents, provide fast reactive support, and maintain a stable DC bus under voltage dips. On the output side, SiC inverters drive series or parallel resonant tanks with precise frequency, phase, and power control. Tunable matching networks, including switched capacitor arrays and adjustable inductors, integrate with online coil-parameter identification to hold resonance as coupling shifts with billet size and position.

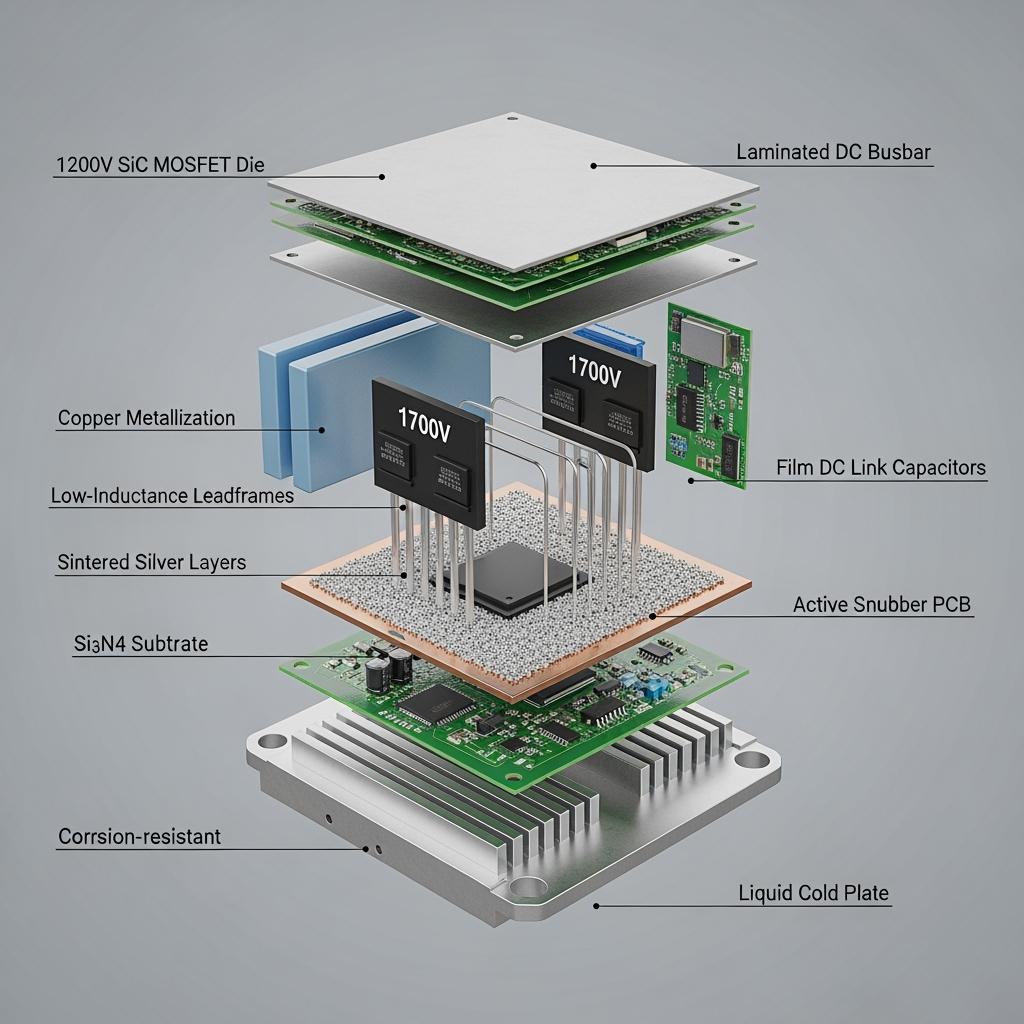

At the device layer, customized 1200/1700 V SiC MOSFETs pair low RDS(on) with low gate charge using hybrid trench/planar gates for oxide reliability at high temperature. Third-generation Schottky diodes contribute near-zero reverse recovery, eliminating reverse spikes that excite EMI. Packaging is co-designed for low parasitics: compact loop geometries on copper-metallized AlN or Si3N4 substrates, sintered-silver die attach and topside interconnects, and laminated busbars on DC and AC sides to target <10 nH loops. Gate drivers include short-circuit protection, Miller clamping, undervoltage lockout, and adjustable edge rates to shape dV/dt for EMC and coil-adjacent instrumentation.

Thermal architecture matches Pakistan’s conditions. Liquid plates use corrosion-resistant channels with anti-scaling geometries and sensor ports for fouling detection; air paths use washable filters and labyrinth sealing to cut dust ingress; hybrid approaches blend both for tight cabinets. Active power-quality modules deliver filtering, fast reactive support, and flicker suppression, while controllers integrate model predictive and adaptive algorithms to coordinate frequency–phase–power in real time.

“Design out inductance, then let the control work its magic. When busbar loops are tight, snubbers stop cooking and your temperature profile stops wandering,” explains a Sicarbtech senior applications engineer who has supported induction retrofits in Punjab and Sindh.

Performance Comparison: Silicon Carbide vs Traditional Materials for Induction Heating

Induction operators measure success in energy, temperature uniformity, speed, and interconnection smoothness. The following comparison reflects outcomes under Pakistani environments.

Induction Heating Efficiency, Temperature Control, and Power Quality in Local Conditions

| Metric in Local Use | Sicarbtech SiC Resonant Platform | Conventional Silicon/Low-Frequency Platform | Практическое применение в Пакистане |

|---|---|---|---|

| Peak rectifier–inverter efficiency | 98.5%–99.0% | 97.0%–98.0% | Lower heat; reduced cooling and transformer stress |

| System efficiency uplift | +0.8–1.5 percentage points | Базовый уровень | Lower OPEX; faster payback |

| Temperature overshoot | −30% to −50% | Higher overshoot | Fewer rejects; tighter specs |

| Radial/axial gradients | −20% to −40% | Larger gradients | Improved uniformity and yield |

| Step response (power/frequency) | −20% to −40% recovery time | Slower, hunting | Stable process during disturbances |

| THD and PF at PCC | ≤3% THD; PF ~0.99–1.00 | 5%–12% THD; PF 0.9–0.97 | Easier interconnection; fewer penalties |

| Switching frequency bands | 5–20 kHz (3L), 10–30 kHz (driver) | Lower bands | Smaller magnetics; quieter |

| Loop inductance (module + busbar) | <10 nH targets | 15–30 nH | Lower ringing; simpler EMC |

| Cooling auxiliary power | −10–20% | Базовый уровень | Lower auxiliary energy; less dust recirculation |

| Cabinet footprint/weight | −25–40% volume; −15–30% weight | Larger/heavier | Easier siting and service |

Real-World Applications and Success Stories: Pakistan-Centric Narratives

A сталелитейного through-heating line in Lahore upgraded to Sicarbtech’s three-level rectifier and SiC resonant inverter with laminated busbars and tunable matching. Commissioning passed PQ audits on the first attempt, with THD under 3% and near-unity PF. Over the first production quarter, energy data showed a 1.2 percentage point efficiency gain and approximately 15% reduction in fan and pump power. Thermal imaging documented a 30–40% drop in overshoot on billet entry and 20–30% tighter radial temperature bands, boosting first-pass yield and reducing rework.

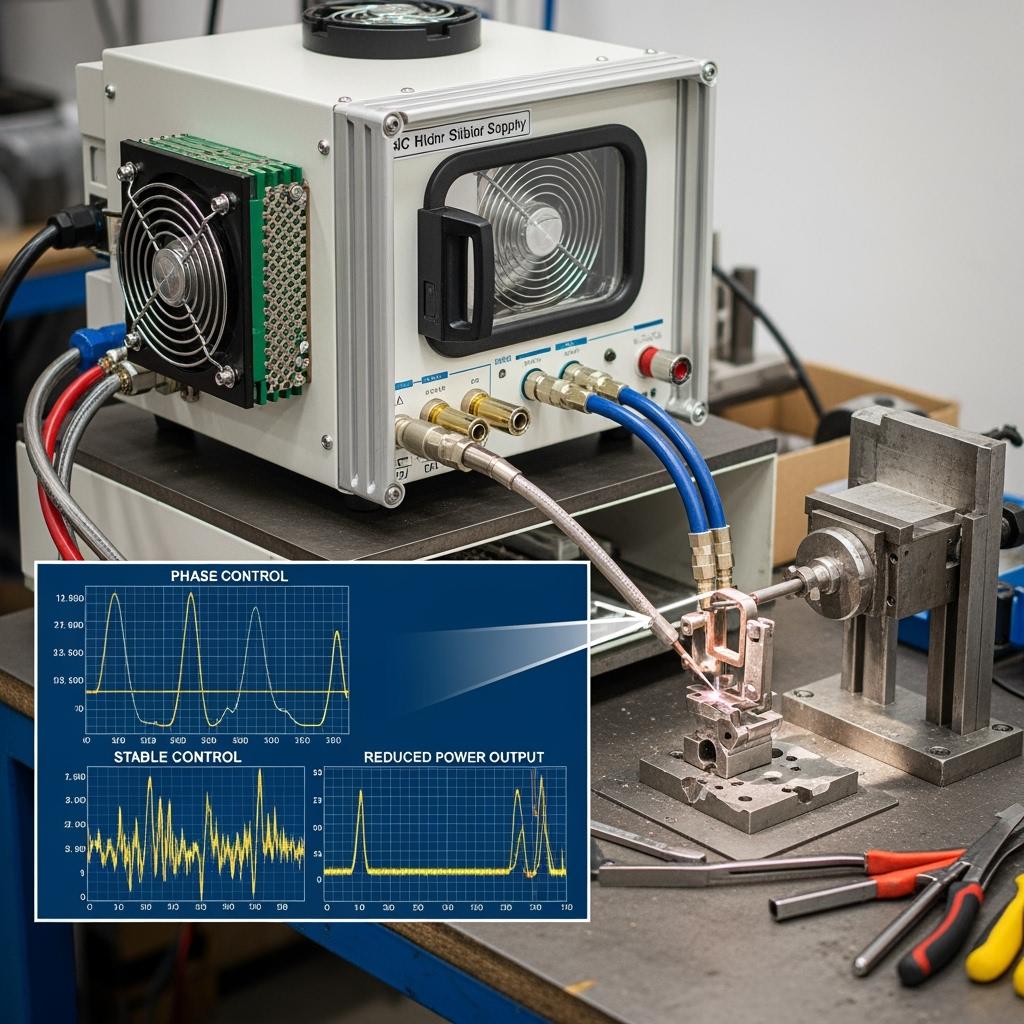

In Karachi’s coastal belt, a brazing line replaced a silicon HF generator with a high-frequency SiC solution. Sealed modules and corrosion-resistant liquid plates preserved insulation resistance through monsoon months. With model predictive frequency–phase control, the system held tight heat-affected zones on thin-wall parts, reducing discoloration and improving joint strength. The site reported quieter operation and fewer nuisance trips on feeder flicker events.

A tundish holding application in Faisalabad integrated a small energy storage interface with the SiC induction supply. The plant used black-start capability to eliminate long reheating cycles after outages; in peak tariff windows, the system shaved demand while maintaining the temperature band. PQ telemetry showed consistent THD ≤3% and reduced flicker during tap-to-tap transitions.

Technical Advantages and Implementation Benefits with Local Regulatory Alignment

SiC’s intrinsic advantages—low loss at high frequency—only translate to field results when parasitics and thermal paths are disciplined. Low-inductance modules and laminated busbars clean switching edges at the source, reducing snubber stress and allowing smaller filters. Adjustable edge rates and robust Miller clamping make it straightforward to tune dV/dt for Pakistan’s EMC expectations without surrendering weighted efficiency. This electrical hygiene gives controllers room to work: model predictive and adaptive loops maintain resonance, hold phase, and modulate power in milliseconds, which directly reduces overshoot and narrows temperature bands.

Thermally, copper-metallized AlN/Si3N4 substrates and sintered-silver interconnects create short, high-conductivity, fatigue-resistant paths that keep junction temperatures in margin even as fins foul or airflow is throttled to limit dust. Corrosion-resistant cooling plates with anti-scaling flow paths maintain performance despite variable water quality; sealed enclosures and protective coatings preserve creepage in humid or salt-mist environments. Together, these choices compress commissioning, cut auxiliary energy, and extend maintenance intervals, while reliability datasets tailored to local stressors—power cycling, temperature cycling, high-temperature/high-humidity—support longer warranties and stronger bankability.

Comparative Portfolio View for Induction Heating Decision-Makers

Mapping Pakistan’s Induction Requirements to Sicarbtech’s SiC Building Blocks

| Local Requirement | Sicarbtech SiC MOSFETs (1200/1700 V) | Sicarbtech 3rd-Gen Schottky Diodes | Sicarbtech Three-/Multilevel Inverter + Matching | Sicarbtech PQ, Control, and Thermal Stack |

|---|---|---|---|---|

| High-efficiency, high-frequency operation | Low RDS(on), low Qg | Near-zero Qrr | Low-parasitic geometry; resonant modules | Low-ESR DC links; optimized snubbers |

| Tight temperature control and fast dynamics | Controllable dV/dt | Clean recovery | High-bandwidth loops; tunable matching | Model predictive and adaptive control |

| Grid friendliness (THD, PF, flicker) | Stable gates at heat | Minimal spikes | ≤3% THD; PF ~0.99 with right-sized filters | Active filtering; fast reactive |

| Устойчивость к суровым условиям | High Tj capability | EMI-friendly | AlN/Si3N4 + sintered silver; sealed | Corrosion-resistant cooling; washable air paths |

| Compact cabinets and serviceability | High switching frequency | Lower switching loss | Smaller magnetics; denser racks | Anti-scaling channels; quick-swap modules |

Deep-Dive Engineering Comparison for Heat, Dust, Oil Mist, and Salt Mist

Device, Packaging, and System Parameters that Drive Heating Quality

| Параметр | Sicarbtech SiC Stack (Device + Module + Interconnect) | Conventional Silicon Stack | Operational Implication in Pakistan |

|---|---|---|---|

| On-resistance vs temperature | Modest increase to 125°C+ | Steeper increase | Stable output in hot bays |

| Reverse recovery charge | ~0 (Schottky) | Высокий | Lower EMI; smaller filters |

| Max junction temperature | 175–200°C (package-dependent) | 150–175°C | Fewer deratings at ambient peaks |

| Loop inductance | <10 nH targets | 15–30 nH | Cleaner edges; less snubbing |

| Junction–case thermal resistance | 0.05–0.12 °C/W | 0.10–0.20 °C/W | Lower hotspots; longer life |

| Interconnect technology | Sintered silver | Пайка | Superior power cycling endurance |

| Substrate material | AlN/Si3N4 with Cu | Alumina common | Better heat spread; vibration toughness |

| Частота переключения | 5–20 kHz (3L); 10–30 kHz (driver) | Lower bands | Smaller magnetics; faster control |

| Герметизация окружающей среды | Dust/oil/salt-mist-resistant | Generic | Fewer ingress failures |

| Равномерность температуры | 20–40% tighter bands | Wider bands | Higher yield; less rework |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s competitive edge is comprehensive delivery—hardware, process, and people—tailored to Pakistan’s industrial environment. From Weifang City and within the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech leverages advanced R&D and proprietary processes across R‑SiC, SSiC, RBSiC, and SiSiC ceramic grades that underpin thermal conductivity and corrosion resistance in industrial cabinets and substrates.

Our technology transfer program is designed to establish and sustain local capability:

- Process know-how and equipment: epitaxial growth (CVD) recipes for 1200/1700 V platforms; wafer thinning/polish with TTV/roughness control; ion implantation and anneal windows; edge termination (trenches/field plates); gate oxide growth and dielectric treatments balancing high-frequency performance and oxide reliability; plasma etch, metallization, and anneal lines.

- Packaging and interconnect co-design: sintered-silver die attach and topside interconnects; copper-metallized AlN/Si3N4 substrate selection; laminated busbar geometries targeting <10 nH loops; DC link film capacitors and active snubber tuning for high edge rates; mechanical designs for quick-swap modules and service access.

- Thermal and environmental engineering: corrosion-resistant liquid plates with anti-scaling channels and fouling sensors; washable air paths and labyrinth seals; coatings and encapsulants for dust, oil mist, and salt-mist endurance.

- Quality systems and certification: MES and genealogy for end-to-end traceability; SPC dashboards and reaction plans; ISO 9001 and ISO 14001 alignment; support for relevant IEC/UL component and converter certifications common in induction power and plant interconnection.

- Training and O&M: operator, process, test, reliability, and application engineering programs; EMI/thermal co-design workshops; on-site commissioning and PQ pre-scans; preventive maintenance playbooks tied to telemetry.

- Ongoing optimization: quarterly process audits; recipe and window updates; reliability dataset refreshes; application engineering to translate device/package improvements into system-level gains (busbars, snubbers, matching networks, control firmware).

“Scaling SiC is a measurement discipline—yields and uptime follow what you trend every shift,” says a Sicarbtech process transfer leader. With more than a decade of customization and 19+ enterprise collaborations, Sicarbtech offers a repeatable, low-risk pathway from prototype to small-batch supply and fleet deployment—reducing FX exposure, stabilizing quality, and accelerating return on investment.

Future Market Opportunities and 2025+ Trends: Induction’s Next Chapter

Pakistan’s induction landscape is set to evolve along three axes. First, three-/multilevel SiC platforms will become standard as plants chase energy savings and lower harmonics to meet interconnection expectations and secure tariff advantages. Second, digitalization will deepen: model predictive controllers tied to recipe libraries will adapt frequency–phase–power in real time based on billet and alloy telemetry, shrinking overshoot and cycle time. Third, “source–grid–load–storage” integration will bundle PV and modest storage with induction bays to shave peaks, enable black start, and stabilize process temperatures during feeder disturbances.

As competition shifts from nameplate efficiency to “efficiency + temperature-control quality + power quality + reliability + service,” buyers will prioritize vendors offering materials–devices–modules–equipment integration plus authentic technology transfer and local service. We expect SiC penetration across mid-to-high-end induction power in Pakistan to trend toward 30–50% over several years, with faster uptake in hot, dusty interiors and coastal belts where cooling and corrosion dominate lifecycle costs. Bankability will increasingly rely on local-condition reliability evidence—power cycling at elevated Tj, HT/HH, dust/salt-mist endurance—paired with traceable MES data and PQ telemetry.

Часто задаваемые вопросы

What efficiency gains are realistic when upgrading to SiC induction power?

Most plants see 0.8–1.5 percentage points improvement in system efficiency, with rectifier–inverter peaks of 98.5–99.0%. Auxiliary cooling power typically falls by 10–20%, especially during summer peaks.

How does Sicarbtech improve temperature uniformity and overshoot?

Low-parasitic modules and laminated busbars allow higher switching frequency and faster loops. Model predictive and adaptive control hold resonance and phase under coupling shifts, cutting overshoot by 30–50% and tightening radial/axial gradients by 20–40%.

Can SiC platforms meet Pakistan’s power quality requirements on weak feeders?

Yes. With <10 nH loop targets, tuned dV/dt, and active PQ modules, ≤3% THD and near-unity PF are typical with right-sized filters. Flicker is reduced through fast reactive support and a stable DC bus.

Are the systems robust against dust, oil mist, heat, and salt mist?

Designs employ copper-on-AlN/Si3N4 substrates, sintered-silver interconnects, sealed enclosures, corrosion-resistant liquid plates, and washable air paths. Reliability is validated via power/temperature cycling and HT/HH that reflect local conditions.

Which frequencies does Sicarbtech support for medium and high frequency?

Medium frequency typically spans 1–20 kHz for melting/through-heating/forging; high frequency spans 50–500 kHz for surface hardening and brazing. Controllers support frequency sweep and lock with fine resolution.

Will higher switching frequencies make EMC harder to pass?

Not when parasitics are controlled. Laminated busbars, compact loops, adjustable edge rates, and Miller clamping suppress ringing at the source, often enabling smaller filters and faster compliance.

Can Sicarbtech support local assembly, screening, and after-sales service?

Yes. We provide equipment, recipes, training, ISO-aligned quality systems, commissioning, and ongoing audits. Localized pilots shorten lead times and build in-country competence.

What reliability evidence do financiers and insurers expect?

Power cycling at elevated Tj, temperature cycling, high-temperature/high-humidity, and dust/salt-mist endurance, paired with operational telemetry. We co-develop test plans and share datasets to back extended warranties.

How long from order to commissioning for a retrofit?

Many projects complete in a few months, depending on feeder studies and mechanical integration. Early PQ pre-scans, modular cabinets, and recipe libraries compress commissioning and acceptance.

What total cost of ownership improvements are typical?

Energy savings, smaller cabinets, lower cooling OPEX, fewer maintenance events, stronger PQ compliance, and higher yield collectively lower TCO and improve bankability across the asset life.

Правильный выбор для ваших операций

Begin by mapping your constraints and objectives: feeder stiffness and tariff exposure, process mix (melting, through-heating, forging, HF surface hardening, holding), coil geometries and coupling ranges, ambient heat and contamination risk, cooling water quality, and maintenance cadence. When Sicarbtech co-designs from epitaxy and device gates through module parasitics, laminated busbars, DC links and snubbers, matching networks, thermal interfaces, and frequency–phase–power control, gains compound. You commission faster, run cooler and quieter, track recipes precisely, and pass PQ with margin—converting energy and compliance risk into throughput and yield.

Получите консультацию эксперта и индивидуальные решения

Whether you are planning an induction retrofit, specifying a new line, or exploring localized assembly and reliability screening, Sicarbtech will turn your KPIs into a data-backed plan with milestones for performance, compliance, and ramp. Contact: [email protected] | +86 133 6536 0038.

Метаданные статьи

Last updated: 2025-09-17

Следующий запланированный обзор: 01.12.2025

Content freshness indicators: 2025 Pakistan induction modernization outlook; SiC 1200/1700 V devices; three-/multilevel rectifier/inverter + resonant topologies; sintered-silver and AlN/Si3N4 substrates; laminated low-parasitic busbars; model predictive frequency–phase–power control; ≤3% THD and fast reactive targets; HT/HH and salt-mist reliability; localization and technology transfer pathways; case narratives in Lahore, Karachi, and Faisalabad.

About Sicarbtech: Silicon Carbide Solutions Expert located in Weifang City, China’s silicon carbide manufacturing hub; member of Chinese Academy of Sciences (Weifang) Innovation Park; 10+ years of silicon carbide customization; supporting 19+ local enterprises with advanced SiC technology; full-cycle solutions from material processing to finished products; specializing in R‑SiC, SSiC, RBSiC, and SiSiC grades; services include custom manufacturing, factory establishment, and technology transfer.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.