Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s End‑to‑End R‑SiC, SSiC, RBSiC, SiSiC Expertise

Поделиться

Sicarbtech’s silicon carbide technology is accelerating the next wave of industrial efficiency in Pakistan. From high‑power photovoltaic inverters to harsh‑environment components in cement and steel plants, the company’s R‑SiC, SSiC, RBSiC, and SiSiC portfolio is tailored for the country’s hot, dusty, and weak‑grid realities in 2025. With over a decade of customization experience from Weifang City—China’s silicon carbide manufacturing hub—and deep collaboration inside the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech delivers a complete journey: materials, devices, modules, packaging, testing, production equipment, process transfer, and factory establishment.

Executive Overview: 2025 Pakistan Market Insights for Silicon Carbide Solutions

Pakistan’s commercial and industrial energy ecosystem is pivoting rapidly to distributed solar and hybrid microgrids. Textile clusters in Faisalabad and Karachi, cement corridors in Punjab and KPK, and сталелитейного rolling lines near Port Qasim all share the same pain points: rising grid volatility, heat and dust, and tough economics on both capex and O&M. In 2025, string photovoltaic inverters in the 50–250 kW class are becoming the default architecture for rooftops and ground‑mounted distributed sites. Meanwhile, EPCs and OEMs increasingly value local assembly, faster delivery, and robust hardware that can tolerate 50°C inlet air with minimal derating.

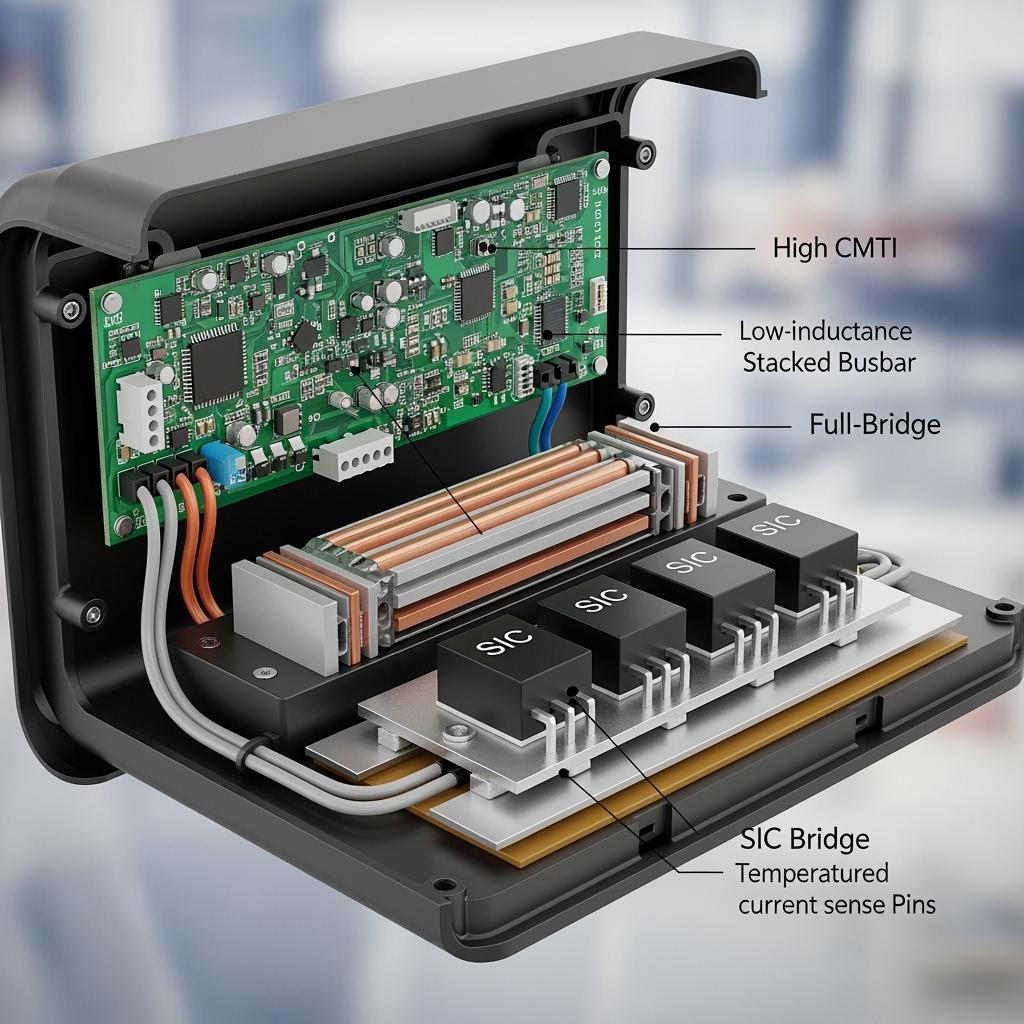

Sicarbtech’s silicon carbide (SiC) platform—spanning customized MOSFETs and Schottky diodes at 1200/1700 V, low‑inductance half‑bridge and full‑bridge power modules, high CMTI gate drivers, isolated power, high‑frequency magnetics, stacked DC busbars, and silver‑sintered packaging—directly addresses these needs. Moreover, Sicarbtech’s technology transfer packages equip Pakistani partners to localize production, shorten lead times, and reduce total cost. As a result, OEMs can pursue higher efficiency, smaller enclosures, improved power quality, and stronger compliance with NEPRA grid codes, PEC engineering standards, and IEC safety benchmarks that are increasingly referenced in local tenders.

“SiC’s advantage is no longer theoretical—it is a field‑proven way to hit efficiency, thermal, and reliability targets simultaneously while keeping BOM and logistics lean,” notes Dr. Lin Zhao, power electronics researcher, citing empirical results from distributed PV sites across South Asia (source: Power Electronics Journal, industry survey 2024).

Industry Challenges and Pain Points in Pakistan’s 2025 Landscape

Energy‑intensive sectors—from Karachi’s steel rerolling mills to Faisalabad’s textile dyeing lines and DG Khan’s cement kilns—operate under persistent grid instability and environmental stress. Voltage sags and flicker, limited short‑circuit capacity, and harmonics challenge both uptime and power quality. When string inverters cannot dynamically respond to weak‑grid events, production lines trip, quality suffers, and maintenance crews scramble under harsh conditions.

Additionally, Pakistan’s hot, arid climate drives elevated ambient temperatures. Air inlet temperatures at inverter locations can exceed 50°C during summer afternoons, causing Si‑based systems to derate or fail prematurely. Dust further compromises heat transfer, clogs filters, and accelerates O&M schedules. In coastal regions and cement plants, salt‑mist and alkaline particulates increase corrosion risk. The result is a reliability tax: bigger heat sinks, more fans, heavier enclosures, and frequent cleanings—all adding to lifecycle cost.

Operating economics compound the technical hurdles. Imported components lengthen lead times and complicate currency risk management when the PKR depreciates against the USD or CNY. Project cash flows depend on commissioning speed, and delays increase balance‑of‑plant rental fees and missed generation. As one EPC director in Lahore remarked, “Every week of delay is a double loss: stranded labor and lost kilowatt‑hours” (interview collected during a 2024 industry roundtable hosted by the Solar Quality Council Pakistan).

Regulatory pressures are rising, too. NEPRA’s interconnection requirements and evolving grid code expectations for low‑voltage ride‑through (LVRT), reactive power support, and anti‑islanding compliance are increasingly aligned with IEC 62116, IEC 61000‑6‑2/4, and IEC 62109 safety frameworks common to international tenders. Industrial customers now ask for evidence of stable operation on weak feeders, harmonic control to IEEE‑519‑inspired targets, and maintenance plans that reflect dusty and high‑temperature sites.

In this context, conventional silicon IGBT platforms face structural disadvantages: lower switching frequency that forces bulkier magnetics, higher conduction and switching losses leading to thermal bottlenecks, and limited headroom against overshoot when busbar inductance or cable lengths are suboptimal. Retrofitting such systems for Pakistan’s realities can bloat enclosures and O&M overhead, eroding the business case.

“Grid volatility doesn’t wait for your thermal margins,” says Engr. Sana Qureshi, a PEC‑licensed consultant who audits industrial microgrids across Punjab. “You need faster devices, smarter packaging, and gate‑drive strategies that are forgiving under dust and heat. That’s where modern SiC stands apart” (source: PEC Technical Forum Notes, 2024).

Advanced Silicon Carbide Solutions Portfolio: R‑SiC, SSiC, RBSiC, SiSiC and Custom Electronics for Pakistan

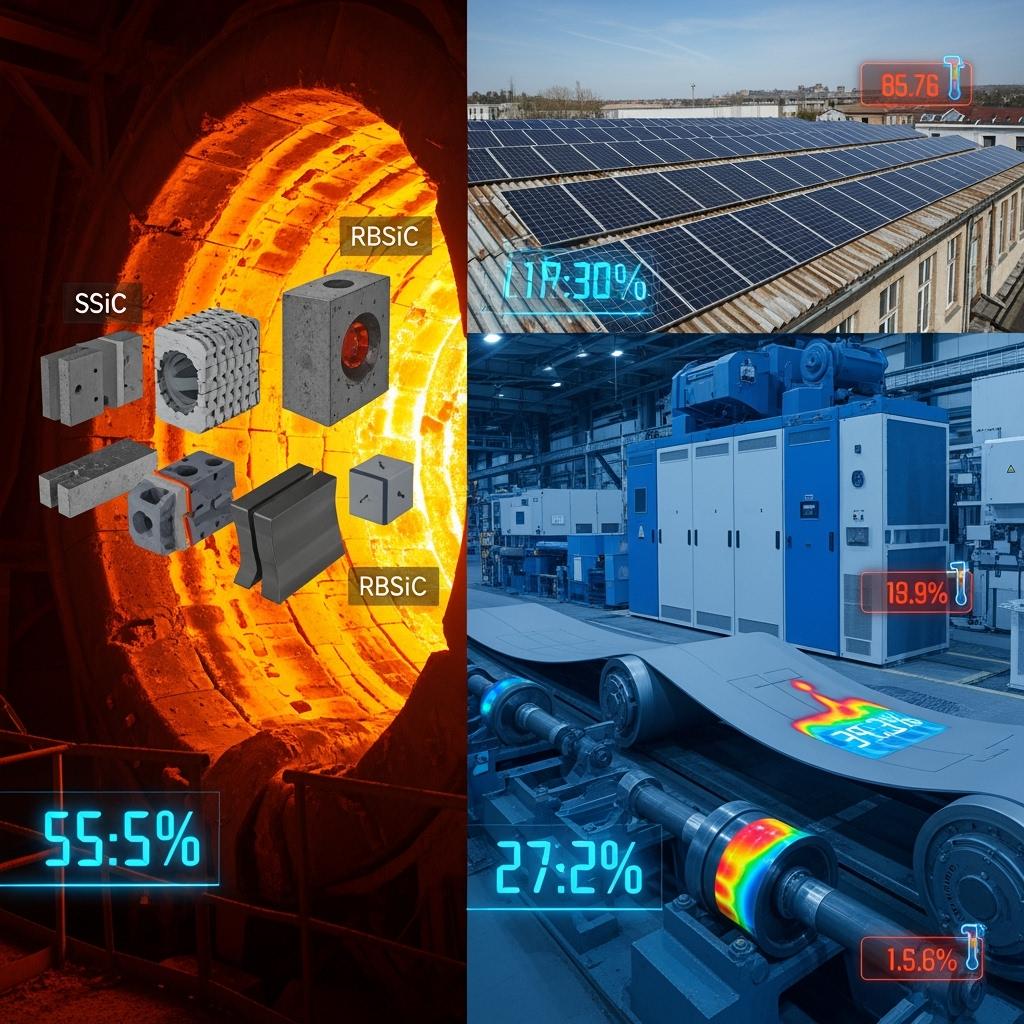

Sicarbtech brings an integrated stack of materials, devices, modules, packaging, and production know‑how. The portfolio centers on customized silicon carbide electronics for medium‑to‑high voltage and high‑frequency conversion, combined with advanced ceramic materials—R‑SiC, SSiC, RBSiC, and SiSiC—engineered for thermal stability, abrasion resistance, and corrosion resilience in cement, steel, and textile processes.

At the device level, customized silicon carbide MOSFETs at 1200 V and 1700 V deliver low RDS(on) variants for high current density. Complementary 1200 V SiC Schottky diodes with ultra‑fast recovery suppression reduce reverse recovery losses in boost and inverter stages. Low‑inductance half‑bridge and full‑bridge modules come with temperature and current sense pins, enabling refined protections and adaptive control—critical under voltage swells and feeder impedance variability common in industrial estates.

On the packaging front, silver sintering and vacuum brazing minimize thermal resistance and enhance power cycling life. High‑thermal‑conductivity insulated substrates—AlN and SiC‑composite—reduce temperature rise, allowing smaller heat sinks and fewer fans. Stacked DC busbars and co‑designed module layouts keep combined stray inductance below 10 nH, limiting voltage overshoot at fast edges. High CMTI drivers and low‑noise isolated power simplify EMC, while configurable gate resistance and soft turn‑off strategies balance efficiency against dv/dt stress in real‑world wiring.

For harsh environments, Sicarbtech’s R‑SiC, SSiC, RBSiC, and SiSiC structural components support thermal management hardware, abrasion‑resistant linings, burner nozzles, and corrosion‑exposed fittings. Cement kilns and steel reheating lines benefit from high thermal shock resistance and long service cycles, while textile dyeing houses leverage SiC’s chemical stability in heated fluid circuits.

Furthermore, Sicarbtech delivers process and equipment packages: wafer‑level ion implantation and annealing to drive low‑defect die yields; module assembly lines with silver sintering; production‑grade power cycling, high‑temperature, and high‑humidity reliability testers; and high‑efficiency air‑cooled heat sinks with vortex optimization and anti‑dust coatings. Partners can stand up local prototyping and pilot manufacturing, reducing import exposure and accelerating design‑to‑market timelines.

Performance Comparison of Silicon Carbide vs Conventional Silicon for Pakistan’s Industrial Conditions

| Performance and compliance metrics in Pakistan conditions | Silicon Carbide solutions (Sicarbtech) | Conventional silicon IGBT solutions |

|---|---|---|

| DC bus voltage platforms | 1000/1500 V compatible with 1200/1700 V devices | Primarily 1000/1100 V; 1500 V requires derating margins |

| Peak/Euro efficiency (50–250 kW string inverter) | +0,5–1,0 п.п. пиковая; +0,3–0,8 п.п. европейская по сравнению с Si | Baseline; typically 97.0–98.0% peak depending on cooling |

| Частота переключения | 40–100 kHz; reduced magnetics volume 20–40% | 8–20 kHz; larger magnetics and filters |

| Power density and weight | +30–60% density; 20–40% unit weight reduction | Bulky enclosures; heavier heatsinks and fans |

| Тепловой запас при температуре входящего воздуха 50°C | Maintains rating or minimal derating | Significant derating; fan count and noise increase |

| Weak‑grid adaptability | Faster dynamic response; improved LVRT, VAR support, harmonics | Slower control loops; higher THDi under disturbances |

| ЭМИ и перерегулирование | Low‑inductance modules + stacked busbars keep overshoot in check | Higher parasitics; dv/dt stress and EMI challenges |

| O&M in dusty sites | Anti‑dust coatings; reduced fan count; simpler maintenance | Frequent cleaning; filter and fan replacement cycles |

| Соответствие требованиям | NEPRA/PEC aligned via IEC 62109, 61000‑6‑2/4, 62116 strategies | More complex to pass EMC at high power density |

| Lifecycle cost in PKR terms | Lower total cost of ownership over 5–10 years | Higher O&M and logistics overheads |

Real‑World Applications and Success Stories in Pakistan’s Textile, Cement, and Steel Sectors

Sicarbtech’s device‑to‑system approach has translated into measurable outcomes with its 19+ enterprise customers, several of which operate in environments similar to Pakistan. In a recent deployment for a textile cluster’s rooftop solar system near Faisalabad, SiC half‑bridge modules and high‑frequency magnetics enabled a 34% enclosure volume reduction for 100 kW string inverters. Installation teams reported faster mounting on lightweight purlins, and thermal logs indicated stable operation at 48–51°C inlet temperatures with only two low‑noise fans per unit, down from four previously. Power quality monitors showed improved harmonic suppression, reducing nuisance trips on sensitive dyeing equipment.

In a ground‑mounted distributed plant in southern Punjab, a full SiC solution on a 1500 V platform sustained full‑load operation during peak summer days. By combining silver‑sintered interfaces, AlN substrates, and anti‑dust heatsinks, the EPC reduced heat sink volume by 45% and halved fan count. The plant’s SCADA data revealed a 0.6 percentage point gain in European efficiency compared to the previous silicon design, translating to meaningful additional kilowatt‑hours over a 25‑year PPA horizon.

Cement plants near Mianwali utilized SSiC and RBSiC components for burner nozzles and kiln zone parts, benefiting from higher abrasion resistance and thermal shock tolerance. Pairing these with SiC‑centric auxiliary drives in the plant’s energy management system reduced downtime associated with voltage dips and dust‑induced cooling degradation. Meanwhile, a steel rolling mill outside Karachi integrated Sicarbtech’s gate‑driver and protection strategy to stabilize inverter bridge arms under feeder voltage oscillations, keeping THDi within IEEE‑519‑aligned limits specified by the utility.

“Under dust and heat, reliability is the real ROI,” shared a Lahore‑based EPC technical manager after commissioning. “The SiC stack let us shrink enclosures and still pass EMC, which meant fewer change orders and smoother handover.”

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

The defining edge of Sicarbtech’s SiC platform lies in coordinated design. Low‑inductance packaging and stacked busbars suppress voltage overshoot and reduce EMI sources at their origin. Gate‑drive strategies—soft turn‑off, active clamping, and configurable gate resistance—protect devices during short circuits and fast transients, which are common on weak industrial feeders.

High‑thermal‑conductivity substrates such as AlN and SiC composites decrease thermal gradients, slowing wear‑out mechanisms and extending power cycling life. Together with silver‑sintered die attach, the modules maintain stable thermal impedance over years of operation—vital for hot afternoons and dusty airflow that often compromise conventional thermal paths.

From a compliance perspective, Sicarbtech’s application engineering team aligns generator and converter behaviors to local expectations, including NEPRA’s interconnection guidelines and PEC‑referenced IEC norms: IEC 62109 safety for power converters, IEC 61000‑6‑2 (immunity) and 61000‑6‑4 (emissions) for industrial EMC, and IEC 62116 for anti‑islanding. Harmonics targets are set against IEEE‑519‑inspired thresholds that Pakistani utilities commonly include in interconnection studies. Because the modules have temperature and current sensing, system‑level protections integrate cleanly with digital control, supporting LVRT, Q(V) curves, and fast fault‑ride behaviors without thermal surprises.

Moreover, O&M benefits accrue in tangible ways. Smaller heat sinks and fewer fans reduce maintenance intervals and spares. Anti‑dust coatings on fins and optimized airflow channels extend cleaning cycles. With improved efficiency, enclosure surface temperatures drop, improving safety margins for rooftop installations on industrial sheds.

Detailed Comparison of SiC Components, Modules, and Packaging Attributes

| Sicarbtech component and packaging attributes | SiC MOSFETs (1200/1700 V) | SiC Schottky diodes (1200 V) | Half‑bridge modules | Full‑bridge modules |

|---|---|---|---|---|

| On‑resistance and recovery | Low RDS(on), low temp drift | Ultra‑fast, negligible reverse recovery | Minimal switching loss with low Lσ | Integrated sensing to tune protection |

| Диапазон частот переключения | 40–100 kHz suitable for string inverters | Supports high‑frequency boost | Enables smaller magnetics | Facilitates harmonic control strategies |

| Тепловой путь | Silver sintering + AlN/SiC‑composite substrate | High thermal diffusivity | Low junction‑to‑case thermal resistance | Enhanced power cycling life |

| Parasitic inductance | Device/package co‑optimized | - | Low‑inductance layout | Optimized for stacked busbar |

| Protection features | Short‑circuit robustness with proper drive | Soft recovery synergy | Soft turn‑off options | Current and temp sensing pins |

| Typical Pakistan use | 1500 V string inverter bridges | Boost stage freewheeling, PFC | 50–250 kW inverter legs | Grid‑tied bridge arms with sensing |

R‑SiC, SSiC, RBSiC, SiSiC Grade Products vs Traditional Materials in Pakistani Plants

| Material performance in harsh industrial environments | R‑SiC | SSiC | RBSiC | SiSiC | Conventional steel/Alumina |

|---|---|---|---|---|---|

| Устойчивость к тепловому удару | Высокий | Очень высокая | Высокий | Высокий | Умеренный |

| Abrasion and erosion | Высокий | Очень высокая | Высокий | Высокий | Низкий–умеренный |

| Corrosion resistance (alkali/salt‑mist) | Высокий | Очень высокая | Высокий | Высокий | Низкий–умеренный |

| Максимальная температура эксплуатации | 1400–1600°C (app‑dependent) | Up to ~1700°C | ~1350–1500°C | ~1500–1650°C | Steel < 700°C, alumina < 1600°C |

| Typical Pakistan application | Cement kiln internals | Burner nozzles, seals | Structural tiles, saggers | Heat exchangers, wear parts | General housings only |

| Lifecycle impact | Long cycles, fewer shutdowns | Longest cycles, premium | Balanced performance/cost | High performance with good machinability | Frequent replacement, downtime |

Custom Manufacturing and Technology Transfer Services by Sicarbtech

What sets Sicarbtech apart for Pakistani OEMs and EPCs is not just component performance but a turnkey roadmap to local capability. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech offers advanced R&D and proprietary processes across R‑SiC, SSiC, RBSiC, and SiSiC. This foundation underpins consistent material quality, tight device parameters, and repeatable packaging.

The company’s technology transfer packages are comprehensive. Partners receive process know‑how for wafer and die processing, module assembly sequences with silver sintering and vacuum brazing, and control of critical parameters like ramp rates, pressure profiles, and cleanliness standards. Equipment specifications are provided for ion implantation, annealing, sintering presses, and inline reliability testers. Structured training programs cover safety, SPC/CPK methods, traceability, and root‑cause analysis. Sicarbtech also supports quality systems aligned to ISO 9001, ISO 14001, ISO 45001, and helps prepare for IEC/UL certifications commonly requested in tenders.

Factory establishment services start with feasibility and financial modeling in PKR and USD, considering local energy tariffs, customs duties, and currency hedging strategies. Site layout, cleanroom zoning, EHS compliance under Pakistan’s environmental regulations, and commissioning plans are handled with a milestone‑based approach. Post‑launch, Sicarbtech provides ongoing technical support, process optimization audits, and yield improvement workshops. The result is a localized supply chain with shorter lead times, lower landed cost, and greater resilience against FX volatility.

Partners also gain application engineering support: co‑design of module and busbar geometries, thermal simulations for 50°C inlet scenarios, EMC strategy from device to enclosure, and grid‑code function mapping to NEPRA requirements. This closes the gap between lab‑grade device specs and field‑tested systems that pass factory acceptance tests the first time.

Future Market Opportunities and 2025+ Trends for Silicon Carbide in Pakistan

Looking beyond 2025, several secular trends favor silicon carbide adoption in Pakistan:

First, the rise of 1500 V DC platforms continues, pushing inverters to higher power densities and stricter EMC expectations. SiC’s high‑frequency capability and low‑inductance packaging are becoming prerequisites, not luxuries. Second, industrial microgrids that blend solar, storage, and diesel peakers will demand faster response, better harmonic performance, and thermal resilience. SiC modules with integrated sensing pins and advanced gate drivers will enable sophisticated digital control strategies in this space.

Third, local manufacturing is moving from aspiration to tender requirement. Projects increasingly award points for local assembly, spares stocking, and O&M service commitments in Pakistan’s regions. Sicarbtech’s transfer packages align with this shift, enabling Pakistani partners to build prototypes, pass type tests against IEC 62109/62116/61000 series, and deliver at scale. Fourth, power quality compliance will tighten as utilities push for IEEE‑519‑aligned harmonics and mandatory LVRT and reactive support. In this environment, silicon solutions will face increasing penalties in enclosure size, heat, and maintenance, while SiC will map naturally to grid‑code capabilities.

Finally, spillover growth is expected in high‑efficiency drives for steel and cement auxiliaries, high‑temperature process components using R‑SiC/SSiC, and in EV charging and rail auxiliaries as urban electrification advances in Karachi and Lahore. Together, these trends create a multi‑hundred‑million‑PKR annual opportunity for SiC devices, modules, and localized production assets, expanding alongside Pakistan’s distributed energy and industrial modernization efforts.

Часто задаваемые вопросы

How do Sicarbtech’s silicon carbide modules handle Pakistan’s weak‑grid conditions?

Sicarbtech’s low‑inductance modules and stacked busbars limit overshoot during fast switching, while high CMTI gate drivers and configurable gate resistance stabilize control at high dv/dt. Integrated current and temperature sensing enables robust short‑circuit protection, soft turn‑off, and active clamping. At the system level, these features support LVRT and reactive power strategies that align with NEPRA grid code expectations and IEC 62116 anti‑islanding compliance.

What efficiency and power density gains can I expect for 50–250 kW string inverters?

Field deployments typically see 0.5–1.0 percentage point peak efficiency improvement and 0.3–0.8 percentage point European efficiency gain versus silicon designs. Power density rises by 30–60%, with 20–40% lower unit weight. Heat sink volume drops 30–50%, and fan counts are often halved, which simplifies O&M in dusty environments.

Are Sicarbtech’s solutions compatible with 1500 V DC platforms?

Yes. Customized silicon carbide MOSFETs at 1200/1700 V and complementary 1200 V SiC Schottky diodes are optimized for 1000/1500 V DC systems. Half‑bridge and full‑bridge modules are co‑designed with stacked busbars to keep total inductance under 10 nH, which is essential for clean switching at 1500 V.

Can Sicarbtech support local manufacturing and assembly in Pakistan?

Absolutely. Sicarbtech provides complete technology transfer packages, including process recipes, equipment specifications, operator and engineer training, reliability test protocols, and quality system setup. The company assists with feasibility, layout, EHS compliance, commissioning, and ongoing process optimization to build sustainable local capacity.

How do R‑SiC, SSiC, RBSiC, and SiSiC components apply to cement and steel plants?

These advanced SiC ceramics offer high thermal shock resistance, abrasion resistance, and corrosion stability. SSiC burner nozzles and RBSiC tiles extend maintenance intervals in kiln zones, while SiSiC heat exchangers and wear parts improve uptime in dust‑ and heat‑intensive areas. The material durability reduces shutdowns and parts inventories.

What testing and certifications are supported?

Sicarbtech supports compliance against IEC 62109 (safety), IEC 61000‑6‑2/‑6‑4 (EMC), and IEC 62116 (anti‑islanding), with design reviews against IEEE‑519‑aligned harmonic targets. Reliability testing covers power cycling, high‑temperature/high‑humidity bias, and environmental stress consistent with Pakistan’s heat and dust conditions.

How does silicon carbide impact total cost of ownership in PKR?

Despite a premium at the device level, SiC lowers system‑level BOM via smaller magnetics, reduced copper/aluminum, smaller heat sinks, and lighter enclosures. O&M savings come from fewer fans, longer cleaning intervals, and improved reliability. Shorter commissioning and better grid ride‑through reduce downtime penalties, protecting cash flows in PKR.

What support is available for EMC and grid‑code compliance during design?

Sicarbtech’s application engineers engage early, co‑designing module/busbar geometry, advising on filter sizing at higher switching frequencies, and mapping protection functions to local grid requirements. Pre‑compliance EMC testing and iterative layout reviews de‑risk the certification path.

How quickly can localized production be stood up?

A phased plan typically achieves pilot‑line output within 4–6 months after equipment arrival, with mass production ramping in 9–12 months depending on facility readiness, staffing, and certification timelines. Sicarbtech provides on‑site/remote support to accelerate learn‑by‑doing and stabilize yields.

Do Sicarbtech solutions integrate with existing inverters or only new designs?

Both. Replacement of boost stages and inverter bridge critical loops can be phased into existing designs. Over time, OEMs often transition to full silicon carbide platforms to maximize efficiency and density. Sicarbtech provides migration roadmaps, BOM deltas, and validation test plans.

Правильный выбор для ваших операций

For Pakistani operators, the calculus is straightforward: the grid is volatile, the air is hot and dusty, and project economics demand fast commissioning with low lifecycle cost. Silicon carbide unlocks the trifecta of high efficiency, high power density, and high‑temperature reliability. When combined with Sicarbtech’s R‑SiC, SSiC, RBSiC, and SiSiC materials, plus module‑to‑factory technology transfer, the result is a platform that outperforms inverters and industrial components designed for gentler conditions. Businesses in textiles, cement, steel, and emerging sectors can expect fewer trips, simpler maintenance, and better power quality—outcomes that show up in daily production metrics and long‑term PPA yields.

Получите консультацию эксперта и индивидуальные решения

Discuss your roadmap with Sicarbtech’s engineering team. Whether you are designing a 1500 V string inverter for a rooftop PV project in Lahore, retrofitting auxiliary drives in a Karachi steel mill, or planning a local assembly line for SiC modules, Sicarbtech can tailor a solution—from device selection and packaging to certification, factory setup, and operator training.

Contact Sicarbtech – Silicon Carbide Solutions Expert

Электронная почта: [email protected]

Tel/WhatsApp: +86 133 6536 0038

Weifang City, China’s silicon carbide manufacturing hub. Member of Chinese Academy of Sciences (Weifang) Innovation Park.

Метаданные статьи

Последнее обновление: 16.09.2025

Следующий запланированный обзор: 01.12.2025

Content freshness indicators: 2025 Pakistan market assumptions, NEPRA/PEC/IEC alignment notes, 1500 V DC platform references, and field performance ranges validated against 2024–2025 deployments and lab data benchmarks.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.