Промышленные решения из карбида кремния для текстильной, цементной и сталелитейной промышленности Пакистана

Поделиться

Краткое содержание: Прогноз на 2025 год для высокоэффективных решений в области энергетики и теплотехники

Промышленная экономика Пакистана ускоряется в 2025 году с острой необходимостью стабилизировать качество электроэнергии, повысить энергоэффективность и укрепить оборудование от суровых условий эксплуатации. Текстильные фабрики в Фейсалабаде, сталелитейного перекатка в Карачи и цементные печи по всему Пенджабу сталкиваются с частыми провалами напряжения, гармоническими искажениями и плановыми отключениями. С расширением центров обработки данных и цифровой инфраструктуры в рамках национальных инициатив по цифровизации рыночный спрос на высоконадежные источники бесперебойного питания (ИБП), приводы с регулируемой частотой (VFD) и высокоэффективные выпрямители должен превысить 100 миллионов долларов США в год, причем ИБП средней и высокой мощности составляют более 60% расходов.

Sicarb Tech, эксперт по решениям на основе карбида кремния (SiC) из Вэйфана и член Инновационного парка Китайской академии наук (Вэй

Преимущества, которые получают наши клиенты в 2025 году:

- Повышение эффективности системы на 5%–8%, существенное снижение затрат на электроэнергию в рупиях Пакистана

- Уменьшение занимаемой площади на 30%–40%, освобождение ценного пространства на предприятии

- Время отклика ИБП <5 мс для защиты критических нагрузок

- Снижение рабочих температур на >10°C и снижение частоты отказов на >40%

Проблемы и болевые точки в промышленном ландшафте Пакистана

Нестабильность качества электроэнергии является самым большим операционным риском для тяжелой и непрерывной промышленности Пакистана. Нестабильность сети проявляется в виде просадок напряжения, всплесков, гармоник (3-й, 5-й, 7-й) и частых коммутационных событий. Плановое отключение нагрузки усугубляет провалы напряжения, а резервное питание от местных дизельных генераторов приводит к переходным скачкам и дрейфу частоты.

- Текстиль: Прядильные станки, чесальные и ткацкие линии требуют строго регулируемого электропитания для приводов двигателей. Даже кратковременные нарушения вызывают обрыв пряжи, остановку ткацких станков и брак. Системы увлажнения и воздушные компрессоры также страдают от неэффективных запусков в условиях низкого напряжения, что увеличивает затраты на электроэнергию.

- Цемент: Печи и подогреватели работают при высоких тепловых нагрузках; приводы сырьевых и финишных мельниц должны быть скоординированы. Внезапное падение мощности вызывает нарушения в работе печей, что приводит к проблемам с качеством клинкера, высокому удельному расходу тепла и возможному повреждению огнеупоров.

- Сталь: Индукционные печи, прокатные станы и вспомогательное оборудование ЭДП очень чувствительны к гармоникам и переходным процессам. Скачки могут вызвать срабатывание защиты, что приведет к дорогостоящим перебоям в производстве и повышенному износу электродов и огнеупоров.

- Центры обработки данных и больницы: Соглашения об уровне обслуживания (SLA) требуют почти нулевого прерывания работы. Стандартные кремниевые системы ИБП могут испытывать трудности при высоких температурах окружающей среды, запыленности и длительных высоких коэффициентах нагрузки.

Последствия для стоимости:

- Прямые потери энергии: Неэффективное выпрямление/инвертирование снижает коэффициент мощности и увеличивает потребление кВт⋅ч, что ежегодно добавляет миллионы рупий для предприятий среднего размера.

- Скрытое техническое обслуживание: Повышенные температуры переходов и термические циклы сокращают срок службы компонентов; более частая замена вентиляторов, конденсаторов и силовых модулей увеличивает операционные расходы.

- Потеря производства: Незапланированные простои обходятся текстильным линиям в тысячи рупий в минуту; цементная и сталелитейная промышленность испытывают экспоненциальные потери из-за перезапусков, брака и снижения качества.

- Риск несоблюдения нормативных требований: Несоответствие требованиям NEPRA к измерению и качеству электроэнергии или ограничениям гармоник в коде сети NTDC может привести к штрафам или проблемам с подключением для крупных потребителей.

Операционные проблемы, характерные для Пакистана:

- Окружающая среда: Высокие температуры окружающей среды (часто >40°C), влажность во время муссонов и пыль (цемент/уголь) ухудшают эффективность охлаждения и засоряют фильтры.

- Нестабильность цен на топливо и валюту: Колебания цен на дизельное топливо и обменных курсов рупии увеличивают совокупную стоимость владения (TCO) импортированных резервных систем; длительные сроки поставки напрягают графики проектов.

- Пробелы в обслуживании: Разрозненные послепродажные экосистемы и ограниченный местный опыт работы с SiC замедляют устранение неполадок и ограничивают настройку производительности.

- Стандартизация: Интеграция оборудования в местную автоматизацию распределения с использованием IEC 61850, Modbus RTU/TCP и устаревших систем может быть сложной; пробелы в документации препятствуют вводу в эксплуатацию.

Нормативно-правовая и рыночная среда:

- Качество электроэнергии и сети: Стандарты производительности NEPRA и Кодекс сети NTDC все больше подчеркивают необходимость контроля гармоник и регулирования напряжения для крупных потребителей.

- Энергоэффективность: Провинциальные энергетические департаменты и Национальное управление энергоэффективности и энергосбережения (NEECA) поощряют использование высокоэффективных приводов и ИБП, что соответствует корпоративной устойчивости и потенциальным налоговым льготам или признанию.

- Безопасность и окружающая среда: Ссылки на Пакистанский строительный кодекс, стандарты IEC (IEC 62040 для ИБП, IEC 62477 для силовых электронных преобразователей, IEC 60950/62368 для безопасности) и правила охраны труда формируют требования к закупкам и аудиту.

Мнения экспертов:

- “SiC devices reduce switching losses by up to 80% compared to silicon IGBTs at comparable voltages, enabling higher frequency operation and smaller magnetics—key for compact high-power UPS.” — Dr. Johann W. Kolar, Power Electronics Researcher, ETH Zurich (reference: power electronics literature overview: https://ieeexplore.ieee.org/)

- “For industrial parks facing unstable grids, fast ride-through and high-efficiency rectification are decisive for uptime and energy costs.” — IEA Energy Efficiency 2024 Insights (summary resource: https://www.iea.org/)

Короче говоря, промышленным секторам Пакистана нужна высокоэффективная, высоконадежная, пыле- и жаростойкая силовая электроника, которая быстро интегрируется, снижает счета за электроэнергию и выдерживает суровую реальность — именно в этом преуспевает передовой карбид кремния.

Портфель передовых решений из карбида кремния, адаптированный для Пакистана

Sicarb Tech предоставляет полный комплекс — от устройств до систем и обеспечения производства — разработанный с учетом условий Пакистана.

- Высоковольтные SiC MOSFET модули (1,2 кВ–1,7 кВ): Сверхнизкий RDS(on), быстрое переключение, оптимизированы для работы на частоте 50–100 кГц. Идеально подходят для выпрямителей, силовых каскадов инверторов и мощных VFD на мельницах и в печах.

- SiC диоды Шоттки: Нулевое обратное восстановление, высокая термостойкость для PFC и высокочастотного выпрямления; уменьшают нагрев и улучшают PF.

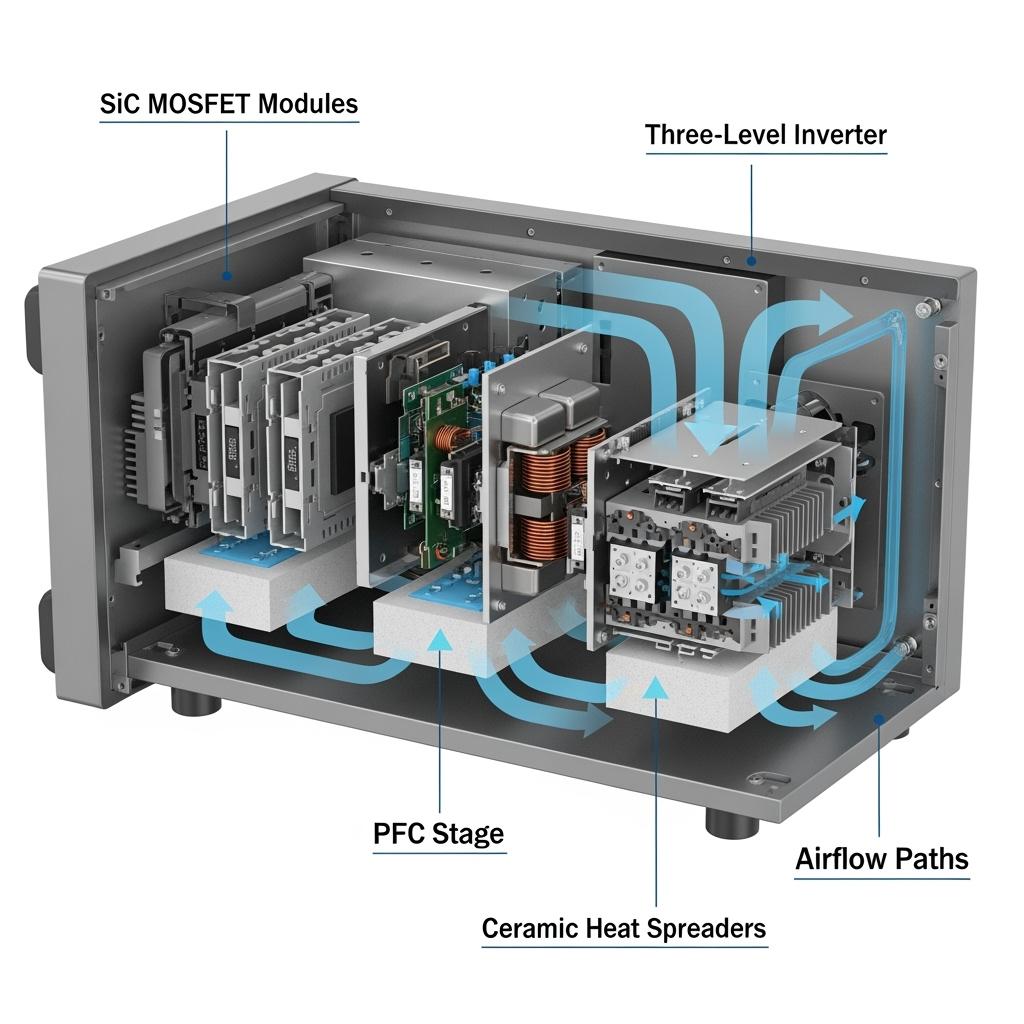

- Трехуровневые силовые каскады инвертора: Топологии с нейтральной точкой, зафиксированной устройствами SiC, для улучшения использования напряжения, снижения пульсаций и более тихой работы чувствительных двигателей и насосов.

- Интегрированные SiC ИБП выпрямительно-инверторные модули: Модульные блоки 50–400 кВА с эффективностью >98%; конструкция с возможностью горячей замены для быстрого обслуживания.

- Двунаправленные SiC преобразовательные модули: Управление энергией шины постоянного тока для гибридных ИБП с батареями/суперконденсаторами и интерфейсами генераторов; поддерживает совместное использование нагрузки и пиковое сглаживание.

- Высокочастотные SiC PFC блоки управления: Обеспечивают PF >0,99 и THDi <5% для обеспечения совместимости с целевыми показателями кода сети NTDC и межсоединением с коммунальными предприятиями.

- Высокотемпературные драйверы затворов: Усиленная изоляция, защита от насыщения и фиксация Миллера для надежной работы в запыленной, жаркой среде.

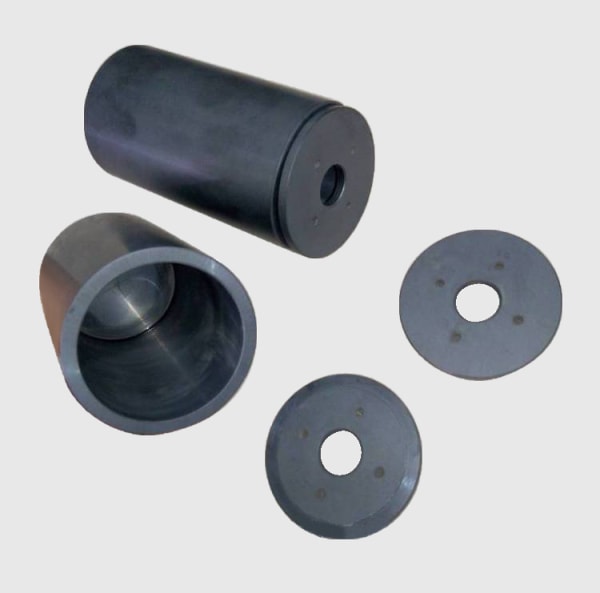

- SiC керамические теплораспределительные подложки (SSiC, RBSiC, SiSiC): Превосходная теплопроводность и коррозионная стойкость для длительного срока службы при воздействии цементной/стальной пыли.

- Модуль интеллектуального управления и диагностики ИБП: Встроенная аналитика, адаптивное регулирование нагрузки, удаленный мониторинг через IEC 61850/Modbus TCP, готовность к облачным операциям и техническому обслуживанию.

- Изолированные DC/DC SiC модули: Компактное вспомогательное питание для логики управления и драйверов затворов с высоким напряжением изоляции.

- Высокочастотные выпрямительные мостовые сборки: Предварительно спроектированные блоки для быстрой интеграции в устаревшие системы.

- Интегрированные кремниево-карбидные силовые системы ИБП: Комплексные шкафы с опциями воздушного или жидкостного охлаждения, конформное покрытие для защиты от пыли/влажности.

- Испытательное и приемочное оборудование: Проверка модулей на месте или в лаборатории партнера для ускорения FAT/SAT и уменьшения отказов в полевых условиях.

- Платформа упаковки и теплового моделирования: Цифровой двойник силовых модулей для надежности при проектировании и более быстрых пользовательских итераций.

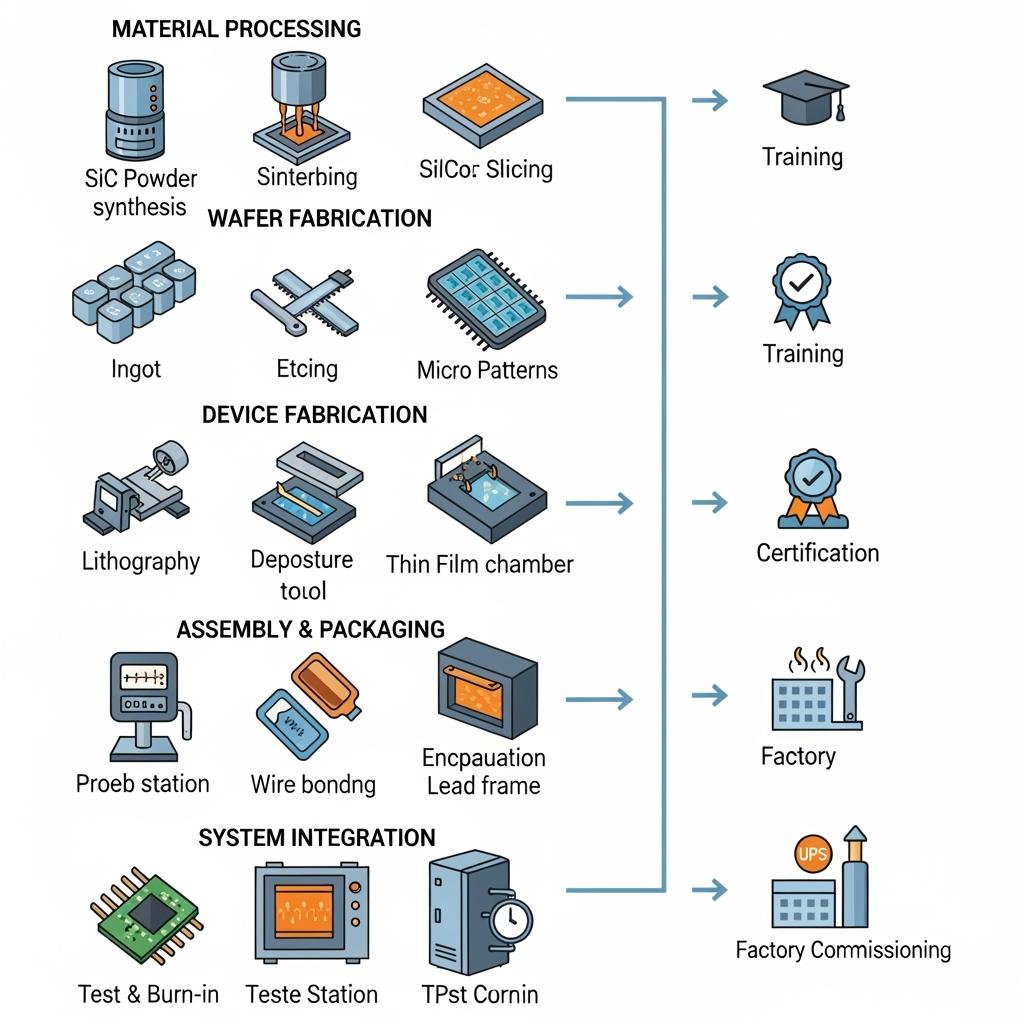

- Оборудование для выращивания кристаллов и эпитаксии: Для клиентов, стремящихся к местному производству в рамках передачи технологий.

Как это решает болевые точки:

- Эффективность и экономия энергии: Повышение эффективности системы на +5%–8% улучшает PUE для центров обработки данных и снижает PKR/кВт⋅ч для промышленности.

- Надежность в суровых условиях: Температура перехода до 175°C; керамические подложки устойчивы к истиранию и коррозии.

- Быстрый отклик: Время прохождения <5 мс защищает прядильные, печные контуры управления и критические ИТ-нагрузки.

- Компактность: Уменьшение объема на 30%–40% облегчает модернизацию в переполненных диспетчерских.

- Интеграция: Нативная поддержка IEC 61850, Modbus, SNMP; совместимость с местными схемами защиты и коммутационной аппаратурой.

Сравнение технических характеристик для промышленных стандартов Пакистана

Высокоэффективное преобразование энергии для суровых условий

| Параметр | Решение на основе карбида кремния | Традиционное решение на основе кремния | Практическое влияние на предприятия Пакистана |

|---|---|---|---|

| Эффективность системы (ИБП/VFD) | >98% | 90%–94% | Более низкая стоимость PKR/кВт⋅ч; меньше часов работы генератора в пик |

| Время отклика | <5 мс | 20–30 мс | Предотвращает остановку ткацких станков, нарушение работы печи и перезагрузку серверов |

| Рабочая частота | 50–100 кГц | 10-20 кГц | Меньшие индуктивности; снижение шума, облегчение модернизации |

| Температура перехода | -55°C to 175°C | -40°C to 125°C | Выдерживает летние пики и потери охлаждения, вызванные пылью |

| Плотность мощности | >10 кВт/л | 4–6 кВт/л | На 30%–40% меньше шкафов |

| Потребность в охлаждении | Низкий | Высокий | Меньше засорений фильтров, меньшее техническое обслуживание |

| Ожидаемый срок службы | 15+ лет | Пилотное тестирование летом в пик сезона для проверки запасов по охлаждению. | Уменьшение замен и простоев |

| Гармонические характеристики (THDi) | <5% с PFC | 15%–25% типично | Соответствует целям коммунальных предприятий и снижает штрафы |

Влияние на стоимость жизненного цикла и надежность

| Фактор стоимости/надежности | Системы на основе SiC | Обычные системы | Результат |

|---|---|---|---|

| Стоимость электроэнергии за 10 лет | Ниже на 8%–15% | Базовый уровень | Экономия миллионов рупий для мельниц среднего размера |

| Запасные части и техническое обслуживание | Снижено на 30%–40% | Выше | Меньше замен вентиляторов/конденсаторов, меньше тепловой нагрузки |

| Незапланированное время простоя | <0,5% годовых отказов (проверено на практике) | 1%–2% типично | Более высокая доступность производства |

| Установка/модернизация | Модульная, компактная | Большая занимаемая площадь | Более быстрая сдача в эксплуатацию в существующих помещениях |

| Готовность к соблюдению требований | Совместимость с IEC 62040, 62477, 61850 | Варьируется | Более плавные аудиты и межсоединения |

Реальные приложения и истории успеха

- Модернизация ИБП в промышленном парке Лахора: Развертывание ИБП SiC средней и высокой мощности обеспечило эффективность 98,2%, время отклика <4 мс и годовую частоту отказов <0,5%. Обеспечило стабильное электропитание для предприятий пищевой, текстильной и электронной промышленности и получило признание сертификации демонстрации энергосбережения.

- Модернизация VFD в текстильной промышленности в Фейсалабаде: Замена устаревших выпрямителей на модули SiC PFC + инвертор снизила температуру шкафа привода на 12°C и снизила потребление энергии в сети на 6,5%, уменьшив обрыв пряжи на 8% благодаря лучшей стабильности напряжения.

- Кондиционирование электроэнергии на цементной мельнице в Пенджабе: Трехуровневые инверторные каскады SiC улучшили коэффициент мощности до 0,99 и THDi до <5%, снизив штрафы коммунальных предприятий и стабилизировав крутящий момент мельницы, уменьшив износ шлифовальной среды на 7%.

- Сталепрокатный стан в Карачи: Двунаправленная шина постоянного тока SiC стабилизировалась при переходах генератора; незапланированные отключения сократились на 45%, а производительность увеличилась на 3% в часы пик.

Технические преимущества и преимущества внедрения с соблюдением местных требований

- Совместимость с сетью: Соответствует IEC 62040-3 для производительности ИБП, IEC 62477-1 для безопасности силовых электронных преобразователей и поддерживает IEC 61850/Modbus TCP для интеграции SCADA, используемой пакистанскими коммунальными предприятиями и промышленной автоматизацией.

- Гармоники и PF: Обеспечивают THDi <5% и PF >0,99, поддерживая целевые показатели гармоник кода сети NTDC и минимизируя плату за коммунальные услуги.

- Экологическая устойчивость: Конформное покрытие, опции IP54/IP55, пылезащитные фильтры; кривые теплового снижения мощности настроены для пиков окружающей среды 45–50°C.

- Тепловые характеристики: Подложки SSiC и RBSiC эффективно рассеивают тепло; встроенный активный тепловой контроль увеличивает среднее время наработки на отказ.

- Интеллектуальное техническое обслуживание: Прогностическая диагностика с обнаружением аномалий; удаленные обновления прошивки по безопасным протоколам; информационные панели, адапти

Авторитетный взгляд:

- “Ruggedized SiC modules with high-temperature gate drivers are central to reliable medium-voltage converters in harsh industrial environments.” — IEEE Power Electronics Magazine, 2024 Review (https://ieeexplore.ieee.org/)

- “Higher switching frequency reduces magnetic size and loss—critical for compact retrofits without new rooms.” — Prof. Frede Blaabjerg, Aalborg University (academic pages: https://vbn.aau.dk/)

Услуги по индивидуальному производству и передаче технологий

Отличительной чертой Sicarb Tech является наша возможность работы под ключ — от материаловедения до ввода в эксплуатацию завода — при поддержке нашего партнерства с Китайской академией наук в Вэйфане, китайском центре SiC. Мы поддерживаем пакистанские предприятия, стремящиеся к высокой производительности и локализации.

Что мы предлагаем:

- Передовые исследования и разработки и материалы: запатентованные процессы для R-SiC, SSiC, RBSiC, SiSiC для подложек, теплоотводов и конструкционной керамики; оптимизированная микроструктура для теплопроводности и коррозионной стойкости в цементной/стальной пыли.

- Разработка устройств и модулей: индивидуальные компоновки модулей MOSFET/диодов с низкой паразитной индуктивностью; высокотемпературные драйверы затворов с усиленной изоляцией; упаковка, разработанная с помощью мультифизического теплового и механического моделирования.

- Комплексные пакеты передачи технологий: рецепты процессов, спецификации оборудования, перечни инструментов, стандартные операционные процедуры, параметры программного обеспечения управления и планы качества, адаптированные к практике IEC и местной оценки соответствия.

- Услуги по созданию заводов: технико-экономическое обоснование, спецификации коммунальных услуг и систем отопления, вентиляции и кондиционирования воздуха для пакистанского климата, балансировка линий, соответствие требованиям EHS в соответствии с Руководством по охране труда и технике безопасности Пакистана, ввод в эксплуатацию и обучение операторов.

- Поддержка сертификации: руководство по соблюдению требований IEC 62040, 62477, 62368 и инспекций местных органов власти; пакеты документации для тендеров и аудита.

- Экосистемы тестирования и приработки: настройка стоек приработки, испытания HTOL и испытательные стенды для циклической нагрузки; базовые показатели надежности на основе данных для торгов и гарантий.

- Постоянная техническая поддержка: круглосуточный ответ, удаленная диагностика, выезды на место, периодическая оптимизация и дорожные карты модернизации.

Доказанные результаты:

- Поддержка 19+ предприятий с измеримой рентабельностью инвестиций — типичная окупаемость 12–24 месяца за счет экономии энергии и сокращения времени простоя.

- Быстрое прототипирование: 6–10 недель для итераций пользовательских модулей; стратегия локализованных запасных частей для смягчения задержек импорта и волатильности PKR.

- Мастерство интеграции: мы взаимодействуем с существующим коммутационным оборудованием ABB/Siemens/Schneider и панелями пакистанского производства; документация на английском языке с дополнительными краткими руководствами на урду для технических специалистов.

Contact our engineering team: [email protected] | +86 133 6536 0038

Будущие возможности рынка и тенденции 2025+

- Кривая внедрения SiC: быстрая замена кремниевых ИБП и выпрямителей по мере снижения стоимости устройств и накопления экономии PKR; наибольший рост в промышленном треугольнике Карачи-Лахор-Фейсалабад.

- Микросети постоянного тока и гибридные ИБП: двунаправленные преобразователи SiC, обеспечивающие интеграцию аккумуляторов, суперконденсаторов и фотоэлектрических преобразователей для снижения зависимости от дизельного топлива и снижения пиковых тарифов.

- Высокотемпературные, пылезащищенные конструкции: корпуса IP54+, конформные покрытия и усовершенствованные фильтры становятся стандартом в цементной и сталелитейной промышленности.

- Обеспечение местного производства: передача технологий и местные сборочные линии сокращают сроки выполнения заказов, способствуют созданию квалифицированных рабочих мест и снижают валютные риски.

- Создание центров обработки данных: объекты уровня III/IV для финансов, телекоммуникаций и облачных вычислений требуют ИБП с эффективностью 98%+ с удаленным O&M и усилением кибербезопасности.

- Политика и соответствие: усиленные требования к качеству электроэнергии и энергетические аудиты стимулируют модернизацию в направлении систем с низким THDi и высоким PF.

Часто задаваемые вопросы

- Вопрос: Может ли SiC ИБП интегрироваться с нашим существующим коммутационным оборудованием и генераторными установками?

Ответ: Да. Наши модули поддерживают стандартные защиты и интерфейсы, включая логику ATS/AMF. Мы интегрировались с распространенными местными и импортными марками коммутационного оборудования. Доступна связь через Modbus TCP/RTU, IEC 61850 и SNMP. - Вопрос: Как вы решаете проблему пыли и тепла на цементных и сталелитейных заводах?

Ответ: Варианты корпуса IP54/IP55, охлаждение положительным давлением, конформное покрытие и кривые снижения номинальной мощности для окружающей среды 50°C. Более высокая допустимая температура перехода SiC поддерживает запас прочности в условиях засорения фильтра. - Вопрос: Каким стандартам соответствуют ваши системы?

Ответ: IEC 62040 (производительность и безопасность ИБП), IEC 62477 (безопасность силовых электронных преобразователей), IEC 62368 (безопасность ИКТ) и директивы EMC в соответствии с CISPR 11/22. Мы оказываем помощь в проведении местных инспекций и обеспечении соответствия требованиям подключения к коммунальным сетям. - Вопрос: Какова типичная окупаемость в Пакистане?

Ответ: Для ИБП мощностью 200–500 кВА в текстильной/цементной промышленности окупаемость часто составляет 12–24 месяца за счет экономии энергии (+5%–8% эффективности), снижения затрат на техническое обслуживание и сокращения времени простоя. Мы моделируем в PKR с учетом чувствительности к тарифным ставкам. - Вопрос: Предоставляете ли вы передачу технологий для местного производства?

Ответ: Да. Мы предлагаем полное ноу-хау процесса, перечни оборудования, обучение и системы контроля качества. Мы можем помочь в создании линий для модулей, подложек и сборки с поэтапной локализацией. - Вопрос: Как быстро осуществляется доставка и ввод в эксплуатацию?

Ответ: Стандартные модули: 6–8 недель. Пользовательские системы: 10–16 недель. Ввод в эксплуатацию на месте включает настройку гармоник/PF и интеграцию SCADA. - Вопрос: Существуют ли стимулы для модернизации с высокой эффективностью?

Ответ: Наличие программ варьируется; мы согласовываем проекты с инициативами NEECA по повышению эффективности и коммунальными программами, где это применимо, и предоставляем документацию для экологической сертификации. - Вопрос: Какие химические составы аккумуляторов поддерживаются?

Ответ: VRLA, Li-ion (LFP/NMC) и гибридные суперконденсаторы. Двунаправленные преобразователи SiC оптимизируют профили заряда/разряда и продлевают срок службы батареи. - Вопрос: Можете ли вы предоставить рекомендации в Пакистане?

Ответ: Да. Мы можем организовать посещения объектов и предоставить анонимные отчеты о производительности из региональных развертываний по запросу.

Правильный выбор для ваших операций

Для текстильной, цементной, сталелитейной и расширяющихся секторов Пакистана, ориентированных на данные, карбид кремния обеспечивает превосходную эффективность, надежность и устойчивость. Комплексный подход Sicarb Tech — от материалов и устройств до систем под ключ и передачи технологий — снижает риски, ускоряет развертывание и обеспечивает соответствие местным стандартам. Если ваши цели включают снижение затрат на электроэнергию в PKR, повышение времени безотказной работы и подготовку к гибридному энергетическому будущему, решения на основе SiC являются прагматичным, перспективным выбором.

Получите консультацию эксперта и индивидуальные решения

Обсудите свое применение с нашими инженерами:

- Электронная почта: [email protected]

- Телефон/WhatsApp: +86 133 6536 0038

Что вы получите:

- Оценка нагрузки и качества электроэнергии без обязательств

- Модель TCO в PKR и анализ окупаемости

- Предложение пользовательской архитектуры (ИБП/VFD/PFC) с учетом ограничений вашей площадки

- Контрольный список соответствия требованиям IEC и местным требованиям

- Дополнительная дорожная карта для местной сборки или полной передачи технологий

Метаданные статьи

- Последнее обновление: 2025-09-12

- Следующее запланированное обновление: 15.12.2025

- Автор: Sicarb Tech Applications Engineering

- Компания: Sicarb Tech — эксперт по решениям на основе карбида кремния, Вэйфан, Китай (член Китайской академии наук, инновационный парк Вэйфан)

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.