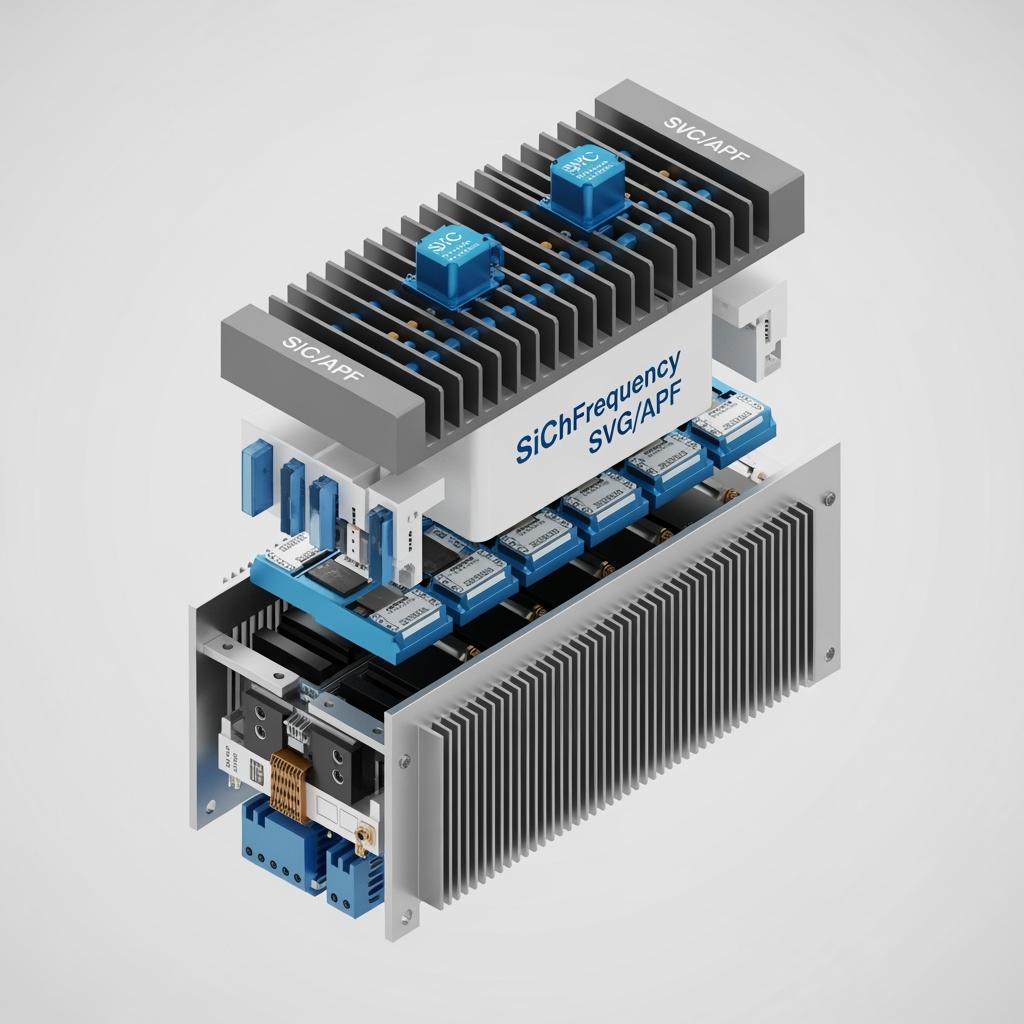

Высокочастотные силовые модули из карбида кремния для SVG/APF и приводов среднего напряжения

Поделиться

Качество электроэнергии и эффективность для промышленного роста Пакистана в 2025 году

Текстильная, цементная и сталелитейного промышленность Пакистана — наряду с быстро расширяющимися ветровыми и солнечными активами — требует надежного, компактного и эффективного преобразования электроэнергии. Высокочастотные силовые модули из карбида кремния (SiC) обеспечивают эффективность преобразования >98% и динамическое время отклика менее 10 мс для статических генераторов переменного тока (SVG/STATCOM), активных фильтров мощности (APF) и приводов среднего напряжения (MV). Эти возможности помогают предприятиям соответствовать критериям межсоединения NTDC/NEPRA, соответствовать гармоническим руководствам IEEE 519 и IEC 61000-3-6 и поддерживать производительность при высоких температурах окружающей среды, распространенных в Синдхе и Южном Пенджабе.

Компания Sicarb Tech, расположенная в городе Вэйфан (китайский центр SiC) и поддерживаемая Китайской академией наук, предоставляет силовые модули SiC, разработанные по индивидуальному заказу, и передачу технологий под ключ. Обладая более чем 10-летним опытом производства SiC и более чем 19 успешными внедрениями, наши модули снижают потери, занимаемую площадь и затраты на техническое обслуживание, одновременно ускоряя соответствие требованиям и рентабельность инвестиций для пакистанских заводов и предприятий возобновляемой энергетики.

Технические характеристики и расширенные функции

- Классы номинального напряжения: устройства 1200 В и 1700 В; стеки модулей, адаптированные для выходных каскадов MV с использованием многоуровневых топологий

- Частота переключения: 50–100 кГц для SVG/APF и высокопроизводительных каскадов инвертора

- Эффективность системы: >98% при номинальной нагрузке; эффективность при частичной нагрузке оптимизирована за счет адаптивной модуляции

- Время отклика: <10 мс реактивный ступенчатый отклик для динамической компенсации и снижения мерцания

- Тепловые характеристики: температура перехода от -55°C до 175°C; подтверждена надежность при тепловом и силовом циклировании

- Плотность мощности: >8 кВт/л за счет усовершенствованной упаковки и конструкции шинопровода с низкой индуктивностью

- Встроенное зондирование: датчики тока Холла/Роговского, прецизионная обратная связь по напряжению для управления с обратной связью

- Управление затвором: высокая устойчивость к dv/dt, зажим Миллера, защита DESAT и изолированное питание для высокочастотной работы

- ЭМС/ЭМИ: оптимированная компоновка, экранирование и RC-снабберы для соответствия промышленным стандартам ЭМС

- Экологическая устойчивость: конформное покрытие, варианты интеграции в шкаф IP55–IP65; снижение воздействия пыли и влажности для цементной/сталелитейной промышленности

Применимые стандарты и интеграция

- Гармоники и качество электроэнергии: IEEE 519, IEC 61000-3-6

- Безопасность преобразователей силовой электроники: IEC 62477-1

- Подключение к сети PV/ветряных электростанций: IEC 62109 (применительно), местные сетевые коды NTDC/NEPRA

- Связь: IEC 61850, Modbus TCP, DNP3 для интеграции SCADA/DCS

Соображения производительности и проектирования для промышленного Пакистана

- Устойчивость к жаре и пыли для площадок в Карачи, Фейсалабаде и Хайбер-Пахтунхва

- Стабилизация слабой сети на узлах ветряных и фотоэлектрических установок в Синдхе и Белуджистане

- Совместимость с существующими парками VFD и системами ИБП на текстильных фабриках и технологических предприятиях

- Уменьшение инфраструктуры охлаждения — снижение эксплуатационных расходов и уменьшение размеров электрощитовых

Описательное сравнение: модули SiC против традиционного кремния для SVG/APF и приводов

| Область производительности | Высокочастотные модули SiC (это решение) | Обычные кремниевые модули (на основе IGBT) | Операционное воздействие в Пакистане |

|---|---|---|---|

| Динамический отклик (SVG/APF) | <10 мс | 25–40 мс | Лучший контроль мерцания для запуска EAF и броска тока двигателя |

| Эффективность при номинальной нагрузке | >98% | 92-95% | Экономия энергии 5–7%; снижение штрафов |

| Частота переключения | 50–100 кГц | 10-20 кГц | Меньшие размеры магнитных компонентов и шкафов; более тихая работа |

| Тепловой запас | Tj до 175°C | Tj до 125°C | Меньшее снижение номинальных характеристик при температуре окружающей среды >45°C |

| Плотность мощности | >8 кВт/л | 3–5 кВт/л | Настройте дроссели CM и конденсаторы X/Y для соответствия IEC 61000-6-4, избегая при этом проблем с утечкой. |

| Диагностика и жизненный цикл: | Включите регистрацию данных PF, THD, пульсаций шины, частоты вращения вентилятора и отклонений температуры. | Выше | Используйте прогнозные оповещения о нагреве дросселя и повышении ESR конденсатора. |

| Раннее исследование гармоник и оценка нагрузки на трансформатор. | Совместное проектирование магнитоэлектрики для высокочастотной работы. | Пилотное тестирование летом в пик сезона для проверки запасов по охлаждению. | Обучение работе с инструментами ввода в эксплуатацию и обновлениям прошивки. |

Ключевые преимущества и доказанные выгоды

- Отзыв (руководитель отдела объектов, крупный банковский центр обработки данных в Карачи):

- «Переход на модули SiC PFC обеспечил соответствие PF и THD требованиям сети со значительным снижением потребности в охлаждении помещения. Ввод в эксплуатацию прошел быстро благодаря встроенной аналитике».

- Более широкое внедрение двунаправленной PFC для гибридов ИБП/BESS (поддержка сети и пиковое сглаживание).

- Адаптивное формирование тока с помощью ИИ в условиях искаженной сети.

- Совместно упакованные контроллер и драйверы затвора для дальнейшей устойчивости к ЭМП.

Экспертный взгляд:

Улучшение затрат за счет масштабирования пластин SiC 200 мм и партнерства по местной сборке.

Реальные приложения и измеримый успех

- «Выпрямители с широкой запрещенной зоной меняют качество электроэнергии на объектах, делая оборудование с высокой плотностью и низким THD жизнеспособным даже в сложных сетях». — IEA Technology Perspectives 2024, раздел Power Electronics.

- Может ли SiC PFC соответствовать PF ≥0,99 и THD ≤3% в искаженной сети Пакистана?

- Да. Благодаря компенсации гармоник и надежному управлению током наши модули поддерживают целевые показатели в широком диапазоне искажений

- Цементный завод (КП): Высокочастотные модули SiC, приводящие в действие вентиляторы рукавных фильтров и вспомогательное оборудование печей, обеспечили более низкий THD и продлили срок службы подшипников и изоляции благодаря более плавным профилям крутящего момента.

Вопросы выбора и обслуживания

- Класс напряжения и топология: Выберите устройства 1200/1700 В и соответствующую многоуровневую топологию (NPC, ANPC, MMC) для совместимости с MV и уменьшения размера фильтра

- Тепловой путь: Проверьте наличие холодной пластины или жидкостного охлаждения, качество хладагента и поток; убедитесь в правильном выборе TIM

- Планирование ЭМС: компоновка шкафа, заземление и экранирование кабелей для соответствия требованиям ЭМС предприятия

- Герметизация окружающей среды: Выберите степень защиты IP и стратегию покрытия для защиты от пыли, влажности и агрессивных сред

- Поддержка жизненного цикла: Планируйте запасные части, обновления прошивки и удаленную диагностику; согласуйте с окнами отключения предприятия

Факторы успеха в отрасли и отзывы клиентов

- Соответствие коду сети Пакистана и требованиям промышленных зон

- Локализованная документация, обучение и круглосуточная поддержка

- Поэтапные стратегии модернизации, минимизирующие сбои производства

Голос клиента (композитный):

«Стабильность нашего ткацкого цеха улучшилась сразу после модернизации SiC SVG/APF — меньше отключений и заметное снижение затрат на электроэнергию и охлаждение». — Операционный менеджер, текстильная фабрика, Пенджаб

Будущие инновации и рыночные тенденции (2025+)

- SiC MOSFET и каскоды среднего напряжения обеспечивают более высокие стеки напряжения с меньшим количеством последовательных устройств

- Более широкое внедрение модульных многоуровневых преобразователей (MMC) для SVG/STATCOM в масштабе коммунальных предприятий в центрах возобновляемой энергетики

- Прогнозирующее техническое обслуживание с использованием искусственного интеллекта, использующее высокочастотные потоки данных для раннего обнаружения неисправностей

- Локальная сборка и передача технологий в Пакистане для сокращения сроков поставки и воздействия валютных рисков

Часто задаваемые вопросы и ответы экспертов

- Соответствуют ли эти модули требованиям пакистанской сети?

Да, конструкции соответствуют правилам межсоединения NTDC/NEPRA и IEEE 519/IEC 61000-3-6. Интеграция поддерживает IEC 61850 для коммунальных SCADA, где это требуется. - Каков типичный срок окупаемости?

На предприятиях с высокой нагрузкой — 18–30 месяцев за счет экономии энергии, снижения штрафов и снижения потребностей в ОВКВ. - Можем ли мы интегрироваться с существующими VFD/ИБП и SCADA?

Да. Наши модули взаимодействуют через Modbus TCP, IEC 61850 и DNP3 и могут модернизировать интерфейсы существующих систем. - Как модули справляются с высокими температурами окружающей среды и пылью?

Возможность работы при высокой температуре перехода, надежная тепловая конструкция, корпуса со степенью защиты IP и конформное покрытие обеспечивают надежную работу при температуре >45°C и в запыленных условиях. - Какая поддержка предоставляется для ввода в эксплуатацию?

Ввод в эксплуатацию на месте/удаленно, обучение и проверка производительности, а также текущая диагностика и обновления прошивки.

Почему это решение работает для ваших операций

Высокочастотные модули SiC сочетают в себе эффективность, скорость и надежность для решения наиболее актуальных проблем Пакистана, связанных с качеством электроэнергии и надежностью. От соответствия гармоническим ограничениям до поддержания бесперебойной работы в суровых условиях — технология предлагает немедленные операционные преимущества и путь к долгосрочному снижению затрат и соответствию требованиям.

Свяжитесь со специалистами для получения индивидуальных решений

Сотрудничайте с Sicarb Tech для проектирования, развертывания или даже производства решений SiC, адаптированных к вашему предприятию:

- Более 10 лет опыта производства SiC в центре SiC в Вэйфане

- Поддержка Китайской академии наук для передовых исследований и разработок

- Индивидуальная разработка для материалов R-SiC, SSiC, RBSiC, SiSiC и силовых модулей

- Передача технологий и создание заводов — от технико-экономического обоснования до ввода в эксплуатацию

- Готовые решения от порошков и подложек до готовых систем SVG/APF

- Подтвержденные результаты с 19+ предприятиями, обеспечивающими измеримую рентабельность инвестиций

Свяжитесь с нами сейчас для получения бесплатной консультации, обзора соответствия требованиям сети и модели рентабельности инвестиций, адаптированной к вашему объекту.

Email: [email protected] | Phone/WhatsApp: +86 133 6536 0038

Метаданные статьи

- Последнее обновление: 11.09.2025

- Следующее запланированное обновление: 15.12.2025

- Подготовлено: Команда инженеров по применению Sicarb Tech

- Ссылки: IEEE 519; IEC 61000-3-6; IEC 61850; IEC 62477-1; Руководство по межсоединениям NTDC/NEPRA; отраслевые анализы IEEE PELS и IRENA по внедрению SiC

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.