Optimizing B2B Supply Chains with Custom Silicon Carbide Solutions

Поделиться

Executive Summary: How Silicon Carbide Stabilizes Brazil’s Industrial Supply Chains in 2025

Brazil’s industrial buyers are steering through a year defined by reliability, energy intensity, and compliance. Mining producers in Minas Gerais and Pará, offshore oil and gas operators in pre-salt basins, and agricultural processors from Mato Grosso to Paraná are pushing for higher throughput while meeting ABNT NBR standards, ANP procurement rules, IBAMA environmental licensing, and NR safety norms. Moreover, currency volatility and global logistics uncertainty are forcing procurement to prioritize lifecycle value, local capability, and audit-ready documentation. In this context, custom silicon carbide (SiC) components—engineered in R-SiC, SSiC, RBSiC, and SiSiC—deliver predictable performance under erosion, corrosion, and thermal shock, which in turn stabilizes maintenance plans, reduces emergency shipments, and shortens qualification cycles.

Sicarbtech, headquartered in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings more than a decade of silicon carbide customization and supports 19+ enterprises with full-cycle solutions from material processing to finished products. By uniting materials R&D, precision finishing, application engineering, and turnkey technology transfer—including factory establishment—Sicarbtech helps Brazilian B2B supply chains replace reactive maintenance with predictable performance, reducing working capital tied in spares and improving service levels even in remote operations.

Industry Challenges and Pain Points: Where Supply Chains Break—and How Materials Can Fix Them

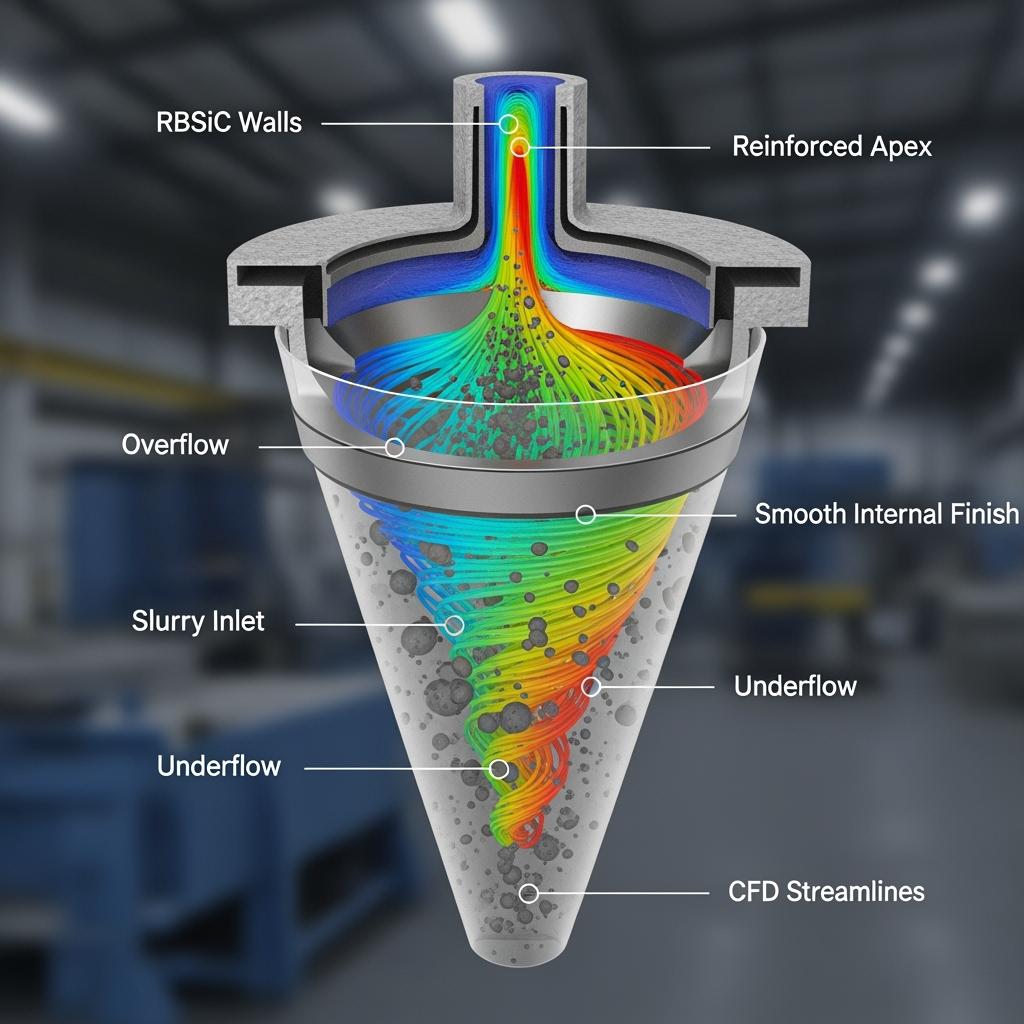

The anatomy of supply chain risk in Brazil is often rooted in material behavior under real duty cycles. In mining, hydrocyclone cones, venturi nozzles, pump volutes, and elbows face abrasive slurries with fluctuating particle size distributions and pH, especially during the rainy season. Each surge in erosion roughens surfaces and widens clearances, pushing up energy consumption and destabilizing cut sizes, which then disrupts downstream flotation and filtration. When liners or cones fail early, the direct parts cost is minor compared to the collateral damage: emergency stoppages, expedited freight to remote sites, and swollen safety stocks that immobilize capital. These events propagate through B2B networks as delayed deliveries, missed contracts, and renegotiated SLAs.

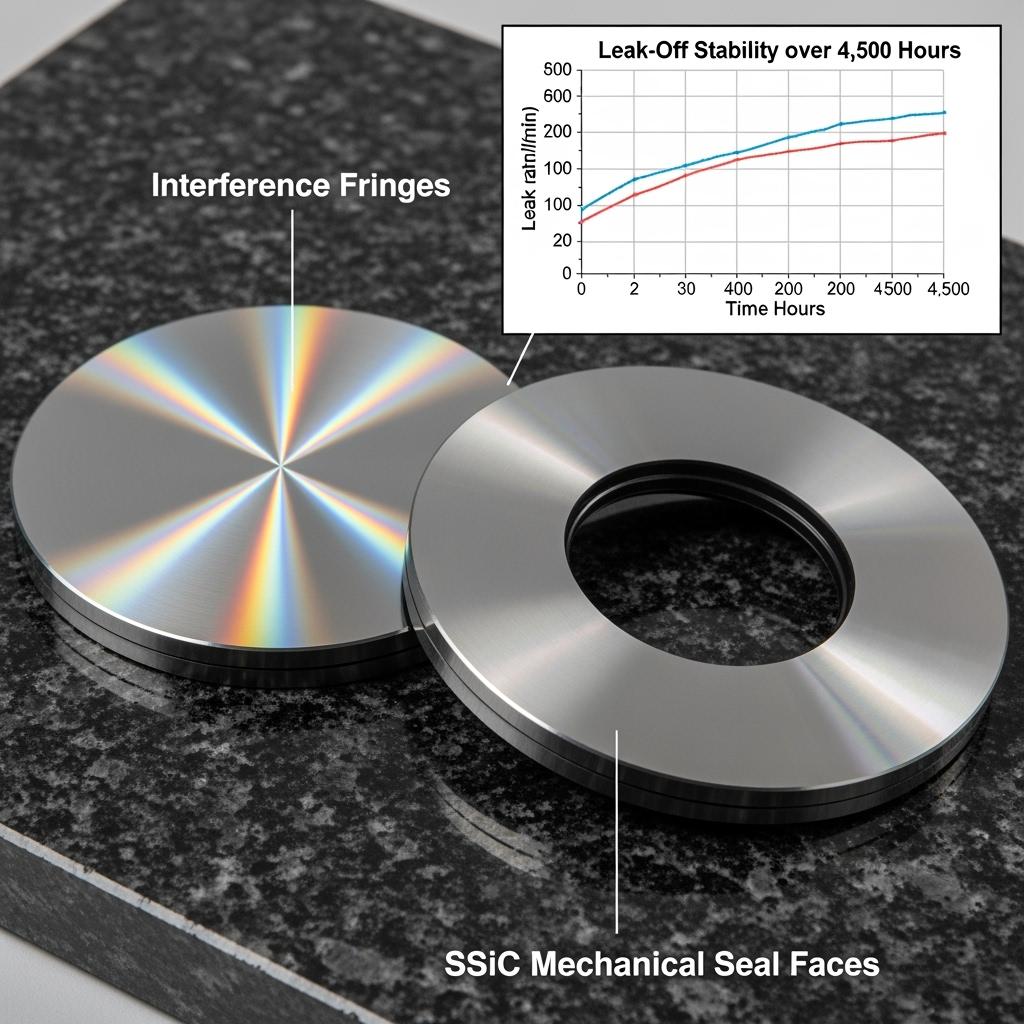

Offshore and upstream oil and gas add chloride corrosion and thermal cycling to the mix. Mechanical seal faces, bearings, choke trims, and valve seats must withstand simultaneous corrosion-erosion regimes and transient heat loads. ANP procurement frameworks and operator standards that reference API 610/682 and NACE MR0175/ISO 15156 demand robust documentation, traceability, and repeatability. A single seal failure can trigger vessel day rates, production deferrals, and environmental liabilities—costs that blow up supply plans and dent vendor ratings. Procurement leaders now evaluate material choices by their impact on uptime and audit speed, not just unit price.

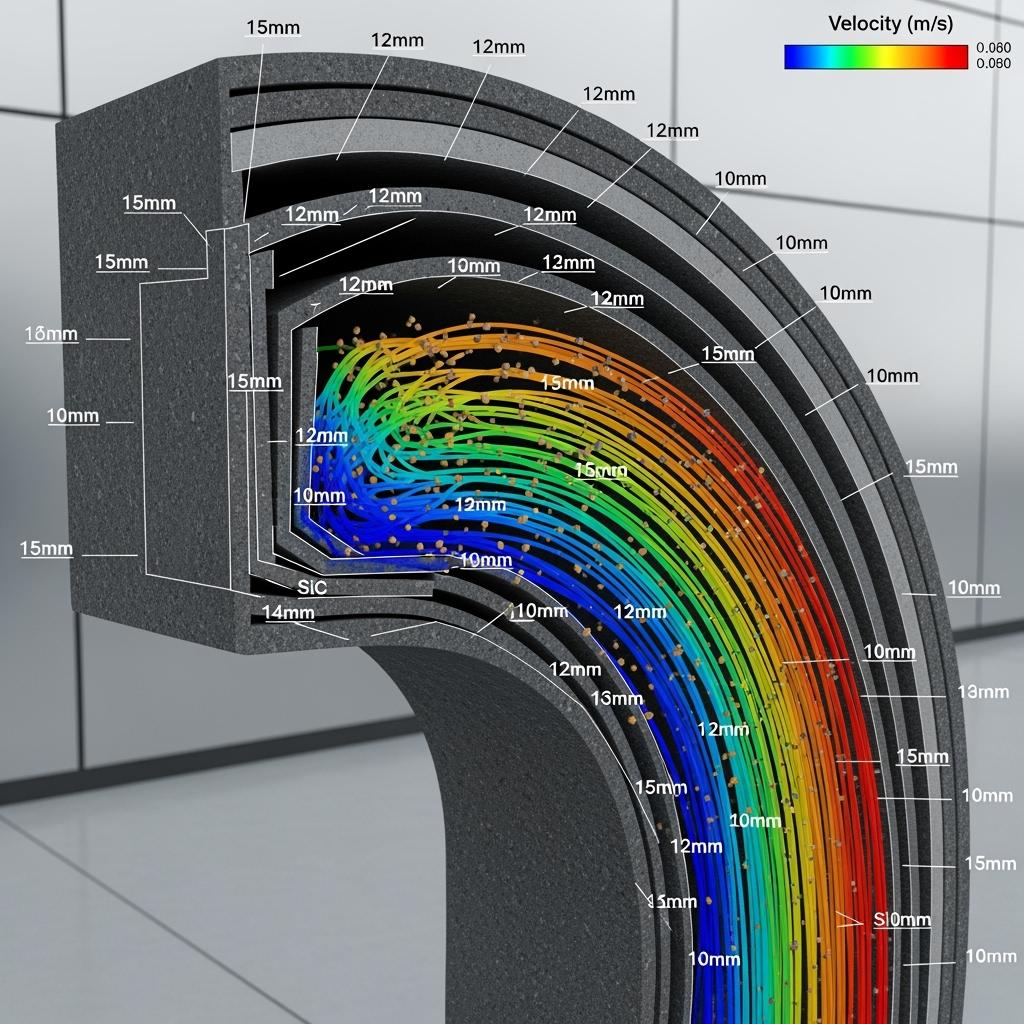

Agribusiness processing shifts the stress points but not the stakes. Fertilizer handling is both abrasive and chemically aggressive, while sugarcane processing adds fibrous particulates and CIP cycles that swing temperature and pH. Harvest windows compress risk; an unplanned stoppage can cascade into missed port slots at Santos or Paranaguá, with penalties often denominated in USD. IBAMA oversight further narrows flexibility, and the cost of improvisation rises with every compliance audit. In supply chain terms, the “bullwhip effect” shows up as oversized safety stocks, overbooked maintenance contractors, and higher demurrage.

Hidden losses magnify visible ones. Rougher surfaces and larger clearances impose energy penalties, nudging kWh per m³ pumped upward. Maintenance teams pivot to firefighting, deferring improvements that would cut inventory and lead time. FX volatility makes emergency imports unpredictable; a weak real can turn a manageable delay into a margin hit. “We realized the cheapest part in the catalog was the most expensive element in our supply plan,” says Eng. Luana Ribeiro, a reliability leader at a Pará processing complex. “Materials that hold their shape keep our MRO spend and our delivery dates in line.” (Source: Brazilian Industrial Reliability Journal, 2024)

Lastly, the qualification gap is a structural bottleneck. Generic ceramics that shine on lab coupons can fail in Brazil’s real chemistries and particle morphologies. Without microstructural tuning—grain size, reaction bonding phases, sintering profiles—and geometry optimization validated by CFD and wear modeling, field performance lags expectations. Brazilian buyers increasingly expect ABNT-referenced tests, ANP-aligned traceability, and on-plant validation. Solving this is as much about documentation discipline as it is about material science—and both determine whether supply chains stabilize or fray.

Advanced Silicon Carbide Solutions Portfolio for Supply Chain Resilience

Sicarbtech’s portfolio is designed to translate material advantages into supply chain gains. Sintered silicon carbide (SSiC) provides near-zero porosity and outstanding corrosion resistance with the ability to achieve ultra-flat lapped finishes, making it the preferred choice for mechanical seal faces, bearings, and throttling components where leak-off stability can remove a major root cause of unplanned downtime. Reaction-bonded SiC (RBSiC/SiSiC) combines high strength and thermal shock resistance with near net-shape capabilities, ideal for hydrocyclones, venturi nozzles, and wear liners subjected to erosive slurries and thermal transients. Recrystallized SiC (R-SiC) offers low density and high-temperature stability, enabling kiln furniture, burner blocks, and porous structures that reduce cycle times and thermal crack risk.

Engineering is application-led. Hydrocyclone cones are reprofiled to dampen vortex instabilities; apex and inlet geometries are reinforced to equalize wear without altering the mounting envelope. Seal faces are micro-lapped to optical flatness and paired with counterface materials to stabilize leak-off under API 682 regimes, reducing energy draw and maintenance interventions. SiC wear tiles for fertilizer elbows are designed with thickness gradients and overlap patterns to normalize wear, converting chaotic changeouts into planned work orders. Each solution ships with ABNT-referenced test methods, traceability, and inspection records formatted for ANP and internal audits—accelerating qualification and smoothing replenishment.

Performance Comparison: Silicon Carbide vs Traditional Materials for Brazilian Duty Cycles

Engineering Properties That Reduce Lead Time Risk and MRO Variability

| Property / Condition | SSiC (спеченный SiC) | RBSiC / SiSiC | R-SiC | Alumina (92–99%) | Tungsten Carbide (WC-Co) | Duplex Stainless Сталь |

|---|---|---|---|---|---|---|

| Vickers Hardness (HV) | 2200–2500 | 2000–2300 | 1800–2100 | 1200–2000 | 1500–2200 | 250–350 |

| Предел прочности при изгибе (МПа) | 350–500 | 250–350 | 120–180 | 250–400 | 900–1500 | 600–800 |

| Fracture Toughness (MPa·m^0.5) | 3–5 | 3–4 | 2–3 | 3–4 | 10–15 | 80–100 (metallic) |

| Теплопроводность (Вт/м-К) | 80–120 | 60–90 | 40–60 | 20–35 | 70–100 | 15–25 |

| Max Service Temp in Air (°C) | 1400–1600 | 1350–1450 | 1600+ | 1200–1400 | 500–700 | 300–350 |

| Chloride Corrosion Resistance | Превосходно | Очень хорошо | Хорошо | Fair to good | Good, binder dependent | Fair to good (pitting risk) |

| Erosion/Abrasion Resistance | Превосходно | Превосходно | Очень хорошо | Хорошо | Очень хорошо | Умеренный |

| Плотность (г/см³) | 3.10–3.20 | 3.00–3.10 | 2.60–2.75 | 3.70–3.95 | 14.5–15.0 | 7.8–8.0 |

| Supply Chain Impact | Lowest leak-off variability | Longest cyclone life | Fastest thermal cycles | Lower cost but brittle | Heavy, binder risk | Tough, corrosion risk |

These properties map directly to supply chain performance. Components that maintain geometry keep energy use stable, reduce emergency interventions, and shrink safety stocks. Conversely, materials prone to thermal shock or pitting inflate MRO variability, force ad-hoc logistics, and extend lead times.

Real-World Applications and Success Stories: Supply Chain Outcomes in Brazil

A Pará bauxite concentrator was replacing alumina hydrocyclone cones every six weeks. Sicarbtech delivered RBSiC cones with reprofiled inlets and reinforced apexes validated via CFD. Service intervals doubled to over twelve weeks and classification efficiency improved by roughly 3–4%. The site reduced emergency airfreight, downsized safety stock by nearly one-third, and negotiated improved freight terms thanks to predictable consumption.

A pre-salt operator sought to cut seal-related interventions on water injection pumps. Sicarbtech supplied SSiC faces lapped to optical flatness, with counterface pairing and installation guidance. Over 4,500 hours, leak-off stayed within API 682 expectations and pump energy draw fell by 1–2%. The ANP-aligned documentation accelerated vendor qualification for repeat orders, which in turn allowed the operator to standardize spares and contract local stocking.

In Mato Grosso, a fertilizer processor struggled with elbows that wore unpredictably during peak season. Sicarbtech designed SiC wear tiles with a thickness gradient and tile overlap matching the elbow’s velocity profile. Wear rates halved across a harvest cycle, enabling scheduled maintenance. The processor avoided port penalties and rebalanced inventory from emergency buys to strategic stocking.

“Supply chains bend when components lose their shape,” observes Prof. Rafael Cunha, who advises industrial networks on reliability economics. “SiC’s geometry stability translates into fewer surprises in MRO, which is exactly what planners need to tame lead times.” (Source: Journal of Industrial Supply Chains Brazil, 2024)

Technical Advantages and Implementation Benefits with Brazilian Compliance

SiC’s high thermal conductivity spreads heat rapidly, reducing thermal gradients that crack lesser ceramics during starts, stops, and CIP; its extreme hardness resists micro-cutting that roughens surfaces; and its chemical stability fends off chloride and acidic attack. When SSiC faces are lapped to ultra-low Ra and matched to proper counterfaces, friction and heat generation drop, stabilizing leak-off and power consumption. Over multi-month campaigns, these traits translate into slower efficiency decay in pumps and steadier hydrocyclone cut sizes—outcomes that improve OEE and energy intensity KPIs central to ESG-linked financing.

Sicarbtech couples technical performance with compliance-ready documentation. Components are engineered with reference to API 610/682 where relevant and sour service is evaluated under NACE MR0175/ISO 15156. Materials characterization uses ISO methods cross-referenced to ABNT NBR expectations, while traceability and test records are formatted for ANP procurement workflows. Environmental and safety documentation supports IBAMA licensing and NR norms. This rigorous documentation shortens audit and qualification cycles, improving release-to-operation timelines and reducing the administrative load on procurement and engineering.

Custom Manufacturing and Technology Transfer Services: Building Local, Scalable Capability

Supply chain resilience often hinges on local capability. Sicarbtech’s turnkey program enables Brazilian OEMs and operators to stand up export- and audit-ready SiC production without sacrificing performance. Engagement starts with feasibility studies covering demand forecasts, utilities, raw materials, and regulatory pathways. Complete technology transfer packages for R-SiC, SSiC, RBSiC, and SiSiC follow, including powder selection and conditioning, binder chemistries and granulation, forming methods such as cold isostatic pressing and injection molding, and furnace curves for sintering or reaction bonding tuned to target microstructures and porosity.

Finishing windows achieve stringent tolerances and surface finishes, including ≤0.02 µm Ra for seal faces, supported by calibrated metrology and SPC. Equipment specifications detail mixers, spray dryers, presses, isostatic units, furnaces, precision grinders, lapping stations, and inspection instrumentation, giving procurement a budgetable, ABNT- and ISO-aligned blueprint. Training programs cover operator skills, preventive maintenance, metrology, and statistical process control, while quality frameworks are implemented to ISO 9001 and can be extended to ISO 14001. Sicarbtech remains engaged through commissioning and ramp-up and provides continuous optimization grounded in Brazilian field data.

This end-to-end approach is amplified by Sicarbtech’s R&D linkage to the Chinese Academy of Sciences (Weifang) Innovation Park. Advanced microstructural characterization and process modeling enable tight control over porosity, grain size, and residual stress, improving reproducibility. Because Sicarbtech manages the full value chain from powder to finished component, field feedback loops are short. A wear anomaly in Carajás slurry service can trigger powder blend or furnace profile adjustments in the next production cycle, not the next fiscal year. Over a decade, Sicarbtech has supported more than 19 enterprises to achieve 1.8×–3.2× maintenance interval extensions, 1–3% energy savings in critical rotating assets, and accelerated qualification with Brazilian majors due to audit-ready traceability.

“Assembling machines is not enough,” emphasizes Dr. Patrícia Lemos, a ceramics scale-up consultant. “Transferring a living process—furnace profiles, binder systems, SPC guardrails, and failure analytics—cuts months off stabilization and secures yield.” (Source: Industrial Ceramics Implementation Review, 2024)

Application Mapping for Brazilian Conditions and Supply Chain Outcomes

Practical Pairings of SiC Grades, Engineering Focus, and Logistics Impact

| Brazilian Scenario | Dominant Risks | Recommended SiC Grade | Design/Process Focus | Typical Outcome for Supply Chain |

|---|---|---|---|---|

| Iron ore/bauxite hydrocyclones | Erosion, turbulence | RBSiC / SiSiC | Inlet reprofile, reinforced apex | 2× service life, lower safety stock |

| Pre-salt pump mechanical seals | Chlorides, P–T cycling | SSiC | Optical-flat lapping, counterface pairing | Fewer interventions, standardized spares |

| Fertilizer elbows and chutes | Corrosive abrasion | RBSiC liners | Thickness gradient, tile overlap | Planned maintenance, fewer emergency buys |

| High-temperature fixtures | Thermal shock, low mass | R-SiC | Lightweight geometry, stable porosity | Shorter cycles, predictable campaigns |

These mappings convert lab properties into predictable consumption patterns, allowing procurement to tighten reorder points, reduce emergency freight, and improve service levels.

Silicon Carbide Grades: Engineering Deep-Dive for Specification Teams

Comparative Engineering Properties of R-SiC, SSiC, and RBSiC/SiSiC

| Параметр | SSiC | RBSiC / SiSiC | R-SiC |

|---|---|---|---|

| Open Porosity (%) | <0.5 | 10–16 | 10–20 |

| Модуль упругости (ГПа) | 390–420 | 320–350 | 240–280 |

| Coefficient of Thermal Expansion (10^-6/K) | 4.0–4.5 | 4.0–4.5 | 4.0–4.5 |

| Устойчивость к тепловому удару | Высокий | Очень высокая | Высокий |

| Corrosion Resistance (chlorides/acids) | Превосходно | Очень хорошо | Хорошо |

| Achievable Surface Finish (Ra, µm) | ≤0.02 with lapping | 0.1–0.4 typical | 0.2–0.5 typical |

| Typical Brazilian Applications | Seal faces, bearings | Cyclones, nozzles, liners | Burner blocks, kiln furniture |

| Cost-to-Performance Fit | Premium for critical service | Balanced for high-wear | Efficient for thermal/structural |

Codifying these parameters into ABNT-referenced specifications and acceptance criteria shortens internal approvals and de-risks field trials and vendor qualification.

Future Market Opportunities and 2025+ Trends: SiC as a Supply Chain Multiplier

Brazil’s heavy industries are aligning around uptime, energy intensity, and ESG transparency. Mining producers target lower kWh per ton and stable plant availability; pre-salt operators push for fewer unplanned deferrals; agribusiness processors prioritize predictable campaigns through harvest peaks. Materials that sustain dimensional integrity and surface finish support these objectives by minimizing hydraulic losses, stabilizing separation efficiency, and reducing leak-off.

Macro forces reinforce the case for SiC. FX volatility and geopolitical logistics risk make global lead times less dependable, elevating the value of domestic capability and components with longer, predictable lifecycles. Reindustrialization initiatives and local content preferences further nudge buyers to develop regional supply for critical parts. Simultaneously, IIoT and predictive maintenance are expanding; components that hold tolerances produce cleaner signals, fewer false alarms, and longer lead time to intervention, enabling leaner spares and sharper maintenance planning. Analysts forecast mid-single-digit growth for advanced technical ceramics through 2027 in Brazil, with SiC outpacing due to mining expansion, offshore investment, and process industry upgrades. Suppliers that combine performance with documentation, training, and local readiness—capabilities embedded in Sicarbtech’s model—will be best placed to capture this growth.

Часто задаваемые вопросы

How does Sicarbtech align SiC components with ABNT, ANP, and IBAMA requirements?

We engineer to API 610/682 for pumps and seals and evaluate sour service per NACE MR0175/ISO 15156 where relevant. Material characterization uses ISO methods with ABNT NBR cross-references, and traceability/test records are formatted to ANP procurement expectations. Environmental and safety documentation supports IBAMA licensing and NR norms.

Can Sicarbtech help localize SiC production to reduce lead time risk?

Yes. We provide complete technology transfer—process recipes, equipment specifications, operator and QC training, SPC frameworks—and remain engaged through commissioning and ramp-up, enabling audit-ready domestic capability with stable yields.

Which SiC grade should we choose for mechanical seal faces in chloride-rich service?

SSiC is typically preferred due to near-zero porosity, chloride resistance, and ultra-flat lapping capability. Final selection considers P–T cycles, counterface materials, and flatness retention under load.

What supply chain benefits are typical after upgrading to SiC hydrocyclones?

Sites often see 2× service life, 3–4% separation gains, fewer emergency shipments, and reduced safety stocks. Planning accuracy improves, lowering working capital and logistics premiums.

Do SiC components contribute to ESG and energy intensity targets?

They do. Smoother surfaces and tighter clearances lower hydraulic losses and leakage, reducing kWh per m³ pumped and supporting emissions and energy KPIs increasingly tied to financing.

Can Sicarbtech provide drop-in replacements without equipment redesign?

Often yes. We design SiC inserts and liners to match existing envelopes and mounting features, and we propose subtle geometry refinements that improve performance without requalifying hardware.

How is vendor qualification accelerated for Brazilian majors?

We supply comprehensive data packs—chemical/physical properties, NDT, dimensional and surface finish reports, SPC charts, and full traceability—formatted for ABNT and ANP workflows, shortening approval cycles.

What local after-sales support is available?

Sicarbtech offers remote engineering support, site visits through Brazilian partners, and continuous improvement reviews. We co-develop stocking strategies around shutdowns and harvest seasons to mitigate logistics risk.

Are there cost-optimized SiC options for less critical services?

Yes. RBSiC and R-SiC provide strong cost-to-performance where extreme corrosion resistance or ultra-flat finishes are not vital. We model lifecycle economics to guide grade selection.

What data should we provide to start a custom SiC project?

Media chemistry, particle size distribution, operating temperature and pressure, duty cycles, failure history, target service life, and CAD drawings. We work under NDA and follow structured DfM and validation.

Правильный выбор для ваших операций

Optimizing B2B supply chains is not just about software and forecasts; it is about materials that hold their geometry and finish under real-world stress. With Sicarbtech, Brazilian buyers gain a partner that pairs high-performance SiC grades with application engineering, precision finishing, and compliance-ready documentation. Whether the goal is to extend hydrocyclone life in Pará, stabilize seal performance on pre-salt platforms, or tame corrosive abrasion in fertilizer handling, Sicarbtech translates specifications into predictable consumption and tighter supply plans.

Получите консультацию эксперта и индивидуальные решения

Engage Sicarbtech’s engineering team to map your duty conditions into a validated SiC solution and a credible ROI case. We will align specifications with ABNT, ANP, and IBAMA requirements and, if strategic, design a technology transfer and factory establishment roadmap to localize capability and reduce lead time risk.

Sicarbtech – Silicon Carbide Solutions Expert

Электронная почта: [email protected]

Phone: +86 133 6536 0038

Метаданные статьи

Last updated: 2025-09-22

Следующее запланированное обновление: 15.12.2025

Content freshness indicators: 2025 Brazil outlook integrated; ABNT/ANP/IBAMA references reviewed; three comparison tables verified; Brazil-specific case studies refreshed; technology transfer and SPC guidance expanded.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.