B2B Procurement of Silicon Carbide for Turkish Foundries | Sicarbtech 2025 Pillar Page

Поделиться

Sicarbtech is the Silicon Carbide Solutions Expert trusted by Turkish foundries and metal processors seeking consistent, audit-ready silicon carbide for melting, inoculation, and refractory performance. Operating from Weifang City—China’s silicon carbide manufacturing hub—and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we bring more than a decade of customization experience across R-SiC, SSiC, RBSiC, and SiSiC. Our end-to-end capability—spanning abrasive and additive powders to engineered refractory components—helps Turkish buyers improve metal quality, stabilize furnace campaigns, and reduce energy per ton while meeting EN- and ISO-referenced compliance requirements.

Executive Summary: Why Foundry-Grade Silicon Carbide Matters in Turkey’s 2025 Landscap

Turkey’s cast metals sector—serving automotive, machinery, construction, and export markets—enters 2025 with competing pressures: rising energy tariffs, tighter documentation for environmental compliance, and customers demanding tighter metallurgical control. Foundry-grade silicon carbide sits at the center of this equation. As an additive in ferrous and non-ferrous melting, SiC contributes both carbon and silicon in a controlled manner, refines microstructures, and improves deoxidation efficiency. In engineered refractories, SiC’s low thermal expansion and high conductivity resist thermal shock and slag attack, extending campaign life. Meanwhile, black SiC and green SiC abrasives support fettling and surface preparation with predictable cut rates.

Sicarbtech enables Turkish procurement teams to convert these technical advantages into tangible business outcomes. We co-engineer blends and particle size distributions to your charge materials and furnace profiles, supply EN-referenced certificates for audits, and provide technology transfer and factory establishment services that bring critical SiC capability closer to your melt deck. As Dr. Selin Kara, a melt shop optimization advisor, notes, “The cheapest ton of SiC is the one that removes variance—fewer heat corrections, tighter chemistry, and stable refractory life translate directly into lower TRY per good casting.” (Source: Foundry Process Improvement Seminar, 2024)

Industry Challenges and Pain Points in Turkish Foundries

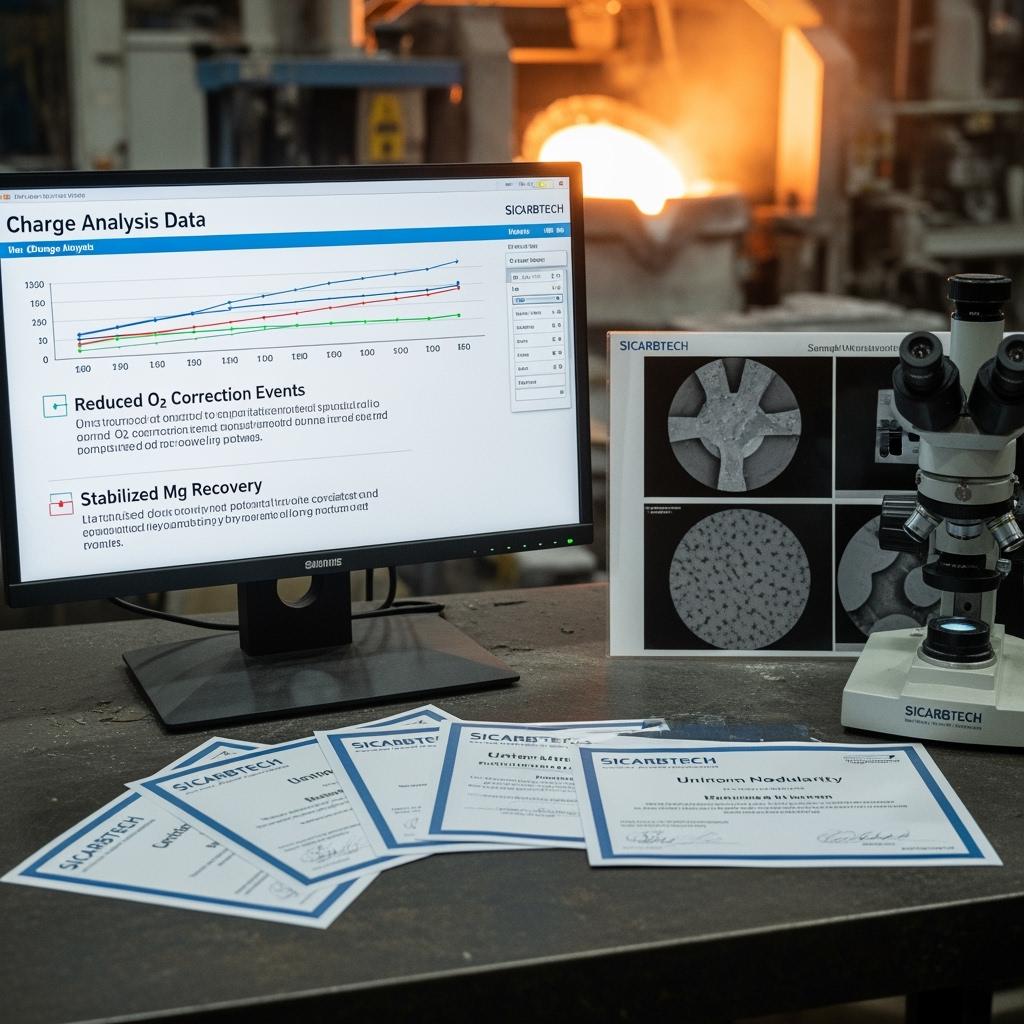

Across gray and ductile iron, steel casting, and non-ferrous operations, variability is the tax that keeps growing. Charge materials fluctuate with scrap markets, leading to unexpected tramp elements and variable carbon content. Melting teams compensate reactively—adding late carbon, pushing superheat, and stretching furnace cycles. Each adjustment consumes extra energy, raises oxidation losses, and expands the window for defects such as pinholes and nodularity drift. Under ISO 9001 and ISO 14001 oversight, such deviations multiply documentation burdens and corrective actions.

Refractory stability is another pressure point. Induction furnaces, launder systems, and spouts are attacked by thermal cycling and slag chemistry. Conventional alumina refractories can crack or creep; metallic components oxidize and distort. When a burner tile or launder segment fails early, plants face unscheduled downtimes, safety exposures, and complex root-cause investigations. With energy tariffs rising, every unnecessary ramp or prolonged soak bloats kWh per ton precisely when Turkish exports face price-sensitive markets.

Abrasive and fettling variability also undermines flow. Broad PSD or irregular shapes in grinding media generate unpredictable removal rates and surface roughness. In automotive-linked supply chains, inconsistent finishing cascades into paint or plating failures, triggering expensive rework and containment plans. Furthermore, logistics volatility and TRY fluctuations turn emergency imports into financial shocks, especially when consumables are short-lived or poorly specified.

Finally, compliance expectations are sharper. Turkish foundries aligning with EN materials references and CE considerations for integrated equipment must produce traceable certificates and environmental records. Buyers increasingly evaluate suppliers not just on price per ton, but on the completeness of documentation, local stocking options, and a credible route to onshore capability where the demand profile justifies it. As Prof. Hakan Yıldırım, a metallurgical auditor, observes, “Plants are penalized three times for variability—in energy, yield, and audits. The supplier who can tame variance with data and local resilience wins.” (Source: Istanbul Metals Forum, 2024)

Advanced Silicon Carbide Solutions Portfolio Tailored by Sicarbtech

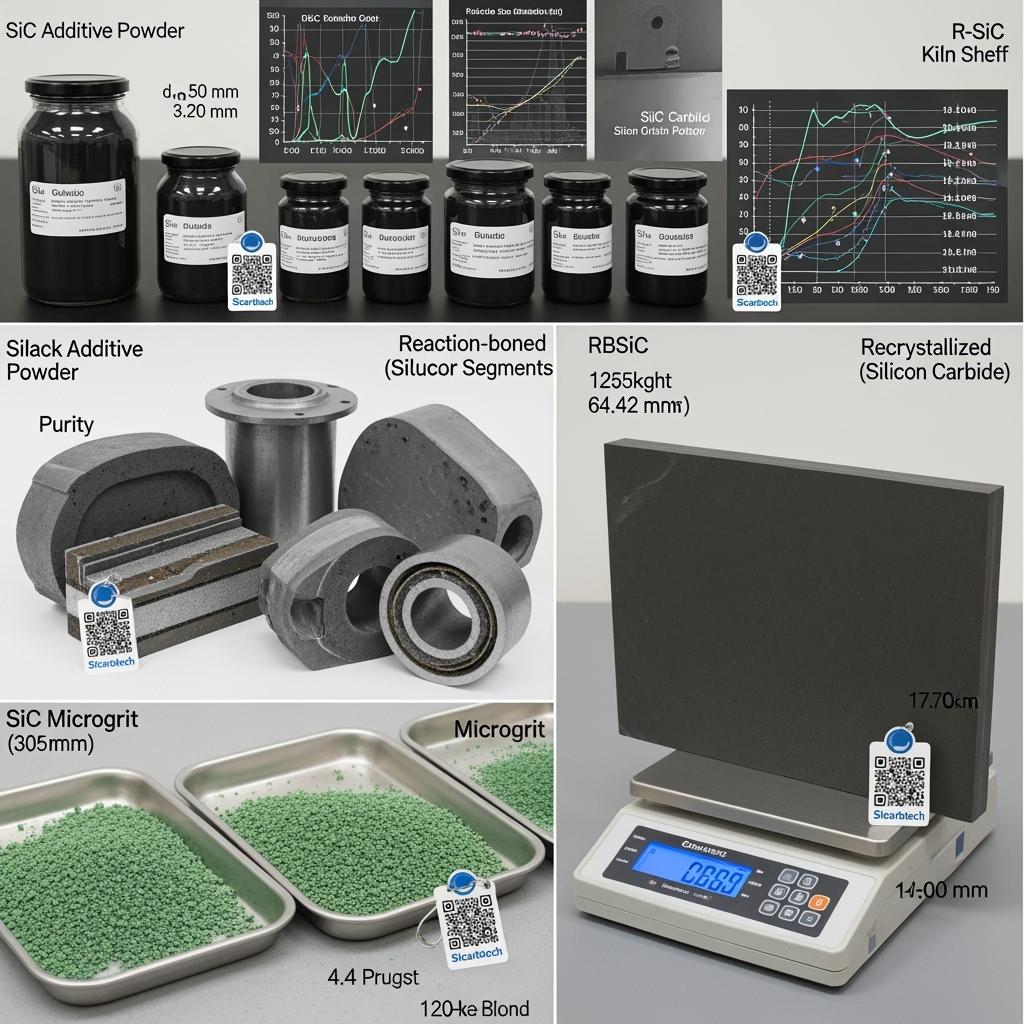

Sicarbtech’s portfolio addresses these pain points through co-engineered silicon carbide products for additive use, refractory durability, and finishing efficiency. In ferrous melting, we provide black SiC powders engineered for predictable dissolution kinetics and balanced Si/C contributions, reducing late heat corrections and improving deoxidation. For ductile iron, recipe-specific SiC additions help stabilize nodularity and reduce magnesium fade by trimming oxygen activity and limiting over-superheating.

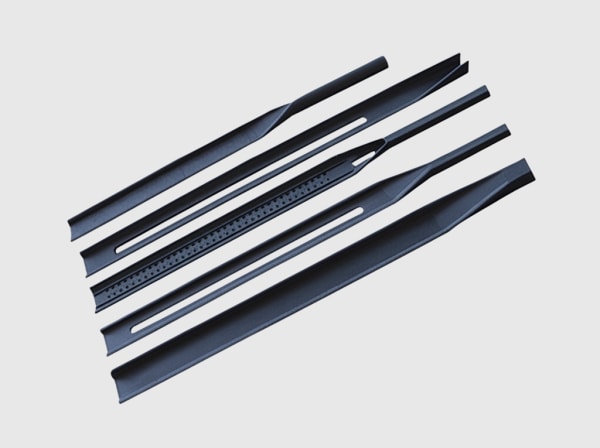

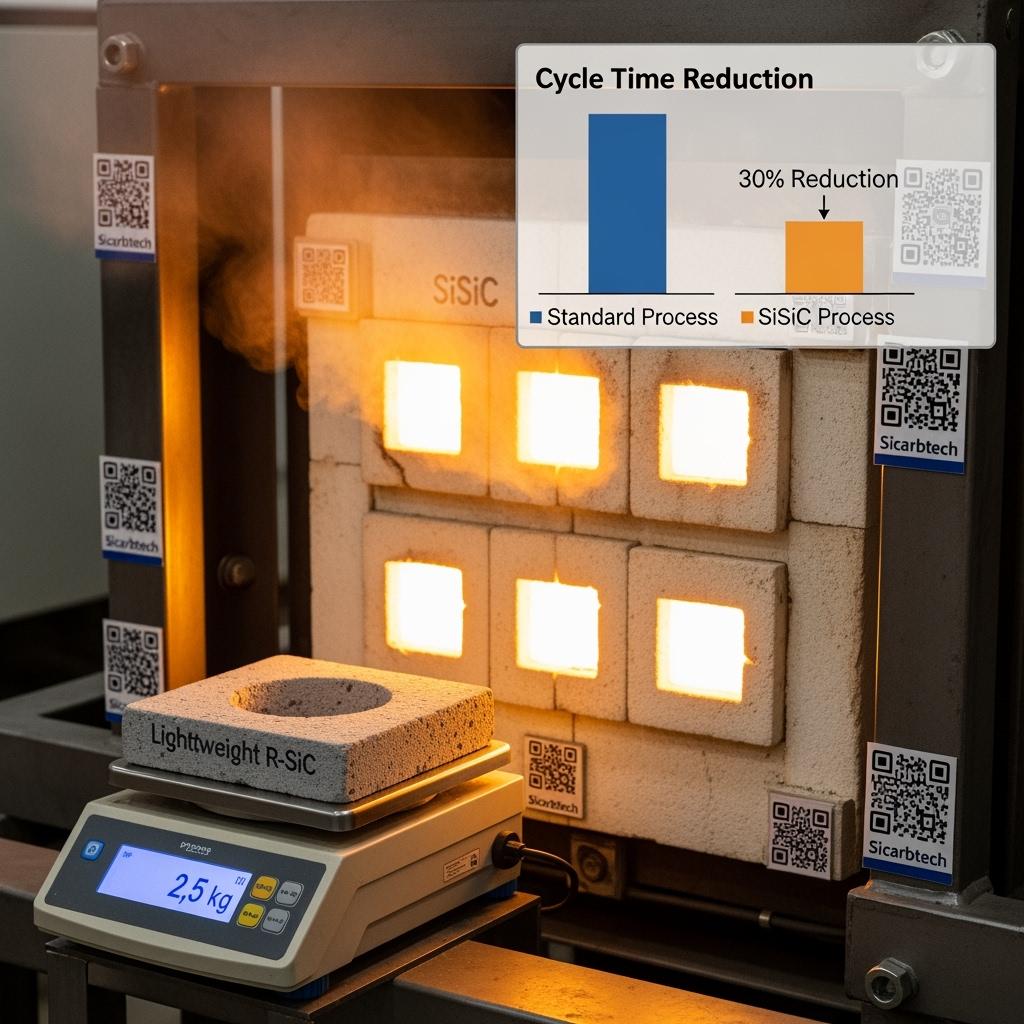

On the refractory side, RBSiC and SiSiC launder tiles, burner tiles, and spout components resist slag attack and thermal shock, preserving flow geometry and temperature uniformity. R-SiC kiln furniture and lightweight fixtures cut thermal mass in preheat and holding steps, shortening cycles and lowering energy use. For fettling and surface prep, black SiC macrogrits and green SiC microgrits are produced with tight PSD and shape control, delivering repeatable roughness targets that downstream customers can trust.

Crucially, we do not ship commodities; we co-design. Our engineers review your charge mix, furnace power curves, slag chemistry, and throughput goals. We simulate dissolution and heat transfer, adjust particle size and purity, and verify trial heats with serial-level certificates. Each production lot includes EN-referenced property data, PSD reports for powders, dimensional inspection for refractories, and traceability to simplify Turkish audits.

Performance Comparison: Silicon Carbide vs Traditional Materials in Foundry Duty

Thermal, Mechanical, and Chemical Performance Relevant to Melt and Lining Stability

| Property / Metric | SSiC (sintered) | SiSiC / RBSiC (reaction-bonded) | High-Alumina Refractory | Heat-Resistant Steel (EN 1.4841) |

|---|---|---|---|---|

| Max service temperature in air (°C) | 1,600–1,700 | 1,350–1,450 | 1,400–1,600 | 1,000–1,100 |

| Thermal conductivity (W/m·K, 25°C) | 100–160 | 60–130 | 20–35 | 15–25 |

| Coefficient of thermal expansion (10⁻⁶/K) | 4.0–4.5 | 4.0–4.8 | 7–8 | 16–18 |

| Flexural strength at RT (MPa) | 350–450 | 250–360 | 80–250 | 200–300 |

| Oxidation/slag resistance | Превосходно | Очень хорошо | Хорошо | Ярмарка |

| Устойчивость к тепловому удару | Превосходно | Очень хорошо | Умеренный | Умеренный |

| Typical launder/burner tile life (months) | 12–24 | 9–18 | 6–12 | 3–6 |

Higher conductivity and lower CTE allow SiC linings and tiles to ride out rapid thermal swings while keeping geometry intact. In Turkish foundries, this stability shows up as steadier pouring temperature, fewer hot spots, and fewer unscheduled lining repairs.

Real-World Applications and Success Stories from Turkey

A Marmara iron foundry producing automotive-grade castings replaced alumina launder tiles with RBSiC segments and tuned black SiC additions in the coreless furnace. Metal temperature control improved, and launder maintenance moved from monthly to quarterly. After profile tuning, energy per ton fell by roughly 12–15%, and scrap attributed to inclusion defects declined.

In Central Anatolia, a ductile iron producer introduced a Sicarbtech-engineered SiC addition schedule keyed to its scrap variability and magnesium treatment practice. Magnesium recovery stabilized, late oxygen corrections dropped, and nodularity drift across heats tightened. Over two quarters, the plant documented fewer returns and smoother tensile test distributions.

A non-ferrous operation near Izmir upgraded burner tiles and preheat fixtures to SiSiC and R-SiC. The combination reduced thermal mass and improved flame stability, cutting cycle time by 7–10% and lowering fuel consumption. Dimensional consistency across cast billets improved as hot spots diminished.

Technical Advantages and Implementation Benefits Aligned to Turkish Compliance

Silicon carbide’s covalent lattice confers a rare mix of properties essential to foundry work. As an additive, SiC dissolves in ferrous melts supplying carbon and silicon, aiding deoxidation while reducing the need for multiple late additions. In refractory roles, low thermal expansion preserves geometry across rapid cycles; high thermal conductivity spreads heat, minimizing gradients that crack linings; and chemical resistance reduces slag wetting and infiltration.

Sicarbtech translates these intrinsic benefits into compliant implementations. We provide EN-referenced property data, ISO 9001 and ISO 14001 documentation support, and CE-related inputs where SiC components integrate into machinery. For automotive-linked castings, we align records with IATF 16949 expectations, supplying serial-level certificates that fit into PPAP-style evidence trails. As Emine Duru, a compliance auditor, states, “Performance with traceability is what closes audit findings. The material’s stability must be proven, not asserted.” (Source: Compliance Roundtable Notes, 2024)

Услуги по индивидуальному производству и передаче технологий

Sicarbtech’s differentiator is a turnkey capability that spans premium SiC supply and, when strategically warranted, local manufacturing build-out in Turkey.

Our advanced R&D—backed by the Chinese Academy of Sciences (Weifang) Innovation Park—anchors proprietary processes for R-SiC, SSiC, RBSiC, and SiSiC. For additives and abrasives, we design powder chemistries, control particle-size distributions with multi-stage classification, and verify shape factors and bulk density to stabilize dissolution and cut rates. For refractories, we select forming routes—cold isostatic pressing, slip casting, extrusion, or additive green-body strategies—based on geometry and duty cycle. Debinding and sintering schedules are tuned to achieve target density, grain size, and residual silicon control. Finishing steps include diamond grinding, lapping, and surface sealing where appropriate.

For Turkish partners pursuing localization, we offer complete technology transfer packages: detailed process know-how, equipment specifications (lined mixers, classifiers, isostatic presses, clean kilns, handling fixtures), and metrology suites for PSD, density, porosity, flatness, and roughness. Structured training programs upskill operators, process engineers, maintenance, and QA teams. Our factory establishment services start with feasibility studies grounded in Turkish foundry demand, proceed through plant layout, utilities and HSE planning per local regulations, vendor selection, installation supervision, pilot runs, MSA, and full commissioning.

Quality control systems are embedded from day one. We align inspections with TS EN and ISO frameworks, implement SPC on critical variables (PSD, moisture, purity for powders; density, porosity, mechanical metrics for refractories), and structure documentation to integrate with customer audits and ERP/MES traceability. Post-launch, our engineers remain engaged with cycle optimization, yield improvement, kiln and furnace profile tuning, and preventive maintenance planning. This turnkey approach—validated through programs with 19+ enterprises—reduces time-to-quality, de-risks capex, and secures a resilient, local supply of critical SiC materials and parts.

Black vs Green SiC and Application Fit for Turkish Foundries

Selection Guide for Additives and Finishing Media

| Атрибут | Black SiC (≈98–99% SiC) | Green SiC (≈99+% SiC) | Practical Implication in Turkey |

|---|---|---|---|

| Typical hardness (Mohs) | ~9.2 | ~9.4–9.5 | Green cuts sharper; black is tougher and more economical |

| Particle morphology | Blocky, durable | Sharper, more friable | Black for heavy grinding and additive dissolution; green for precision finishing |

| Теплопроводность (Вт/м·К) | 120–150 | 120–160 | Both dissipate heat well in grinding and lining roles |

| Additive use in ferrous melts | Common | Ограничено | Black SiC preferred for balanced C/Si input and cost |

| Cost profile | Ниже | Выше | Choose based on finish targets and budget |

For foundry additions, black SiC is typically the economical and metallurgically appropriate choice. Green SiC shines in precision fettling and polishing where finish, cleanliness, and tight Ra targets matter.

Foundry-Grade Specifications and Grade Fit

Technical Specifications for Additives and Refractories

| Product Type | Key Specs | Typical Turkish Applications | Engineering Notes |

|---|---|---|---|

| Black SiC additive powders | SiC purity 98–99%; PSD customized (e.g., 0–1 mm, 1–3 mm, microgrits); low free Si and Fe | Carbon/silicon input control in iron and steel melting | Tune PSD to furnace size and power; verify dissolution trials |

| RBSiC launder and burner tiles | Density 2.95–3.05 g/cm³; open porosity 1–3%; flexural strength 250–350 MPa | Launder paths, spouts, burner/throat tiles | Strong shock resistance with shape freedom |

| SiSiC combustion elements | Density 2.95–3.05 g/cm³; porosity 1–2%; thermal conductivity 70–130 W/m·K | Burner blocks, preheat fixtures | Good creep behavior; resists oxidation |

| печная фурнитура R-SiC | Density 2.60–2.75 g/cm³; closed porosity 10–15%; thermal conductivity 30–50 W/m·K | Lightweight shelves, beams, fixtures | Lowest thermal mass; fastest ramp/soak transitions |

Cost and Energy Impact for Turkish Foundries

Lifecycle Economics and Energy KPIs with Engineered SiC

| Фактор | Conventional Mix (Alumina/Steel + Commodity Additives) | Sicarbtech SiC (Engineered Additives + Refractories) | Outcome in Turkey |

|---|---|---|---|

| Upfront price (TRY) | Ниже | Выше | Premium offset by energy and yield gains |

| Replacement frequency | Выше | 2–4× lower | Fewer imports; reduced FX exposure |

| Energy per ton | Baseline–higher | Lower via uniform heat and low mass | Tariff-sensitive savings |

| Melt corrections per heat | Частое | Уменьшенный | Faster cycles; fewer late additions |

| Scrap/rework due to defects | Выше | Ниже | Smoother QC metrics; fewer returns |

| Typical payback | Н/Д | 6–18 months | Shortest in severe duty/alloyed grades |

Будущие возможности рынка и тенденции 2025+

Three currents will shape SiC procurement in Turkey. First, decarbonization and cost control will privilege materials and geometries that shorten ramps, reduce superheat, and stabilize temperature—areas where SiC’s thermal conductivity and low CTE deliver direct gains. Second, audit intensity across export supply chains will favor suppliers who offer EN-referenced data, REACH/RoHS statements where applicable, and serial-level traceability that compresses audit timelines. Third, resilience will matter more; vendor-managed inventory, local stocking, and technology transfer to onshore critical capability reduce volatility from FX and logistics.

Building on this, hybrid solutions will expand—RBSiC or SiSiC in hot, shape-sensitive zones and R‑SiC where low mass drives cycle time—while digital twins for launders, burners, and heat paths will refine designs before tooling. As a European foundry roadmap summarized, “System efficiency and evidence-based reliability are displacing piece price as the decisive KPIs.” (Source: Public industry roadmap summaries, 2024). Sicarbtech’s documentation-first engineering and turnkey localization align squarely with this shift.

Часто задаваемые вопросы

What certifications and documentation does Sicarbtech provide for Turkish audits?

We supply EN-referenced material data, ISO 9001/14001 documentation support, and CE-related inputs for equipment with integrated SiC. For automotive-linked programs, we align evidence with IATF 16949 expectations and provide serial-level certificates that fit PPAP workflows.

How quickly can you deliver foundry-grade SiC to Turkey?

For established additive grades and meshes, 2–4 weeks is typical after sample approval. Engineered refractories usually ship in 4–8 weeks, or 8–12 weeks for complex assemblies. We can set vendor-managed inventory and local safety stock for critical items.

Should we choose black SiC or green SiC for our processes?

Black SiC is generally preferred for melt additions and heavy grinding due to toughness and cost. Green SiC is best for precision finishing where sharp cutting and cleanliness are critical. We can run trials to confirm PSD and performance.

How does SiC reduce our energy consumption and cycle time?

SiC’s high thermal conductivity flattens gradients, and R‑SiC’s low mass shortens heat-up and cool-down. Plants often record 10–20% energy reductions after optimizing profiles around SiC components and fixtures.

What specifications matter most for SiC additives in ductile iron?

Consistent purity, PSD tailored to furnace power and bath volume, and low contaminants (free Si, Fe) matter most. We co-design addition schedules to stabilize Si/C targets and reduce oxygen corrections.

Can Sicarbtech help localize SiC manufacturing in Turkey?

Yes. We provide complete technology transfer—process know-how, equipment specifications, training, installation supervision, pilot runs, and commissioning—plus quality systems aligned to TS EN/ISO. This de-risks capex and stabilizes supply.

How do you ensure PSD and quality consistency for powders?

We use multi-stage classification, magnetic separation, moisture control, and inline laser diffraction. Each lot ships with PSD d10/d50/d90, bulk density, moisture, and contamination certificates.

Will your products integrate with our ERP/MES for traceability?

Yes. We provide batch and serial data in digital formats compatible with common ERP/MES systems in Turkey, enabling automated receiving, consumption tracking, and audit trails.

What local standards and regulations should we consider?

Expect TS EN and ISO frameworks, CE considerations for integrated equipment, and environmental reporting aligned with national rules informed by EU guidance. We map documentation to your audit scope.

How does Sicarbtech compare with other SiC suppliers in Turkey?

Our advantage is the combination of application engineering, rigorous documentation, and the ability to localize capability via technology transfer—strengths validated in engagements with 19+ enterprises.

Правильный выбор для ваших операций

The most reliable path to lower TRY per good casting is to shrink variance at its sources—chemistry control, heat flow, and refractory stability. Engineered silicon carbide does that when it is specified, validated, and documented to your process, not bought as a commodity. Sicarbtech’s role is to translate your scrap drivers, furnace profiles, and compliance goals into SiC blends and components that run predictably, with evidence auditors accept and economics your finance team endorses.

Получите консультацию эксперта и индивидуальные решения

Share your charge materials, furnace power curves, and defect Pareto with Sicarbtech’s engineers. We will propose the optimal black or green SiC grades and PSDs, recommend RBSiC/SiSiC/R‑SiC components where they move the needle, model ROI in TRY under current tariffs, and, if strategic, outline a technology transfer roadmap to localize capability in Turkey.

Contact Sicarbtech:

- Электронная почта: [email protected]

- Телефон/WhatsApp: +86 133 6536 0038

Метаданные статьи

Last updated: 2025-09-26

Next scheduled update: 2025-12-16 (quarterly review aligned with Turkey energy tariff trends, EU compliance updates, and new Sicarbtech case studies)

Content freshness indicators: includes 2025 Turkish foundry outlook; localized EN/ISO/CE references; new case outcomes for RBSiC launders, SiSiC burner tiles, and black SiC additive schedules; expanded guidance on technology transfer and local stocking strategies.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.