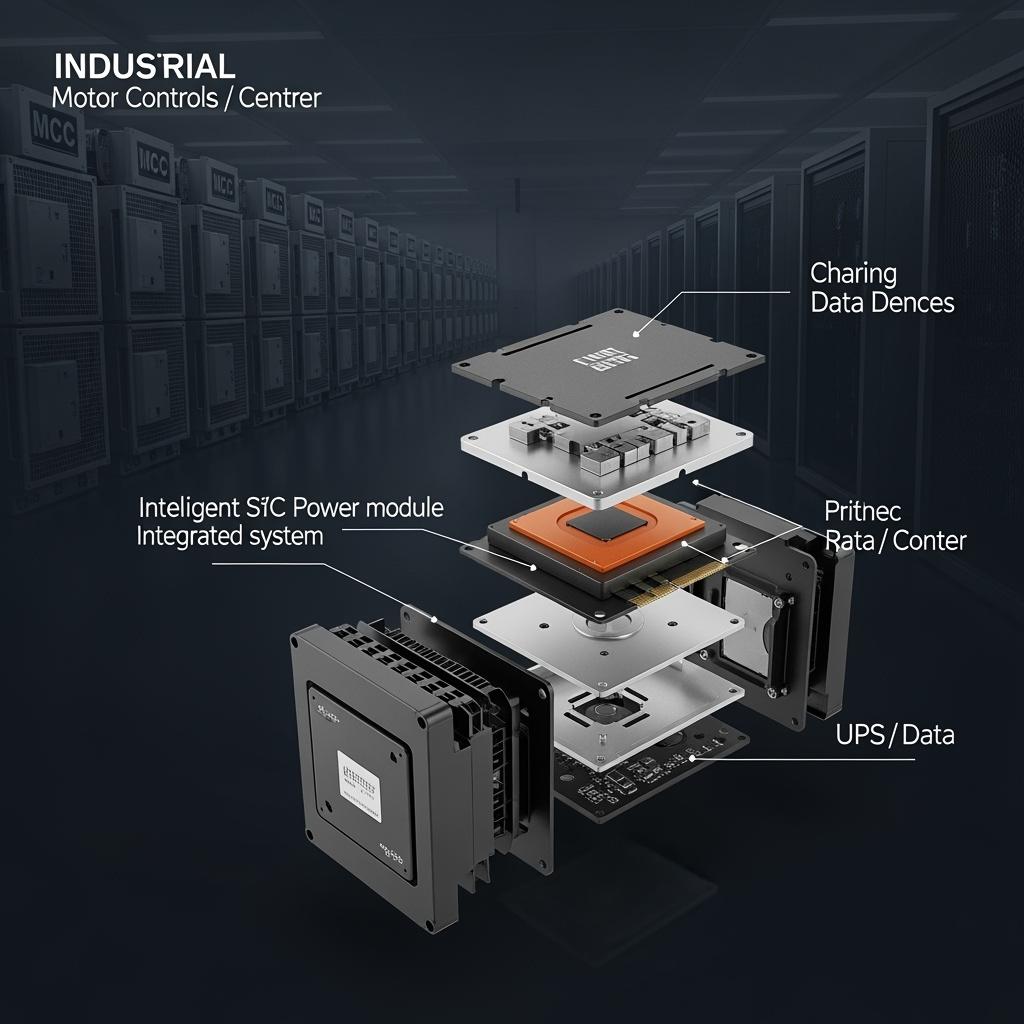

Интеллектуальные интегрированные системы на основе SiC-модулей питания с диагностикой в реальном времени и модульной масштабируемостью

Поделиться

Обзор продукции и актуальность на рынке 2025 года

TLP-связь для высокотемпературной стабильности

Для текстильной, цементной промышленности Пакистана сталелитейногоВысоконадежные варианты пайки, когда важна стоимость (SnAgCu с улучшениями надежности)

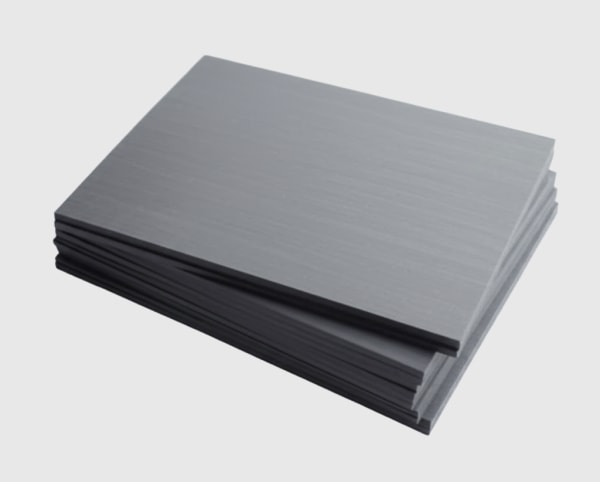

- Теплораспределители и опорные плиты

- Опорные плиты RBSiC/SSiC (120–200+ Вт/м·К эффективно; высокая жесткость, коррозионная/эрозионная стойкость)

- Дополнительные вставки Cu или CuMo для согласования CTE

- Спецификация плоскостности: ≤50 мкм по площади модуля для оптимальной производительности TIM

Тепловой интерфейс и охлаждение

Технические характеристики и расширенные функции

TIM: фазовый переход или передовые смазки (<0,02 K·м²/Вт), или графитовые прокладки для удобства обслуживания

- Охлаждение: воздушно-охлаждаемые ребра, испарительная камера или жидкостные холодные плиты (нержавеющая сталь или Al с ингибиторами коррозии)

- Целевое тепловое сопротивление: RθJC до 0,05–0,15 K/Вт на положение переключателя (в зависимости от области применения)

- Защита окружающей среды

- Инкапсуляция: силиконовый гель или эпоксидная смола с учетом степени загрязнения

- Конформные покрытия: акрил/уретан/силикон в соответствии с воздействием пыли/химикатов

- Корпуса со степенью защиты IP; варианты с избыточным давлением для цементных/текстильных участков

- Цели соответствия

- IEC 60664 (координация изоляции), IEC 62477-1 (безопасность преобразователя), IEC 60068 (экологическое тестирование), IEC 61800 (приводы) и практики, соответствующие PEC

- Функции надежности Sicarb Tech:

- Скрининг HALT/HASS, циклирование мощности до отказа (ΔTj до 80–100 K) и проверка теплового удара

- Квалификация на влагостойкость и проникновение пыли для промышленных условий Пакистана

- Встроенные датчики NTC/RTD и волоконно-брэгговские датчики (опционально) для теплового картирования и диагностики

- Прочный тепловой путь и межсоединения для высокой температуры окружающей среды и пыли в Пакистане

- Улучшенная упаковка SiC с RBSiC/SSiC (Sicarb Tech)

- Обычный силовой модуль кремниевой эры

- Тепловой путь (RθJC)

- Очень низкий с серебряным спеканием + AlN DBC

- Выше с пайкой + Al2O3 DBC

- Надежность при циклировании

- Цели соответствия

- Высокая (бессвязочный/зажим; спеченное крепление)

- Средняя (отрыв соединительного провода, усталость пайки)

Коррозионная/пылевая стойкость

- Высокая (керамические опорные плиты, герметичная конструкция)

- Умеренная; риск окисления/коррозии металла

- Запас рабочей температуры

Серебряное спекание (>200 Вт/м·К, высокотемпературное, надежное при циклировании)

| Поддерживается работоспособность устройств до 175–200°C | Обычно ≤125–150°C | Расширенная (стабильный TIM, диагностика) |

|---|---|---|

| Более частая переклейка/перетяжка | Более низкое тепловое сопротивление и более высокое время безотказной работы: серебряно-спеченные кристаллы на AlN/Si3N4 DBC с опорными плитами RBSiC/SSiC снижают температуру перехода, повышая эффективность и срок службы. | Превосходная надежность при циклировании: бессвязочные медные зажимы выдерживают высокие ΔTj и вибрацию, обнаруженные на сталелитейных и цементных заводах. |

| Устойчивость к | >10 кВт/л; шкафы на 30–35% меньше | Средняя плотность; шкафы большего размера |

| Надежность и защита | Быстрое DESAT, мягкое отключение, прогностические журналы | Основные отключения; ограниченное ведение журналов |

| THD и PF (с PFC) | Достижимы THD <3%, PF >0,99 | Более высокое THD; требуется коррекция PF |

| Модель технического обслуживания | На основе состояния, удаленная диагностика | На основе времени, устранение неполадок на месте |

Ключевые преимущества и доказанные выгоды

- Более высокая эффективность и меньшие эксплуатационные расходы: экономия энергии 5–8% по сравнению с кремнием; снижение затрат на ОВКВ за счет меньшего отвода тепла.

- Более быстрое развертывание и масштабирование: предварительно спроектированные блоки с разъемами blind-mate сокращают время установки на 30–40%.

- Бесперебойная работа благодаря интеллекту: диагностика в реальном времени и анализ тенденций сокращают незапланированные простои и ускоряют анализ первопричин.

- Термическая и экологическая устойчивость: стабильность при высокой Tj и в помещениях с температурой 45°C с пылезащищенной конструкцией.

- Соответствие требованиям и дружественность к сети: более чистые формы сигналов и скоординированный PFC помогают достичь целевых показателей THD и PF в соответствии с кодексом сети NTDC.

Цитата эксперта:

«Интеллектуальные силовые модули, которые интегрируют датчики, защиту и аналитику, необходимы для повышения эффективности SiC при сохранении надежности при высоких скоростях переключения». — IEEE Power Electronics Magazine, Market Watch 2024 (аналитика промышленной интеграции)

Реальные области применения и измеримые истории успеха

- Модернизация ИБП для центра обработки данных в Лахоре:

- Интеллектуальные SiC интегрированные блоки выпрямителя/инвертора заменили устаревшие рамы.

- Результаты: КПД ИБП 97,3%; сокращение занимаемой площади помещения примерно на 35%; снижение затрат на электроэнергию за первый год примерно на 12,6%; прогностические сигналы тревоги предотвратили два потенциальных отказа, связанных с деградацией вентилятора охлаждения.

- Модернизация текстильного VFD в Фейсалабаде:

- 45 кВт интеллектуальные SiC блоки инвертора с адаптивным dv/dt и мониторингом состояния.

- Результаты: экономия энергии 5,5%; снижение температуры шкафа на 18%; на 20% меньше отключений во время просадок напряжения в фидере; техническое обслуживание переведено с ежеквартального на обслуживание на основе состояния.

- Цементные преднагреватели/вентиляторы ID в Пенджабе:

- 3-уровневые интегрированные системы ANPC с пылеустойчивыми корпусами и охлаждением с положительным давлением.

- Производительность: THD <3% со ступенью PFC, снижение энергопотребления вентилятора примерно на 7%; увеличенные интервалы замены фильтров; меньше сигналов тревоги, связанных с ЭМИ.

【Подсказка изображения: подробное техническое описание】 Раздельная сцена: 1) стойка интеллектуальных модулей SiC со светодиодами диагностики Ethernet/CAN; 2) наложение пользовательского интерфейса панели управления, отображающее ток, температуру, THD, PF, запас SOA; 3) техник, выполняющий замену модуля blind-mate; включите аннотации для плотности мощности, кривой эффективности и предупреждений о профилактическом обслуживании; фотореалистичность, 4K.

Вопросы выбора и обслуживания

- Определение размеров и топология

- Выберите напряжение/ток с запасом 20–30% для просадок/скачков и перегрузок.

- Выберите 2-уровневую схему для простоты или 3-уровневую NPC/ANPC для снижения коммутационного напряжения и повышения эффективности в силовых рамах большей мощности.

- Тепловые характеристики и окружающая среда

- Проверьте охлаждение для окружающей среды 40–45°C; рассмотрите жидкостное охлаждение выше ~250 кВт или на большой высоте.

- На пыльных предприятиях используйте корпуса с положительным давлением или со степенью защиты IP и платы с конформным покрытием.

- ЭМС и проводка

- Используйте ламинированные шины и короткие петли; соблюдайте требования IEC 61000-6-4 для выбросов и 6-2 для помехоустойчивости.

- Длинные кабели двигателей могут потребовать фильтров dV/dt или синусоидальных фильтров.

- Интеграция диагностики

- Подключите CAN/Ethernet к SCADA объекта; настройте пороги для индикаторов срока службы вентилятора/конденсатора.

- Настройте рабочий процесс удаленного обновления прошивки и архивирования журналов событий.

- Практика обслуживания

- Поддерживайте крутящий момент на клеммах; проверяйте разъемы во время остановок.

- Используйте аналитику для планирования замены вентиляторов и фильтров, сводя к минимуму влияние на производство.

Факторы успеха в отрасли и отзывы клиентов

- Факторы успеха:

- Исследование гармоник на входе и проверка нагрузки трансформатора

- Пилотные испытания в условиях пикового лета для проверки тепловых запасов

- Обучение персонала работе с панелями управления и интерпретации сигналов тревоги

- Стратегия запасных модулей для быстрой горячей замены и минимального времени простоя

- Отзыв (начальник отдела эксплуатации, вспомогательные системы сталелитейного завода в Карачи):

- «Модульные блоки SiC и диагностика в реальном времени позволяют нам выявлять проблемы до того, как они остановят производство. Замена модуля занимает минуты, а не часы».

Будущие инновации и тенденции рынка

- Прогноз на 2025–2027 годы:

- Более глубокое объединение датчиков и периферийный ИИ для обнаружения аномалий и моделирования срока службы

- Более широкое использование SiC 1700 В для многоуровневых приводов MV в цементной/сталелитейной промышленности

- Снижение затрат за счет использования пластин SiC 200 мм и партнерства по региональной сборке

- Стандартизированные экосистемы модулей с подключаемыми стеками управления и цифровыми двойниками

Отраслевой взгляд:

«Цифровизация, модульное преобразование энергии объединяется с широкозонными полупроводниками для обеспечения беспрецедентной эффективности и удобства обслуживания». — IEA Technology Perspectives 2024, раздел Power Electronics

Часто задаваемые вопросы и ответы экспертов

- Могут ли интеллектуальные модули интегрироваться с существующими SCADA/EMS?

- Да. Мы поддерживаем Modbus/RS485, CAN и Ethernet с документированными регистрами и безопасными шлюзами для интеграции.

- Как работают предупреждения о профилактическом обслуживании?

- Встроенные модели отслеживают температурные циклы, частоту вращения вентилятора, ESR конденсатора и коммутационное напряжение, чтобы прогнозировать оставшийся срок службы и запускать оповещения.

- Какие THD и PF могут быть достигнуты?

- С опцией SiC PFC: THD <3% и PF ≥0,99 в широком диапазоне нагрузок, поддерживая цели качества кодекса сети NTDC.

- Подходят ли системы для 220/400 В, 50 Гц и пыльных сред?

- Полностью. Мы адаптируем зазоры/пути утечки, покрытия и давление в корпусе к местным условиям и практике PEC.

- Каков типичный ROI?

- 18–30 месяцев экономии энергии и охлаждения, сокращения времени простоя и снижения затрат на техническое обслуживание — быстрее для круглосуточной работы.

Почему это решение работает для ваших операций

Интеллектуальные интегрированные системы силовых модулей SiC сочетают в себе лучшую в своем классе эффективность с практичной диагностикой и модульной масштабируемостью. В жарком, пыльном и нестабильном промышленном ландшафте Пакистана они обеспечивают более низкие эксплуатационные расходы, более высокую эксплуатационную готовность и более быстрое развертывание, поддерживая стабильность технологических процессов в текстильной промышленности, надежность вентиляторов в цементной промышленности, управление вспомогательными системами в сталелитейной промышленности и критически важные операции ИБП/центров обработки данных.

Свяжитесь со специалистами для получения индивидуальных решений

Ускорьте свой путь к интеллектуальному, высокоэффективному преобразованию энергии с Sicarb Tech:

- Более 10 лет опыта производства SiC, подтвержденного Китайской академией наук

- Индивидуальная разработка для R-SiC, SSiC, RBSiC и SiSiC, а также передовая упаковка интеллектуальных модулей

- Услуги по передаче технологий и созданию заводов для создания местной добавленной стоимости

- Готовые решения от обработки материалов до готовых интеллектуальных модулей с инженерной поддержкой приложений

- Проверенный опыт работы с 19+ предприятиями в сложных условиях; быстрое прототипирование и пилотные проекты

Получите бесплатную консультацию, аудит объекта и модель рентабельности, адаптированную для вашего предприятия или центра обработки данных.

- Электронная почта: [email protected]

- Телефон/WhatsApp: +86 133 6536 0038

Зарезервируйте слоты сборки на 4 квартал 2025 года сейчас, чтобы обеспечить сроки поставки и максимизировать экономию энергии в пиковый сезон.

Метаданные статьи

- Последнее обновление: 11.09.2025

- Следующий запланированный обзор: 15.12.2025

- Автор: Команда инженеров по применению Sicarb Tech

- Contact: [email protected] | +86 133 6536 0038

- Ориентация на стандарты: IEC 61800, IEC 62040, IEC 62109, IEC 62477-1, IEC 61000; в соответствии с практикой PEC и критериями качества кодекса сети NTDC

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.