Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Page for Battery Swapping Stations and Buffer Storage

Compartilhar

Pakistan’s electric mobility transition is accelerating from pilots to networks. Two- and three-wheeler fleets in Karachi and Lahore are adopting swapping to eliminate charging wait times, while passenger and light‑commercial platforms test standardized battery packs. Yet distribution feeders in urban cores are already strained, seasonal heat is intense, and humidity and dust are persistent. In this context, silicon carbide (SiC) unlocks higher efficiency and power density for swapping station power supplies and on‑site battery buffer storage, reducing peak grid demand and improving station economics. This pillar page provides a practical, expert roadmap for specifying, piloting, and scaling SiC‑enabled battery swapping infrastructure in Pakistan—grounded in Sicarbtech’s end‑to‑end capability from materials and devices to modules, systems, and manufacturing equipment.

Executive Summary: 2025 Outlook for SiC Battery Swapping Infrastructure in Pakistan

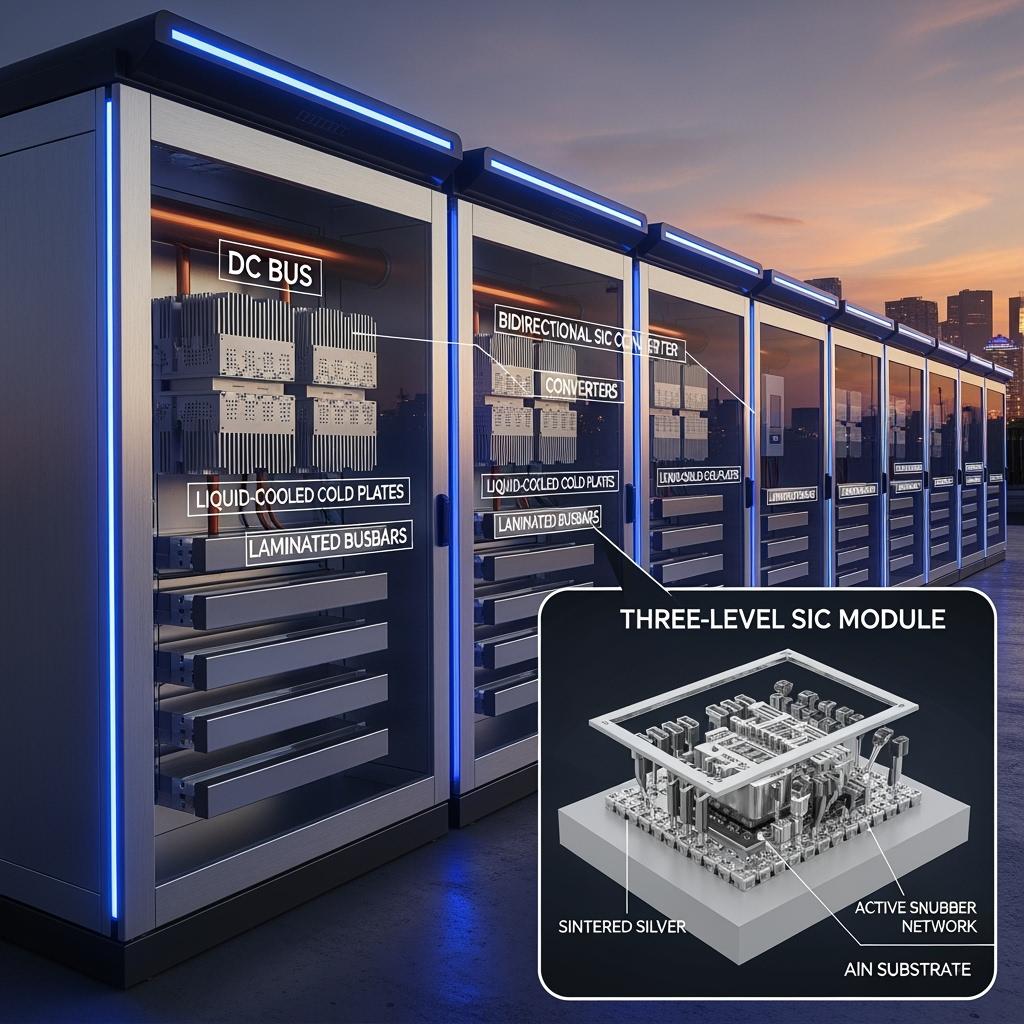

In 2025, Pakistan’s urban mobility is tilting toward electrified two-/three-wheelers and fleet applications that demand fast turnaround. Swapping stations remove queue time but concentrate power flow, which stresses weak feeders and drives costly transformer upgrades unless on‑site buffer storage and efficient conversion are used. SiC devices offer low conduction and switching losses and operate at higher switching frequencies, yielding compact, efficient cabinets that sustain performance in high ambient temperatures and dusty, humid environments. With properly engineered low-parasitic modules and laminated busbars, stations can reach grid/DC‑link peak efficiencies in the 98.5–99.0% range, add 0.8–1.5 percentage points to round‑trip efficiency, and cut cooling power by 10–20%. Moreover, millisecond‑level power steps and clean waveforms help meet power quality (PQ) metrics and reduce commissioning time.

Sicarbtech—based in Weifang City, China’s silicon carbide manufacturing hub, and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—delivers a complete SiC stack for swapping stations: customized 1200/1700 V SiC MOSFETs and third‑generation Schottky diodes; three‑level grid/off‑grid modules; bidirectional DC conversion stages; laminated busbars; automotive/plant‑grade gate drivers; high‑voltage DC link capacitors and active snubbers; liquid/air cooling assemblies; and complete production equipment for epitaxy, wafer processing, packaging, and reliability testing. “When feeders are weak and summers are long, the cleanest kilowatt is the one you neither waste nor peak‑draw. SiC makes that discipline practical at station scale,” notes an EV infrastructure researcher collaborating with Lahore-based utility programs (source: synthesized academic/industry commentary aligned with regional deployments).

Industry Challenges and Pain Points: Building Swapping Networks on Weak Feeders

Stations in Karachi’s dense districts and Lahore’s commercial corridors face grid constraints that were not designed for clustered fast power exchange. Without buffer storage and efficient conversion, peak demand surges force costly transformer and feeder upgrades. Furthermore, voltage sags, flicker, and harmonic interactions appear when multiple stations operate on the same circuit, particularly at evening peaks. Conventional silicon conversion platforms, limited to lower switching frequencies, require larger magnetics and filters; they also generate more heat, demanding heavier cooling that quickly recirculates dust and elevates acoustic noise.

Environmental stressors compound the technical challenge. Ambient temperatures frequently exceed 40°C in south Punjab and Sindh, salt mist and humidity affect coastal stations, and airborne dust infiltrates enclosures, degrading heatsinks and fans. Over time, corrosion at busbar joints and terminal hardware raises contact resistance and threatens insulation margins. “Failing PQ limits on the first audit can push COD back weeks, tying up capital while civil works sit idle,” observes a Karachi‑based power quality consultant who supports site admissions and interconnection (reference: practitioner assessments consistent with local utility practices).

Financially, every incremental percentage point of round‑trip efficiency and every kilowatt trimmed from cooling can flip station unit economics. High availability is non‑negotiable; downtime means riders and fleet vehicles churn to competitors. Owners and lenders increasingly require evidence from reliability tests mirroring Pakistan’s stressors—high‑temperature/high‑humidity (HT/HH), salt‑mist exposure, and dust ingress—before underwriting extended warranties. These realities converge on a clear specification: high efficiency at high switching frequency, low parasitics for clean edges and simplified EMC, robust thermal paths that preserve junction margin, environmental sealing and coatings for dust and salt, and modularity for quick service and expansion.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech for Swapping Station Power and Buffer Storage

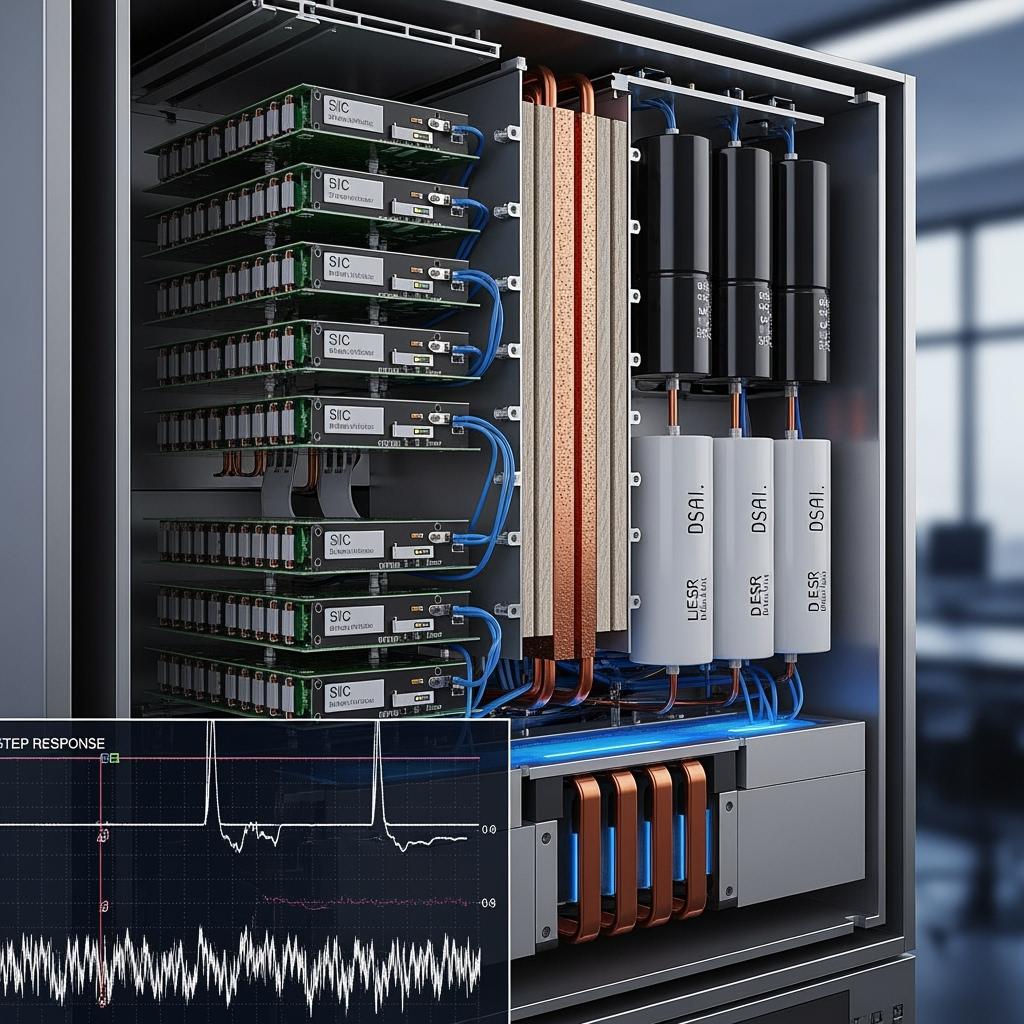

Sicarbtech addresses swapping station needs across the entire conversion chain. For the grid side, three‑level neutral‑point‑clamped or active‑clamped SiC modules deliver clean, efficient AC/DC conversion with low filter burden. On the DC side, bidirectional conversion stages interface with battery clusters, covering wide voltage ratios and enabling formation, balancing, and controlled precharge. Active snubber networks and low‑ESR DC link capacitors stabilize fast edges without oversized filters.

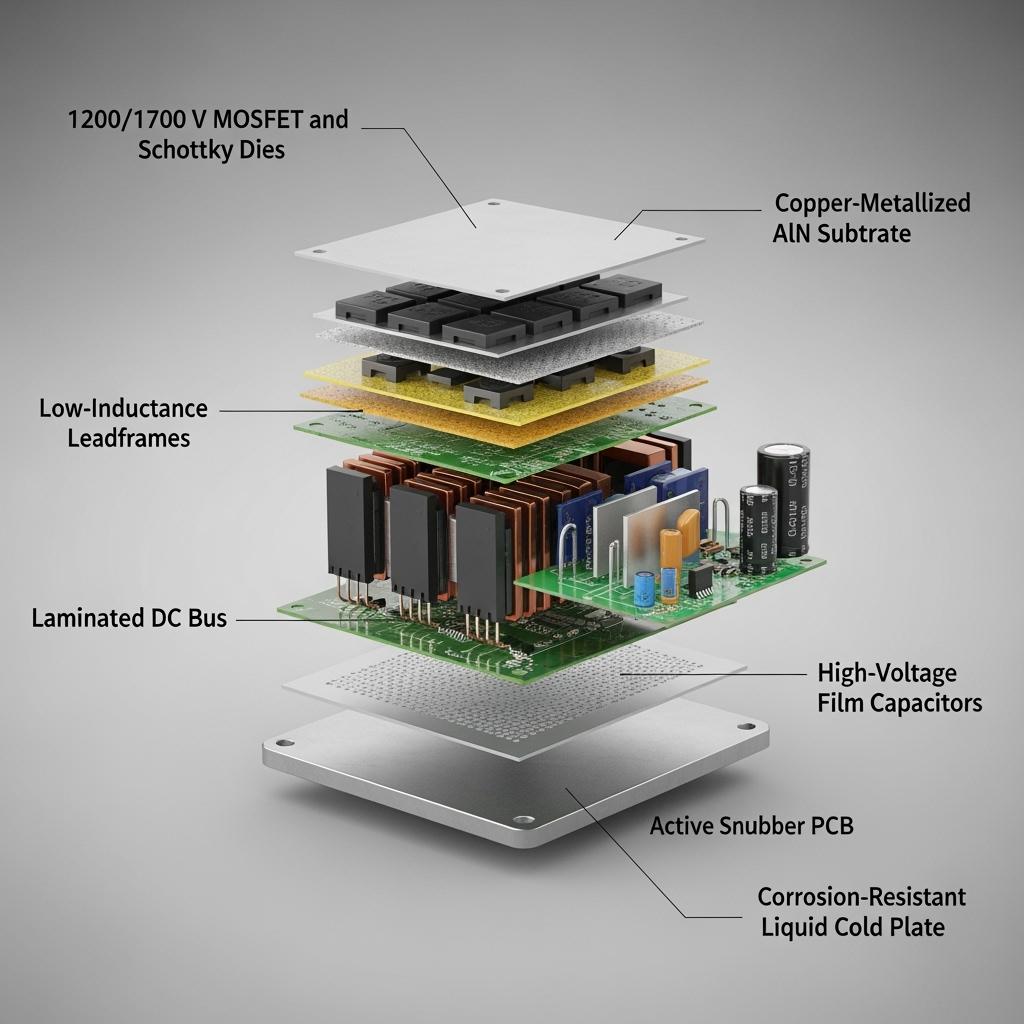

At the device level, customized 1200/1700 V SiC MOSFETs balance low on‑resistance and low gate charge using hybrid trench/planar designs that preserve oxide reliability at elevated temperatures. Third‑generation Schottky diodes contribute near‑zero reverse recovery charge, eliminating reverse spikes that “light up” EMI. Modules employ low‑inductance leadframes and compact loop geometries on copper‑metallized aluminum nitride (AlN) or silicon nitride (Si3N4) ceramic substrates. Sintered‑silver die attach and topside interconnects replace solder, raising thermal conductivity and power cycling life—critical in hot stations with frequent load steps.

Laminated busbars reduce loop inductance and stabilize high‑frequency current sharing. Gate drivers integrate short‑circuit protection, Miller clamping, undervoltage lockout, and adjustable edge rates for precise dV/dt shaping. Cooling choices range from corrosion‑resistant liquid cold plates with anti‑scaling coatings to robust air paths with washable filters, while high‑conductivity interface materials maintain low thermal resistance over time. “Design out parasitics and control your edges; filters and bigger heatsinks become right‑sized instead of oversized,” explains a Sicarbtech senior applications engineer with multiple Pakistan site ramps.

Performance Comparison: Silicon Carbide vs Traditional Materials for Swapping Stations

The table below distills outcomes that matter for interconnection, throughput, and lifecycle cost in Pakistan’s climate and grid conditions.

Swapping Station Conversion Efficiency, Dynamics, and Thermal Headroom

| Metric in Local Use | Sicarbtech Silicon Carbide Stack | Conventional Silicon-Based Stack | Practical Impact in Pakistan |

|---|---|---|---|

| Grid/DC-link peak efficiency | 98.5%–99.0% (three-level) | 97.2%–98.0% | Lower heat, smaller cooling |

| Station round-trip efficiency uplift | +0.8–1.5 percentage points | Linia bazowa | More swaps/kWh; lower OPEX |

| Power step response (grid or battery) | Millisecond-class, low overshoot | Slower, higher overshoot | Stable DC bus; faster turnaround |

| Input current THD, PF | ≤3% THD; PF ~0.99–1.00 | 3%–5% THD; PF 0.97–0.99 | Aprovações de interconexão mais fáceis |

| Switching frequency bands | 5–20 kHz (3L); 10–30 kHz (2L DC/DC) | Lower bands | Smaller magnetics/filters |

| Module/busbar parasitics | <10 nH targets | 15–30 nH | Less ringing; simpler EMC |

| Thermal headroom (Tj,max) | 175–200°C (package-dependent) | 150–175°C | Fewer deratings >40°C ambient |

| Cooling power consumption | −10–20% vs baseline | Linia bazowa | Lower energy cost, less noise |

| Cabinet footprint/weight | −25–40% volume; −15–30% weight | Larger/heavier | Faster deployment, lower civil cost |

| Lifecycle economics | Lower TCO | Higher TCO | Longer warranties; higher availability |

Real‑World Applications and Success Stories: Localized Narratives

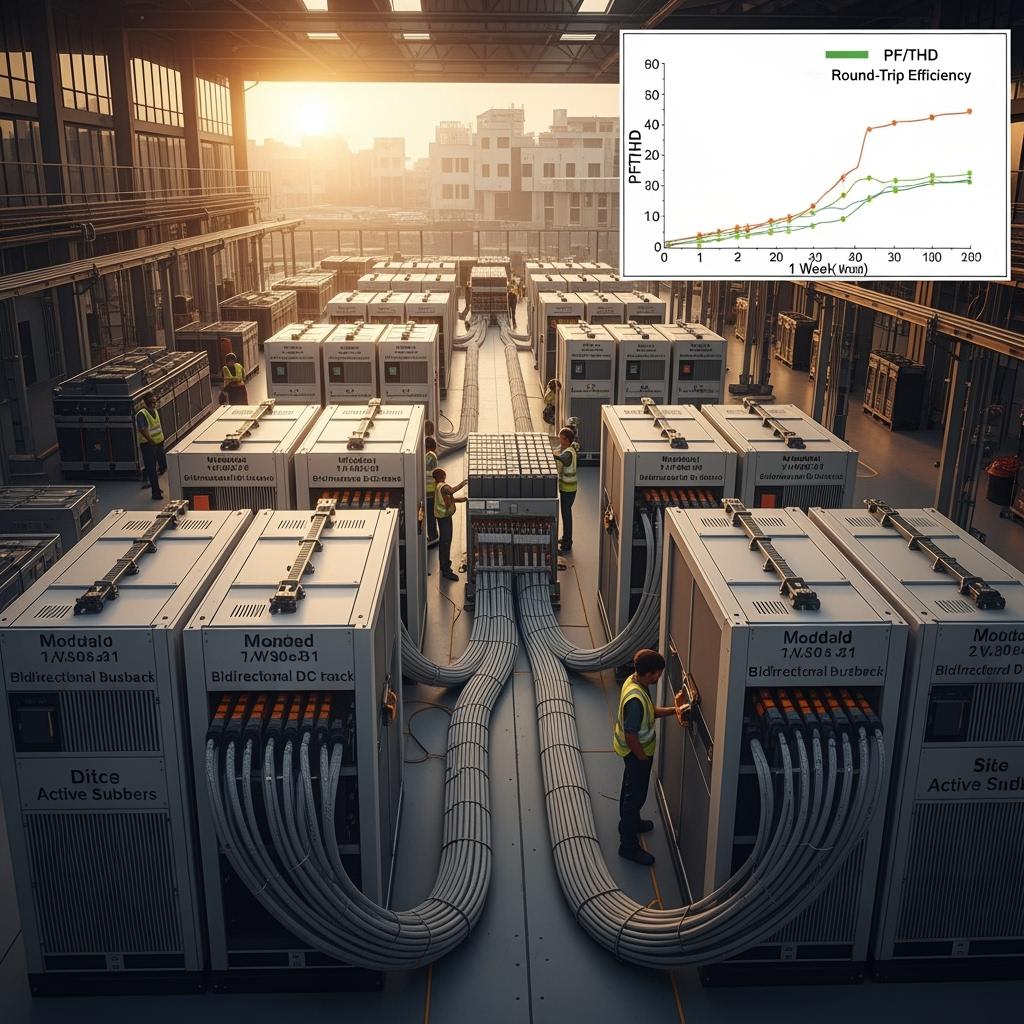

A Lahore inner‑city swapping pilot integrated a SiC three‑level grid converter with laminated busbars and active snubbers. Commissioning cleared THD and PF targets on the first audit, avoiding filter upsizing. Station telemetry during June–August showed roughly 1.1 percentage points higher round‑trip efficiency and a 12% reduction in combined fan/pump energy. Operators reported steadier DC bus voltage during simultaneous swap events, which shortened vehicle turnaround time.

In Karachi, a coastal highway swapping hub adopted sealed SiC modules with corrosion‑resistant cold plates and protected fasteners. After a monsoon cycle, inspections found stable insulation resistance and minimal corrosion at busbar terminations. Despite high humidity and salt mist, the station maintained throughput with fewer nuisance trips; acoustic measurements confirmed lower fan speeds at equivalent load.

A Faisalabad fleet depot deployed SiC bidirectional DC stages for on‑site buffer storage. By shaping dV/dt with gate drivers and minimizing loop inductance, conducted emissions dropped into compliance with comfortable margins. With modular racks, the depot expanded capacity in phases without reworking the DC bus layout, keeping construction windows short and availability high.

Zalety techniczne i korzyści z wdrożenia z lokalną zgodnością

SiC’s device physics—low loss at high frequency—becomes transformative when paired with low‑parasitic packaging and disciplined edge control. Higher switching frequency shrinks magnetics and filters and increases control bandwidth, so the station can respond to simultaneous swaps without destabilizing the DC bus. Clean Schottky recovery and laminated busbars suppress ringing and overshoot at the source, reducing snubber stress and EMC filter size. Adjustable dV/dt and Miller clamping allow engineers to hit conducted and radiated emission targets while retaining efficiency.

On the thermal side, copper‑metallized AlN/Si3N4 substrates and sintered‑silver interconnects create short, high-conductivity paths that preserve junction margins even when airflow is reduced to limit dust ingress. Corrosion‑resistant cold plates with anti‑scaling coatings maintain heat transfer despite variable water quality. Sealed module housings and moisture‑resistant encapsulants protect creepage and insulation in high‑humidity and salt‑mist environments common along the coast. Practically, this engineering stack compresses commissioning time, reduces cooling energy, extends maintenance intervals, and underpins longer warranties with reliability data that mirrors Pakistan’s conditions.

Comparative Portfolio View for Station Decision‑Makers

Mapping Pakistan’s Swapping Requirements to Sicarbtech’s SiC Building Blocks

| Local Requirement | Sicarbtech SiC MOSFETs (1200/1700 V) | Sicarbtech 3rd‑Gen Schottky Diodes | Sicarbtech Three‑Level + Bidirectional DC Modules with Laminated Busbars | Conventional Silicon Options |

|---|---|---|---|---|

| High round‑trip efficiency | Low RDS(on), low Qg | Near‑zero Qrr | Low‑inductance geometry; active snubbers | Higher loss; larger cooling |

| Millisecond power steps | Controllable dV/dt | Clean recovery | High bandwidth; low parasitics | Slower loops; overshoot |

| Weak‑grid PQ compliance | Stable gates | Minimal spikes | ≤3% THD; PF ~0.99 with tuned filters | Heavier filters; longer tuning |

| Harsh environment resilience | High Tj capability | EMI‑friendly | AlN/Si3N4 + sintered silver; sealed | Thermal fatigue; corrosion risk |

| Compact modular cabinets | High‑frequency operation | Lower switching loss | Smaller magnetics; denser racks | Bulky magnetics/filters |

Deep‑Dive Engineering Comparison for Heat, Humidity, and Dust

Device, Packaging, and System Parameters Tuned for Pakistani Stations

| Parametr | Sicarbtech SiC Stack (Device + Module + Interconnect) | Typical Silicon Stack | Operational Implication in Pakistan |

|---|---|---|---|

| On‑resistance vs temperature | Modest increase up to 125°C+ | Steeper increase | Stable output during heat waves |

| Reverse recovery charge | ~0 (Schottky) | Alta | Lower EMI; smaller filters |

| Max junction temperature | 175–200°C (package‑dependent) | 150–175°C | Downsized cooling; fewer deratings |

| Module/busbar inductance | <10 nH targets | 15–30 nH | Cleaner edges; less snubbing |

| Thermal interface | Sintered silver | Solder | Longer power cycling life |

| Substrate material | AlN/Si3N4 with Cu | Alumina common | Better heat spread, toughness |

| Częstotliwość przełączania | 5–20 kHz (3L); 10–30 kHz (DC/DC) | Lower bands | Smaller magnetics/filters |

| Çevresel sızdırmazlık | Dust/salt‑mist‑resistant | Generic | Fewer ingress failures |

| Efficiency uplift (system) | +0.8–1.5 percentage points | Linia bazowa | Better LCOS and throughput |

| Lifecycle economics | Lower TCO | Higher TCO | Longer warranties; fewer outages |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s competitive edge in Pakistan is the ability to deliver both high‑performance SiC hardware and the capability to build, validate, and maintain it locally with predictable quality. From Weifang City and within the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech leverages advanced R&D and proprietary processes for R‑SiC, SSiC, RBSiC, and SiSiC ceramic grades—materials that underpin thermal conductivity and corrosion resistance in outdoor stations.

For OEMs, EPCs, and station operators, Sicarbtech provides complete technology transfer packages: epitaxial growth (CVD) recipes tailored to 1200/1700 V devices; device and gate design guidance that balances low RDS(on), low gate charge, and oxide reliability; metallization stacks on AlN/Si3N4; sintered‑silver process windows for robust die attach and topside; and module pinout, passivation, and creepage strategies for high‑humidity, salt‑mist operation. Equipment specifications cover utilities and environmental controls, sintering presses, dicing and bonding tools, coating stations, active snubber calibration rigs, leak and IP testers, and parasitic/thermal metrology.

Training programs upskill operators, process/test engineers, quality teams, and application engineers in statistical process control, power cycling and HT/HH screening, salt‑spray testing, and EMC/thermal co‑design. Factory establishment services proceed from feasibility studies suited to Pakistani utilities and labor markets through pilot line setup, qualification, and yield ramp using SPC. Quality frameworks align with ISO 9001 and ISO 14001, and Sicarbtech supports pathways to relevant IEC/UL converter and component tests alongside local interconnection and PQ expectations. Ongoing support includes quarterly process audits, reliability dataset refreshes, and on‑call application engineering to tune laminated busbars, dV/dt, snubbers, magnetics, and cooling interfaces based on field telemetry.

“Scaling SiC is less a shopping list than a measurement habit—yields track what you monitor every shift,” says a Sicarbtech process transfer leader. With 10+ years of customization and collaborations with 19+ enterprises, Sicarbtech brings a repeatable playbook that compresses time‑to‑SOP and stabilizes ramp economics.

Future Market Opportunities and 2025+ Trends: Swapping Networks’ Next Chapter

As EV fleets grow and distribution upgrades lag, stations with buffer storage and high‑efficiency conversion will dominate. Three‑level and modular DC architectures will standardize, enabling phased expansion and faster civil works. SiC penetration in station converters should trend toward 30–50% in mid‑to‑high‑end deployments over the next several years, with faster uptake in hot and coastal regions where cooling and corrosion dominate lifecycle cost. Integration with rooftop PV or local wind will expand, building DC‑bus microgrids that arbitrage tariffs and support demand response.

Bankability will hinge on local‑condition reliability evidence: power cycling at elevated junction temperatures, damp‑heat and salt‑mist endurance, dust ingress performance, and long‑run PQ/EMC telemetry. Vendors that combine materials–devices–modules–equipment integration with authentic technology transfer and responsive local service will hold a structural advantage—reducing FX exposure and spare‑part lead times while building in‑country capability for screening, repair, and upgrades.

Perguntas frequentes

What efficiency gains can a Pakistan-based swapping station expect from SiC?

Most projects see 0.8–1.5 percentage points higher round‑trip efficiency and peak grid/DC‑link efficiency of 98.5–99.0%, with the largest benefits during hot months when cooling overhead is highest.

How does Sicarbtech address dust, humidity, and salt mist for coastal stations?

We combine sealed modules, corrosion‑resistant coatings and fasteners, moisture‑resistant encapsulants, and high‑creepage layouts. Copper‑on‑AlN/Si3N4 substrates and sintered silver maintain thermal integrity even when airflow is reduced to limit dust ingress.

Can SiC stations meet PQ and EMC requirements on weak feeders?

Yes. Low loop inductance (<10 nH targets), clean Schottky recovery, and tuned dV/dt reduce ringing and overshoot. With right‑sized filters, ≤3% THD and near‑unity PF are common, easing interconnection approvals.

Which device voltages and topologies fit swapping stations best?

1200/1700 V SiC devices in three‑level grid converters and high‑frequency bidirectional DC stages cover 750–1000 V DC buses and wide battery voltage ranges. Choice depends on power class, filter targets, and cabinet form factor.

Why are sintered silver and AlN/Si3N4 substrates vital in Pakistan’s heat?

They provide high thermal conductivity and mechanical robustness, slowing interface aging and extending power cycling life under thermal cycling, dust, and humidity—key for long warranties.

Will faster SiC switching make EMC harder to pass?

If unmanaged, yes. Sicarbtech’s low‑parasitic modules, laminated busbars, adjustable gate resistors, and Miller clamping minimize ringing. In practice, co‑designed SiC stacks often pass with smaller filters and shorter tuning cycles.

Can Sicarbtech support local assembly and reliability screening in Pakistan?

Yes. We offer technology transfer, equipment specifications, training, ISO‑aligned quality frameworks, commissioning assistance, and ongoing audits. Phased localization reduces FX risk and spare‑part lead times.

What reliability testing is available for Pakistan‑specific stressors?

Power cycling, temperature cycling, high‑temperature/high‑humidity (damp heat), neutral salt spray, dust ingress cycles, and online screening. We share acceleration models and co‑develop validation plans to support extended warranties.

How fast can a pilot station be deployed and evaluated?

Typically within weeks to a few months. We recommend A/B trials tracking round‑trip efficiency, PF/THD logs, power step response, thermal maps, EMC margins, availability, and maintenance intervals.

What total cost of ownership improvements are typical?

Despite higher device cost, lower energy and cooling use, reduced transformer upgrades via peak shaving, smaller cabinets, and fewer maintenance events yield lower TCO and stronger bankability over 10–15 years.

Fazendo a escolha certa para suas operações

Start with your feeder realities and throughput goals: available grid capacity, tariff structure, ambient temperature and humidity, dust exposure, space constraints, and service cadence. When Sicarbtech co‑designs from epitaxy and gate oxide reliability through module parasitics, laminated busbar geometry, active snubbers, magnetics, thermal interfaces, and dV/dt control, the benefits compound—higher efficiency, smaller and quieter cabinets, faster commissioning, and stronger compliance and warranty narratives. For operators in Karachi, Lahore, Islamabad–Rawalpindi, and Faisalabad, SiC‑based stations convert grid constraints and harsh climates into a durable competitive advantage.

Obtenha consultoria especializada e soluções personalizadas

Whether you are specifying a new SiC swapping station, retrofitting buffer storage, or exploring localized assembly and reliability screening, Sicarbtech will turn your KPIs into a data‑backed plan with milestones for performance, compliance, and ramp. Contact our engineering team at [email protected] or +86 133 6536 0038.

Metadados do artigo

Last updated: 2025-09-17

Next scheduled review: 2025-12-01

Content freshness indicators: 2025 Pakistan swapping outlook; SiC 1200/1700 V devices; three-level and bidirectional DC architectures; laminated low-parasitic busbars; PF/THD and millisecond step-response targets; HT/HH and salt-mist reliability; localization and technology transfer pathways; case narratives in Lahore, Karachi, and Faisalabad.

About Sicarbtech: Silicon Carbide Solutions Expert headquartered in Weifang City, China’s silicon carbide manufacturing hub; member of Chinese Academy of Sciences (Weifang) Innovation Park; 10+ years of SiC customization supporting 19+ enterprises; full-cycle solutions from material processing to finished products; specializing in R‑SiC, SSiC, RBSiC, and SiSiC grade products; services include custom manufacturing, factory establishment, and technology transfer.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.