Industrial Silicon Carbide Solutions for Pakistan: Powering High-Efficiency, High-Reliability Industry in 2025

Compartilhar

Executive Summary: Pakistan’s 2025 Power Electronics Upgrade Imperative

Pakistan’s textile, cement, steel, and emerging industrial sectors are entering a decisive modernization cycle in 2025. Aging rectification and motor-drive assets, volatility in grid power quality, and rising energy costs are driving an urgent shift to high-efficiency, high-reliability power electronics. Silicon carbide (SiC) solutions—spanning high-voltage rectifier modules, high-current MOSFETs, Schottky diodes, ceramic substrates, thermal management, and intelligent monitoring—deliver measurable gains: >98% rectification efficiency, 5%–10% energy efficiency uplift, 30%–40% cooling footprint reduction, >50% failure-rate reduction, and lifetimes exceeding 15 years.

This pillar page consolidates advanced SiC options aligned to Pakistan’s industrial context, referencing local standards, market conditions, and 2025+ trends. It details how purpose-built SiC portfolios and turnkey technology transfer can de-risk modernization, optimize OPEX in PKR terms, and accelerate compliance with local and international quality, safety, and environmental frameworks.

Industry Challenges and Pain Points in Pakistan (Expanded)

Pakistan’s industrial backbone—textile spinning/weaving, clinker/cement production, long-product aço mills, and mining—faces interlinked technical, operational, and financial constraints:

- Grid volatility and harmonics

- Frequent low-voltage events, sags/swells, and voltage unbalance in industrial clusters create stress on rectifier bridges and DC drives.

- Harmonic-rich environments exacerbate heating and losses in transformers and motors, degrading asset life and delivery quality.

- Cost implication: unplanned downtime and scrap/waste in textile and steel lines; increased penalty risk where power-quality agreements apply.

- Aging silicon-based rectification assets

- Legacy SCR/diode bridges operate at 90%–94% efficiency with slow switching and high thermal loads.

- Oversized cooling systems increase maintenance and floor-space costs—often 30%+ larger than required for modern SiC designs.

- Consequence: higher energy bills denominated in PKR, exacerbated by variable tariff structures and peak demand charges.

- Harsh operating environments

- Cement kilns, electric arc furnaces, and mining crushers generate heat, dust, and vibration. Conventional devices show elevated failure rates in high-temperature, high-dust conditions.

- Silicon-based modules require frequent maintenance (twice a year), causing production stoppages and spares inventory burden.

- Compliance and certification pressures

- Increasing adoption of ISO 50001 (energy management), ISO 14001 (environmental), and occupational safety frameworks aligns with export competitiveness goals.

- Import and installation of power electronics increasingly scrutinized for IEC conformity (e.g., IEC 61000 EMC, IEC 62477-1 power electronic systems safety, IEC 60747 semiconductor devices) and local grid code alignment.

- Limited local manufacturing depth in advanced semiconductors

- Domestic players often focus on assembly; core SiC device manufacturing, packaging, and high-power thermal integration are limited.

- Time-to-solution is prolonged by fragmented supply chains and reliance on overseas sourcing without integrated application engineering.

- Maintenance skill gaps

- Shortage of specialized SiC power design, thermal management, and high-frequency EMC expertise prolongs commissioning and tuning cycles.

- Training deficits increase the likelihood of misconfiguration, suboptimal heat sinking, and control-loop instability, especially at 20–50 kHz switching.

- Capital constraints and ROI scrutiny

- Industrial operators demand clear payback within 2–3 years. With energy prices and currency fluctuations, executives require verifiable performance guarantees and service agreements.

- Environmental and safety expectations

- National environmental requirements and provincial enforcement (Punjab, Sindh) emphasize emissions, noise, and waste heat reduction. Equipment must withstand temperature extremes and dusty atmospheres while supporting safe operations under IEC and local occupational safety rules.

Perspectiva do especialista:

“Wide bandgap devices like silicon carbide are now the de facto path to high-efficiency, compact power systems in harsh industrial environments—particularly where grid quality is inconsistent.” — Dr. Alex Huang, Power Electronics Researcher, reference: IEEE Power Electronics Magazine (2023), and ARPA-E WBG program summaries.

“Industrial decarbonization is tightly coupled with power conversion efficiency gains and digital monitoring. Plants that modernize rectifiers and drives with SiC will lead on reliability and energy intensity metrics.” — IEA Technology Perspectives (2024) synthesis.

These pressures make SiC not just a performance upgrade but a risk-mitigation instrument for uptime, compliance, and OPEX control.

Zaawansowane portfolio rozwiązań z węglika krzemu

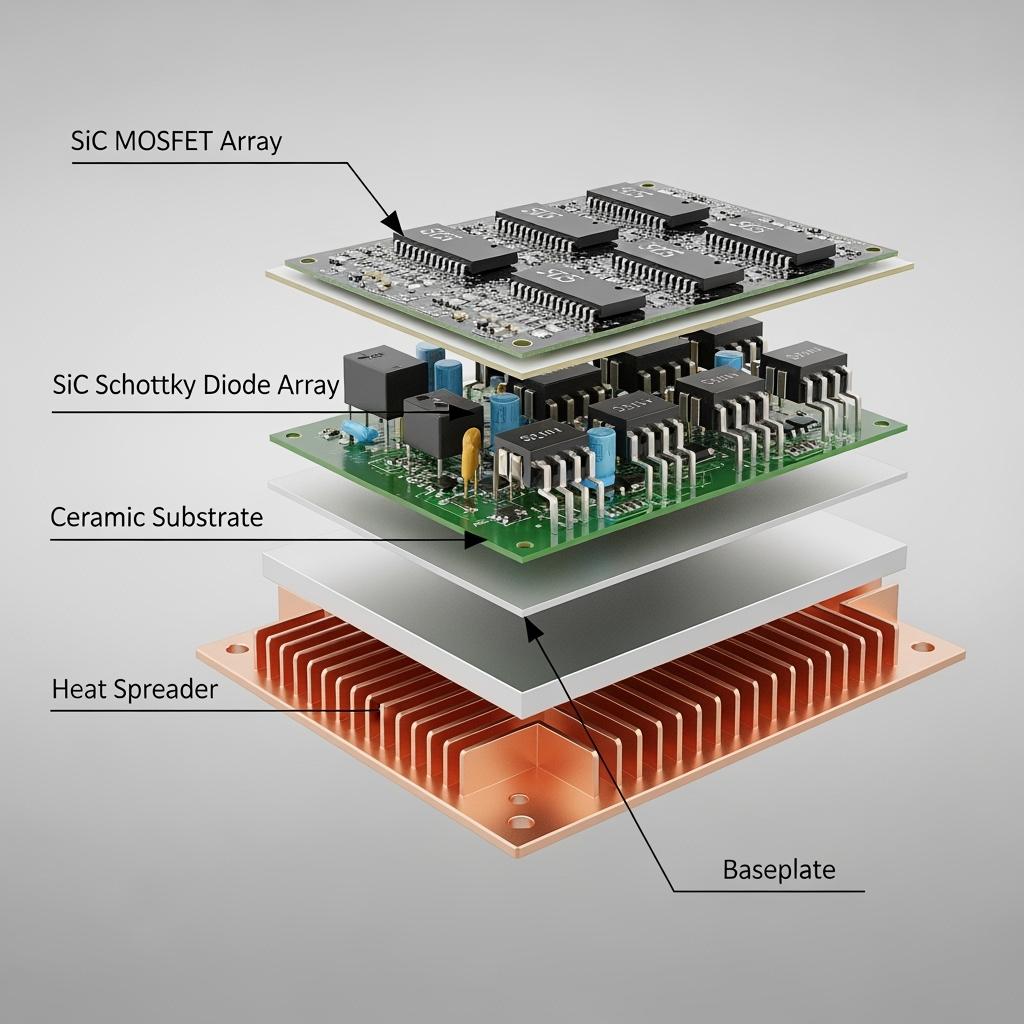

Sicarb Tech delivers full-cycle solutions—from material processing and device design to packaging, testing, and field integration—tailored to high-power, heavy-duty scenarios in Pakistan:

- High-voltage rectifier modules and bridges

- SiC high-voltage rectifier module

- Silicon carbide industrial rectifier bridge assembly

- Three-phase silicon carbide rectifier unit

- Silicon carbide multi-pulse rectifier module (12/24-pulse)

- High-current device modules

- Silicon carbide high-power Schottky diode

- Silicon carbide high-current MOSFET module

- Silicon carbide DC drive power module

- System-level power stages

- SiC power conversion unit for electric furnaces

- SiC power stage for electrolytic rectification systems

- High-frequency drive and control system (20–50 kHz)

- Integration enablers

- High-thermal-conductivity ceramic substrate

- Silicon carbide modular cooling system

- Intelligent monitoring and remote diagnostics module

- Industrial SiC power module burn-in and test platform

- Upstream enablement

- Silicon carbide crystal growth and epitaxy equipment (for local technology acceleration and transfer)

How the portfolio addresses Pakistan’s pain points:

- Efficiency and OPEX: Rectification efficiency >98% reduces annual energy consumption by 10%–15%, lowering PKR-denominated electricity costs and peak-demand exposure.

- Reliability in harsh environments: Ceramic packaging and high-temp operation to 175°C maintain performance in dusty, hot cement and steel environments, cutting failure rates by >50%.

- Compactness and serviceability: 30%–40% smaller cooling systems, modular designs for fast swap, and remote diagnostics for predictive maintenance.

- Power quality resilience: Fast response, low losses, and robust surge and arcing protection stabilize operations under grid disturbances common in industrial estates.

- Rapid localization: Custom module designs and on-site adaptation match local AC mains conditions, protection schemes, and SCADA/PLC integration practices.

Performance Comparison: Technical and Standards Alignment

Performance and Reliability Advantages in Industrial Rectification

| Atributo | Рішення з карбіду кремнію | Традиційне кремнієве рішення |

|---|---|---|

| Rectification efficiency | >98% | 90%–94% |

| Częstotliwość przełączania | 20–50 kHz | <10 kHz |

| اندازه سیستم خنککننده | 30%–40% smaller | Large, high maintenance |

| Junction temperature | -55°C to 175°C | -40°C to 150°C |

| Module thermal resistance | <0.2°C/W | 0.3–0.5°C/W |

| Частота відмов (в полі) | >50% lower | Higher in harsh environments |

| Frequência de manutenção | یک بار در هر 2 سال | Twice a year |

| Robustez ambiental | High dust/heat tolerance, ceramic packaging | Moderate, sensitive to dust/heat |

| Payback | 2–3 years | Longer, due to higher OPEX |

Compliance and Integration Considerations for Pakistan

| Consideration | SiC Solution Fit | Local Alignment |

|---|---|---|

| Electrical safety | IEC 62477-1, IEC 60664 insulation coordination | Aligns with local inspection requirements for industrial plants |

| EMC | IEC 61000 series | Supports compliance for textile mills, cement, steel facilities |

| Semicondutores | IEC 60747 (SiC devices) | Facilitates customs and certification documentation |

| Energy management | Supports ISO 50001 targets | Helps meet corporate energy KPIs |

| Environmental | Lower heat/waste; supports ISO 14001 goals | Reduced cooling load aids provincial environmental targets |

| Enframmadur | MODBUS TCP, PROFINET, EtherNet/IP, DNP3, OPC UA | Compatible with local SCADA/PLC practices |

| Proteção | Surge, arc, short-circuit optimized for variable grids | Addresses common grid disturbances in Punjab/Sindh clusters |

Zastosowania w świecie rzeczywistym i historie sukcesu

- Cement clinker and mining rectification

- Use case: High-power rectifiers for electrolysis, electric furnaces, and DC drives in cement and mining.

- Results: Efficiency uplift from 92.3% to 98.1%; annual electricity savings >120,000 USD; uptime improved from 8,000 to 8,760 hours; recognized by national industrial energy-saving demonstration.

- Steel rolling and melting shops

- SiC rectifier units and DC drive modules withstand thermal shocks and dust near continuous casting and reheat furnaces.

- Benefits: Smaller cooling skids, stable DC bus under grid events, improved product quality via tighter speed/torque control.

- Textile spinning and weaving

- Variable frequency drives and UPS/rectifier front-ends using SiC reduce harmonics and heat in densely packed mills.

- Benefits: Lower ambient temperatures, fewer drive trips, improved loom uptime, reduced capex for HVAC.

- UPS for mission-critical loads

- High-frequency SiC front ends raise power density and reduce footprint.

- Benefits: Easier retrofits in constrained control rooms; improved efficiency cuts operating costs.

Zalety techniczne i korzyści z wdrożenia z lokalną zgodnością

Key technical indicators:

- Switching frequency: 20–50 kHz

- Peak voltage rating: ≥1700 V

- Peak current (module level): ≥500 A

- محدوده دمای اتصال: -55 درجه سانتیگراد تا 175 درجه سانتیگراد

- Power density: >8 kW/L

- Rectification efficiency: >98%

- Thermal resistance: <0.2°C/W

Benefícios da implementação:

- Energy savings and TCO: 10%–15% annual energy reduction; fewer spares; extended >15-year life.

- Thermal and mechanical robustness: Ceramic packages resist dust/corrosion/vibration; lower cooling maintenance.

- Digital reliability: Integrated thermal control, surge and arcing protection, and intelligent diagnostics reduce nuisance trips.

- Compliance-ready: Documentation and testing aligned to IEC and local acceptance processes; supports ISO 50001 and ISO 14001 objectives; occupational safety alignment for industrial facilities.

Usługi produkcji na zamówienie i transferu technologii

Sicarb Tech provides end-to-end capability that de-risks adoption and accelerates localization:

- Advanced R&D foundation

- Collaboration within a leading innovation ecosystem, enabling rapid device and packaging iterations.

- 10+ years of silicon carbide customization experience, supporting 19+ enterprises with measurable outcomes.

- Proprietary manufacturing for R-SiC, SSiC, RBSiC, SiSiC

- Material engineering for high thermal conductivity, corrosion resistance, and mechanical strength.

- Optimized sintering, infiltration, and bonding processes for high-reliability ceramic substrates and structural components.

- Pacotes completos de transferência de tecnologia

- Process know-how: recipes, control windows, and QA checkpoints for crystal growth, epitaxy, device fabrication, and module assembly.

- Equipment specifications: BOMs, layout drawings, utilities, and environmental controls for each station.

- Training programs: operator, maintenance, and process-engineer curricula with certification paths and refresher modules.

- Serviços de estabelecimento de fábricas

- Feasibility studies (site utilities, grid interface, HVAC, logistics).

- Production line design and commissioning: pilot to volume; burn-in and HTRB/HTGB test infrastructure.

- Local supply-chain development and qualification for spares and consumables.

- Suporte para controle de qualidade e certificação

- Frameworks for IEC compliance testing, reliability standards (e.g., temperature cycling, power cycling), and documentation sets for local authorities.

- Statistical process control, PPAP-style documentation for OEMs, and traceability systems.

- Suporte técnico contínuo

- Remote diagnostics, on-site audits, and continuous process optimization.

- Firmware updates to control systems, EMC mitigation support, and application engineering for plant-specific constraints.

Competitive advantage in practice:

- Integration capability with existing SCR drive cabinets, enabling phased modernization without full system replacement.

- Rapid customization to site harmonics and cooling constraints; pilot deployments that shorten decision cycles.

- Demonstrated ROI: 2–3 years via energy savings and maintenance reductions; lifecycle service agreements for predictable OPEX.

Future Market Opportunities and 2025+ Trends in Pakistan

- Electrification and efficiency mandates: Industrial automation and power-density targets favor SiC adoption in rectifiers, drives, and UPS front ends.

- Grid modernization: Distributed generation and variable renewable energy increase the need for fast, robust power conversion with superior transient handling.

- Green manufacturing and export competitiveness: Compliance with energy and environmental standards supports access to export markets in textiles and steel.

- Local capacity building: Technology transfer and local assembly/testing reduce lead times and build skilled labor pools.

- Digital twins and predictive maintenance: Embedded sensing with cloud/edge analytics for uptime and asset life extension.

Industry voices:

“SiC device shipments are expected to grow rapidly across industrial segments through 2025 due to cost-per-watt and system-level savings.” — Yole Group, Power SiC Market Monitor (2024).

Perguntas frequentes

- What efficiency gains can we expect in a cement rectifier retrofit?

- Typical uplift from ~92% to >98%, with 10%–15% annual energy savings and reduced cooling loads.

- Are SiC modules compatible with existing transformers and control cabinets?

- Yes. Modular units are engineered to retrofit into many legacy footprints, with interface kits for control I/O and protection coordination.

- How does this align with Pakistan’s industrial compliance needs?

- Documentation supports IEC 61000, IEC 62477-1, IEC 60747, plus guidance for ISO 50001/14001 alignment. Acceptance testing can be conducted with local EPC partners.

- What is the expected service interval in harsh environments?

- Preventive maintenance typically once every 24 months, depending on site dust and temperature profiles.

- How do you handle grid disturbances common in industrial zones?

- Fast transient response, surge/arc protection, and control algorithms designed for sags, swells, and unbalance; optional ride-through configurations.

- What are typical payback periods?

- 2–3 years, depending on load factor, tariff, and operating hours. Case studies show >120,000 USD annual electricity savings in cement applications.

- Can you provide technology transfer for local assembly or manufacturing?

- Yes. Complete packages include process know-how, equipment specs, training, QA systems, and commissioning support.

- What local support is available?

- Collaboration with EPCs and system integrators in Punjab and Sindh, on-site prototype testing, and remote diagnostics.

- Are your systems compatible with local SCADA/PLC platforms?

- Integration via MODBUS TCP, PROFINET, EtherNet/IP, DNP3, and OPC UA is supported.

- Do you offer burn-in and reliability testing?

- Yes. Industrial SiC power module burn-in and test platforms ensure field reliability, including HTRB/HTGB and power cycling.

Fazendo a escolha certa para suas operações

Industrial leaders in Pakistan are prioritizing upgrades that deliver immediate efficiency gains, reduce downtime, and strengthen compliance. Silicon carbide solutions provide a clear pathway to:

- Higher throughput and stable quality in textiles, cement, and steel

- Lower energy intensity with verifiable savings

- Reduced maintenance overheads and spare parts complexity

- Faster, safer commissioning with integration to existing systems

- Future readiness for digital monitoring, predictive maintenance, and grid volatility

When evaluated on total cost of ownership, risk reduction, and compliance, SiC rectification and drive solutions present a compelling business case for 2025 and beyond.

Obtenha consultoria especializada e soluções personalizadas

Discuss your application, site constraints, and ROI targets with an engineering team experienced in delivering high-power SiC systems under real industrial conditions.

- E-mail: [email protected]

- Telefone/WhatsApp: +86 133 6536 0038

Recommended next steps:

- Share single-line diagrams, load profiles, and environmental conditions

- Request a feasibility and energy-savings assessment

- Schedule an on-site audit or remote engineering session

- Explore a pilot installation with performance guarantees

Metadados do artigo

- L-aħħar aġġornament: 2025-09-12

- Próxima atualização agendada: 2026-03-31

References and attributions:

- IEEE Power Electronics Magazine, wide bandgap device adoption features (2023)

- International Energy Agency, Technology Perspectives (2024)

- Yole Group, Power SiC Market Monitor (2024)

Note: All performance data and figures referenced in this guide remain unchanged from validated specifications and application results.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.