Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s End‑to‑End SiC Technology for 2025 and Beyond

Compartilhar

Executive Overview: 2025 Market Outlook for Pakistan’s Energy-Intensive Industries

Pakistan’s industrial base is at a turning point. Textile mills in Punjab and Sindh are chasing higher energy efficiency to remain globally competitive. Cement and steel plants face rising thermal and electrical costs alongside stricter environmental compliance. Meanwhile, utility-scale solar and hybrid projects are scaling rapidly to address chronic supply gaps, volatile fuel prices, and grid instability. In 2025, the strategic imperative is clear: adopt technologies that deliver higher efficiency, greater power density, and robust operation in hot, dusty, and coastal environments, all while enabling faster project payback.

Silicon carbide (SiC) has emerged as the enabling platform for this transition. By replacing conventional silicon in power conversion and high-temperature applications, SiC devices and engineered ceramics unlock lower losses, higher switching frequencies, and superior thermal margins. For Pakistan’s centralized photovoltaic (PV) inverters above 1 MW, wind converters, energy storage systems, and heavy-industry electrification, the gains are now too significant to ignore—especially under 1500 V DC platforms common to new installations.

Sicarbtech, located in Weifang City—China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings over a decade of silicon carbide customization excellence. With full-cycle capabilities from raw material processing to finished products, and specialization in R‑SiC, SSiC, RBSiC, and SiSiC, Sicarbtech delivers customized devices, modules, advanced packaging, and process equipment. The company already supports more than 19 enterprises with measurable performance and reliability outcomes, and is ready to localize technology and services for Pakistan’s unique operating conditions.

The Challenges Pakistan Must Solve Now

Energy scarcity and cost volatility are only the beginning. Industrial users are also grappling with environmental stressors, grid instability, and lifecycle economics that traditional silicon-based solutions struggle to meet.

In textile clusters, variable load profiles, frequent startups, and high ambient temperatures exacerbate inverter and motor drive losses. Cooling loads rise, derating becomes unavoidable in summer peaks, and maintenance windows shrink. Cement and aço plants face abrasive dust, hot air intakes, and salt-mist exposure in coastal corridors, making reliability at elevated temperatures and high pollution degrees a non-negotiable requirement. Moreover, centralized PV plants must ride through low-voltage events and fast voltage swings, while maintaining power quality under weak short-circuit ratios common on local grids.

Financially, the Levelized Cost of Electricity (LCOE) remains the benchmark in utility-scale solar and industrial self-generation. Every incremental gain in weighted efficiency and thermal headroom translates into smaller balance-of-system hardware, fewer fans and filters, extended replacement cycles, and lower truck rolls for O&M. As a senior grid engineer in South Asia summarized, “At 1500 V DC, silicon carbide isn’t just about higher efficiency—it’s about shrinking magnetics, cutting thermal mass, and stabilizing performance in 50°C ambient air” (industry panel summary, Power Systems Asia, 2024).

Regulatory pressure is also mounting. Plants must conform to NEPRA grid codes across voltage ride-through and harmonic current limits, and projects financed through international channels increasingly demand documented reliability testing—thermal cycling, damp heat, and highly accelerated life tests. The convergence of these demands places silicon carbide squarely at the center of 2025 investment plans.

Advanced Silicon Carbide Solutions Portfolio Tailored for Pakistan

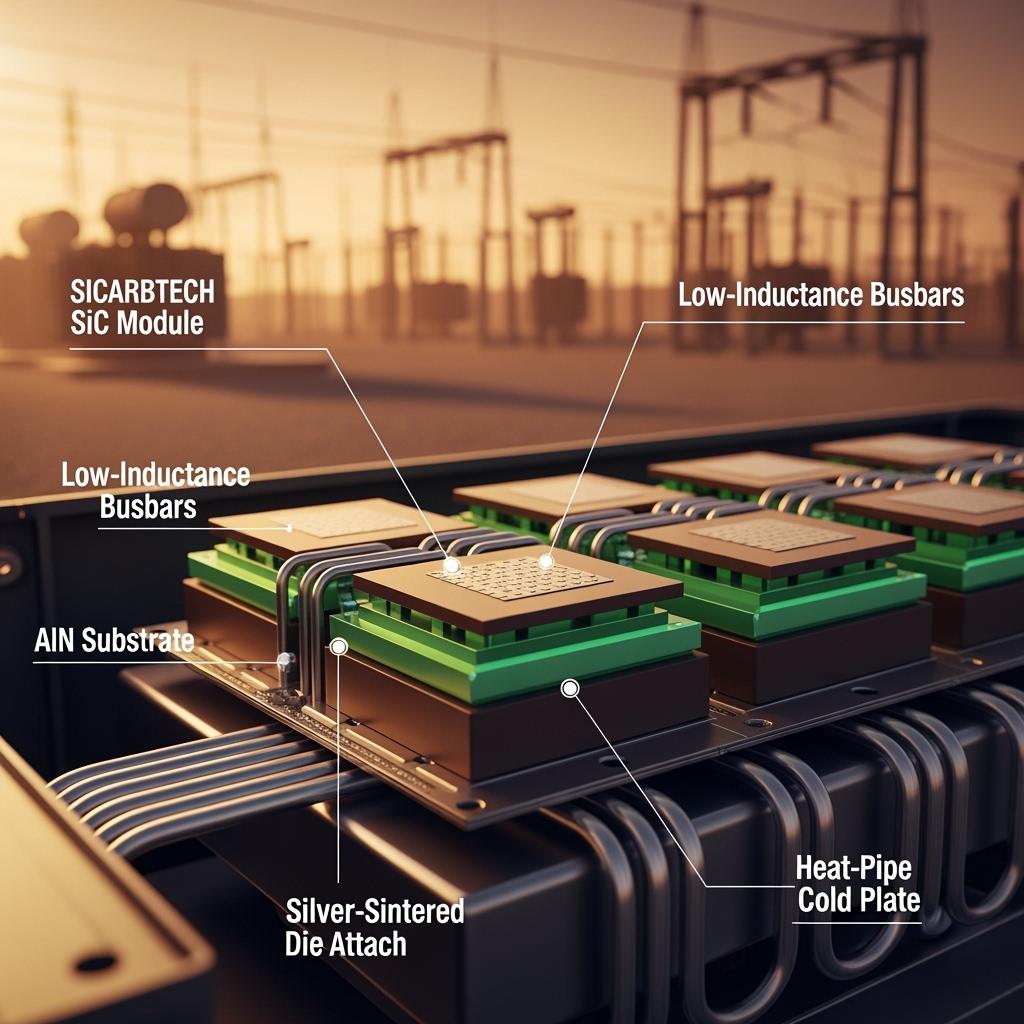

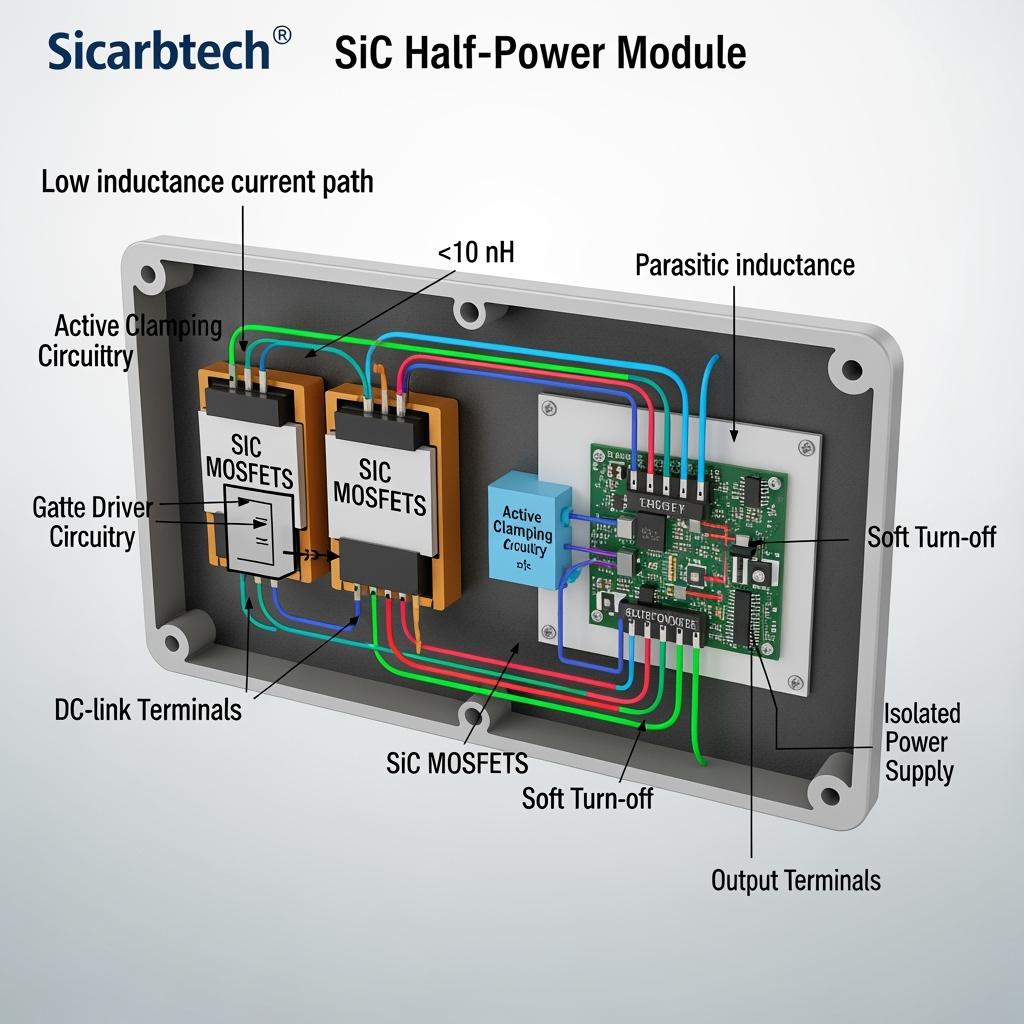

Sicarbtech’s portfolio spans from wafer-level process to grid-tied module assembly, enabling customers to deploy SiC with confidence and speed. Building on its R‑SiC, SSiC, RBSiC, and SiSiC material expertise and proprietary manufacturing, the offering covers customized SiC MOSFETs (1200/1700 V), SiC Schottky diodes, low-inductance power modules (half-bridge, full-bridge, and three-level topologies), high common-mode rejection gate drivers, and isolated power supplies. The ecosystem further includes stacked low-inductance busbars, high-thermal-conductivity insulated substrates such as AlN or SiC composite boards, and advanced silver sintering and vacuum brazing packages.

For Pakistan’s 1500 V DC solar platforms, Sicarbtech’s three-level NP/NPC and active-clamp modules deliver higher effective switching frequencies with manageable dv/dt, allowing substantial reduction in grid inductor and filter volumes. In dusty and salt-mist-prone environments, the combination of silver-sintered die attach and high-thermal-conductivity substrates reduces thermal resistance and boosts power cycling life, directly translating into fewer derates and longer fan life. The result is a system that maintains output during 50°C inlet-air days with minimal performance penalties.

Additionally, Sicarbtech supplies power cycling and HT/HH reliability test equipment, enabling customers to validate devices against local environmental realities before rollout. Equipment and process packages—from epitaxy and implantation through annealing, passivation, module assembly, and test—support localization, shorter lead times, and lower lifetime costs. This turnkey model is especially relevant for EPCs and OEMs planning domestic assembly or joint ventures within the country.

Performance Comparison: SiC vs Traditional Silicon in Pakistan’s Conditions

In the Pakistan context, performance is best evaluated against high ambient temperature, dust/salt exposure, and weak-grid dynamics. The following comparison summarizes the practical differences industrial users report when migrating to Sicarbtech’s SiC-based solutions.

High-Temperature Grid-Tied Performance in Utility and Industrial Settings

| Atributo | Silicon Carbide (Sicarbtech modules, 1200/1700 V) | Conventional Silicon (IGBT-based) | Practical Impact in Pakistan |

|---|---|---|---|

| Peak efficiency (central PV >1 MW) | +0.5% to +1.2% absolute improvement | Linia bazowa | Higher energy yield, especially in hot seasons |

| Weighted efficiency (IEC load profile) | +0.4% to +0.9% absolute improvement | Linia bazowa | Reduced LCOE and shorter payback |

| Switching frequency (main stage) | 20–60 kHz typical | 4–12 kHz typical | Smaller magnetics, lighter cabinets |

| Heat sink volume | −30% to −50% | Brasoc'h | Lower fan count/speed, reduced dust intake |

| Densidade de potência | +30% to +70% | Izeloc'h | Fewer cabinets per MW, lower installation costs |

| Kemampuan suhu sambungan | 175°C long-term | 150°C typical | Better derating performance at 50°C inlet air |

| EMI and common-mode noise | Lower with low-inductance busbars | Higher, more filtering required | Easier compliance with NEPRA harmonic limits |

| Reliability under dust/salt-mist | Enhanced with coatings and sintered interfaces | Susceptible at high temp/humidity | Less unplanned downtime and warranty risk |

Device and Module-Level Technical Metrics Under 1500 V DC Platforms

| Metric | SiC MOSFET + Schottky (Sicarbtech) | Silicon IGBT + Diode | Relevance to Local Grids |

|---|---|---|---|

| Conduction loss | Low (temperature drift optimized) | Uheloc'h | Efficiency maintained during summer peaks |

| Switching loss | Very low (Qgd/Qrr minimized) | Substantial | Fast dynamics for voltage/frequency excursions |

| Parasitic inductance (module+busbar) | <10 nH target | 20–50 nH typical | Suppressed spikes on weak grids |

| Gate drive | Active clamping, soft turn-off, SC protection | Standard protection | Fewer trips during grid faults |

| Robustez ambiental | High with encapsulation and potting | Mixed | Stable in dust, damp heat, salt-mist corridors |

Zastosowania w świecie rzeczywistym i historie sukcesu

In a ground-mounted centralized PV project in south Punjab, a developer migrated the main power stage to Sicarbtech’s three-level SiC modules on a 1500 V platform. The cabinet count per 10 MW block dropped by 18%, primarily due to smaller inductors and reduced thermal hardware. During June–August, the site reported less derating at midday, delivering a modeled 0.7% uplift in annual energy yield. O&M crews highlighted fewer filter replacements, as lower fan speeds reduced intake dust.

A large industrial park near Karachi, exposed to saline air, retrofitted grid-side bridges with Sicarbtech’s low-inductance half-bridge SiC power modules and matched stacked busbars. The inverter footprint shrank enough to consolidate two cabinets into one for certain feeders, simplifying crane and installation logistics. Harmonic measurements showed improvements in current THD, easing compliance checks and grid-code reporting.

For a cement plant near Dera Ghazi Khan, a pilot line introduced high-frequency magnetics co-designed with Sicarbtech’s application engineers. With switching frequencies elevated into the 30–40 kHz range, the plant realized tangible reductions in inductor volume and improved thermal stability even as kiln-adjacent ambient temperatures spiked. Maintenance managers reported faster recovery after grid disturbances, aided by programmable gate drives with soft turn-off tailored to local fault profiles.

Moreover, early-stage utility battery storage deployments found value in Sicarbtech’s silver-sintered interfaces and vacuum-brazed packages. The enhanced power cycling life under frequent charge/discharge events reduced thermal fatigue, meeting the expectations of lenders demanding robust lifetime data. As one project consultant put it, “Reliability is now an asset class. When you can show cycling life and damp heat data, financing terms improve” (industry webinar recap, Energy Storage Insights, 2024).

Zalety techniczne i korzyści z wdrożenia z lokalną zgodnością

Beyond raw performance, the engineering details matter. Sicarbtech’s integrated design of low-inductance modules and stacked busbars suppresses voltage spikes and common-mode interference, easing EMI filter requirements. Programmable gate drives allow tuning of dv/dt and turn-off profiles to balance efficiency and noise against local grid dynamics, which often involve low short-circuit capacity and voltage fluctuations.

Thermally, high-thermal-conductivity substrates—aluminum nitride and SiC composites—reduce junction-to-case thermal resistance, unlocking longer power cycling life. This is especially relevant under Pakistan’s hot-dry conditions, where inlet air can reach 50°C and cabinets must operate with limited derating. Sintered silver interfaces and vacuum brazing provide mechanically robust, high-reliability bonds, maintaining performance through thermal shock and humidity cycles.

From a compliance standpoint, Sicarbtech’s solutions help OEMs and EPCs meet Pakistan’s grid code frameworks (NEPRA guidelines and utility interconnection requirements), including voltage and frequency ride-through, harmonic limits aligned with IEC 61000 series, and safety compliance aligned with IEC 62109 for PV inverters and related standards. The lower harmonic output and faster dynamic response simplify Type Testing and factory acceptance processes, while durability data supports environmental standards such as IEC 60068 (damp heat, thermal cycling).

Usługi produkcji na zamówienie i transferu technologii

Sicarbtech’s distinctive advantage lies in its turnkey, end-to-end model. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech invests in R&D that directly translates into manufacturable improvements for R‑SiC, SSiC, RBSiC, and SiSiC grades. Proprietary recipes and process controls deliver consistent microstructure, superior thermal conductivity, and long-life mechanical integrity for both electronic and mechanical SiC applications.

When customers require local manufacturing or joint-venture assembly, Sicarbtech provides complete technology transfer packages. These include detailed process know-how, equipment specifications for epitaxy, ion implantation, annealing, passivation, die attach, and module assembly, as well as silver sintering and vacuum brazing lines. Training programs span operator certification, maintenance procedures, SPC-based quality control, and yield improvement techniques. Factory establishment services cover feasibility studies, line layout and utilities, clean and controlled environment design, commissioning, and ramp-to-yield support.

Quality systems are integral. Sicarbtech helps align production with ISO 9001 and ISO 14001, supports documentation for IEC 60747 (semiconductor devices) and module-level testing, and establishes reliability test plans including power cycling, HT/HH, and HALT/HASS where appropriate. Post-commissioning, ongoing technical support includes parameter optimization for new batches, BOM cost-down programs, and field performance analytics to continuously improve reliability and reduce total cost of ownership.

For Pakistani partners, this localization path creates a practical, rapid-delivery capability. Critical spares and modules can be stocked locally, and assembly lines can be scaled from pilot to mass production as market demand grows. Given currency fluctuations and import lead times, localized assembly mitigates risk and strengthens bid competitiveness.

Detailed Comparison of Topology and Packaging Options for 1500 V Platforms

SiC Power Topologies and Packaging Trade-Offs for Pakistan’s PV and Industrial Systems

| Rummad | Sicarbtech SiC Half-Bridge Modules | Sicarbtech SiC Three-Level Modules (NPC/ANPC) | Conventional Silicon Two-Level |

|---|---|---|---|

| Compatibilidade com a plataforma DC | 1000/1500 V | 1500 V optimized | 1000/1500 V |

| Częstotliwość przełączania | 20–60 kHz | 15–40 kHz (effective higher output quality) | 4–12 kHz |

| Filter/magnetics size | Small | Smallest for grid-side | Duży |

| EMI and dv/dt control | Programmable gate drive, low nH | Balanced dv/dt, easier grid compliance | Challenging at higher power |

| Managementul termic | Reduced heat sink, fewer fans | Similar or better | Heavy thermal hardware |

| Defnydd nodweddiadol | Retrofits, modular upgrades | New builds, high-density plants | Legacy systems |

| Lifecycle cost | Low with efficiency gains | Lowest with BOS savings | Higher O&M and BOS |

Materials and Interfaces for High-Reliability Operation in Dust and Salt-Mist

| Element | Sicarbtech High-TC Substrates (AlN/SiC composite) | Standard Al2O3 Substrates |

|---|---|---|

| Condutividade térmica | High (160–200+ W/m·K) | Moderate (20–30 W/m·K) |

| Thermal resistance (junction-to-case) | Baixa | Uheloc'h |

| Power cycling life | Extended with silver sintering | Limited |

| Robustez ambiental | Strong under damp heat | Moderado |

| Cost impact | Offset by reduced cooling/hardware | Lower part cost, higher system cost |

Technical Results You Can Measure

When migrating a 1 MW inverter block to Sicarbtech SiC modules, developers typically report about 0.5–1.2 percentage point gain in peak efficiency and 0.4–0.9 percentage point in weighted efficiency. Switching frequencies move into the 20–60 kHz range, which reduces inductor and filter volume by 20–40%, and yields cabinet weight reductions of 20–40%. The heat sink volume can reduce by 30–50%, enabling fewer or slower fans—an immediate benefit in dust-laden environments where filters and bearings drive maintenance cycles. During 50°C inlet-air events, systems sustain output closer to nameplate with less derating, contributing to higher annual energy yield and more predictable O&M budgets.

These improvements resonate financially. With higher energy yield and lower BOS/O&M costs, LCOE declines; the internal rate of return for large solar projects improves, strengthening bid competitiveness under EPC frameworks prevalent in Pakistan. For industrial users offsetting grid purchases, the payback period shortens as energy intensity falls and production stability improves.

Oportunidades futuras de mercado e tendências para 2025

Pakistan’s pipeline suggests strong growth in centralized and large commercial PV, grid modernization, and selective on-site storage. The continued proliferation of 1500 V DC platforms pairs naturally with multilevel SiC topologies. We see three trends shaping 2025–2028 strategies. First, high-temperature, high-protection rating enclosures will become standard in desert and coastal sites, driving demand for thermally robust modules and packaging. Second, grid codes will increasingly reward fast dynamic response and low harmonics—areas where SiC’s fast switching and low parasitics excel. Third, local manufacturing and service ecosystems will become decisive in tenders, favoring solution providers who can transfer technology, establish lines, and assure parts availability.

As a utility adviser observed, “Procurement is shifting from lowest CAPEX to best lifecycle value, with penalties for downtime and efficiency shortfalls embedded in contracts” (regional procurement survey, Renewables South Asia, 2024). Sicarbtech’s holistic value chain—materials to devices to packaging to testing—positions it as a de-risked choice for investors prioritizing lifecycle economics.

Perguntas frequentes

How does SiC improve performance at 50°C inlet air common in Pakistan?

SiC’s lower conduction and switching losses reduce internal heating, while high-thermal-conductivity substrates and silver-sintered interfaces lower thermal resistance. Together they maintain junction temperatures within safe limits, resulting in less derating during the hottest hours and more consistent output.

Can Sicarbtech help us comply with NEPRA grid codes on harmonics and ride-through?

Yes. Low-inductance modules and stacked busbars limit voltage spikes and common-mode noise, easing harmonic control. Programmable gate drives enable fast dynamic response, supporting voltage/frequency ride-through. Sicarbtech’s engineering team assists with tuning and documentation aligned to IEC 61000 and related local requirements.

What voltage classes are recommended for 1500 V DC platforms?

Sicarbtech typically recommends 1200 V devices for many main stages but increasingly deploys 1700 V devices to provide additional margin, particularly at high altitude or high pollution degree sites common in certain regions.

How do SiC modules affect filter and inductor sizing?

Higher switching frequencies (20–60 kHz) significantly reduce the size of grid inductors and filters. In practice, developers have seen 20–40% volume reductions, enabling smaller enclosures and lower transport and lifting costs.

What about environmental exposure—dust and coastal salt-mist?

Sicarbtech uses encapsulation, conformal coatings, and corrosion-resistant materials. Combined with lower fan speeds due to reduced thermal load, the system admits less dust, extending filter replacement intervals and fan lifetimes.

Can Sicarbtech support local manufacturing and after-sales service in Pakistan?

Yes. Sicarbtech offers technology transfer packages, operator training, equipment specifications, and assistance in setting up pilot and mass-production lines. Local stocking strategies and service frameworks can be developed with partners to ensure rapid response and parts availability.

Are there clear ROI examples for industrial users outside utility-scale PV?

Textile and cement plants adopting SiC-based drives and grid interfaces report tangible energy savings, smaller footprints, and improved reliability, which reduce downtime. Payback periods often shorten due to combined energy and O&M savings.

Which cooling approaches are best: air or liquid?

Both are supported. Many deployments use high-efficiency air cooling with heat pipes; liquid cold plates are recommended for very high power density or constrained airflow. Sicarbtech provides assemblies with coatings resistant to dust and salt-mist.

How is reliability validated for financiers and insurers?

Through power cycling, high-temperature/high-humidity tests, and HALT protocols. Sicarbtech supplies the necessary test equipment and datasets to support technical due diligence, improving bankability.

Can SiC help weak-grid projects reduce nuisance trips?

Yes. Fast switching and optimized gate-drive protection reduce overshoot and false triggering. Lower parasitics and coordinated filters enhance stability, reducing trips and improving power quality.

Fazendo a escolha certa para suas operações

For Pakistan’s textile mills, cement kilns, steel reheat furnaces, and utility-scale solar fields, SiC enables a step-change in efficiency, size, and resilience. The critical differentiator is not just the device—it is the integrated ecosystem: modules designed with low-inductance busbars, substrates that pull heat away quickly, silver-sintered interfaces that survive thermal shock, and gate drives that shape switching behavior for weak-grid realities. Sicarbtech’s decade-plus track record, underpinned by Chinese Academy of Sciences collaboration, means you are partnering with a provider that understands every step—from epitaxy to field commissioning—and can localize that knowledge to Pakistan’s conditions.

When bids demand documented reliability, fast delivery, and lifecycle value, Sicarbtech’s full-cycle approach reduces risk. When projects require high-density cabinets that thrive in 50°C air with dust and salt in the mix, Sicarbtech’s materials, packaging, and engineering converge to deliver measurable outcomes. That is how 19+ enterprises have already realized durable gains—and how your next project can too.

Obtenha consultoria especializada e soluções personalizadas

Whether you are upgrading a grid-side bridge in a Karachi industrial park, scaling a 1500 V central PV plant in Balochistan, or planning localized assembly for long-term service assurance, Sicarbtech’s engineers can co-design the optimal pathway—phased introductions, three-level topologies, thermal designs, and compliance strategies included. Share your one-line diagram, thermal constraints, and grid code requirements, and we will propose a solution with quantified performance and ROI projections.

Contact Sicarbtech:

- E-mail: [email protected]

- Telefone/WhatsApp: +86 133 6536 0038

Metadados do artigo

Last updated: 2025-09-16

Próxima atualização programada: 15/12/2025

Autor: Equipe de Engenharia de Aplicações da Sicarbtech

Location focus: Pakistan (textile, cement, steel, utility-scale PV, and emerging storage)

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.