SiC-Based Wear-Resistant Components for Heavy Industries

Compartilhar

Sicarbtech — Silicon Carbide Solutions Expert. Located in Weifang City, China’s silicon carbide manufacturing hub, and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we help Pakistan’s heavy industries source and deploy wear‑resistant silicon carbide (SiC) components that extend uptime, stabilize energy intensity, and simplify compliance. With more than a decade of SiC customization and 19+ successful enterprise collaborations, Sicarbtech delivers full‑cycle solutions from powder processing to finished parts, including factory establishment and technology transfer for local capability.

Executive Summary: 2025 Outlook for Wear-Resistant SiC in Pakistan’s Heavy Industries

Pakistan’s heavy industries—cement, steel, mining and mineral processing, power and cogeneration, and industrial textiles—are pivoting from purchase price to lifecycle value. Energy volatility, PKR fluctuations, and tougher provincial environmental enforcement have made unplanned downtime and frequent part replacement economically and reputationally untenable. In this climate, SiC‑based wear‑resistant components are transitioning from experimental upgrades to standard practice. Their unique combination of extreme hardness, oxidation resistance, high thermal conductivity, and low thermal expansion directly addresses abrasive and thermally cycled environments that defeat conventional refractories and high‑Mn aços.

Moreover, export‑connected plants in Punjab and Sindh are advancing ISO 9001/14001/45001 programs and, in some cases, IATF 16949 discipline for automotive‑adjacent lines. Procurement is increasingly specifying PSQCA‑referenced conformity and third‑party testing in tenders. Building on this shift, Sicarbtech’s tailored R‑SiC, SSiC, RBSiC, and SiSiC portfolios—supported by finite element analysis, installation SOPs, and PKR‑based ROI models—help buyers defend decisions internally, align interventions with planned shutdowns, and document improvements during audits.

Industry Challenges and Pain Points in Pakistan’s Abrasive and Thermal Environments

The pain points in Pakistan’s heavy industries share a common theme: compounding losses triggered by materials that cannot survive abrasive, corrosive, or thermally unstable conditions. In cement, clinker chutes, cyclones, and dip tubes wear prematurely under high‑velocity particle streams, while burner assemblies crack under thermal shock during frequent restarts. Steel reheat furnaces, continuous casting lines, and rolling mills contend with scale, oxidation, and creep that deform alloy components, widening temperature bands and inflating scrap. Mining and mineral processing face relentless abrasion in chutes, hoppers, and slurry transport, where high‑Mn liners erode quickly and create unplanned stoppages. Even textile cogeneration units and dryers encounter erosive dust and cyclic heat that degrade ducts and heat‑recovery surfaces.

These technical failures trigger a financial cascade. A chute liner that fails on a weekend does not just cost the liner; it brings overtime labor, emergency freight, lost production, and sometimes quality drift when the process restarts under suboptimal conditions. Distributors and maintenance managers must either tie up capital in heavy spares or accept stockout risk, both of which the PKR volatility amplifies. “Every unplanned outage writes a bill that is larger than the invoice you see,” notes Engr. Faraz Khan, a reliability auditor active across Punjab’s cement and steel corridor (South Asia Reliability Insights, 2024). He emphasizes that mean time between failures needs to synchronize with planned shutdowns to contain indirect costs.

Additionally, compliance expectations are rising. Provincial Environmental Protection Agencies are enforcing stricter particulate emissions and energy‑efficiency baselines; tenders increasingly reference PSQCA guidelines; and insurers want evidence of reliability controls and scheduled maintenance. Export buyers expect ISO‑aligned documentation and traceability, while some OEMs demand PPAP and statistical control. “Materials that reduce dust and extend interventions create a compliance dividend by cutting waste and stabilizing operation,” says Dr. Nadia Rahman, EHS advisor to multiple industrial estates (EHS & Industry Review, 2024).

In contrast, conventional options—high‑alumina castables, basalt tiles, or high‑Mn wear plates—often look attractive on unit price but fall short in Pakistan’s abrasive, moisture‑laden, alternative‑fuel reality. Thermal shock and oxidation open cracks; softening at temperature deforms geometry; and erosion accelerates after the first surface layer is lost. Piecemeal replacement without modeling heat flux or particle trajectories yields parts that fit dimensions but fail the duty. “Reliability is engineered, not purchased off a catalog,” adds Prof. Liu, a ceramics specialist associated with the Chinese Academy of Sciences (Materials Engineering Commentaries, 2024). In 2025, the winners will pair high‑performance materials with engineered geometries, controlled microstructures, and disciplined installation.

Advanced Silicon Carbide Solutions Portfolio for Wear and Erosion Resistance

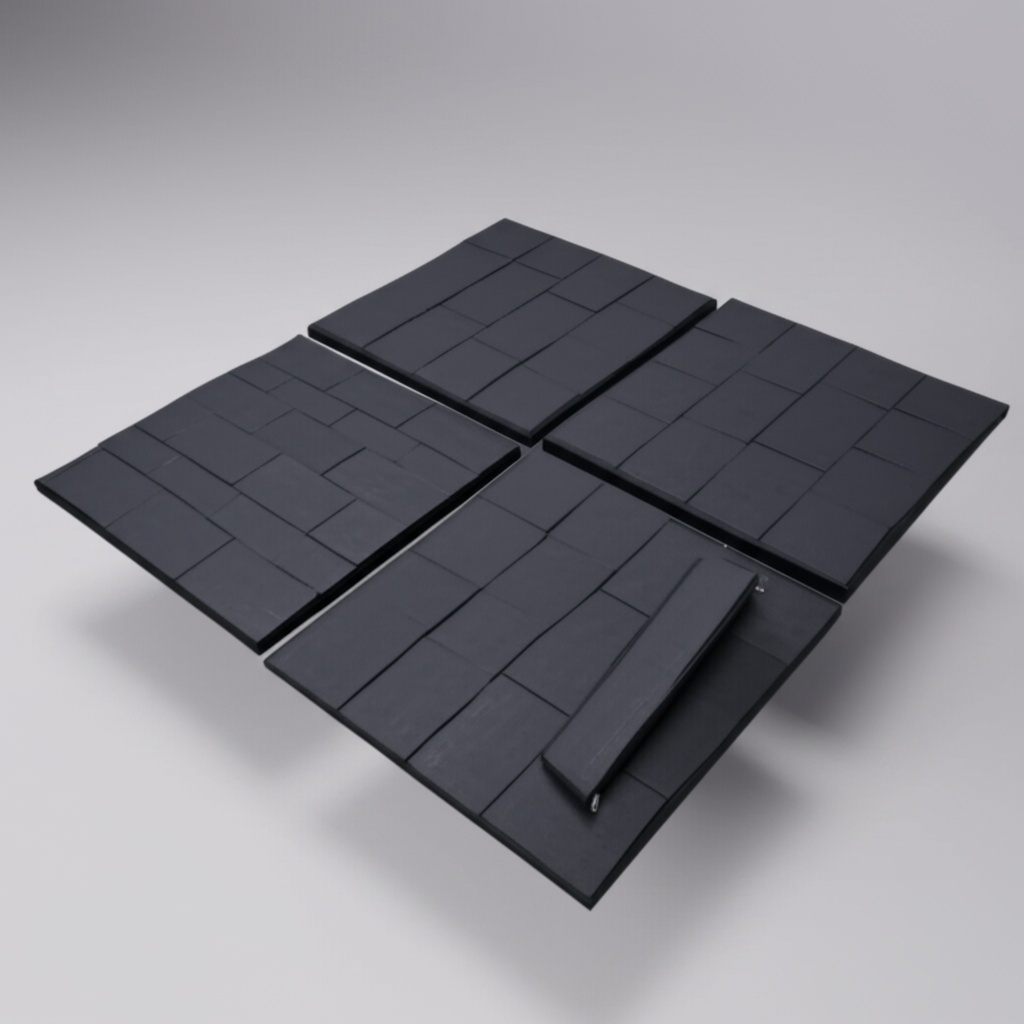

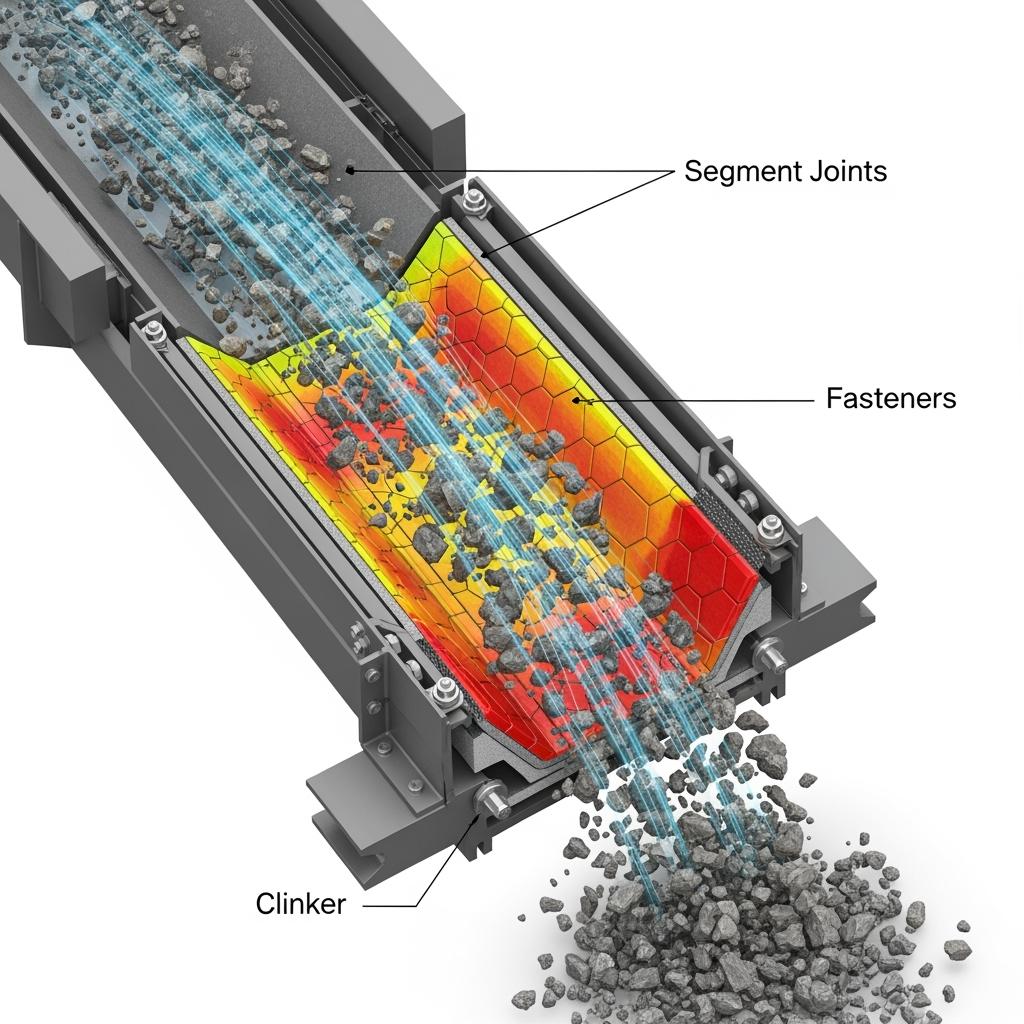

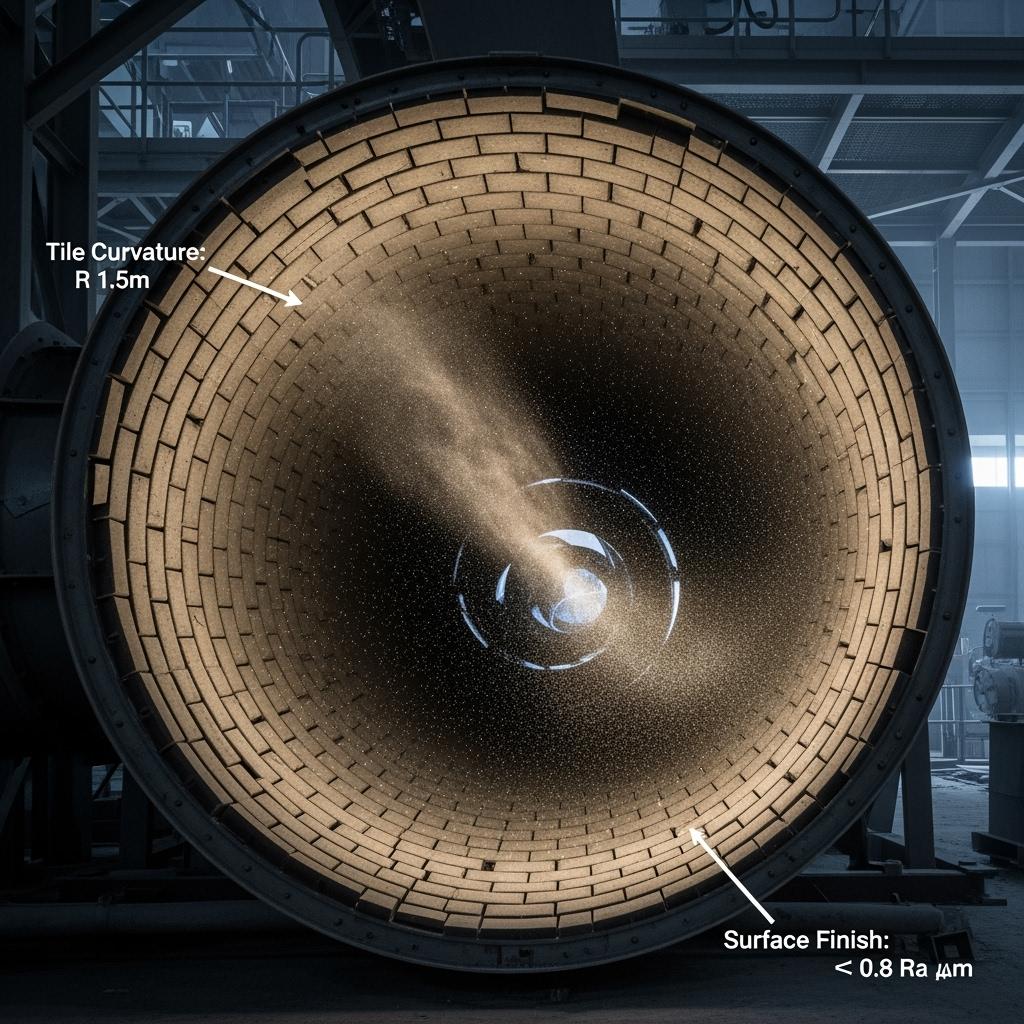

Sicarbtech designs SiC components around real duty cycles in Pakistan. For high‑energy particle streams in cement and mining, we specify RBSiC/SiSiC segmented liners for cyclones, elbows, and chutes. The segments allow targeted replacement and reduce downtime, while controlled surface finishes discourage fine particle adhesion that accelerates wear. For burner tiles, flame tubes, kiln furniture, and heat‑treatment fixtures where dimensional stability at temperature matters, we use R‑SiC with tailored wall thickness and rib geometry to dissipate thermal gradients and mitigate shock.

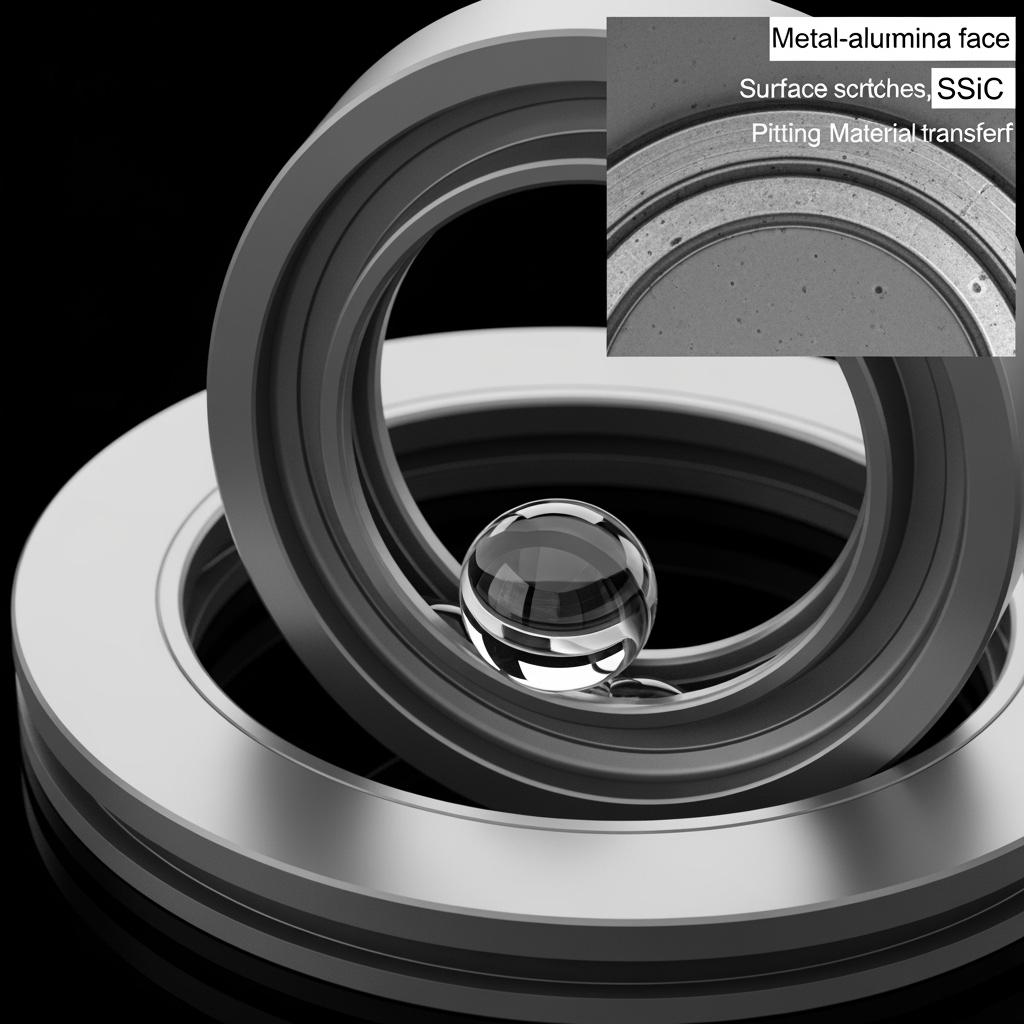

In slurry pumps, degassing systems, and valve seats exposed to corrosive media, SSiC’s near‑theoretical density and high hardness resist both chemical attack and abrasion. For reheat furnaces and process heaters, SiSiC radiant elements maintain geometry and emissivity under oxidizing atmospheres, reducing hot‑spotting and improving thermal uniformity—an indirect but powerful lever against thermal erosion elsewhere in the system.

Beyond materials, our application engineering is integral. We model particle trajectories, impact angles, and heat flux through finite element and CFD‑assisted methods, iterating geometry before fabrication. Microstructure targets are achieved through proprietary firing or infiltration profiles and controlled powder distributions. Each project is delivered with installation SOPs—surface preparation, bonding or mechanical fastening methods, expansion allowances—and inspection checklists. Documentation aligns with ISO 9001 and 14001, with PSQCA‑referenced conformity packs for local tendering; OEM programs receive IATF 16949‑aligned control plans and PPAP evidence.

Comparative Technical Performance of SiC vs Conventional Wear Materials

Wear, thermal, and corrosion properties in harsh industrial service

| Property and operating relevance | R‑SiC (Recrystallized) | SSiC (Sintered) | RBSiC / SiSiC (Reaction‑bonded) | High‑Mn wear steel | High‑alumina castable |

|---|---|---|---|---|---|

| Hardness (HV10) | 22–24 GPa | 24–26 GPa | 20–22 GPa | 2–4 GPa | 10–12 GPa |

| Abrasion resistance (relative index) | Дуже висока | Дуже висока | Дуже висока | Moderado | Moderado |

| Max service temperature in air (°C) | 1,650–1,700 | 1,600–1,700 | 1,380–1,480 | 400–600 (softening) | 1,400–1,600 |

| Thermal conductivity at 25°C (W/m·K) | 20–35 | 90–120 | 60–80 | 16–25 | 2–6 |

| Oxidation resistance at 1,200°C | Excelente | Excelente | Çox yaxşı | Fall | Bom |

| Resistência ao choque térmico | Alta | Alta | Alta | Baixo-moderado | Moderado |

| Chemical/caustic resistance | Alta | Дуже висока | Дуже висока | Moderado | Moderado |

In Pakistan’s abrasive lines—cement raw meal, clinker streams, limestone aggregates, and iron oxides—SiC’s extreme hardness and oxidation resistance deliver a step‑change in wear life, while its conductivity and low expansion help maintain geometry through rapid cycles.

Lifecycle economics and reliability outcomes under Pakistani duty cycles

| Application in Pakistan | Conventional baseline | Sicarbtech SiC solution | Energy impact | Maintenance impact | Typical payback (months) |

|---|---|---|---|---|---|

| Clinker chute liners (cement) | High‑Mn plates | RBSiC segmented liners | Reduced blockages, smoother flow | 3–4× wear life | 6–10 |

| Cyclone cone/scroll liners | Castable/basalt tiles | SiSiC custom panels | Lower dust generation | 2–3× service interval | 8–12 |

| Slurry pump seal/seat (mining) | Alloy/Al₂O₃ | SSiC precision rings | Lower leakage, friction | Longer MTBF | 4–9 |

| Reheat furnace radiant elements | Heat‑resistant alloys | SiSiC elements | Faster heat‑up, uniformity | 2× intervention interval | 10–16 |

While results vary with particle size distribution, velocities, and maintenance discipline, the trend across Punjab and Sindh facilities is consistent: SiC stabilizes operation and pays back within typical board horizons.

SiC versus Tungsten Carbide in heavy-wear use cases

| Consideration | Silicon Carbide (RBSiC/SSiC) | Tungsten Carbide (WC‑Co) |

|---|---|---|

| Hardness and abrasion | Very high; strong against sliding abrasion and fine particle erosion | Extremely high hardness; excels in impact/point contact |

| Temperature capability in oxidizing atmospheres | Excellent up to 1,380–1,700°C (grade dependent) with strong oxidation resistance | Limited in high‑temperature oxidizing atmospheres due to cobalt binder oxidation |

| Corrosion resistance in caustics/acids | Very high (especially SSiC) | Variable; cobalt binder can be attacked in certain chemistries |

| Density and weight | Low density; lighter components reduce mechanical load | High density; heavier, increases inertia and support requirements |

| Shape complexity and large panels | Strong for large tiles/panels and complex ceramics via infiltration/sintering | Typically smaller wear inserts/brazed tips; large panels are uncommon |

| Cost for large area lining | Cost‑effective for large surfaces and panels | High cost; economical mainly as small inserts |

In Pakistan’s large‑area liners and high‑temperature oxidizing environments, SiC is generally the pragmatic choice. Tungsten carbide remains attractive for extreme point‑impact tools, but for cyclones, chutes, and radiant parts, SiC provides a better balance of performance, weight, and cost.

Real-World Applications and Success Stories from Pakistani Heavy Industries

At a central Punjab cement plant, high‑Mn liners in a clinker transfer chute required replacement every 4–6 months, with frequent blockages after monsoon humidity spikes. Sicarbtech replaced the system with RBSiC segmented liners, optimizing impact angles via CFD‑informed geometry. Over the first year, liner life more than tripled, blockages fell sharply, and the site reported a payback in roughly nine months after factoring fuel, labor, and emergency logistics.

In an iron‑ore handling line serving a Karachi‑area steel integrator, elbow wear caused dust generation and fines carryover. SiSiC custom elbow panels with smooth internal surfaces reduced turbulence and wall shear. Dust emissions decreased visibly at the downstream filter house, maintenance aligned to planned shutdowns, and energy use dipped slightly due to lower pressure drop across the line.

A mining slurry pump at a Khyber Pakhtunkhwa site suffered seal failures in abrasive, chemically aggressive service. Sicarbtech supplied SSiC precision seal rings lapped to sub‑micron flatness, together with a flush plan and torque protocol. Leakage dropped significantly, and mean time between seal rebuilds extended beyond two planned maintenance cycles. “Quality follows stability,” remarks Engr. S. Aftab, a reliability consultant to several OEMs and processors (Pakistan Maintenance & Reliability Exchange, 2024). “When your geometry and surfaces stay intact under stress, your entire cost curve flattens.”

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

SiC’s edge stems from fundamentals. Extreme hardness resists abrasion and micro‑cutting; oxidation resistance preserves surfaces in hot, oxygen‑rich flows; and thermal conductivity plus low expansion stabilize geometry during rapid cycles. The engineering translation is fewer wear‑initiated turbulence zones, less dust generation, lower pressure drop, and stable heat transfer—outcomes that improve energy intensity and ease environmental compliance.

Realizing these gains requires disciplined implementation. Sicarbtech delivers designs vetted by FEA and, where relevant, CFD for particle and flow behavior. We define tolerances, finishes, and fastening/bonding approaches that integrate with Pakistani OEM hardware. Installation SOPs specify substrate prep, adhesive or mechanical fixation, expansion joints, and inspection intervals. For hot‑zone parts, we provide preheat profiles and ramp rates; for sealed components, we define flatness, surface finish, torque sequences, and flush plans. Our documentation supports ISO 9001 and 14001 audits; EHS procedures align with ISO 45001; and PSQCA‑referenced conformity packs streamline local tenders. For OEM programs, we supply IATF 16949‑aligned control plans and PPAP packages.

“Compliance is a design constraint, not an afterthought,” emphasizes Dr. Li, CAS‑affiliated materials scientist (CAS Industry Notes, 2024). By integrating documentation and safety into the engineering package, Sicarbtech shortens acceptance cycles and de‑risks deployment.

Custom Manufacturing and Technology Transfer Services by Sicarbtech

Sicarbtech’s competitive advantage for Pakistan’s heavy industry buyers is a turnkey capability that spans materials science, production execution, and knowledge transfer. Our R&D, anchored in the Chinese Academy of Sciences (Weifang) Innovation Park, supports proprietary processes for R‑SiC, SSiC, RBSiC, and SiSiC. We control powder size distributions, apply advanced forming methods—such as isostatic pressing, slip casting, and extrusion—and tune firing or infiltration profiles to produce repeatable microstructures with tight porosity and strength distributions. This microstructural consistency maps directly to predictable field wear and thermal behavior.

For operators and investors pursuing localization, Sicarbtech delivers complete technology transfer packages. We provide end‑to‑end process know‑how from green body formation through debinding, sintering/infiltration, machining, and lapping; equipment specifications for kilns, furnaces, presses, mixers, and finishing cells; and training curricula for operators, QC, and maintenance. Our factory establishment services cover feasibility studies, utilities planning, plant layout, EHS alignment with Pakistani regulations, and production line commissioning. Hybrid models retain critical high‑temperature steps in Weifang while machining, assembly, and inspection occur in Pakistan, reducing lead time and FX exposure while building domestic skills.

Quality systems are embedded throughout. Statistical process control tracks density, porosity, and critical dimensions; mechanical testing verifies flexural strength and hardness; and leak/pressure testing qualifies sealed components. For OEM projects, we align with IATF 16949, preparing control plans, capability studies, and PPAP documentation that speed supplier onboarding. After launch, our engineers continue to optimize firing curves, tooling, and yields, preserving margins and sustaining field performance. Over 10+ years and more than 19 enterprise collaborations, this comprehensive, transferable capability has produced faster qualifications, fewer first‑run issues, and clear PKR‑based ROI.

Future Market Opportunities and 2025+ Trends for Wear-Resistant SiC in Pakistan

Three converging forces will shape the market beyond 2025. First, energy economics and ESG reporting will keep rewarding components that lower pressure drop, minimize dust, and hold geometry at temperature—areas where SiC excels. Second, export‑oriented manufacturers will tighten certification and traceability requirements, making engineered SiC with robust documentation a straightforward route to audit success. Third, as cement lines expand alternative fuels and mining scales up beneficiation, erosive and variable‑atmosphere conditions will intensify, favoring SiC’s oxidation‑resistant and abrasion‑proof profile.

Distribution models will also mature. Engineering‑led channels will win by stocking critical SiC spares, offering first‑fit supervision, and partnering on data‑driven design refreshes. Localization through technology transfer will shorten response times and reduce currency risk. In essence, SiC will continue moving from tactical wear patches to strategic reliability infrastructure—supporting higher OEE, lower energy intensity, and smoother compliance.

Perguntas frequentes

Which SiC grade should I choose for heavy-wear applications in Pakistan?

RBSiC/SiSiC is often the first choice for liners, cyclones, elbows, and chutes due to its strong wear resistance and shape flexibility. R‑SiC suits high‑temperature structural parts like burner tiles and kiln furniture where dimensional stability is crucial. SSiC excels in corrosive or sealed environments such as slurry pump seats and mechanical seals.

Can Sicarbtech support PSQCA and ISO documentation for tenders?

Yes. We provide PSQCA‑referenced conformity packs, ISO 9001/14001/45001 documentation, and structured third‑party test reports where required. For OEM programs, we prepare IATF 16949‑aligned control plans and PPAP submissions.

What payback period can I expect when switching to SiC liners or tiles?

Most Pakistani projects see 6–12 months for large‑area liners and 10–16 months for radiant elements, depending on particle velocities, duty cycles, and energy prices. We build PKR‑based ROI models that include duties, installation, and maintenance savings.

How does SiC reduce dust and improve environmental compliance?

Smooth, hard SiC surfaces resist micro‑cutting and maintain geometry, reducing turbulence and abrasive re‑entrainment that create fines. Improved flow and fewer blockages lower dust generation and stabilize filter house loads.

Can Sicarbtech localize manufacturing or finishing in Pakistan?

Absolutely. Through technology transfer, we provide process know‑how, equipment specs, SOPs, QC protocols, and training. Hybrid models keep critical firing in Weifang while machining and assembly occur locally, reducing lead times and FX exposure.

What information do you need to engineer a custom SiC lining system?

We typically request particle size distribution, velocity and impact angles, temperature and atmosphere, chemical composition (chlorides, alkalis, sulfur), geometry and tolerances, failure history, and target service interval. This informs FEA/CFD, grade selection, and mounting design.

How are SiC liners installed to maximize life?

We supply installation SOPs covering substrate prep, adhesive or mechanical fixation, expansion joints, and cure schedules. For hot‑zone parts, we provide preheat profiles and ramp rates. First‑fit supervision is available to de‑risk installation.

What logistics and lead times can Pakistani buyers expect?

Custom lead times are typically 4–10 weeks depending on complexity. We align shipments with outage calendars and can phase deliveries. Under technology transfer or local finishing, lead times shorten and safety stock can be positioned locally.

Do you provide after‑sales engineering and inspection support?

Yes. We offer remote diagnostics, on‑site commissioning, wear audits, and continuous improvement engagements. We also co‑develop inspection schedules and spares strategies aligned with your shutdown plan.

How does Sicarbtech ensure consistent wear performance batch-to-batch?

Controlled powder distributions, proprietary firing/infiltration profiles, SPC on density/porosity/dimensions, and mechanical testing underpin consistency. For OEMs, we align control plans with IATF 16949 and provide PPAP documentation.

Fazendo a escolha certa para suas operações

Choosing wear‑resistant SiC is not just a materials decision; it is a strategic step toward predictable uptime, cleaner operations, and audit‑ready performance. Sicarbtech’s integrated approach—R‑SiC, SSiC, RBSiC, and SiSiC materials; application‑driven engineering; documented compliance; and transferable manufacturing know‑how—gives Pakistani plants a de‑risked path from specification to measurable ROI. Whether your bottleneck is a cyclone liner, clinker chute, slurry pump seal, or radiant element, the right SiC solution will flatten your cost curve and stabilize throughput.

Obtenha consultoria especializada e soluções personalizadas

Share your wear maps, particle data, and operating envelope with Sicarbtech’s engineering team. We will recommend the optimal SiC grade and geometry, simulate performance against your duty cycle, and plan an implementation synchronized with your shutdown schedule—complete with a PKR‑based ROI model. Contact: [email protected] or +86 133 6536 0038.

Explore Related Cluster Resources

- Custom Wear-Resistant SiC Parts for Industrial Applications

- Silicon Carbide Ceramic Solutions for Harsh Environments

- High-Durability SiC Components for Mining and Metallurgy

- Abrasion-Resistant Ceramics for Heavy Industry Operations

- Custom Capabilities for Extreme Wear and Corrosion

- Design Options for Custom Silicon Carbide Lining Systems

- Performance Comparison of SiC and Tungsten Carbide Parts

- Applications of Wear-Resistant SiC in Heavy Industries

- Certified SiC Manufacturer for Industrial OEM Projects

- Quality Assurance and Testing for SiC Industrial Components

Metadados do artigo

Last updated: 2025-09-23

Next scheduled review: 2026-01-15

Content freshness indicators: 2025 Pakistan heavy‑industry outlook integrated; PSQCA, ISO 9001/14001/45001, and IATF 16949 considerations reflected; ROI modeled in PKR; case insights from 2023–2025 Sicarbtech deployments with 19+ enterprises; trends calibrated to energy volatility, ESG pressures, alternative fuels, and localization initiatives.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.