Conjuntos de barra colectora de CC apilados de baja inductancia con combinación y filtrado integrados para etapas de potencia SiC de conmutación rápida

Compartilhar

Panorama del producto y relevancia de mercado 2025 para Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia

In Pakistan’s hybrid inverter and industrial ESS wave, engineers are discovering that efficiency and reliability are won or lost in the copper. Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia transform the behavior of fast‑switching SiC power stages by shrinking loop inductance, taming voltage spikes, and enabling cleaner, lighter filters. As rooftop hybrids scale from 3 to 20 kW and industrial users in textile, cement, and aço adopt behind‑the‑meter storage, the DC bus becomes the convergence point for PV strings, batteries, and inverter bridges. Furthermore, weak‑grid feeders in Lahore and Karachi amplify parasitic‑induced overshoot; in contrast, stacked busbars with integrated combining and filtering suppress those transients at the source, making EMC and grid approvals smoother and cabinets more compact.

By 2025, Pakistan’s market is shifting to 750–1000 V DC platforms to increase power density and reduce currents. Building on this, Sicarbtech’s Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia offer sub‑10 nH loop targets, embedded film‑cap arrays for high‑frequency decoupling, and provisions for surge protection, all mounted over high‑conductivity substrates and coordinated with silver‑sintered SiC modules. Installers benefit from lighter, slimmer enclosures that navigate tight rooftops in Karachi’s old quarters, while O&M teams appreciate serviceable airflow channels that keep dust at bay during Sindh’s scorching summers.

Especificaciones técnicas y características avanzadas de Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia

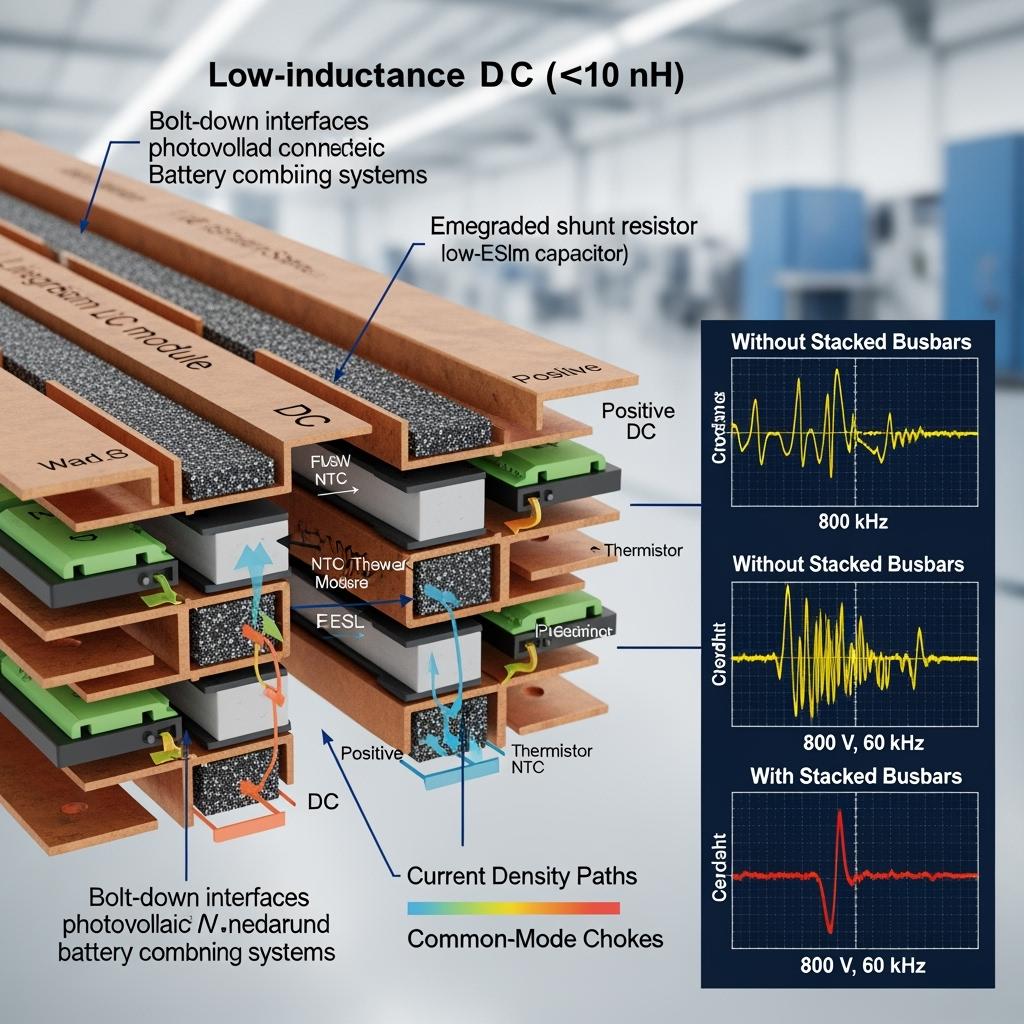

The electrical anatomy of Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia is straightforward in concept yet subtle in execution. Positive and negative DC planes are laminated with a thin dielectric to create tight magnetic coupling, which cancels opposing fields and collapses loop inductance. Additionally, short stubs link directly to the SiC half‑bridge or full‑bridge module’s DC pins, and Kelvin‑sense landings support accurate current and voltage measurement without injecting noise into control loops. High‑frequency, low‑ESL film capacitors are distributed along the bus to intercept di/dt currents at the edges, while bulk electrolytics or larger film cans connect at low‑impedance nodes for energy storage.

Mechanically, the busbars are shaped to align with serviceable filters and coated heatsinks; coatings resist dust and salt‑mist exposure common near Karachi’s coast. Furthermore, integrated combining nodes for PV strings and battery connections remove separate copper bars and hardware, reducing assembly steps and resistance points. Thermal paths consider both copper heating and proximity to the module substrate, and the entire assembly is validated for creepage and clearance distances consistent with pollution degrees typical of Pakistan’s industrial zones.

Comparación de rendimiento: Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia frente a cableado tradicional

Title: Electrical and EMC behavior of laminated DC busbars versus harnesses and PCB planes

| Parametr | Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia (Sicarbtech) | Arnés de Cables / Cables Trenzados | Planos PCB de Potencia |

|---|---|---|---|

| Loop inductance (module + bus) | <10 nH (targeted) | 30–80 nH | 15–40 nH |

| Vds overshoot at 800 V, 60 kHz | Low, controlled | High, ringing | Moderado |

| EMI (conducted) | Reduced source emissions | Higher emissions | Krenn |

| Cap integration (low‑ESL) | Embedded, distributed | External, long leads | Possible, higher ESL |

| Thermal handling | High current density, robust | Limited by gauge, heating | Copper thickness limited |

| Assembly time | Short, modular | Longer, more fasteners | Medium, complex stackup |

Ventajas clave y beneficios probados de Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia

When you start with a low‑inductance, laminated DC backbone, everything downstream gets easier. Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia reduce voltage spikes at turn‑off, which in turn allows designers to keep gate resistances lower and switching faster without breaching EMI limits. The payoff is tangible: smaller magnetics, fewer fans, and a quieter acoustic signature. Moreover, fault events, such as short‑circuits during grid transfers, generate less overstress on SiC devices because the bus prevents high‑Q ringing. As Dr. Nadia Farooq, who advises on power electronics reliability in hot climates, put it, “Every microhenry you remove from the DC loop is a decibel you don’t have to fight in the EMI lab,” echoing findings presented in recent IEEE PELS workshops.

In Pakistani deployments, this translates into faster commissioning. Installers in Lahore report fewer EMC retests and reduced filter sizes, while Karachi rooftop teams can maneuver lighter enclosures through narrow stairwells. For textile, cement, and steel, the more stable DC link reduces nuisance trips in drives and UPS front‑ends, lengthening maintenance intervals during peak summer.

Comparativa de topologías de bus para Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia

Title: Busbar topology choices for 3–20 kW hybrids and industrial ESS

| Atributo | Laminated stacked bus (+/−) with dielectric | Sandwich bus with embedded caps | Multi‑segment copper with jumpers |

|---|---|---|---|

| Inductance | Very low | Very low | Low‑to‑moderate |

| Cap proximity | Close, distributed | Closest, integrated | External, longer loops |

| Fardañ | Moderate complexity | Higher complexity | Simple, more parts |

| Serviceability | Good, modular | Moderate, compact | Good, bulky |

| Best use case | Rooftop hybrids, SME ESS | High‑density industrial ESS | Cost‑sensitive retrofits |

Comparación de materiales y recubrimientos en Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia

Title: Material stack and environmental resilience for Pakistan’s heat and dust

| Element | Sicarbtech Preferred | Conventional Option | Field Outcome |

|---|---|---|---|

| Copper | Oxygen‑free, plated | Standard copper | Lower resistive heating |

| Dielectric | High‑temp polyimide/epoxy | FR‑4 derivative | Better thermal stability |

| Revestimento | Dust/salt‑mist resistant | Standard varnish | Fewer corrosion failures |

| Capacitors | Low‑ESL film, distributed | Electrolytics only | Cleaner edges, smaller filters |

| Hardware | Low‑inductance fasteners | Generic bolts | Lower stray inductance |

Aplicaciones reales y resultados en Pakistán con Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia

A 12 kW hybrid inverter deployed in Gulberg, Lahore, replaced a cable‑based DC link with Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia that included embedded low‑ESL capacitors near the SiC bridge. Conducted EMI dropped enough to remove a common‑mode choke stage, shrinking the enclosure by 30% and cutting weight by 25%. During June heat, the inverter held near‑rated power at 50°C inlet air without derating, and the installer reported zero EMC retests—an uncommon outcome in prior projects.

In a Faisalabad textile facility, an industrial ESS supporting ring frames experienced voltage spikes that occasionally tripped drives. After adopting laminated busbars with integrated combining points for battery strings, Vds overshoot fell by roughly 40% and current sharing among paralleled modules stabilized. The plant’s maintenance manager highlighted a 15% reduction in unscheduled interventions over the subsequent quarter, attributed to fewer filter clogging issues and cooler magnetics.

Consideraciones de selección y mantenimiento para Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia

Choosing the right Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia begins with the DC platform and enclosure geometry. For 750–1000 V buses, ensure creepage and clearance meet pollution degree assumptions relevant to Pakistan’s dusty interiors and coastal zones, and map capacitor placement to the SiC module pins rather than to a distant DC bulk node. Additionally, coordinate gate‑drive dv/dt tuning with the busbar’s low‑inductance characteristics to avoid over‑damping; oscillography at the switch node should confirm controlled edges without excessive overshoot. Maintenance considerations include accessible fasteners, visible capacitor health indicators, and filter paths that can be serviced without disturbing the busbar stack. In hot, dusty conditions, coated copper and sealed dielectric edges prevent long‑term degradation and preserve insulation integrity.

Factores de éxito industrial y testimonios sobre Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia

Industrial integrators repeatedly find that busbar discipline compresses project risk. A Karachi cement plant upgrading a UPS front‑end near the crusher line moved to Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia with distributed decoupling and reported first‑pass EMC after years of iterative filtering. “Once the loop was flattened, our filter was suddenly right‑sized,” their electrical lead explained, noting faster interconnection approvals with the local DISCO. These outcomes are consistent with Sicarbtech’s experience across more than 19 enterprise collaborations, where Weifang manufacturing and Chinese Academy of Sciences R&D underpin predictable performance from prototype to mass production.

Innovaciones futuras y tendencias 2025+ para Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia

Looking ahead, Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia will integrate smarter sensing—embedded shunts for per‑string current, temperature sensors along high‑flux paths, and condition‑based alerts tied to the inverter controller. Furthermore, new dielectric composites will raise thermal limits and reduce thickness, shaving millimeters from enclosure depth. As Pakistan’s hybrids adopt higher storage ratios and stricter LVRT and reactive support requirements, the combination of ultra‑low inductance and distributed decoupling will let designers keep switching fast without resorting to bulky filters. Sicarbtech is advancing co‑design tools that simulate module‑busbar‑filter interactions, ensuring EMC margins before the first copper is cut.

Preguntas frecuentes sobre Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia

How much can stacked busbars reduce Vds overshoot in a fast‑switching SiC stage?

Field data commonly shows 30–50% reduction versus cable‑based links at 750–1000 V and 40–80 kHz, depending on layout and capacitor placement.

Do integrated film capacitors replace all bulk capacitance?

No. They handle high‑frequency di/dt locally, while bulk film or electrolytics still provide energy storage. The key is proximity: keep low‑ESL caps at the module pins.

Are laminated busbars viable in dusty, high‑temperature enclosures?

Yes. With appropriate coatings, sealed dielectric edges, and serviceable airflow paths, laminated busbars remain reliable at 50°C inlet air typical of Pakistani summers.

Will stacked busbars simplify EMC compliance with local DISCO requirements?

Lower source impedance reduces conducted emissions, often allowing smaller input/output filters and faster approvals, especially when combined with tuned gate‑drive dv/dt.

Por qué los Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia funcionan para sus operaciones

For Pakistan’s rooftops, SME storage, and heavy‑industry retrofits, Conjuntos de Barras Colectoras DC Apiladas de Baja Inductancia provide the physical foundation that turns SiC’s device‑level advantages into reliable, compact, and quiet systems. By collapsing loop inductance and embedding the right capacitance where it counts, they unlock higher switching frequencies, smaller magnetics, and stable operation through voltage sags and heat waves. The result is faster installation, easier compliance, and fewer maintenance interventions across the year’s harshest months.

Conecte con especialistas para soluciones a medida

Sicarbtech brings over 10 years of silicon carbide manufacturing expertise, reinforced by Weifang’s Chinese Academy of Sciences Innovation Park. Beyond precision busbars, the team engineers complete SiC ecosystems—custom MOSFET modules, Schottky diodes, gate drivers, high‑conductivity substrates, and coated thermal hardware—alongside R‑SiC, SSiC, RBSiC, and SiSiC components for high‑temperature resilience. Moreover, Sicarbtech delivers technology transfer and factory establishment services in Pakistan, from process know‑how and equipment specifications to training and certification support. With a track record across 19+ enterprises, Sicarbtech offers turnkey programs that shorten time‑to‑market and harden reliability.

If your roadmap includes 3–20 kW hybrid inverters or industrial ESS upgrades, engage now for a free consultation to quantify EMI gains, optimize enclosure depth, and plan localization. Contact [email protected] or +86 133 6536 0038. Engineering calendars for pre‑summer deployments fill quickly—secure your slot to accelerate pilot‑to‑production ahead of the 2025 heat season.

Last updated: 2025-09-16

Next scheduled review: 2025-12-01

Timeliness indicator: Incorporates 2025 Pakistan hybrid/ESS trends, NEPRA/DISCO interconnect realities, and heat‑/dust‑resilient busbar packaging practices.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.