SiC Products for Industrial Furnaces and Kilns in Pakistan

Compartilhar

Sicarbtech — Silicon Carbide Solutions Expert. From Weifang City, China’s silicon carbide manufacturing hub, and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we help Pakistani furnace builders, kiln operators, EPCs, and distributors design, procure, and implement silicon carbide bricks, tubes, shelves, and hot‑zone components that stand up to harsh thermal cycles. With 10+ years of customization experience and field results across 19+ enterprises, Sicarbtech delivers full‑cycle support—from powder engineering and forming to firing, machining, documentation, and technology transfer for localized capability.

Executive Summary: 2025 Outlook for Silicon Carbide in Furnaces and Kilns

Pakistan’s industrial furnace landscape is changing quickly. Energy volatility and PKR fluctuations are reshaping maintenance strategies in cement, steel, ceramics, and glass; meanwhile, provincial environmental enforcement is tightening expectations around fuel intensity, thermal efficiency, and particulate control. In this setting, silicon carbide (SiC) furnace components are no longer niche. Their combination of high thermal conductivity, low thermal expansion, extreme hardness, and oxidation resistance directly translates into smoother heat profiles, lower fuel consumption, and longer campaigns.

Furthermore, procurement frameworks are maturing. PSQCA‑referenced conformity appears more often in tenders; ISO 9001/14001/45001 documentation is expected; and insurers and export buyers increasingly ask for reliability evidence and preventive maintenance plans. This makes engineered SiC—supported by FEA/CFD validation, installation SOPs, and PKR‑based ROI models—especially attractive to Pakistani operators who must defend investments and synchronize deliveries with planned shutdowns. The 2025 outlook favors partners who combine materials science with documentation discipline and dependable local support.

Industry Challenges and Pain Points in Pakistan’s Furnace Operations

Across Punjab’s cement corridor, Sindh’s aço and glass clusters, and Khyber Pakhtunkhwa’s ceramics lines, the same pattern repeats: parts that look economical at purchase fail prematurely in service. High‑alumina bricks in hot‑flux zones of preheaters and reheat furnaces develop hot spots because their low thermal conductivity cannot dissipate transient heat loads; the resulting gradients seed cracks and spalling. Alloy radiant tubes creep and oxidize in oxidizing atmospheres, distorting geometry and widening temperature bands, which increases scrap and energy intensity. Kiln furniture in ceramic kilns sags under load, while shelves with inadequate shock resistance fracture during rapid start‑stop cycles driven by power interruptions.

The operational repercussions are costly. A Friday‑night failure means overtime maintenance, emergency air freight, and non‑productive thermal ramps that stress refractories and elements. Distributors carry more inventory than they would like, yet stockouts still occur when import lead times slip. Currency swings then complicate landed‑cost planning. “Every unplanned hour costs more than the invoice,” says Engr. Faraz Khan, a reliability auditor active across Punjab’s industrial estates (South Asia Reliability Insights, 2024). “Mean time between failures must be engineered to align with planned shutdowns; otherwise, indirect costs—quality drift, waste, and lost orders—overwhelm unit‑price savings.”

Compliance pressures heighten the stakes. Provincial Environmental Protection Agencies are pushing for lower specific fuel consumption and better particulate control; PSQCA‑referenced conformity and ISO documentation appear frequently in tenders; and insurers ask for evidence of reliability engineering. “Materials that stabilize heat flow and extend service intervals produce a compliance dividend,” notes Dr. Nadia Rahman, EHS advisor to multiple estates (EHS & Industry Review, 2024). In contrast, piecemeal substitutions—swapping a brick for a brick without considering heat flux, flow trajectories, anchoring, or joint design—yield parts that match drawings but miss duties. “Reliability is engineered, not purchased off a catalog,” adds Prof. Liu, a ceramics specialist associated with the Chinese Academy of Sciences (Materials Engineering Commentaries, 2024).

Additionally, local environmental realities complicate materials performance. Monsoon humidity alters dust behavior in cement preheaters, accelerating fouling. Mixed fuels in kilns and furnaces change oxidation chemistry cycle‑to‑cycle, punishing alloys and marginal refractories. Ambient heat in workshops strains cooling margins. Without integrated engineering and documentation, these factors combine to reduce campaign length and increase emergency interventions.

Advanced Silicon Carbide Solutions Portfolio for Industrial Furnaces and Kilns

Sicarbtech designs SiC components around the physics of your furnace rather than the convenience of a catalog. For high‑flux and erosive zones in cement preheaters and steel reheat lines, SiC‑rich refractory bricks and segmented tiles spread heat, reduce gradients, and resist abrasive streams. In glass and ceramic kilns, R‑SiC and SiSiC kiln furniture—shelves, beams, posts, and setters—retain stiffness and geometry at temperature while tolerating rapid cycling. For process heaters and reheat furnaces, SiSiC radiant tubes and elements maintain emissivity and shape in oxidizing atmospheres, tightening temperature bands and shortening heat‑up time.

Where corrosion and precision matter, SSiC shines. Burners, flame tubes, and hot‑face tiles engineered in R‑SiC handle thermal shock during frequent starts and fuel changes. Recuperator cores and flue‑gas heat exchangers formed in SiSiC keep heat transfer coefficients up and fouling down, especially when channel geometry is tuned via CFD. Each program begins with duty mapping—temperature, atmosphere, flow/particle behavior, and structural loads—then proceeds to FEA and, when relevant, CFD to validate stresses and heat flux distribution. Microstructure targets are locked by proprietary firing or infiltration, and installation SOPs specify substrate preparation, anchoring, joints, compatible mortars, torque sequences, and ramp‑up/dry‑out protocols. Documentation aligns with ISO 9001/14001/45001 and PSQCA references; OEM/EPC programs receive IATF 16949‑aligned control plans and PPAP‑style evidence.

Performance Comparison: SiC vs Traditional Furnace Materials

Thermo‑mechanical properties relevant to furnace and kiln components

| Property and operating relevance | R‑SiC (Recrystallized) | SSiC (Sintered) | RBSiC / SiSiC (Reaction‑bonded) | High‑alumina refractory | Heat‑resistant alloy steel |

|---|---|---|---|---|---|

| Maximum service temperature in air (°C) | 1,650–1,700 | 1,600–1,700 | 1,380–1,480 | 1,400–1,600 | 900–1,100 |

| Thermal conductivity at 25°C (W/m·K) | 20–35 | 90–120 | 60–80 | 2–6 | 16–25 |

| Coefficient of thermal expansion (×10⁻⁶/K) | ~4.0–4.5 | ~4.0–4.2 | ~4.2–4.8 | 6–8 | 14–17 |

| Flexural strength at RT (MPa) | 100–180 | 350–450 | 280–380 | 30–60 | 150–220 |

| Oxidation resistance at 1,200°C | Excelente | Excelente | Çox yaxşı | Bom | Justo |

| Resistência ao choque térmico | Alta | Alta | Alta | Moderado | Moderado |

SiC’s high conductivity and low expansion flatten thermal gradients and protect geometry under rapid cycling. In practice, this reduces hot‑spot failures, keeps temperature uniformity tight, and shortens heat‑up times—crucial for Pakistani plants with start‑stop duty and mixed fuels.

Lifecycle economics and reliability in Pakistani duty cycles

| Local application | Conventional baseline | Sicarbtech SiC solution | Energy/throughput impact | Maintenance impact | Indicative payback (months) |

|---|---|---|---|---|---|

| Cement preheater elbows/risers | High‑alumina bricks | SiC‑rich segmented tiles | Lower pressure drop; fewer blockages | 2–3× wear life | 6–12 |

| Reheat/process furnace radiant | Alloy tubes/elements | SiSiC radiant tubes/elements | Faster heat‑up; tighter uniformity | 2× interval between swaps | 10–16 |

| Kiln furniture (ceramics/glass) | Alumina/mullite shelves | R‑SiC/SiSiC shelves and beams | Less sag; faster turnaround | Longer campaigns | 8–14 |

While duty specifics vary, data from plants across Punjab and Sindh confirms the pattern: engineered SiC improves energy intensity and aligns interventions with planned outages.

Kiln furniture performance trade‑offs for ceramics and glass

| Consideration | R‑SiC Shelves/Beams | SiSiC Shelves/Beams | High‑Alumina/Mullite Shelves |

|---|---|---|---|

| Stiffness/creep at temperature | High; excellent sag resistance | Very high; superior at high T in oxidizing atmospheres | Moderate; sag under sustained load |

| Thermal shock tolerance | Excelente | Excelente | Moderado |

| Thermal mass and heat‑up | Moderate; good cycle time | Moderate; efficient heat transfer | Higher; slower cycles |

| Surface durability | High; resists glaze sticking with proper finish | High; smooth finish options | Moderate; glaze interactions common |

| Cost vs life | Higher initial; longer life | Higher initial; longest life in oxidizing | Lower initial; shorter life in high‑flux zones |

For Pakistani kilns pushing throughput and consistent quality, SiC furniture enables faster cycles and stable geometry, minimizing rework and breakage.

Real‑World Applications and Success Stories in Pakistan

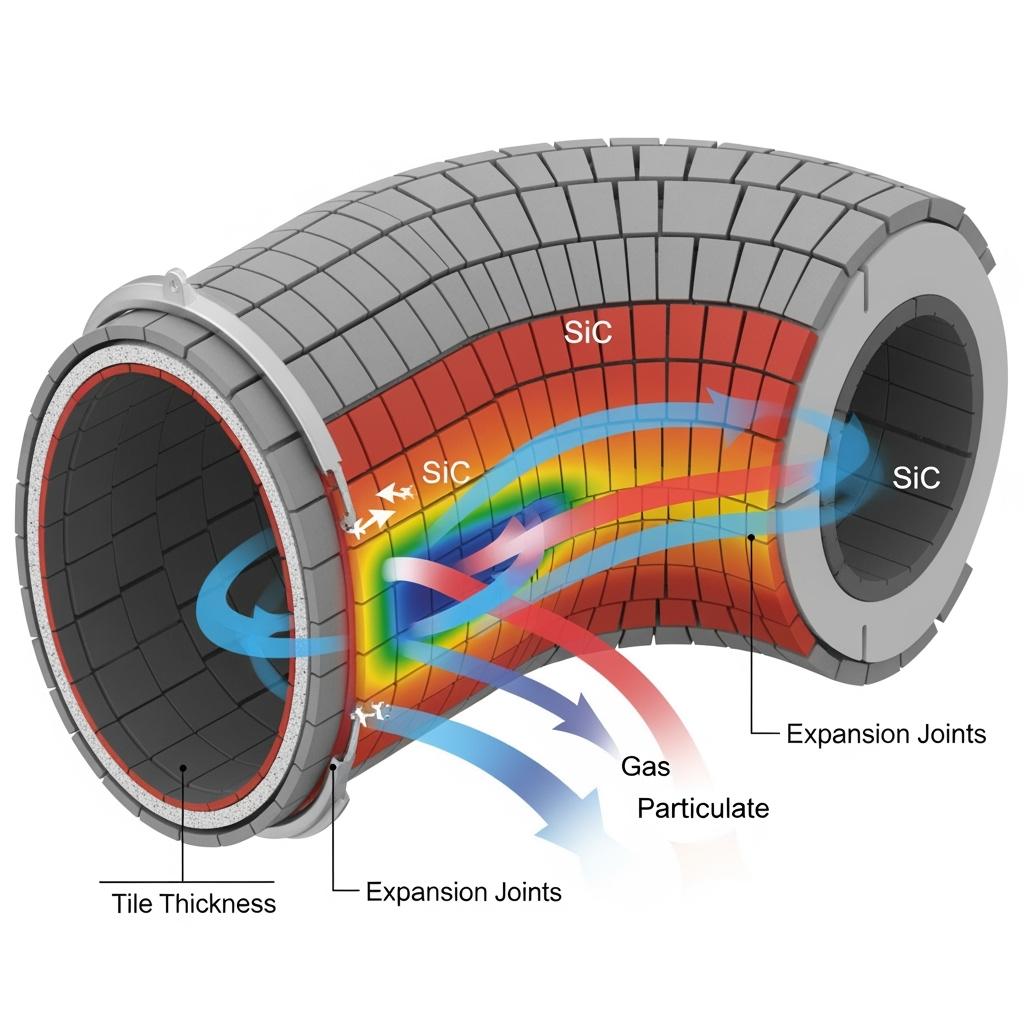

A North Punjab cement line struggled with rapid wear and fouling in preheater elbows during monsoon season. Sicarbtech designed SiC‑rich segmented tiles with a finish that discouraged fine dust adhesion and with expansion joints tuned to the duct’s movement. Pressure drop stabilized, fouling intervals extended, and maintenance aligned with scheduled shutdowns, yielding a payback within a year once emergency interventions were counted.

In a Sindh steel reheat furnace, alloy radiant tubes distorted under oxidizing atmospheres, producing uneven soak temperatures and frequent corrections. We installed SiSiC radiant elements sized to the furnace’s load profile and atmosphere, confirmed via FEA. Heat‑up times shortened, the temperature band tightened, and tube‑related downtime fell close to zero in the first year. “Quality follows stability,” remarks Engr. S. Aftab, a reliability consultant to several OEMs (Pakistan Maintenance & Reliability Exchange, 2024). “When geometry stays true at temperature, OEE rises and scrap falls.”

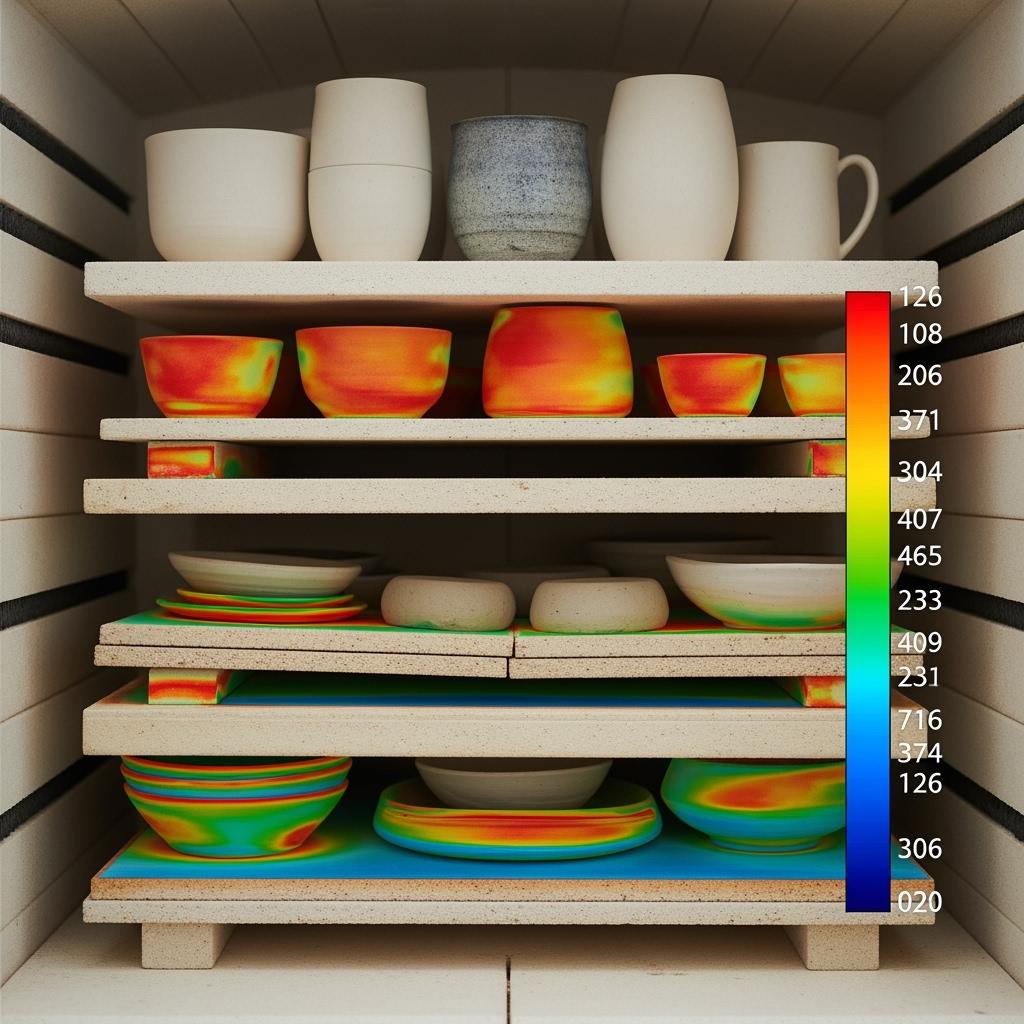

A Karachi ceramics producer faced shelf sagging and breakage that stalled throughput. Sicarbtech supplied R‑SiC shelves and beams with controlled thickness and surface finish tailored to the firing curve. The plant reported improved flatness, fewer product defects, and shorter cycles due to lower thermal mass, with ROI realized inside 12 months.

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

Silicon carbide’s physics lines up with Pakistan’s operational reality. High thermal conductivity and low thermal expansion reduce hot spots and thermal stresses; oxidation resistance maintains surface integrity in oxygen‑rich flue gases; and extreme hardness resists erosion from abrasive particles. For furnace operators, this means lower specific fuel consumption, tighter temperature control, and longer campaigns. For QA teams, it means fewer defect clusters linked to geometry drift or thermal inconsistency. And for EHS officers, SiC’s stability aids emissions and energy‑efficiency targets.

Sicarbtech turns these advantages into documented outcomes. We provide PSQCA‑referenced conformity, ISO 9001/14001/45001 documentation, and third‑party test reports where required. Installation SOPs detail substrate preparation, anchoring and joint design, compatible mortars or gaskets, torque sequences, and controlled dry‑out and heat‑up curves. For OEM/EPC programs, we deliver IATF 16949‑aligned control plans and PPAP‑style submissions. “Compliance is a design constraint, not an afterthought,” emphasizes Dr. Li, CAS‑affiliated materials scientist (CAS Industry Notes, 2024). By engineering for documentation, acceptance cycles shorten and audit risk drops.

Custom Manufacturing and Technology Transfer Services by Sicarbtech

Sicarbtech’s competitive edge is a turnkey capability that fuses R&D depth, manufacturing discipline, and knowledge transfer—anchored by the Chinese Academy of Sciences (Weifang) Innovation Park.

We specialize in R‑SiC, SSiC, RBSiC, and SiSiC. Controlled powder size distributions and chemistry underpin repeatable microstructures. Forming methods—cold isostatic pressing, slip casting, and extrusion—support complex shapes, thin walls, and large formats. Proprietary firing and reaction‑bonding profiles lock in density, porosity, and grain structure, while machining and finishing deliver tolerances, flatness, and surface finishes tuned to thermal contact and flow requirements. For radiant elements and recuperator cores, we co‑optimize conductivity, wall thickness, and channel geometry to balance heat transfer and structural integrity.

Technology transfer is available for Pakistani partners who want to localize value. We provide process know‑how from green body formation through debinding, sintering or infiltration, machining, lapping, and inspection; detailed equipment specifications for presses, mixers, kilns/furnaces, classifiers, and finishing lines; and training programs for operators, QC, and maintenance. Factory establishment services cover feasibility studies, utilities and HVAC design, plant layout, EHS alignment with local regulations, and line commissioning. Hybrid models retain critical high‑temperature steps in Weifang while machining, assembly, packaging, and inspection occur locally—reducing lead times, mitigating FX risk, and building domestic capability.

Quality control systems and certification support are integral. Statistical process control monitors density, open porosity, and critical dimensions; mechanical testing validates flexural strength and hardness; thermal testing confirms conductivity and shock resistance; and, where needed, pressure/leak tests qualify heat‑exchange and flue‑gas parts. For OEM programs, we prepare IATF 16949‑aligned control plans, run capability studies, and deliver PPAP documentation. Post‑launch, our engineers remain engaged—tuning firing curves, improving tooling, raising yields, and conducting root‑cause analyses as field data accumulates. Over a decade and 19+ enterprise partnerships, this comprehensive, transferable model has delivered faster qualifications, fewer first‑run issues, and clear PKR‑based ROI.

Future Market Opportunities and 2025+ Trends for Furnace‑Grade SiC

Three trends will accelerate SiC adoption beyond 2025. First, energy economics and ESG reporting will keep rewarding materials that stabilize heat transfer and extend service intervals, especially in mixed‑fuel cement lines and steel reheat furnaces. Second, process intensification in ceramics and glass will push higher temperatures and tighter uniformity, where SiC’s conductivity and oxidation resistance shine. Third, procurement will continue to prioritize documentation and traceability; suppliers who can tie batch properties to field KPIs will win tenders and insurer confidence.

On the channel side, engineering‑led distributors will differentiate by stocking critical SiC components, supervising first‑fits, and partnering on design refreshes driven by operating data. Localization through technology transfer will shorten response times and reduce FX exposure. As tenders pivot from unit price to total cost of ownership and OEE, SiC will move from tactical substitution to strategic reliability infrastructure across Pakistan’s furnace and kiln base.

Perguntas frequentes

Which SiC grade should I choose for my furnace application?

R‑SiC excels in thermal‑shock‑prone tiles and kiln furniture; SSiC provides premium density and surface finish for precision or corrosive services; SiSiC (RBSiC) balances shape complexity with strong conductivity for radiant elements and liners. We confirm grade selection after reviewing temperature, atmosphere, load cases, particle flows, and outage cadence.

Can Sicarbtech provide PSQCA and ISO documentation for tenders?

Yes. We supply PSQCA‑referenced conformity, ISO 9001/14001/45001 documentation, and structured third‑party tests where required. For OEM/EPC programs, we prepare IATF 16949‑aligned control plans and PPAP‑style submissions.

What payback can Pakistani plants expect when switching to SiC?

Typical ranges are 6–12 months for SiC‑rich preheater tiles, 8–14 months for kiln furniture upgrades, and 10–16 months for SiSiC radiant elements. We build PKR‑based ROI models that include duties, installation, and downtime reductions.

How do you ensure batch‑to‑batch consistency?

We control powders and forming, run proprietary firing/infiltration profiles, and apply SPC on density, porosity, and dimensions. COAs include mechanical and thermal data. For critical parts, we provide first‑article inspections and capability studies.

Can Sicarbtech localize finishing and assembly in Pakistan?

Absolutely. Through technology transfer, we establish machining, finishing, inspection, and packaging cells locally, while retaining critical high‑temperature steps in Weifang. This reduces lead times and FX exposure and builds domestic skills.

What information is needed to engineer a custom SiC component?

We typically request operating temperature and atmosphere, gas chemistry (including alkali and sulfur), flow and particle data, structural loads, geometry and anchoring details, failure history, target campaign length, and shutdown schedules.

How are SiC components installed to achieve full service life?

We provide SOPs covering substrate preparation, anchoring and joint design, compatible mortars/adhesives, torque sequences, and controlled dry‑out and heat‑up curves. First‑fit supervision is available on site or remotely.

Do you supply CAD drawings and datasheets for engineers?

Yes. We can provide datasheets, CAD files, and installation guides tailored to your project, along with FEA/CFD summaries where applicable to accelerate approvals.

What lead times should Pakistani buyers expect?

Custom parts typically ship in 4–10 weeks depending on complexity and volume. We align deliveries with outage calendars and can phase shipments. Under localization, we position safety stock for critical items.

Do you support failure analysis and continuous improvement?

Yes. We run on‑site audits, wear and heat‑flux studies, and root‑cause investigations. Insights loop back into design or process refinements, improving life and reliability over successive campaigns.

Fazendo a escolha certa para suas operações

Choosing silicon carbide for furnaces and kilns is not a cosmetic upgrade; it is a structural change in how heat is moved, held, and controlled. Sicarbtech’s integrated approach—R‑SiC, SSiC, RBSiC, and SiSiC materials; application‑driven engineering with FEA/CFD; PSQCA/ISO/IATF‑aligned documentation; and transferable manufacturing know‑how—gives Pakistani operators a clear path from specification to measurable ROI. Whether your bottleneck is an overheating preheater bend, a creeping radiant tube, or a sagging shelf, the right SiC solution will stabilize your process and strengthen your margins.

Obtenha consultoria especializada e soluções personalizadas

Share your duty cycle, firing curve, gas chemistry, and pain points with Sicarbtech’s engineering team. We will recommend the optimal SiC grade and geometry, simulate performance, and map an implementation plan synchronized with planned outages—complete with a PKR‑based ROI model and acceptance documentation. Contact: [email protected] or +86 133 6536 0038.

Explore Related Cluster Resources

- Benefits of Using Silicon Carbide in Industrial Kilns and Furnaces

- Why SiC Is Ideal for High-Temperature Furnace Applications

- Tailored SiC Bricks, Tubes, and Shelves for Furnace Builders

- Technical Specs of SiC Parts for Furnace Performance Optimization

- OEM and ODM Services for Furnace-Grade Silicon Carbide

- How to Customize SiC Components for High-Heat Applications

- Use Cases of SiC Ceramics in Steel, Glass, and Ceramic Kilns

- Procurement Guide for SiC Products in the Pakistani Market

- Downloadable SiC Datasheets and CAD Drawings for Engineers

- FAQs for Custom Furnace-Grade SiC Buyers and Designers

Metadados do artigo

Last updated: 2025-09-23

Next scheduled review: 2026-01-15

Content freshness indicators: 2025 Pakistan furnace/kiln outlook integrated; PSQCA and ISO 9001/14001/45001 considerations reflected; IATF 16949 support for OEM/EPC programs; ROI modeled in PKR; case insights from 2023–2025 Sicarbtech deployments with 19+ enterprises; trends aligned with energy volatility, ESG pressures, mixed‑fuel usage, and localization initiatives.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.