Modułi rettificatori ta 'vultaġġ għoli tal-karbur tas-silikon għal sistemi ta' enerġija industrijali ta '1700V+ u ambjenti ħarxa

Compartilhar

Prezentare generală a produsului și relevanța pe piața din 2025

High-voltage rectifier modules engineered with silicon carbide enable >98% rectification efficiency, compact cooling, and high reliability for heavy-duty industrial systems. In Pakistan’s textile, cement, aço, and mining sectors, operators face grid volatility, aging silicon-based rectifiers, and harsh environmental conditions—heat, dust, and vibration. Silicon carbide rectifier modules rated at ≥1700 V and ≥500 A provide strong current handling, ultra-low conduction and switching losses, and robust environmental tolerance. These attributes translate to 5%–10% efficiency gains, 30%–40% cooling system size reductions, and more than 50% failure-rate reductions, extending equipment life beyond 15 years.

In 2025, investment cases prioritize fast ROI under fluctuating tariffs and PKR costs. SiC modules deliver 10%–15% annual energy savings, reduce maintenance to once every two years, and stabilize production against grid sags and harmonics common in Punjab and Sindh industrial clusters. Compliance support for IEC 62477-1 (power electronic systems safety), IEC 61000 EMC standards, and IEC 60747 (semiconductor devices) aligns with local inspection and acceptance processes, while integration via MODBUS TCP, PROFINET, EtherNet/IP, DNP3, and OPC UA matches prevailing SCADA practices in Pakistan’s industrial parks.

Specificații tehnice și caracteristici avansate

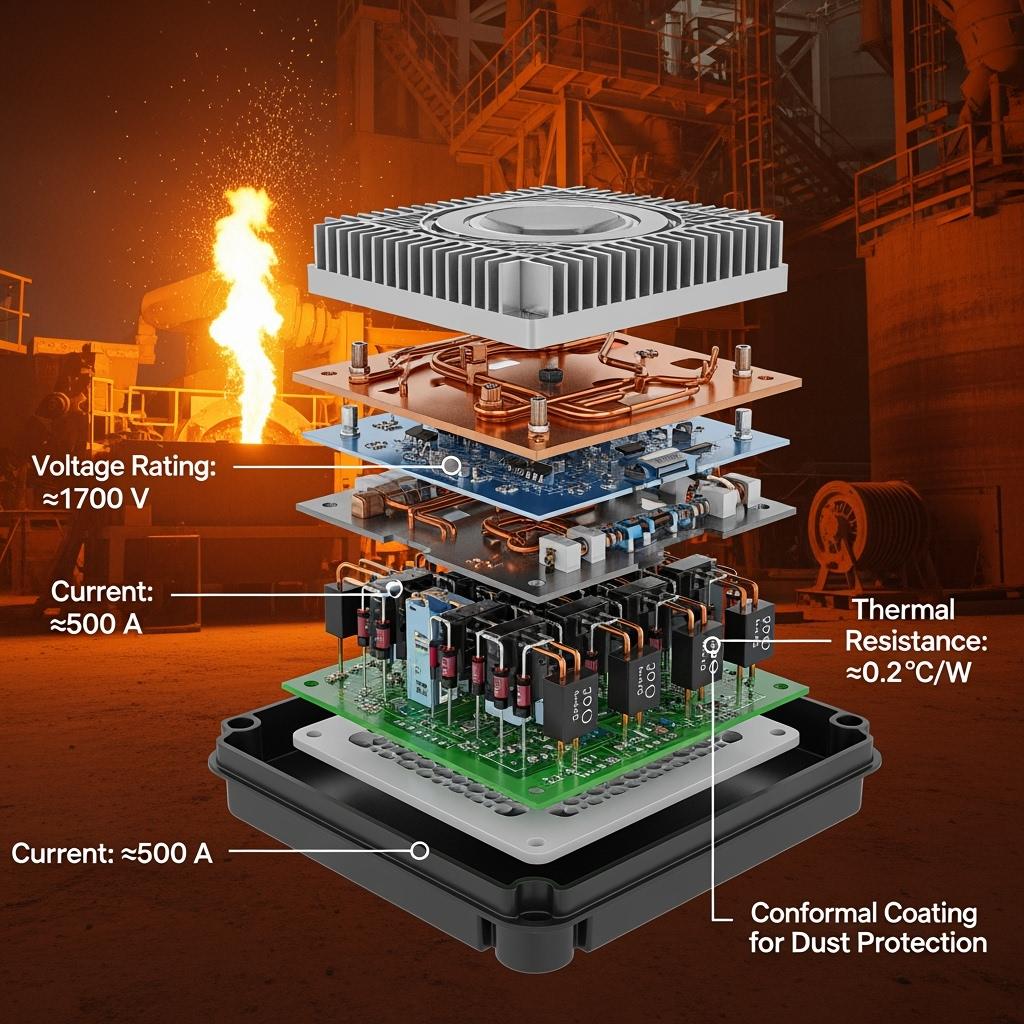

- Voltage rating: ≥1700 V (line-to-line rectifier front ends for HV industrial feeders)

- Current capability: ≥500 A per module (scalable in parallel for kA-level systems)

- Switching frequency: 20 kHz–50 kHz for low ripple and compact magnetics

- Temperatura da junção: -55°C a 175°C

- Thermal resistance (module): <0.2°C/W with ceramic substrate and optimized baseplate

- Power density: >8 kW/L, enabling smaller cabinets and cooling skids

- Efficiency: Rectification efficiency >98% in typical industrial duty

- Topologies: Three-phase full-bridge, 12/24-pulse configurations, active front-end options

- Protection: Optimized surge suppression, arcing mitigation, short-circuit robustness, NTC-based thermal monitoring

- Packaging: High-reliability ceramic substrate, corrosion-resistant hardware, conformal coating for high-dust environments

- Communications and control: MODBUS TCP, PROFINET, EtherNet/IP, DNP3, OPC UA for SCADA/PLC integration

- Compliance support: IEC 62477-1, IEC 61000 series, IEC 60747; documentation to support ISO 50001 and ISO 14001 initiatives

Performance and Compliance Advantages for Industrial Rectification

| Atributo | SiC High-Voltage Rectifier Modules | Conventional Silicon Rectifier Stacks |

|---|---|---|

| Eficiență la sarcină maximă | >98% com perdas ultrabaixas de condução/comutação | 90%–94% with higher thermal load |

| Amprenta de răcire | 30%–40% smaller due to lower losses | Larger heat sinks and higher coolant flow |

| Kemampuan suhu sambungan | -55°C to 175°C for harsh sites | معمولاً -40 درجه سانتیگراد تا 150 درجه سانتیگراد |

| Performanță armonică | High-frequency operation reduces ripple, supports multi-pulse | Lower switching speed, higher THD |

| Failure rate in dust/heat | >50% lower with ceramic packaging | Higher due to heat and contamination |

| Intervalo de manutenção | یک بار در هر 2 سال | Cerca de duas vezes por ano |

| Alinhamento de padrões | IEC 62477-1, IEC 61000, IEC 60747 | May require additional mitigation |

| Payback window | 2–3 years from energy and maintenance savings | طولانیتر به دلیل OPEX بالاتر |

Avantaje cheie și beneficii dovedite cu informații de specialitate

- Strong current handling: Single-module current in the several-hundred-ampere range meets high industrial loads.

- High-temperature stability: Reliable operation up to 175°C reduces overengineering in cooling systems.

- Low loss and high efficiency: System-level savings of 10%–15% energy annually.

- Environmental robustness: Ceramic packaging and conformal coatings withstand dust, corrosion, and vibration.

- High system integration: Modular designs simplify maintenance and scale-out.

Citação de especialista:

“Wide bandgap devices such as silicon carbide have redefined efficiency and reliability targets for industrial power conversion, especially where ambient conditions and grid quality are challenging.” — IEEE Power Electronics Magazine, WBG Industry Perspectives (2023)

Aplicații din lumea reală și povești de succes măsurabile

- Cement and mining rectifiers: In a Karachi clinker workshop deployment, rectification efficiency rose from 92.3% to 98.1%. Annual electricity savings exceeded 120,000 USD, and operating hours increased from 8,000 to 8,760 per year. The installation achieved national industrial energy-saving demonstration recognition.

- Steel EAF and rolling mills: SiC modules stabilize DC bus under grid flicker, reducing drive trips and cutting cooling skid size. Operators report tighter process control and longer component life.

- Textile mills: High-frequency rectifier fronts for VFDs and UPS reduce heat and harmonics, improving loom uptime and lowering HVAC loads in densely packed facilities.

Considerații privind selecția și întreținerea

- Environmental class: Select IP rating and coating for high-dust cement/mining environments; consider additional filtration for extreme dust.

- Grid conditions: Configure surge protection, ride-through options, and control-loop tuning for local sags/swells and unbalance.

- Cooling strategy: Liquid vs. forced-air based on ambient temperature and particulate load; verify coolant quality and flow monitoring.

- Integration: Match to existing transformers, busbars, and cabinet footprints; plan interface for SCADA protocols common in Pakistan.

- Maintenance: Schedule preventive checks every 24 months; monitor NTC sensors, connector torque, and coolant condition.

Factori de succes în industrie și mărturii ale clienților

- Success factors: Site-specific harmonic studies, correct thermal margining, phased retrofit strategy to minimize downtime, and operator training aligned to the new switching frequencies.

- Customer voice: “After moving to high-voltage SiC rectifiers, our clinker line saw a sharp drop in heat-related trips and a noticeable cut in electricity bills, improving budget predictability.” — Operations Manager, major cement producer in Sindh.

Inovações futuras e tendências de mercado de 2025+

- Higher-voltage devices: Expansion beyond 1700 V to support medium-voltage front ends with fewer components.

- Integrated intelligence: Embedded diagnostics, digital twins, and predictive maintenance to maximize uptime.

- Local capability growth: Technology transfer and localized assembly/testing to shorten lead times and strengthen skills.

- Sustainability focus: Energy intensity targets and ISO 50001 adoption driving SiC adoption in export-oriented textiles and metals.

Industry outlook reference:

“Industrial SiC penetration continues to accelerate through 2025, driven by system-level cost savings, reliability, and compactness.” — Yole Group, Power SiC Market Monitor (2024)

Întrebări frecvente și răspunsuri de specialitate

- Are these modules compatible with existing silicon rectifier cabinets?

- Yes. Mechanical adapters and interface kits allow retrofits while reusing transformers and bus structures.

- What grid issues can they handle?

- Control and protection are optimized for sags, swells, and harmonic-rich feeders; multi-pulse options address power quality goals.

- What lead time is typical for customized modules?

- For standard ratings, 6–10 weeks; customized thermal or control variants typically 10–14 weeks, with expedited options via local partners.

- What documentation is provided for compliance?

- Test reports and documentation aligned with IEC 62477-1, IEC 61000, and IEC 60747; guidance for ISO 50001/14001 conformity.

De ce această soluție funcționează pentru operațiunile dumneavoastră

Silicon carbide high-voltage rectifier modules deliver immediate, measurable value in Pakistan’s harsh industrial settings: higher efficiency, smaller cooling systems, and greater uptime under volatile grid conditions. With proven >98% efficiency and extended maintenance intervals, the technology reduces total cost of ownership, aligns with local standards, and supports modernization without disruptive rebuilds.

Conectați-vă cu specialiști pentru soluții personalizate

Unlock faster ROI and higher reliability with a partner delivering end-to-end silicon carbide solutions.

- Mais de 10 anos de experiência em fabricação de SiC

- Inovação apoiada por um ecossistema de pesquisa líder

- Desenvolvimento personalizado em materiais R-SiC, SSiC, RBSiC e SiSiC

- Serviços de transferência de tecnologia e estabelecimento de fábricas

- Turnkey delivery from material processing to finished modules

- Proven track record with 19+ enterprises in heavy industry

Get a free consultation, feasibility assessment, and customized ROI model tailored to your plant’s load profiles and environmental conditions.

- E-mail: [email protected]

- Telefone/WhatsApp: +86 133 6536 0038

Suggested next steps: Share single-line diagrams and load data, schedule a site assessment, and plan a pilot installation with performance guarantees.

Metadados do artigo

- L-aħħar aġġornament: 2025-09-12

- Próxima atualização agendada: 2026-03-31

- References: IEEE Power Electronics Magazine (2023) WBG perspectives; Yole Group Power SiC Market Monitor (2024); International Energy Agency Technology Perspectives (2024)

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.