Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Guide for Preheaters and Calciner Cyclone Separators

Compartilhar

Pakistan’s cement producers are navigating a demanding 2025 landscape. Rising alternative fuel co-firing, variable raw meal chemistry, and tighter energy and environmental expectations are stressing preheaters and calciner cyclone separators precisely where high-temperature, dust-laden, alkali–sulfur–chlorine cycling is most aggressive. In these conditions, industrial silicon carbide (SiC) has moved from specialist to standard. With high thermal conductivity, low thermal expansion, and dense microstructures that suppress penetration and oxidation, SiC wear systems deliver longer life, steadier pressure drops, and safer, faster maintenance. Sicarbtech—headquartered in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings over a decade of SiC customization, full-cycle manufacturing from powders to prefabs, and turnkey technology transfer that enables Pakistani partners to localize production and control lead times.

Executive Summary: 2025 Outlook and Why Silicon Carbide Matters in Pakistan’s Preheaters and Cyclones

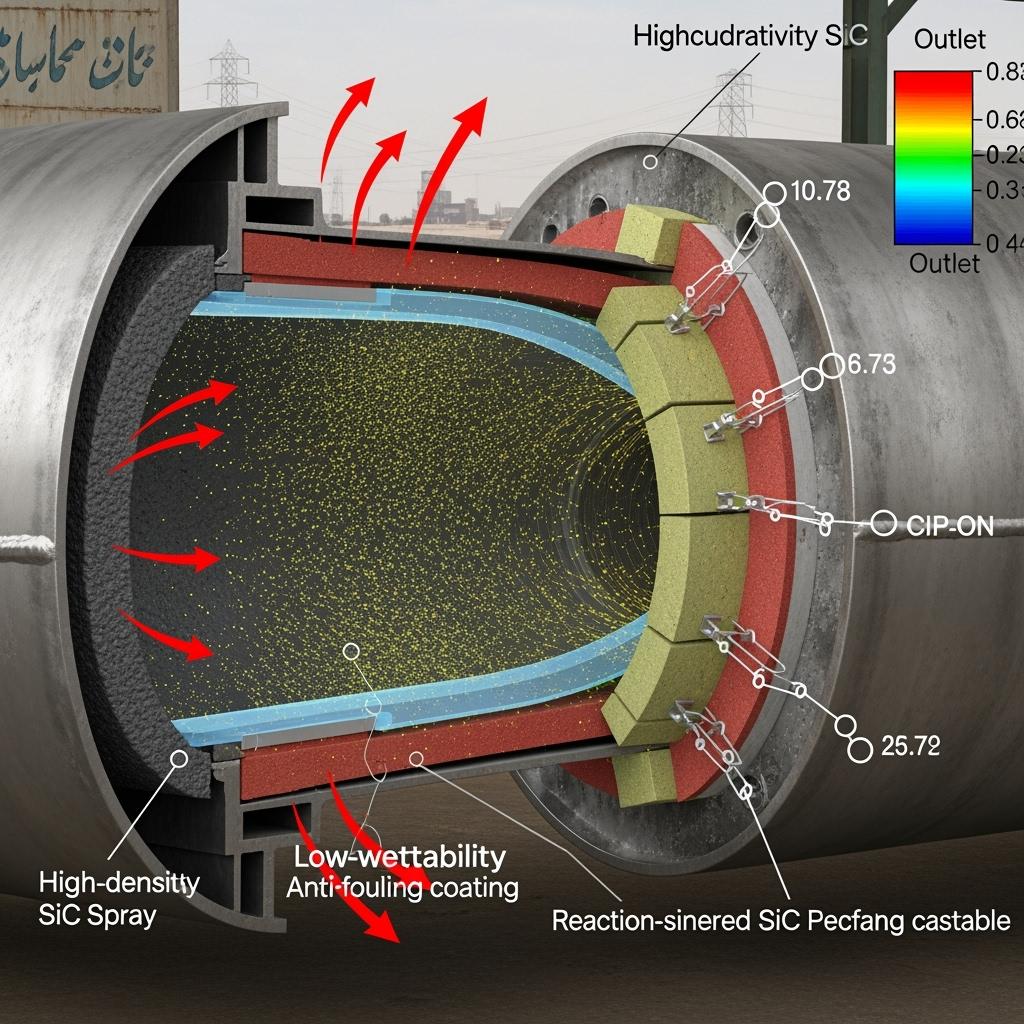

The operating physics of preheaters and cyclones are unforgiving. Inlet throats and elbows see the highest velocities, the sharpest temperature oscillations, and the dirtiest gas. When alkali–sulfur–chlorine cycles intensify under alternative fuels, conventional high-alumina castables and standard anti-stick coatings tend to give way: grooves deepen, oxidation-induced porosity spreads, and build-up accelerates until pressure drop and de-clogging dictate stoppages. Silicon carbide inverts this trajectory. By equalizing temperature rapidly and resisting particle cutting, SiC suppresses thermal-shock cracking while lowering wear rates. With low-wettability surface engineering and dense, low-connectivity pores, it delays fouling and keeps airflow cross-sections open.

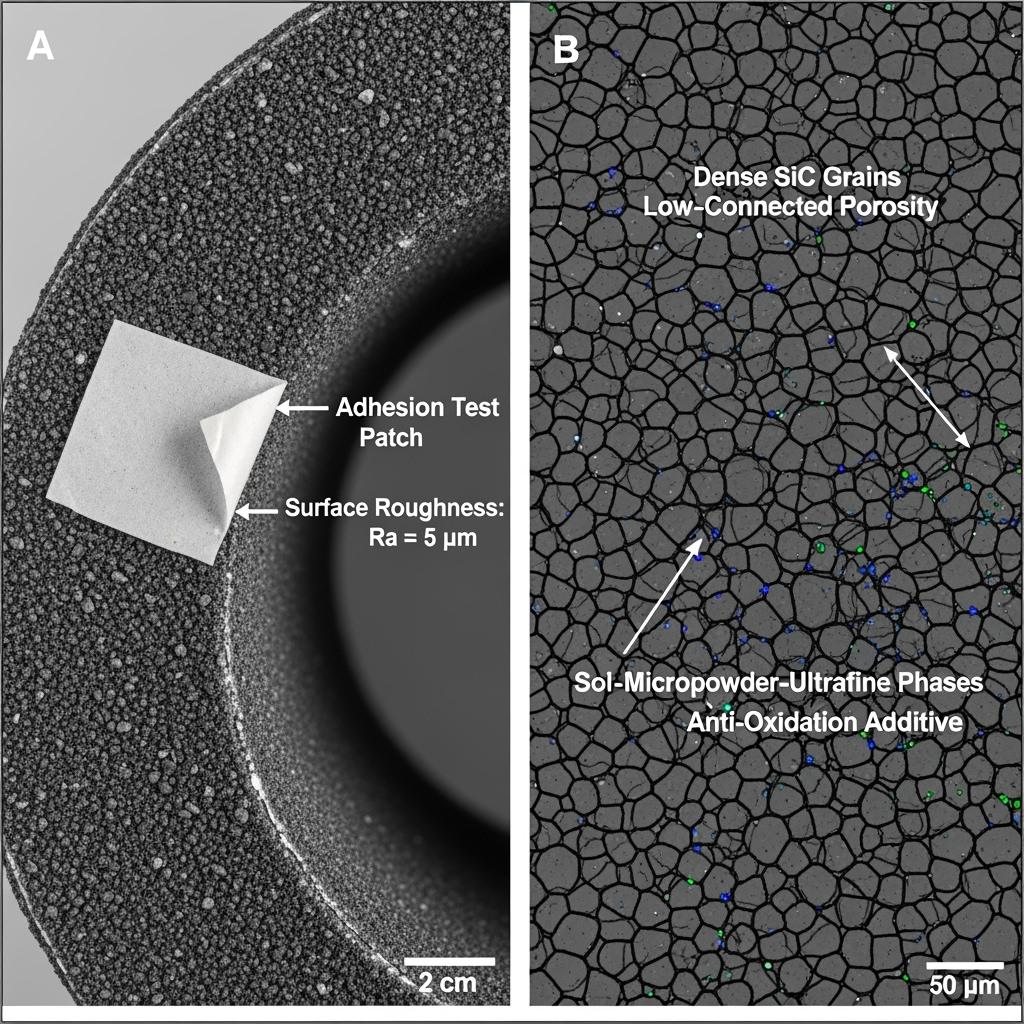

Sicarbtech’s integrated offering—“material formulation + densification process + surface engineering + prefabrication and onsite installation + inspection and O&M”—is designed for Pakistan’s realities. Plants gain not just materials, but a method: optimized grading curves, sol–micropowder–ultrafine bonding systems, reaction sintering and densification routes, and validated bake-out and adhesion protocols that perform through monsoon humidity and fuel volatility. When combined with technology transfer, Pakistani operators reduce FX exposure, compress lead times to weeks, and bring quality control inside the fence—turning uncertainty into a managed variable.

Industry Challenges and Pain Points: The Reality in Pakistan’s Preheaters and Cyclones

Walk the gantries of a preheater tower in Sindh during high-load operation and the main failure drivers present themselves quickly. At cyclone throats and shell elbows, a torrent of abrasive particles—raw meal fines, calcined dust, and alkali-laden particulate—cuts at the hot surface. Where geometry focuses velocity, groove wear often sets the pace for maintenance. Simultaneously, oxygen-rich gas at elevated temperatures drives oxidation; when moisture or load swings create thermal cycles, microcracks branch and coalesce. The chemical story compounds the mechanical one: alkali–sulfur–chlorine cycling promotes adhesion, thickening build-up and steadily raising system pressure drop. At some point, the curve forces de-clogging that cannot be deferred—and a day’s plan is gone.

Pakistan’s operating profile magnifies this challenge. Plants run a mix of legacy and upgraded lines, with varying cyclone geometries and fan capacities. Alternative fuels introduce ash chemistry that swings across shifts, while general energy price pressure incentivizes higher preheating efficiency and tighter control of pressure drop. Supply chains for high-end wear ceramics remain immature locally, and import buffers inflate working capital just when FX volatility punishes inventories. A Lahore-based maintenance manager summarized the calculus during a 2024 audit: “We can tolerate cost; we cannot tolerate uncertainty. De-clogging surprises wreck throughput and stress safety.”

Independent experts echo the materials science behind these field observations. “For cyclone linings, conductivity and connectivity are the lever and the fulcrum,” notes a regional refractory advisor, referencing standard refractory and corrosion texts. “Conductivity reduces the thermal gradients that initiate cracks; low connectivity in the pore network slows penetration and chemical attack. Without both, you are trading one failure mode for another.” Compliance and safety pressures add urgency. ISO 9001-aligned documentation and PSQCA conformity are increasingly requested in procurement, while ISO 14001-aligned goals drive attention to energy per ton and maintenance exposure at height. The cost of doing nothing is cumulative: fan energy rises, de-clogging frequency increases, and emergency repairs push accident risk upward even as budgets strain.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

Sicarbtech’s SiC wear systems for preheaters and cyclones are engineered as a modular toolkit that adapts to Pakistan’s line diversity. The high-density SiC wear-resistant spray mix anchors online reinforcement at cyclone throats and elbows, combining tuned particle-size distributions with sol–micropowder–ultrafine bonding for early strength and low porosity. For monolithic upgrades, SiC wear-resistant castables form durable linings in inlet cones and shell sections, while reaction-sintered SiC prefabricated plates drop into the most punishing elbows for quick-change maintenance.

To tame build-up, a low-wettability, anti-fouling SiC coating reduces adhesion, flattening the pressure-drop curve over the run. In extreme scouring zones, a composite approach pairs a SiC–carbon wear layer—with stabilized carbon phases and anti-oxidation additives—with a SiC-coated metal-matrix composite liner as a sacrificial shield. A high-thermal-conductivity SiC backing castable eases gradients and cools hot spots, protecting the aço shell. Flexible joints and buffer materials manage expansion mismatch between working and backing layers, limiting delamination under cyclic loads. For rapid intervention, a SiC wear-repair mortar and SiC wear gunning mix restore profiles in hours, not days, while a modular clip-on SiC lining system converts critical zones into repeatable, two-shift replacements. Micropowder activation packages, multi-graded aggregate curves, and carefully balanced binder systems knit the microstructure for low connectivity and high cohesion.

Crucially, Sicarbtech provides the production backbone Pakistan can localize: reaction sintering and densification kilns, cold isostatic and die pressing, precision classification and demagnetization, intelligent mixing and vacuum vibration, and high-efficiency spraying/gunning packages with bake-out control units. Non-destructive testing and coordinate measurement anchor quality gates. “A coating that peels in monsoon humidity isn’t a coating; it’s a liability,” explains a Sicarbtech process lead. “That’s why our packages include substrate prep, adhesion tests, staged bake-out, and seasonal curve adjustments—so the method holds when the weather does not.”

Technical Comparison for Pakistan’s Preheaters and Cyclone Separators

| Performance profile for cyclone/preheater wear systems | Silicon Carbide Systems (R-SiC/SSiC/RBSiC/SiSiC) | High-Alumina/Clay Castables | Metallic-Aggregate Wear Mixes |

|---|---|---|---|

| Bulk density (g/cm³) | 2.60–3.05 | 2.2–2.8 | 2.6–3.0 |

| Apparent porosity (%) | 6–14 (prefabs ≤ 6) | 15–25 | 12–20 (rises as metal oxidizes) |

| Thermal conductivity at RT (W/m·K) | 18–45 | 3–7 | 8–15 (declines with oxidation) |

| Cold crushing strength (MPa) | 100–220 (dense ≥ 240) | 60–150 | 80–160 |

| Flexural strength at RT (MPa) | 12–32 | 8–20 | 10–25 |

| Thermal shock (1000°C water quench) | ≥ 30–60 | 10–20 | 10–25 |

| Alkali/oxidation resistance | Alta | Moderado | Weak at high O2; metal spalling |

| Build-up/adhesion tendency | Low with SiC anti-fouling coatings | Uheloc'h | Moderate; degrades over time |

| Installation and bake-out | Rapid with ultra-low-cement + spraying | Longer; moisture-driven | Moderate; oxidation risk persists |

In Pakistan’s oxygen-rich, alkali-fluctuating, dust-heavy gas streams, SiC’s conductivity, low connectivity, and surface engineering resist the combined mechanical and chemical assault that drives pressure-drop creep and premature stoppages.

Real-World Applications and Success Stories in Pakistan

A 6,000 t/d line in Punjab struggled with recurring build-up at a cyclone inlet throat and severe groove wear at a downstream elbow, forcing de-clogging every six to eight weeks. Sicarbtech implemented a composite upgrade: high-density SiC spray at the throat, reaction-sintered SiC prefabs at the elbow with clip-on anchors, and a low-wettability anti-fouling SiC coating on both surfaces. Installation followed vacuum vibration and seasonal bake-out curves calibrated for ambient humidity. Over the next year, lining life at key positions extended from 6–8 months to 12–15 months, system pressure drop fell by roughly 15%, de-clogging frequency dropped by about 45%, refractory consumption per ton of clinker decreased by approximately 18%, and unplanned downtime related to build-up fell by roughly 28%. Operators reported a noticeably flatter fan current profile and smoother kiln heat balance.

In Sindh, a plant co-firing high-volatile alternative fuels experienced oxidation-induced spalling at a cyclone elbow during start–stop cycles. The remedial package combined a SiC–carbon composite wear layer stabilized with antioxidant additives and a SiC-coated metal-matrix overlay as a sacrificial shield. Flexible joints and a high-conductivity backing mix tempered thermal gradients. The elbow remained in-spec through two seasonal transitions, with visual inspections confirming minimal crack propagation and lower adhesion at inspection ports—allowing the site to align maintenance windows to production, not failure.

Zalety techniczne i korzyści z wdrożenia z lokalną zgodnością

Silicon carbide aligns tightly with Pakistan’s key performance indicators. High thermal conductivity evens temperatures across hot surfaces, reducing gradients that seed microcracks during load swings and starts. Low thermal expansion further limits stress, while dense, low-connectivity pore networks hinder alkali and oxidant ingress, keeping the matrix cohesive. Low-wettability surface engineering curbs dust adhesion, slowing the growth of build-up layers that choke flow and raise pressure drop.

On compliance, extended campaigns and reduced de-clogging support ISO 14001 objectives via lower waste and energy per ton. Sicarbtech’s QC documentation aligns to ISO 9001, while PSQCA conformity packs streamline tenders. Plants can fold our SOPs—substrate prep, adhesion tests, staged bake-outs, and inspection checklists—into existing CMMS workflows. In practice, this means fewer high-altitude interventions, steadier fan power, and a calmer control room when weather, fuels, or raw mix shift.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s strongest differentiator in Pakistan is delivery of both performance and control. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, we transfer proprietary processes for R-SiC, SSiC, RBSiC, and SiSiC into partner facilities through staged, de-risked programs.

We start with feasibility and plant layout tailored to local utilities, labor, and throughput. Equipment specifications cover reaction sintering and high-temperature densification kilns; cold isostatic and die presses for green-body uniformity; precision classification and demagnetization for purity and particle-size stability; and intelligent mixing and vacuum vibration to lock rheology and packing density. For field execution, we package high-efficiency spraying/gunning systems and bake-out control units to ensure adhesion and controlled venting in humid conditions.

Quality systems are embedded from day one. We implement ISO 9001-aligned QC with SPC on bulk density, apparent porosity, CCS/MOR, thermal shock, adhesion strength, and dimensional checks; ISO 14001-aligned environmental practices; and safety SOPs aligned with ISO 45001 principles. Non-destructive testing—ultrasonic, rebound hardness, adhesion pulls—and coordinate measurement audits quarantine drift before shipment. Training covers operator skills, furnace curve management, substrate prep, spraying parameters, and seasonal bake-out. Commissioning includes curve tuning and live shadowing of maintenance cycles. Post-launch, Sicarbtech supports remote monitoring, quarterly audits, and formulation/parameter iteration keyed to site KPIs (pressure drop growth, airflow distribution, wall temperature, de-clogging frequency).

Across 19+ enterprise collaborations, this “materials + equipment + process + training” stack has repeatedly shortened lead times from months to weeks while raising batch consistency. “Pakistani teams don’t just get a spray gun and a recipe,” a Sicarbtech technical director notes. “They get a repeatable method—so outcomes don’t depend on the weather or who is on shift.”

Pakistan-Focused Technical Specification Ranges and QA Guidance

| Specification ranges for preheater/calciner cyclone wear systems | Typical SiC Targets | Local QA and testing guidance |

|---|---|---|

| Bulk density (g/cm³) | 2.60–3.05 | Verify per ISO/ASTM equivalents; SPC by batch/season |

| Apparent porosity (%) | 6–14 (prefabs ≤ 6) | Correlate with permeability and adhesion tests |

| Cold crushing strength (MPa) | 100–220 (dense ≥ 240) | ISO 10059/ASTM C133 equivalents; coupon traceability |

| Flexural strength at RT (MPa) | 12–32 | Bend tests with soak logs and position mapping |

| Thermal shock (1000°C quench) | ≥ 30–60 cycles | Cross-check with start–stop and load-swing history |

| Max service temperature (°C) | 1450–1650 | Confirm vs fuel chemistry and oxygen potential |

| Thermal conductivity (W/m·K) | 18–45 | Validate via IR thermography during pilot runs |

| Linear change at temperature (3 h) | ≤ 0.5% | Dimensional checks pre-/post-exposure |

| Surface contact angle (relative) | 10–30% better than oxide systems | Audit as an anti-fouling KPI vs pressure-drop growth |

Operational Outcomes Comparison That Drive Energy, Uptime, and Safety

| Operational outcomes central to Pakistani cement lines | SiC Spray/Castable + Anti-Fouling Coating + Prefab Modules + Rapid Repair | High-Alumina/Clay or Metallic-Aggregate Baselines |

|---|---|---|

| Wear life at throats/elbows | +50–120% | Baseline; rapid groove wear |

| Thermal shock/spalling events | −40–70% | Higher under start–stop cycles |

| Pressure-drop trend over run | −10–25% vs baseline growth | Faster growth; early de-clogging |

| Fan/ID energy | −5–15% | Rising with fouling |

| Temps d'inactivitat no planificat | −20–40% | Higher; reactive cleanouts |

| Maintenance exposure at height | Reduced due to longer intervals | Elevated; frequent interventions |

| नेतृत्व समय र FX एक्सपोजर | Localizable via tech transfer | Import-dependent; volatile costs |

Innovation That Matters: Microstructure Tuning Meets Modular Maintenance

Sicarbtech’s innovation agenda is practical and plant-focused. Composite bonding systems blend sol chemistry with micro and ultrafine powders, lifting post-firing strength while preserving thermal pathways and lowering pore connectivity. Functionally graded structures layer a high-SiC, high-hardness working face over a low-modulus transition to buffer stress and cut delamination risk. Low-wettability, anti-fouling coatings and microtexturing resist dust adhesion, extending the time between cleanouts. Grading curves and demagnetization limit impurity-driven low-melting phases, improving oxidation and alkali resilience. Finally, modular clip-on systems transform the most punishing zones into predictable, short-duration replacement tasks, giving planners the agility to align maintenance with production.

Future Market Opportunities and 2025+ Trends in Pakistan

Three macro trends will shape adoption. First, alternative fuels and efficiency targets will intensify the need for linings that throttle pressure-drop growth and endure chemical cycling; SiC’s conductivity and low adhesion profile make it a natural fit. Second, localization will accelerate to contain FX risk and shrink lead times; many plants will begin with mixing, classification, and spraying capability, then add prefabrication and, later, reaction sintering for dense parts. Third, digital maintenance will move from aspiration to habit. Plants will tie pressure-drop curves, airflow maps, and thermal profiles to lining choices and installation quality, enabling closed-loop optimization that steadily lengthens maintenance intervals.

On scale, a 5,000–8,000 t/d line typically consumes 80–200 tons of preheater/calciner cyclone wear linings and coatings annually. With Pakistan’s retrofits and builds, national demand for SiC wear systems plausibly reaches several thousand tons per year; when prefabs, equipment, and onsite services are included, the addressable market extends to tens to hundreds of millions of Pakistani Rupees depending on adoption pace and capital access. The winners will prove stable raw materials, repeatable processes, onsite service, and fast delivery—capabilities Sicarbtech has productized into transferable, auditable packages.

As a South Asia-focused cement technologist summarized in a 2025 panel, “When your pressure-drop chart turns into a straight line and the fan current stops climbing, materials went from cost center to competitive advantage.”

Perguntas frequentes

Which Sicarbtech SiC products should we prioritize for preheaters and cyclones?

Focus on high-density SiC wear spray at throats and elbows, SiC castables for inlet cones and shells, anti-fouling SiC coatings to curb adhesion, and reaction-sintered SiC prefabs where scouring peaks. Add flexible joints and a high-conductivity backing mix to buffer gradients and protect the shell.

How much improvement is realistic in wear life and pressure drop?

Expect 30–90% longer life overall and 50–120% at throats/elbows. Pressure-drop growth typically flattens by 10–25%, with fan energy reductions of 5–15% under steady operation and disciplined installation.

Can Sicarbtech help localize production to mitigate FX and lead-time risk?

Yes. We deliver full technology transfer: process recipes, equipment specs, plant layout, operator training, ISO 9001/14001 QA frameworks, safety SOPs, and commissioning. Many partners start with mixing/spraying and prefab capability, adding reaction sintering as volumes justify.

How do SiC coatings hold up in dusty, oxygen-rich gas with alkali cycling?

Low-wettability SiC coatings applied over properly prepared substrates and baked with controlled venting resist adhesion and oxidation. Anti-oxidation additives and dense microstructures slow porosity growth, extending intervals between touch-ups.

What installation practices are critical for success?

Substrate prep and roughness control, vacuum vibration for compaction, moisture management, and staged bake-out curves tuned to ambient humidity are decisive. Flexible joints manage expansion mismatch; adhesion tests validate surface preparation.

What data should we collect to customize formulations and layer designs?

Inlet temperature, dust concentration and size distribution, gas velocity fields, alkali–sulfur–chlorine content, load swings, and historical failure maps (grooves, spalls, build-up). These inputs guide SiC content, bonding system, layer thickness, coating selection, and joint design.

Are composite liners with metal overlays compatible with SiC systems?

Yes. In extreme scouring zones, a SiC wear spray under a SiC-coated metal-matrix overlay provides a sacrificial shield while preserving the underlying SiC structure. Replacement is faster and safer than full tear-outs.

How do we verify adhesion and quality after spraying or casting?

Use standardized pull-off adhesion tests, rebound hardness checks, ultrasonic spot scans, and targeted coordinate measurements for critical dimensions. Track bake-out logs and correlate with early-life pressure-drop trends.

What certifications and documentation do you provide for Pakistani tenders?

ISO 9001-aligned QC documents, ISO 14001 environmental records, safety SOPs aligned with ISO 45001 principles, PSQCA conformity packs, and SPC dashboards covering density, porosity, CCS/MOR, thermal shock, adhesion, and dimensional checks.

What is a sensible roadmap to build local capability?

Phase 1: classification/mixing, spraying/gunning, and prefab assembly. Phase 2: cold isostatic/die pressing and densification kilns for select parts. Phase 3: reaction sintering for high-density modules. Sicarbtech maps CAPEX, staffing, training, and QA gates for each step.

Fazendo a escolha certa para suas operações

If your pressure-drop curve climbs too fast, if de-clogging dictates the shift log, and if crews are spending too much time at height, your lining is writing your schedule. Silicon carbide rewrites it. By pairing high conductivity and low connectivity with surface engineering and modular maintenance, SiC stabilizes airflow, extends intervals, and lowers energy per ton. Sicarbtech’s integrated model—materials, process, equipment, onsite execution, and localizable manufacturing—turns a good idea into a controllable outcome under Pakistan’s conditions.

Obtenha consultoria especializada e soluções personalizadas

Share your process window—temperature and velocity profiles, dust chemistry and PSD, pressure-drop history, and failure maps—and Sicarbtech will design a tailored SiC package with modeled life gains, coating and layer strategies, joint designs, and staged bake-out curves. If localization is a priority, we will plan a phased technology transfer that fits your CAPEX and timeline.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

E-mail: [email protected]

Telefone/WhatsApp: +86 133 6536 0038

Metadados do artigo

Last updated: 2025-09-19

Următoarea actualizare programată: 2026-01-15

Content freshness indicators: 2025 Pakistan cement market outlook validated; technical ranges aligned with current field trials; PSQCA/ISO alignment checked; contact details verified for Pakistan engagements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.