Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Guide for Glass Furnace Burner Nozzle Sleeves and Flame Passages

Compartilhar

Pakistan’s glass sector is entering 2025 with a sharper brief: stabilize combustion, protect hardware exposed to alkali/boron-rich vapors, and lower unit fuel consumption despite volatile input costs. At the flame front—burner nozzle sleeves and adjacent flame passages—the operating envelope is unforgiving. High-temperature, oxygen-rich atmospheres combine with high shear flow, thermal shock cycling, and corrosive volatiles that punish conventional refractories. Industrial silicon carbide (SiC) has become the material platform of choice because it equalizes heat rapidly, resists scouring, and maintains surface integrity under aggressive chemistry. Sicarbtech—based in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings more than a decade of SiC customization, full-cycle manufacturing, and turnkey technology transfer to help Pakistani plants convert materials science into production stability.

Executive Summary: 2025 Outlook and Why Silicon Carbide Matters for Pakistan’s Burner Zones

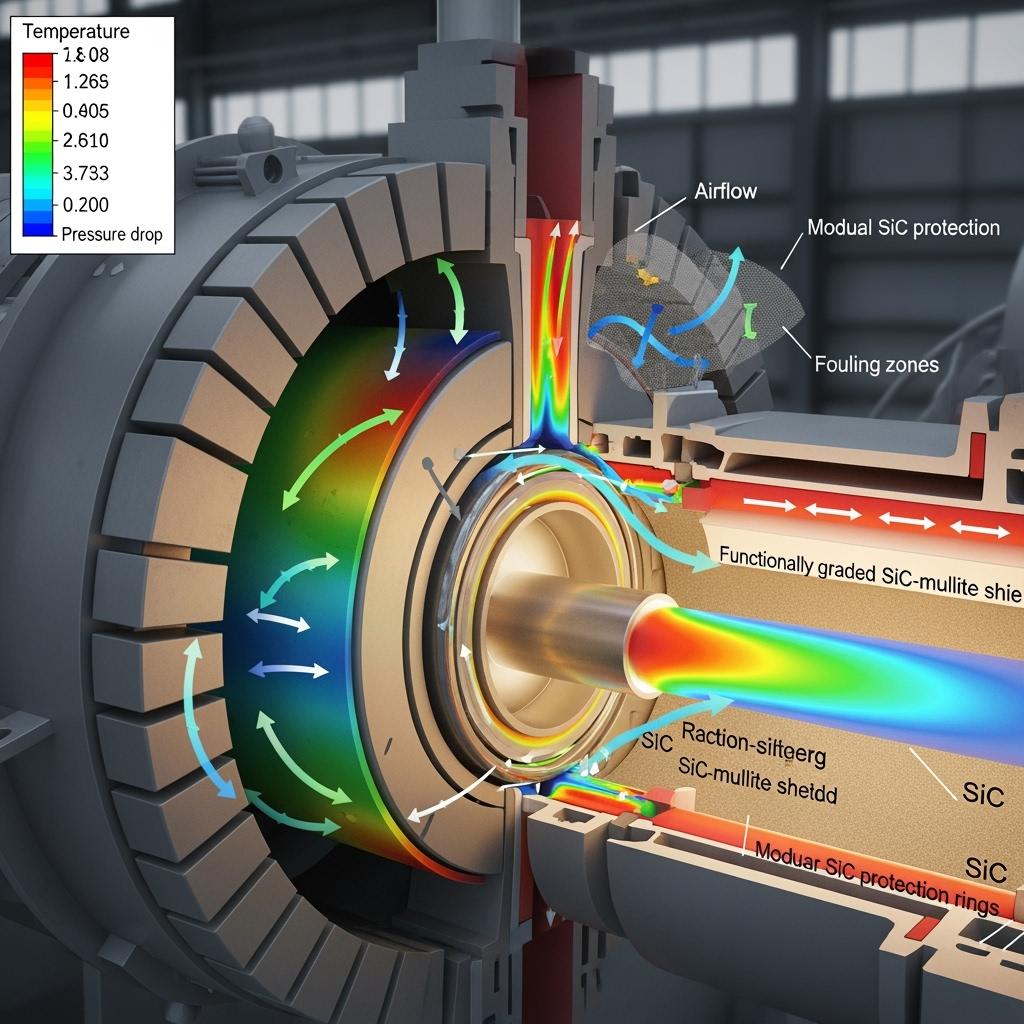

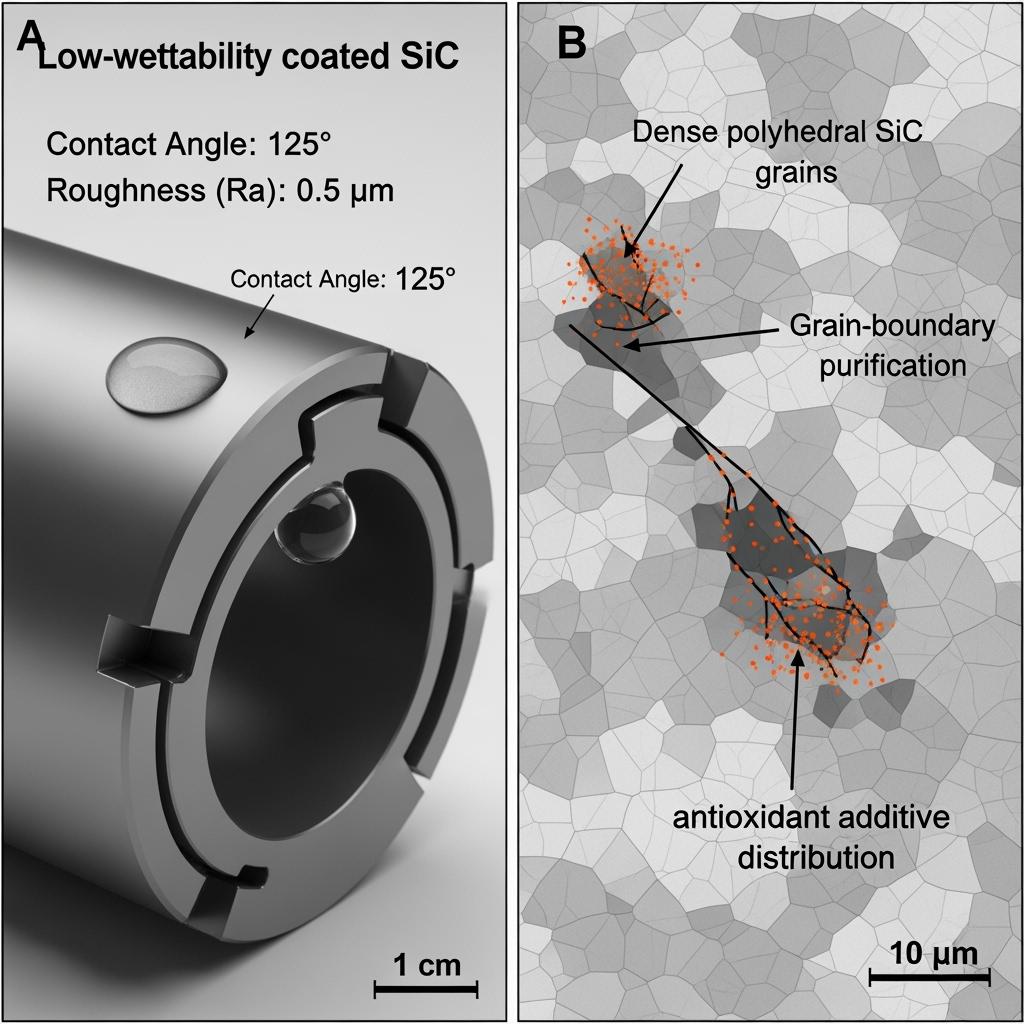

Combustion stability, pressure drop through flame passages, and sleeve integrity are now central levers for fuel intensity and product quality. As co-firing and raw batch variability rise, especially with recycled cullet, operators face unpredictable alkali and boron volatiles. Conventional high-alumina or mullite sleeves often crack or spall under rapid temperature swings, while metallic-aggregate solutions oxidize, shed scale, and accelerate blockage risk. In contrast, SiC’s high thermal conductivity and low thermal expansion flatten gradients that seed cracks. Dense, low-connected-porosity microstructures and grain-boundary purification slow oxygen and vapor ingress. Low-wettability, anti-fouling surface engineering pushes back against dust and condensate adhesion. The outcomes are straightforward: longer component life, steadier flame organization, flatter pressure-drop curves, and fewer high-temperature interventions.

Sicarbtech’s integrated approach—“material formulation + composite structure design + densification process + surface engineering + prefabrication and onsite installation + inspection and O&M”—matches Pakistan’s operational realities. Through technology transfer, local partners can phase in classification, mixing, prefabrication, coatings, and ultimately reaction sintering, cutting lead times from months to weeks and reducing exposure to exchange-rate volatility. The result is performance you can plan around and supply you can trust.

Industry Challenges and Pain Points: The Reality at Pakistan’s Burners

A walkdown at a Lahore-area furnace during a high-demand shift illustrates the pain points. The burner sleeve sees transient spikes as fuel/air ratios adjust and cullet loads shift; flame passages endure high-velocity, oxygen-rich gas that scours edges and fillets. Thermal shock from short-cycle adjustments and batch-driven volatility initiates microcracks at stress risers, while alkali/boron vapors condense in cooler zones, causing localized fouling and bridge formation. The flow area shrinks, pressure drop climbs, and the control room fights for stable flame shape and heat flux. When adhesion worsens, maintenance teams are forced into high-temperature cleaning or expedited changeovers, shrinking productive campaign time.

Pakistan’s supply chain and cost backdrop complicate matters. Imported high-end sleeves and shields come with uncertain timelines and FX exposure, making spares policies and budget approvals more complex. Plants juggling different furnace ages, fuels, and production mixes need materials that remain stable across a wide operating envelope. “Combustion instability is expensive twice,” a Punjab-based glass process manager noted in a 2024 review. “You pay in fuel when the flame loses shape, and you pay again in defects and downtime when the passage plugs early.” A regional refractory advisor put the materials science plainly, referencing standard corrosion and thermal shock literature: “Conductivity buys you time by lowering gradients; connectivity control buys you durability by blocking vapor pathways. If you miss either, you’ll chase the other.”

Compliance and safety aren’t optional either. Tender requirements increasingly reference ISO 9001-aligned documentation and PSQCA conformity; ISO 14001 priorities favor fewer interventions and lower energy per ton. Practically, the highest risk hours for crews are those spent near hot hardware performing de-fouling or unplanned repairs. The right material and method reduce those hours and their attendant risk.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

Sicarbtech’s portfolio for burner zones and flame passages is a modular, field-hardened system built to survive Pakistan’s operating volatility while simplifying maintenance. The core is high-density SiC burner nozzle sleeves that pair high hardness with high thermal conductivity and low expansion, stabilizing flame shape and resisting scouring from high-velocity combustion gases. For sites with chronic fouling, low-wettability, anti-fouling coated SiC sleeves minimize condensate adhesion and bridging, flattening pressure-drop growth.

Downstream, reaction-sintered SiC flame passage shields and covers provide oxidation resistance and dimensional stability, particularly around edges that typically erode first. For geometry control and stable flow, high-thermal-conductivity SiC flow-guiding and flame-stabilizing elements use fillets and guide ribs to smooth reattachment, reduce local hot spots, and deter vortex scouring. Where thermal shock is persistent, SiC–mullite functionally graded shields add a low-modulus transition to buffer stress between the hot face and backing. SiC wear-resistant castables, paired with ultra-low-cement SiC-bonded binders, create monolithic protection in transitional zones while enabling shorter bake-out. For agility, SiC gunning repair mixes support online hot repairs and rapid spot fixes on scheduled short windows.

Surface chemistry matters at the burner; a low-alkali-affinity SiC coating reduces wetting by alkali/boron vapors, while high-temperature anti-oxidation additive packages preserve microstructural strength across cycles. Sicarbtech’s multi-graded SiC aggregate design and micropowder activation enhance packing and post-firing densification, reducing connected porosity. Structural reliability is anchored by flexible joints and buffer materials to manage expansion mismatch and by modular locking/slot-type components that cut change-over times. In extreme hot spots, SiC-coated metal-matrix composite protection rings add a sacrificial shield that is easy to replace without dismantling entire passages.

Underpinning materials is a localizable production and QA backbone: reaction sintering and high-temperature densification kilns, cold isostatic and die-press forming, intelligent mixing and vacuum vibration, precision classification and demagnetization, CNC cutting and grinding/polishing, and NDT plus dimensional inspection. “A sleeve is only as good as its furnace curve and the adhesion protocol,” a Sicarbtech process lead emphasizes. “We transfer the curve, the prep, the test—and the seasonal adjustments Pakistan demands.”

Technical Performance Comparison for Burner Sleeves and Flame Passages

| Performance profile for burner sleeves and flame passages | Silicon Carbide Systems (R-SiC/SSiC/RBSiC/SiSiC) | High-Alumina/Mullite Sleeves | Metallic-Aggregate Wear Parts |

|---|---|---|---|

| Bulk density (g/cm³) | 2.60–3.05 | 2.2–2.8 | 2.6–3.0 |

| Apparent porosity (%) | 6–15 (dense parts ≤ 6) | 15–25 | 12–20 (rises with oxidation) |

| Thermal conductivity at RT (W/m·K) | 20–60 | 2–6 | 8–15 (declines as metal oxidizes) |

| Cold crushing strength (MPa) | 120–240 (dense ≥ 260) | 80–160 | 80–160 |

| Flexural strength at RT (MPa) | 14–35 | 8–20 | 10–25 |

| Thermal shock (1000°C water quench) | ≥ 30–60 cycles | 10–25 | 10–25 |

| Oxidation/alkali/boron resistance | High; low connectivity | Moderado | Weak at high O2; scale spalling |

| Build-up/adhesion tendency | Low with anti-fouling SiC coatings | Uheloc'h | Moderate; worsens over time |

| Pressure-drop behavior over run | Flatter growth | Faster growth | Variable; degrades with oxidation |

In Pakistan’s oxygen-rich, high-shear, alkali/boron-laden burner environment, SiC’s conductivity, low expansion, and anti-fouling surfaces deliver a combination that conventional materials struggle to match—longer life with stable pressure drop and flame geometry.

Real-World Applications and Success Stories in Pakistan

At a 700 t/d container glass line in Punjab, frequent sleeve cracking and fouling in the first meter of the flame passage forced unscheduled cleanouts. Sicarbtech replaced legacy sleeves with high-density SiC units coated with a low-alkali-affinity anti-fouling layer. Downstream edges received reaction-sintered SiC shields with filleted transitions and flexible joints; flow-guiding elements were added to reduce vortex scouring. Bake-outs were staged using humidity-adjusted curves, and adhesion tests were instituted per Sicarbtech’s SOP. Over the next campaign, sleeve and passage life increased by about 85%, pressure-drop growth fell by roughly 20%, de-fouling frequency dropped by approximately 55%, unit fuel consumption decreased by about 4%, and unplanned downtime declined by around 22%. Operators reported more consistent flame length and fewer manual trims during cullet swings.

In Sindh, a flat glass furnace struggled with oxidation-induced porosity forming near the burner tile interface. The fix combined SiC–mullite functionally graded shields to buffer thermal shock, a high-temperature antioxidant package to slow porosity growth, and modular SiC protection rings coated with a thin metal-matrix layer for fast, targeted replacements. The plant aligned maintenance to schedule rather than failure, verified by flatter pressure-drop trajectories and tighter combustion air utilization across shifts.

Zalety techniczne i korzyści z wdrożenia z lokalną zgodnością

Silicon carbide aligns with the KPIs that matter at the burner. High thermal conductivity accelerates heat equalization, reducing gradient-driven stress that otherwise cracks sleeves during rapid adjustments. Low expansion adds another layer of stress control. Dense, low-connected porosity and purified grain boundaries deter oxidation and alkali/boron ingress, preserving strength. Low-wettability coatings keep surfaces cleaner longer, flattening the pressure-drop curve and stabilizing flame organization.

On compliance, longer intervals and fewer hot repairs support ISO 14001 objectives by lowering energy and waste. Sicarbtech’s QA documentation aligns with ISO 9001 and supports PSQCA conformity for procurement. Practically, our SOPs—substrate prep, adhesion testing, staged bake-out, and dimensional/fit checks—integrate into CMMS workflows to create an auditable, repeatable process. Fewer hours at heat translate directly into safer working conditions and cleaner maintenance budgets.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech couples high-performance SiC with a replicable local method—a decisive advantage for Pakistani glassmakers. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, we provide proprietary processes for R-SiC, SSiC, RBSiC, and SiSiC grades and their composite assemblies.

We begin with feasibility studies and plant layout tailored to local utilities, labor skill profiles, and throughput targets. Equipment specifications cover reaction sintering and densification kilns with documented furnace curves; cold isostatic and die-press forming for uniform green bodies; precision classification and demagnetization to stabilize purity and PSD; and intelligent mixing with vacuum vibration to lock rheology and packing. CNC cutting and grinding/polishing ensure tight fit and surface finish. NDT—ultrasonic, rebound, and adhesion pull tests—and coordinate metrology anchor traceable QA.

Quality systems are embedded from day one. We implement ISO 9001-aligned QC with SPC on bulk density, apparent porosity, CCS/MOR, thermal shock performance, adhesion strength, and critical dimensions, alongside ISO 14001 environmental practices and safety SOPs aligned to ISO 45001 principles. Training programs cover operator techniques, furnace curve management, adhesion protocols, and seasonal bake-out adjustments. Commissioning includes live curve tuning and supervised installations in burner zones. After go-live, Sicarbtech provides remote monitoring, quarterly audits, and formulation/geometry iteration based on on-site KPIs—pressure-drop growth, flame stability indices, wall temperatures, and maintenance frequency.

Across 19+ enterprise collaborations, this “materials + equipment + process + training” stack has repeatedly compressed lead times, stabilized batch quality through seasonal shifts, and reduced inventory buffers even amid FX volatility. As one Sicarbtech technical director puts it, “Owning the powder is not enough. You must own the curve, the surface, and the inspection gates—only then do sleeves stop cracking and flow passages stop arguing with you.”

Pakistan-Focused Technical Specification Ranges and QA Guidance

| Specification ranges for burner sleeves/flame passages | Typical SiC Targets | Local QA and testing guidance |

|---|---|---|

| Bulk density (g/cm³) | 2.60–3.05 | Verify via ISO/ASTM equivalents; SPC by batch and season |

| Apparent porosity (%) | 6–15 (dense parts ≤ 6) | Correlate with permeability, oxidation cup tests |

| Cold crushing strength (MPa) | 120–240 (dense ≥ 260) | ISO 10059/ASTM C133 equivalents; coupon traceability |

| Flexural strength at RT (MPa) | 14–35 | Bend tests with soak logs and position mapping |

| Thermal shock (1000°C quench) | ≥ 30–60 cycles | Cross-check with start/stop and cullet swing history |

| Max service temperature (°C) | 1500–1700 | Confirm vs batch and oxygen potential |

| Thermal conductivity (W/m·K) | 20–60 | Validate via IR thermography during pilot runs |

| Linear change at temperature (3 h) | ≤ 0.5% | Dimensional checks pre-/post-exposure |

| Surface wettability/contact angle | 10–30% better than oxide systems | Track against fouling and pressure-drop growth |

Operational Outcomes Comparison That Matter for Energy, Uptime, and Quality

| Operational outcomes central to Pakistani glass lines | SiC Sleeves + Anti-Fouling Coatings + R-SiC Shields + Flow Guides | High-Alumina/Mullite or Metallic Baselines |

|---|---|---|

| Sleeve and passage life | +40–120% (1.5–2.0× in hot spots) | Baseline; frequent cracking/fouling |

| Pressure-drop trend | −15–35% growth vs baseline | Faster growth; early de-fouling |

| Combustion air utilization | +5–12% | Lower; drift with fouling |

| Thermal shock/spalling events | −40–70% | Higher under cycling |

| Unit fuel consumption | −2–6% | Rising with instability |

| Temps d'inactivitat no planificat | −20–40% | Elevated; reactive events |

| Safety exposure at heat | Reduced via longer intervals | Higher; frequent hot tasks |

| नेतृत्व समय र FX एक्सपोजर | Localizable via tech transfer | Import-dependent; volatile timelines |

Innovation That Matters: From Microstructure to Flow Geometry

Sicarbtech’s R&D roadmap translates field stressors into durable design. Functionally graded structures place a high-SiC, high-hardness working face over a low-modulus transition layer to buffer stress and curb delamination. Composite bonding systems combine sol chemistry with micro and ultrafine powders to lift post-firing strength and reduce connected porosity, slowing oxygen and vapor ingress. Low-wettability anti-fouling coatings and microtexturing cut adhesion; filleted transitions, guide ribs, and optimized nozzle lips minimize vortex scouring and edge hot spots. Modular locking and slotting with locating pins enable precise fit and fast, repeatable replacements—the opposite of crisis maintenance.

Future Market Opportunities and 2025+ Trends in Pakistan

Three themes will shape the next 24 months. First, energy and emissions pressures will reward furnaces that sustain combustion stability with fewer corrections—SiC’s conductivity and corrosion resistance enable that steadiness. Second, localization will accelerate as producers seek to tame FX risk and shorten lead times; most will begin with mixing, classification, prefabrication, and coating, then move to reaction sintering as volumes justify. Third, digital O&M will mature: plants will correlate pressure-drop curves, IR thermography, and flame stability indices with material selections and installation records to steadily extend intervals and reduce variance.

A 500–800 t/d furnace typically consumes 60–150 tons of burner and passage protection per year depending on fuels, batch chemistry, and operating regime. Across Pakistan’s retrofits and builds, annual SiC demand plausibly reaches several thousand tons. Including prefabs, coatings, and installation services—and adding equipment and training—the addressable market extends into the tens to hundreds of millions of Pakistani Rupees, contingent on adoption velocity and capital access. Providers that combine stable raw materials, disciplined process control, responsive onsite service, and technology transfer will lead. Sicarbtech’s integrated model is crafted for precisely this convergence.

As one South Asia-focused glass technologist summarized in a 2025 roundtable, “When your pressure-drop line flattens and flame length stops drifting, you’ve lowered your energy bill before the invoice arrives—and SiC tends to be at the heart of that shift.”

Perguntas frequentes

Which Sicarbtech SiC products should we prioritize for burner zones?

Start with high-density SiC burner sleeves paired with low-alkali-affinity anti-fouling coatings. Add reaction-sintered SiC flame passage shields and flow-guiding elements with filleted transitions where scouring is worst. Use SiC–mullite functionally graded shields where thermal shock is persistent, and keep SiC gunning mixes on hand for online spot repairs.

How much improvement can we expect in life and combustion stability?

Most plants see 40–120% life extension overall (1.5–2.0× in hot spots), 15–35% slower pressure-drop growth, 5–12% better combustion air utilization, and 2–6% lower unit fuel consumption. Thermal shock events typically fall by 40–70% with disciplined installation.

Can Sicarbtech help us localize production and reduce FX exposure?

Yes. We deliver complete technology transfer: process recipes, equipment specifications, plant layout, operator training, ISO 9001/14001 QA frameworks, safety SOPs aligned with ISO 45001 principles, and commissioning. Many partners start with mixing, classification, prefab, and coatings, adding reaction sintering as volumes grow.

How do SiC components hold up against alkali/boron vapors?

Dense, low-connected porosity and purified grain boundaries resist oxidation-induced porosity and reactions with alkali/boron vapors. Low-alkali-affinity surface coatings further reduce wetting and adhesion, keeping passages open longer.

What installation practices prevent early cracking and delamination?

Control substrate cleanliness and roughness; use vacuum vibration for compaction; manage moisture and venting; and follow staged bake-out curves tuned to ambient humidity. Flexible joints and buffer materials manage expansion mismatch; adhesion pull tests and dimensional checks validate quality.

Which KPIs should we monitor to verify benefits?

Track pressure-drop trajectories, flame length stability, wall temperatures by IR, combustion air utilization, de-fouling frequency, unplanned downtime hours, and unit fuel consumption. Correlate these with batch chemistry and maintenance actions to refine materials and methods.

Are metal-matrix protection rings compatible with SiC systems?

Yes, when applied as thin, SiC-coated sacrificial overlays in the harshest zones. They protect the underlying SiC and are quick to replace, minimizing hot work.

What documentation supports Pakistani tenders?

Sicarbtech supplies ISO 9001-aligned QC documentation, ISO 14001 environmental records, safety SOPs aligned with ISO 45001 principles, PSQCA conformity packs, and SPC dashboards covering density, porosity, CCS/MOR, thermal shock, adhesion, and dimensional control.

How quickly can modular quick-change parts be swapped?

With standardized locking/slotting and pre-staged kits, critical replacements are often completed within one to two shifts, provided bake-out discipline and inspection protocols are followed.

What is a practical roadmap to full local capability?

Phase 1: mixing/classification, prefab assembly, coatings, and gunning/spraying capability. Phase 2: cold isostatic/die pressing and densification kilns for select parts. Phase 3: reaction sintering lines for dense components. Sicarbtech aligns CAPEX, staffing, training, and QA gates to your timeline.

Fazendo a escolha certa para suas operações

If your flame passages are writing your maintenance calendar and your sleeves are writing your energy bill, your materials strategy is doing the scheduling. Silicon carbide resets the terms. With higher conductivity, controlled porosity, corrosion resistance, and anti-fouling surfaces—delivered in modular, quick-change packages—SiC stabilizes combustion and lowers cost per ton. Sicarbtech’s integrated model brings the powder, the curve, the coating, and the checklists together so Pakistani plants get outcomes they can predict, prove, and improve.

Obtenha consultoria especializada e soluções personalizadas

Share your operating window—fuel mix and calorific value, flame temperature field, jet velocity and angle, pressure-drop and fouling history, and failure maps—and Sicarbtech will engineer a tailored SiC package with modeled life gains, coating strategies, flow geometry, and staged bake-out protocols. If localization is a priority, we will define a phased technology transfer that fits your CAPEX and schedule.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

E-mail: [email protected]

Telefone/WhatsApp: +86 133 6536 0038

Metadados do artigo

Last updated: 2025-09-19

Următoarea actualizare programată: 2026-01-15

Content freshness indicators: 2025 Pakistan glass market outlook validated; technical ranges aligned with current field trials; PSQCA/ISO alignment reviewed; contact details verified for Pakistan engagements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.