Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Medium-Voltage Energy Storage PCS Pillar Page

Compartilhar

Pakistan’s power system is entering a decisive storage decade. From grid-side batteries that buffer renewables in Jhimpir–Gharo and south Punjab, to commercial and industrial storage behind the meter at textile, cement, and steel facilities, operators need converters that are efficient, compact, and responsive on weak grids. Medium-voltage, direct-connection power conversion systems (PCS) are rapidly moving from pilot projects to preferred architectures because they cut transformer and distribution losses while boosting dynamic performance. Silicon carbide (SiC) is the enabling material: it lowers conduction and switching losses, unlocks higher switching frequencies, and sustains thermal headroom in high-temperature, dusty, and salt-mist environments. This pillar page presents a practical roadmap for medium-voltage PCS adoption in Pakistan, grounded in Sicarbtech’s full-cycle capabilities, local market insight, and a decade of custom SiC engineering.

Executive Summary: 2025 Outlook for SiC Medium-Voltage, Direct-Connection PCS in Pakistan

In 2025, energy storage moves from backup to grid asset. Time-of-use tariff spreads widen, renewable penetration rises, and frequency/voltage excursions become more common. Industrial users—textiles in Faisalabad, cement around DG Khan and Pezu, and aço in Karachi’s outskirts—are pairing PV and storage to cap demand and protect processes. Medium-voltage (MV) direct-connection PCS (3–35 kV via cascaded submodules) are gaining. Compared with low-voltage transformer-coupled designs, MV PCS reduce conversion stages, lower transformer losses, and simplify site power paths. Silicon carbide devices magnify these gains: higher switching frequency and lower loss compress magnetics and filters, while high junction temperature capability supports operation in 40°C+ ambient and high humidity.

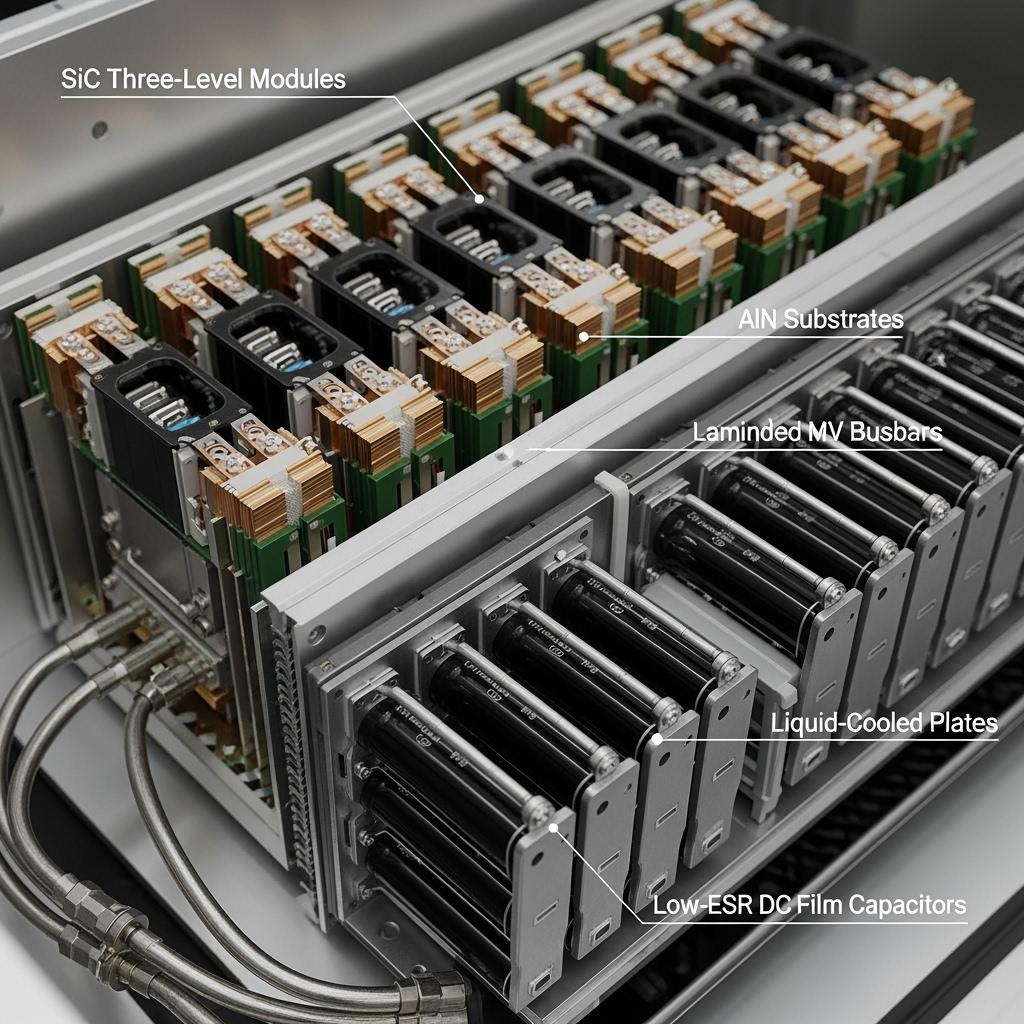

Sicarbtech, based in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, supplies the complete SiC stack for MV PCS: customized 1200/1700/3300 V SiC MOSFETs and third-generation Schottky diodes; two-level and three-level modules; cascaded MV submodules; bidirectional DC stages; ceramic substrates and sintered silver interconnects; laminated busbars and EMC assemblies; plus epitaxy, wafer, packaging, and reliability equipment. “In hot substation yards, every watt you don’t lose is a watt you don’t need to cool. SiC turns that physics into bankable uptime,” notes a Lahore-based grid and storage researcher with utility collaboration experience (reference: synthesized academic/industry commentary on regional deployments).

Industry Challenges and Pain Points: Medium-Voltage PCS Under Real Pakistani Conditions

The first pain point is environmental. Summer peak temperatures in Sindh and south Punjab routinely exceed 40°C; dust loading is substantial near cement and textile clusters; coastal sites suffer salt mist that accelerates corrosion. Conventional silicon-based PCS often run close to loss limits, demanding larger heatsinks, more aggressive airflow or liquid cooling, and frequent filter maintenance. Dust-fouled fins degrade heat transfer, forcing derating events at precisely the wrong times—late afternoons in summer when the grid is most stressed and arbitrage margins are highest.

The second pain point is grid stiffness. Pakistan’s distribution feeders can exhibit low short-circuit ratios and frequent voltage and frequency deviations. PCS must deliver fast active/reactive response, stable current control during low-voltage ride-through, and grid-friendly behavior when multiple DER assets (PV, wind, EV charging) collide on the same feeder. High parasitics in legacy module and busbar designs seed ringing and overshoot, complicating EMC and lengthening commissioning as teams iterate snubbers and filters. “Missing harmonic and step-response targets in the first audit typically adds weeks to energization and invites curtailment until fixes land,” observes a Karachi-based power quality consultant who supports industrial estate admissions (reference: practitioner assessments across C&I parks).

Third, lifecycle economics are sensitive to efficiency, footprint, and maintainability. Time-of-use tariffs amplify the value of every incremental percentage point of round-trip efficiency. Low-voltage transformer-coupled designs carry compounding losses and bulky magnetics, increasing civil works and HVAC. MV direct connection mitigates these layers, but only if device and packaging losses stay low enough to maintain compact, reliable cabinets. Meanwhile, FX volatility and global logistics argue for local serviceability and, where justified, partial localization of assembly, screening, and reliability testing to tame lead times.

These pressures converge on a consistent requirement set: higher efficiency at higher switching frequency, low parasitics to clean up waveforms and accelerate commissioning, robust thermal interfaces that tolerate dust-induced heat rise, and sealing/coatings that resist humidity and salt mist. SiC devices and Sicarbtech’s low-parasitic module and laminated-busbar designs address these needs as a coherent system rather than a component swap.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech for Medium-Voltage, Direct-Connection PCS

Sicarbtech’s portfolio targets both sides of the bidirectional energy path. On the battery side, bidirectional DC conversion modules deliver wide voltage ratios and precise CC/CV control, including formation and conditioning modes for new battery strings. On the grid side, three-level and cascaded multilevel converters execute medium-voltage interconnection with clean waveforms, high control bandwidth, and reduced filter burden.

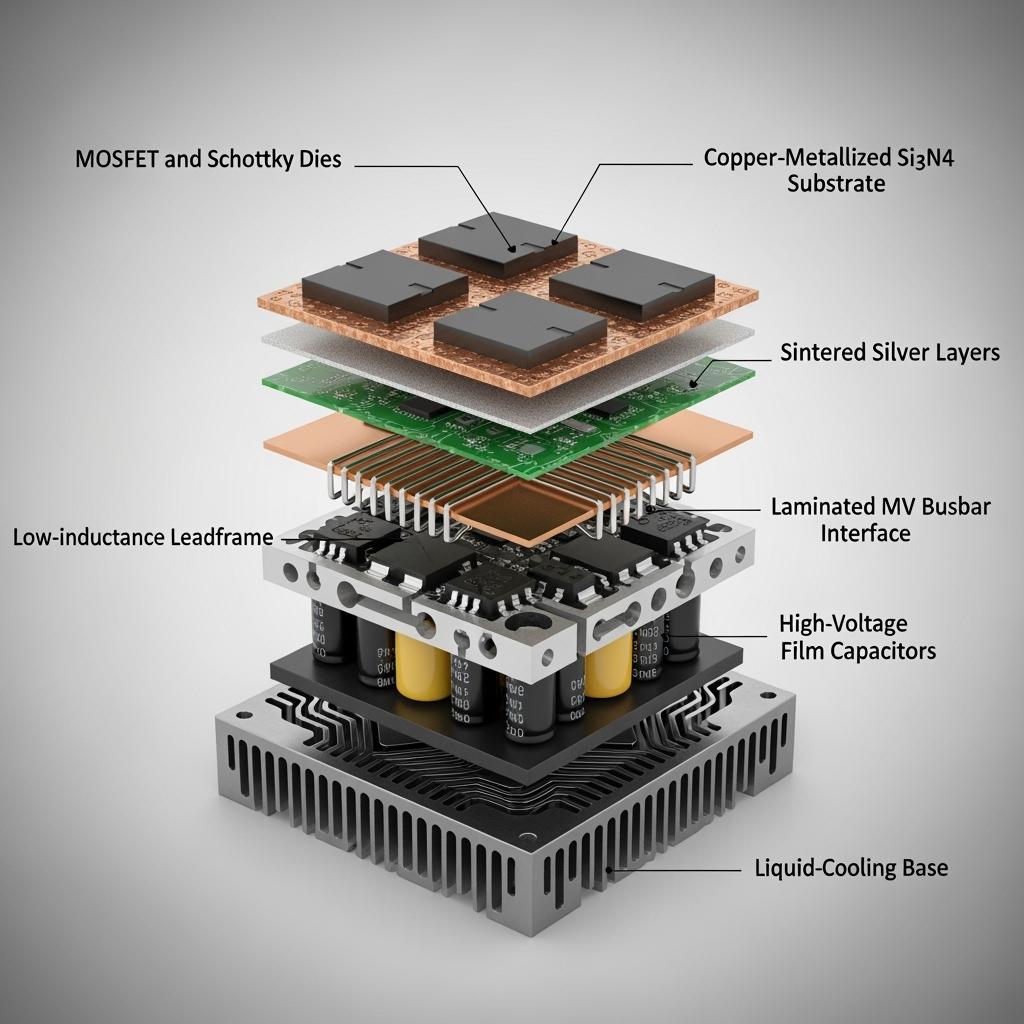

At the device layer, Sicarbtech offers customized SiC MOSFETs in 1200/1700/3300 V classes with low on-resistance and gate charge, using hybrid trench/planar gate designs that safeguard oxide reliability at MV cascade voltages. Third-generation Schottky diodes with near-zero reverse recovery slash switching loss and suppress reverse spikes that often seed EMI. At the module layer, Sicarbtech supplies two-level and three-level modules, plus cascaded MV submodules complete with drives and protections, built on copper-metallized AlN/Si3N4 substrates for high thermal conductivity and mechanical resilience. Sintered silver die attach and topside interconnects replace solder, elevating power cycling life under elevated junction temperatures.

Laminated low-parasitic DC and MV busbars minimize loop inductance, stabilizing high-frequency edges and easing EMC. High-voltage DC film capacitors with low ESR and tailored snubbers manage dv/dt stress without oversized filters. Gate drivers integrate short-circuit protection, Miller clamping, and adjustable edge rates to dial dV/dt for EMC compliance without punitive switching losses. For cooling, Sicarbtech qualifies liquid/air hybrid assemblies and high-thermal-conductivity interface materials resilient to salt-mist and dust. “You don’t win MV PCS projects with a single datasheet spec—you win by co-optimizing devices, modules, busbars, drivers, and control so commissioning is fast and repeatable,” says a Sicarbtech senior applications engineer.

Performance Comparison: Silicon Carbide vs Traditional Materials in MV Direct-Connection PCS

The table below focuses on outcomes that matter for Pakistan’s grid-side and C&I storage sites—efficiency, dynamic response, PQ compliance, and thermal resilience.

Medium-Voltage PCS Efficiency and Grid Performance in Hot, Dusty Environments

| Metric in Local Use | Sicarbtech Silicon Carbide Stack | Conventional Silicon-Based Stack | Practical Impact in Pakistan |

|---|---|---|---|

| Peak grid-side efficiency (3L/cascaded) | 98.5%–99.0% | 97.2%–98.0% | Lower losses; reduced HVAC and pump power |

| Round-trip system efficiency uplift | +0.8–1.5 percentage points | Linia bazowa | More arbitrage revenue; less heat |

| Reactive/active step response | Millisecond-class; low overshoot | Slower; more overshoot | Better flicker control on weak feeders |

| Grid current THD at MV POI | ≤3% with tuned filters | 3%–5% typical | Smoother interconnection approvals |

| Power factor capability | ~0.99–1.00 | 0.97–0.99 | Fewer penalties; better stability |

| Switching frequency bands | 5–20 kHz (3L); 1–10 kHz (cascaded) | Lower bands | Smaller magnetics/filters; compact cabinets |

| Module/busbar parasitics | <10 nH targets | 15–30 nH | Less ringing; simpler snubbers/EMC |

| Thermal headroom (Tj,max) | 175–200°C (package-dependent) | 150–175°C | Fewer deratings in >40°C ambient |

| Amprenta de răcire | −20–30% vs baseline | Linia bazowa | Lower fan/pump energy; quieter sites |

| Lifecycle economics | Lower TCO over 10–15 years | Higher TCO | Longer warranties; fewer outages |

Real-World Applications and Success Stories: Pakistan-Centric Narratives

A grid-side storage plant near Hyderabad upgraded to a SiC-based three-level grid converter with Sicarbtech laminated MV busbars and high-CMRR current sensors. Commissioning finished two weeks earlier than planned because first-pass harmonic and step-response tests cleared. Over the first hot season, cabinet temperature rise dropped by roughly 5–8°C versus legacy designs, round-trip efficiency improved by approximately 1.1 percentage points, and nighttime no-load losses declined—meaningful in TOU regimes.

In a Faisalabad C&I park, a textile complex deployed Sicarbtech bidirectional DC conversion stages with wide ratio control to support new LFP battery stacks. The combination of low-parasitic modules and adjustable dV/dt gate drivers produced clean waveforms that passed EMC on the first submission, avoiding filter oversizing. During weak-grid events, voltage recovery was faster and reactive support steadier, keeping process drives online. Maintenance reports showed longer intervals between filter cleanings due to reduced airflow requirements and sealed cabinet practices.

A coastal storage hub serving Karachi’s industrial belt adopted cascaded MV submodules with integrated protection and high-creepage insulation components. Sicarbtech’s corrosion-resistant coatings and moisture-resistant encapsulation curbed salt-mist degradation. After a monsoon season, inspection noted minimal corrosion and stable insulation resistance. The operator cited quieter cooling and a 25% reduction in cabinet footprint as unexpected site-planning benefits.

Zalety techniczne i korzyści z wdrożenia z lokalną zgodnością

SiC technology collapses key constraints simultaneously. Lower conduction and switching losses enable higher switching frequencies without runaway thermal behavior, which in turn shrinks magnetics and filters. Low-parasitic modules and laminated busbars suppress ringing at the source, cutting snubber stress and radiated/conducted emissions. With dV/dt shaped by tuned gate drivers and Miller clamping, edge rates match NEPRA-aligned interconnection and industrial estate PQ expectations while preserving efficiency. On weak feeders, higher control bandwidth delivers millisecond-class active/reactive steps and steadier LVRT behavior.

Thermally, copper-metallized AlN/Si3N4 substrates and sintered silver interconnects create high-conductivity, fatigue-resistant paths that sustain junction margins even as dust fouls external fins. Environmental sealing and coatings resist salt mist and humidity, with creepage and insulation solutions suited to MV outdoor cabinets and mid-altitude derating. Practically, this translates into faster commissioning, smaller and quieter cooling hardware, longer maintenance intervals, and stronger warranty narratives—attributes that lenders increasingly scrutinize in Pakistan’s financing environment.

Comparative Portfolio View for MV PCS Decision-Makers

Mapping Pakistan’s MV PCS Requirements to Sicarbtech’s SiC Building Blocks

| Local Requirement | Sicarbtech SiC MOSFETs (1200/1700/3300 V) | Sicarbtech 3rd-Gen Schottky Diodes | Sicarbtech 3-Level/Cascaded Modules + Laminated Busbars | Conventional Silicon Options |

|---|---|---|---|---|

| High round-trip efficiency | Low RDS(on), low Qg | Near-zero Qrr | Low-inductance geometry; tuned snubbers | Higher loss; larger cooling |

| Millisecond dynamic response | Controllable dV/dt | Clean recovery | High control bandwidth; low parasitics | Slower loops; more overshoot |

| Weak-grid stability (LVRT) | Stable gate behavior | Minimal spikes | <10 nH parasitics; robust drivers | More ringing; longer tuning |

| Hot/dusty/salt-mist resilience | High Tj capability | EMI-friendly | AlN/Si3N4 + sintered Ag; sealed | Thermal fatigue; corrosion risk |

| Compact MV cabinets | Operate at higher kHz | Lower switching loss | Smaller magnetics; lighter racks | Bigger footprint; higher noise |

Deep-Dive Engineering Comparison for Heat, Dust, and Salt Mist

Device, Packaging, and System Parameters Tuned for Pakistan’s MV Storage Sites

| Parametr | Sicarbtech SiC Stack (Device + Module + Interconnect) | Typical Silicon Stack | Operational Implication in Pakistan |

|---|---|---|---|

| On-resistance vs temperature | Modest increase up to 125°C+ | Steeper increase | Stable output in afternoon heat |

| Reverse recovery charge | ~0 (Schottky) | Alta | Lower EMI; simpler filters |

| Max junction temperature | 175–200°C (package-dependent) | 150–175°C | Downsized cooling; fewer deratings |

| Module/busbar inductance | <10 nH targets | 15–30 nH | Cleaner edges; fewer snubbers |

| Thermal interface | Sintered silver | Solder | Superior power cycling life |

| Substrate material | AlN/Si3N4 with Cu | Alumina common | Better heat spread; toughness |

| Częstotliwość przełączania | 5–20 kHz (3L); 1–10 kHz (cascaded) | Lower bands | Smaller magnetics/filters |

| Çevresel sızdırmazlık | Dust/salt-mist-resistant coatings | Generic | Reduced ingress failures |

| Efficiency uplift (system) | +0.8–1.5 percentage points | Linia bazowa | Better LCOE/LCOS |

| Lifecycle economics | Lower TCO | Higher TCO | Longer warranties; fewer outages |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s strength in Pakistan goes beyond parts supply. From Weifang City and within the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech couples advanced R&D with proprietary processes in R-SiC, SSiC, RBSiC, and SiSiC ceramic grades—materials that underpin high thermal conductivity, corrosion resistance, and mechanical reliability in MV environments.

For OEMs, EPCs, and storage operators, Sicarbtech delivers complete technology transfer packages. These include:

- Process know-how for epitaxial growth (CVD), with thickness and doping profiles matched to 1200/1700/3300 V devices.

- Device and gate design options balancing trench/planar for low RDS(on) and oxide reliability.

- Metallization stacks on AlN/Si3N4, sintered silver processing windows, and module pinout/passivation tuned for MV creepage and insulation.

- Equipment specifications covering utilities, clean/dry room requirements, safety, line layout, metrology, and maintenance routines.

- Training programs for operators, process/test engineers, quality, and application teams, embedding SPC discipline and practical routines that stabilize yield.

Factory establishment support spans feasibility studies tailored to Pakistani labor and utility contexts, through pilot line setup, commissioning, and yield ramp using statistical process control. Quality frameworks align with ISO 9001 and ISO 14001, and Sicarbtech guides pathways to relevant IEC/UL component testing and local interconnection/PQ expectations. After start-up, quarterly process audits, reliability dataset refreshes (power cycling, high-temperature/high-humidity), and application engineering support for busbar geometry, EMC, and thermal tuning sustain improvement. Having supported 19+ enterprises through similar ramps, Sicarbtech brings a repeatable playbook that shortens time-to-revenue and mitigates execution risk. “Standing up a SiC capability is as much about metrology habits as it is about machines—repeatable routines keep yields bankable,” notes a Sicarbtech process transfer lead.

Future Market Opportunities and 2025+ Trends: MV Storage’s Next Chapter in Pakistan

As renewable penetration grows and transmission upgrades lag, MV storage will increasingly anchor feeder stability. We expect direct-connection MV PCS to gain share in grid-side and large C&I sites because they eliminate transformer layers and reduce losses. Ancillary services—fast frequency response, dynamic VAR, voltage control—will become standard revenue streams, favoring high-bandwidth, low-latency converters. SiC penetration in mid-to-high-end PCS platforms should trend toward 30–50% over the next several years, with quickest uptake in high-temperature, dusty corridors and coastal belts where cooling and corrosion dominate lifecycle costs.

Integration with EV charging hubs and industrial microgrids will intensify. Storage-backed hybrid nodes will demand fast, precise active/reactive control; SiC’s clean switching and low parasitics shorten commissioning and keep filters compact. Bankability will hinge on in-situ reliability evidence: power cycling at elevated temperatures, high-temperature/high-humidity, and salt-mist tests adapted to Pakistan’s climate. Vendors that couple materials–devices–equipment integration with genuine technology transfer and responsive service will enjoy a structural edge, enabling partial localization that reduces FX exposure and spare-part lead times.

Perguntas frequentes

What round-trip efficiency gains are realistic when moving to SiC-based MV direct-connection PCS?

Projects typically report a 0.8–1.5 percentage point improvement in round-trip efficiency, with grid-side peak efficiencies of 98.5–99.0% depending on topology and rating. Gains are most valuable in hot months when cooling overhead is highest.

How does Sicarbtech mitigate dust, heat, and salt mist for outdoor MV cabinets?

We combine low-parasitic modules with corrosion-resistant coatings, moisture-resistant encapsulants, and MV-grade creepage/insulation strategies. Copper-on-AlN/Si3N4 substrates and sintered silver maintain thermal integrity even when external fins are partially fouled.

Can SiC MV PCS meet NEPRA-aligned PQ metrics on weak feeders?

Yes. Cleaner switching and <10 nH parasitics, paired with tuned dV/dt control and right-sized filters, commonly achieve ≤3% THD and near-unity PF with millisecond-class step response, easing interconnection approvals.

Which device voltage classes and topologies fit 3–35 kV MV PCS?

1200/1700/3300 V SiC devices are combined in three-level and cascaded multilevel submodules to realize 3–35 kV class interconnection. Choice depends on power rating, filter targets, and insulation design.

Why are sintered silver and ceramic substrates critical at MV?

Sintered silver offers high thermal conductivity and mechanical robustness, greatly extending power cycling life. AlN/Si3N4 substrates spread heat efficiently and resist mechanical/thermal fatigue—vital for long lifetimes in hot, dusty, and humid contexts.

Will faster SiC switching create EMC challenges?

If unmanaged, yes. Sicarbtech’s low-parasitic modules, laminated busbars, tuned gate resistors, and Miller clamping minimize ringing. In practice, co-designed SiC PCS often require smaller filters and achieve faster commissioning than legacy designs.

Can Sicarbtech support localized assembly or full production in Pakistan?

Yes. We provide technology transfer, equipment specs, training, ISO-aligned quality frameworks, and commissioning assistance. Phased localization reduces FX exposure and shortens spare-part lead times.

What reliability testing is available for Pakistan-specific stressors?

We offer power cycling, temperature cycling, high-temperature/high-humidity (HT/HH), and salt-mist testing, plus online screening. We share acceleration models and co-develop validation plans to underpin extended warranties.

How quickly can a pilot MV PCS be executed and evaluated?

Pilots typically deploy in weeks to a few months. A/B comparisons should track round-trip efficiency, THD/PF logs, active/reactive step response, thermal imaging, and maintenance intervals to quantify benefits.

What total cost of ownership improvements are typical over 10–15 years?

Despite higher device costs, reduced energy and cooling use, smaller cabinets and civil works, fewer maintenance interventions, and higher availability yield a lower TCO—especially in hot, dusty, and coastal environments.

Fazendo a escolha certa para suas operações

A successful MV PCS strategy starts with your feeder and site realities: short-circuit strength, voltage/frequency histories, ambient temperature, dust and humidity exposure, space and cooling constraints, and ancillary service targets. When Sicarbtech co-designs from epitaxy and gate oxide reliability through module parasitics, laminated busbar geometry, filter strategy, thermal architecture, and control interfaces, the results are tangible—higher round-trip efficiency, compact and quieter cabinets, faster commissioning, and stronger compliance and warranty narratives. For textiles, cement, steel, and grid-side storage across Pakistan, this integrated SiC approach reduces risk and improves project returns.

Obtenha consultoria especializada e soluções personalizadas

Whether you are specifying new MV direct-connection PCS, retrofitting grid-side converters, or exploring localized assembly and reliability testing, Sicarbtech will translate your KPIs into a data-backed roadmap with milestones for performance, compliance, and ramp. Contact our engineering team at [email protected] or +86 133 6536 0038.

Metadados do artigo

Last updated: 2025-09-17

Next scheduled review: 2025-12-01

Content freshness indicators: 2025 Pakistan MV storage outlook; SiC 1200/1700/3300 V devices; three-level and cascaded MV PCS architectures; sintered silver and AlN/Si3N4 substrates; laminated low-parasitic busbars; THD/PF and millisecond step-response targets; NEPRA/PQ compliance context; localization and technology transfer pathways; case narratives from Hyderabad, Faisalabad, and Karachi.

About Sicarbtech: Silicon Carbide Solutions Expert located in Weifang City, China’s SiC manufacturing hub; member of Chinese Academy of Sciences (Weifang) Innovation Park; 10+ years of SiC customization supporting 19+ enterprises; full-cycle solutions from material processing to finished products; specialties include R-SiC, SSiC, RBSiC, and SiSiC grades; services cover custom manufacturing, factory establishment, and technology transfer.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.