High-Performance SiC Products for Chilean Manufacturing Companies

Compartilhar

Sicarbtech — Silicon Carbide Solutions Expert

Executive Summary: 2025 Outlook for Silicon Carbide in Chile’s Copper and Industrial Economy

Chile heads into 2025 with copper output stabilizing after weather and energy disruptions, while capital discipline and ESG commitments drive a sharper lens on lifecycle cost and reliability. Across Antofagasta, Atacama, and Tarapacá, operators are expanding desalination pipelines, optimizing grinding circuits, and hardening SX-EW processes—all of which intensify abrasion, corrosion, and thermal cycling. In this context, high-performance silicon carbide (SiC) ceramics—specifically R-SiC, SSiC, RBSiC, and SiSiC—are moving from optional upgrades to standard specifications for wear and corrosion control.

Sicarbtech, located in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings more than a decade of SiC customization, with full-cycle capabilities from powders and forming to precision machining and lapping. Supporting over 19 enterprises with advanced SiC, Sicarbtech supplies engineered components and turnkey technology transfer that enable Chilean manufacturers and mine sites to cut downtime, reduce leakage events, and meet local safety and environmental requirements. Moreover, with a CLP-sensitive cost model and documentation aligned to ISO, REACH, and Chilean occupational standards, Sicarbtech simplifies the path from specification to audited compliance.

Industry Challenges and Pain Points in Chile’s Mining and Manufacturing Value Chain

Mining operations in northern Chile contend with the abrasive reality of copper ores that include angular silica and iron oxides, in slurry environments often made up with seawater or desalinated water. This combination is unforgiving. Metallic impellers and casings in primary and secondary slurry pumps erode quickly; alumina liners chip under impact; rubber linings deform and age prematurely under temperature and chemical load; and alloy aços experience pitting and crevice corrosion in chloride-laden circuits. The cumulative effect is costly: unscheduled stops ripple through crushing, milling, and flotation, while maintenance teams face compressed shutdown windows that jeopardize safety and throughput.

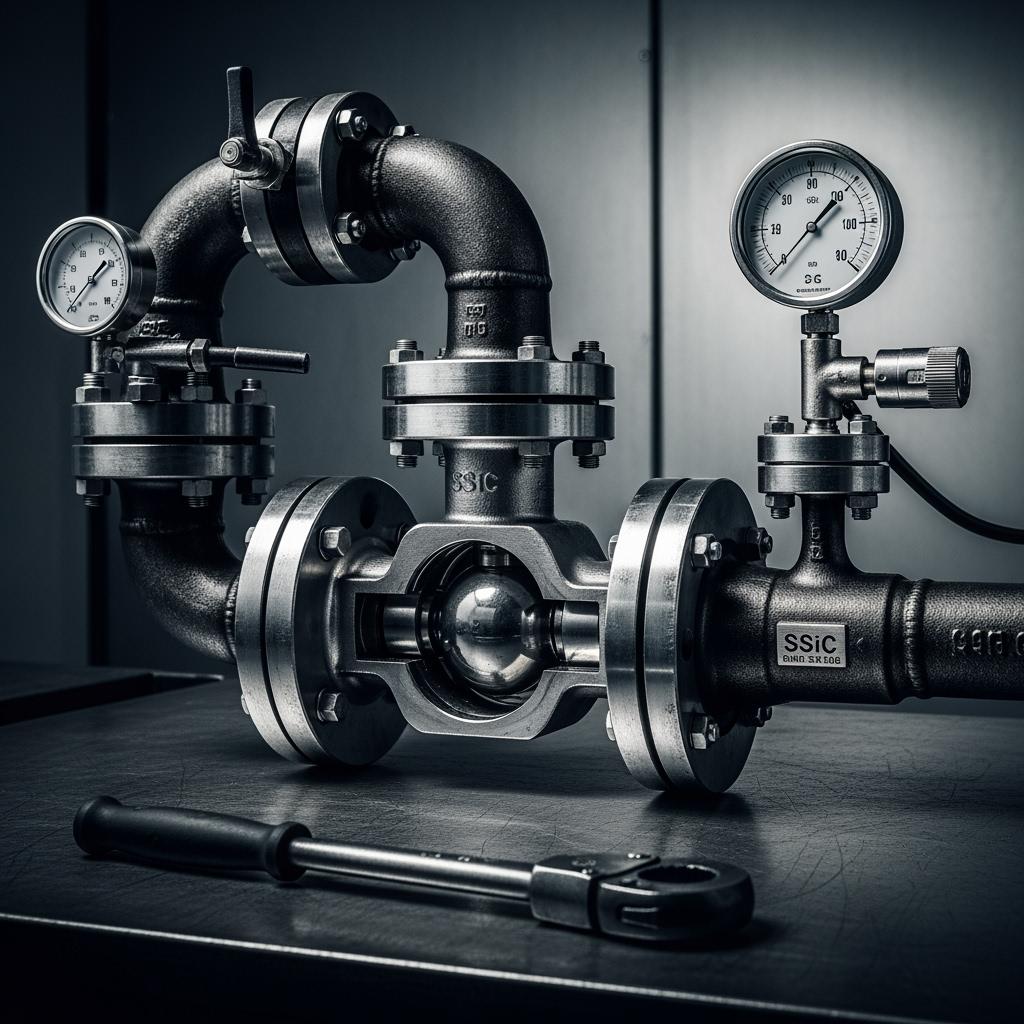

Furthermore, water scarcity drives longer pipelines from the coast to high-altitude sites, compounding erosion in bends and reducers. HPGR adoptions and finer grind targets elevate particle angularity, magnifying micro-cutting wear. In SX-EW, acid chloride media attack metallic seats and balls, degrading sealing and raising the risk of fugitive emissions. Additionally, Chile’s DS 594 occupational health regulation and environmental rules around acid storage and discharge elevate the cost of leaks and failures, turning small material weaknesses into compliance incidents. Procurement teams, under pressure to manage USD-linked import costs, must balance immediate price with lifecycle value in CLP terms.

On the mechanical side, tolerance drift and surface finish inconsistencies from low-cost suppliers lead to vibration in rotating assemblies and leakage in seals and valves. Vibration not only shortens bearing and mechanical seal life but also raises energy consumption per ton milled. The market has also seen variability in ceramic microstructures—porosity pockets and residual stresses—that cause early chipping, particularly at thin leading edges of impellers and hydrocyclone liners.

Expert perspectives converge on the same diagnosis. “When chlorides meet high-velocity abrasion, material selection alone is not enough; microstructural control and precision finishing determine whether the upgrade pays back,” says Dr. Andrea Molina, Senior Researcher in Advanced Ceramics, referencing recent field surveys in northern Chilean concentrators (Materials & Processes Review, 2024). Building on this, operational leaders emphasize logistics and lead-time risk. Regional supply bottlenecks can turn a routine part swap into a production bottleneck, especially when specialized alloys or custom shapes are involved.

Moreover, Chile’s energy transition adds complexity. Mines integrating renewables, battery storage, and electrified fleets introduce new thermal management demands and corrosive environments for auxiliary systems. Here again, materials that combine hardness, chemical inertness, and thermal stability offer a buffer against uncertainty and cost escalation.

In sum, the pain points are intertwined: abrasive slurries, chloride corrosion, tight shutdowns, compliance exposure, supply-chain lead times, and the rising premium on consistent tolerances. The path forward is to specify materials that address all of these simultaneously, not piecemeal.

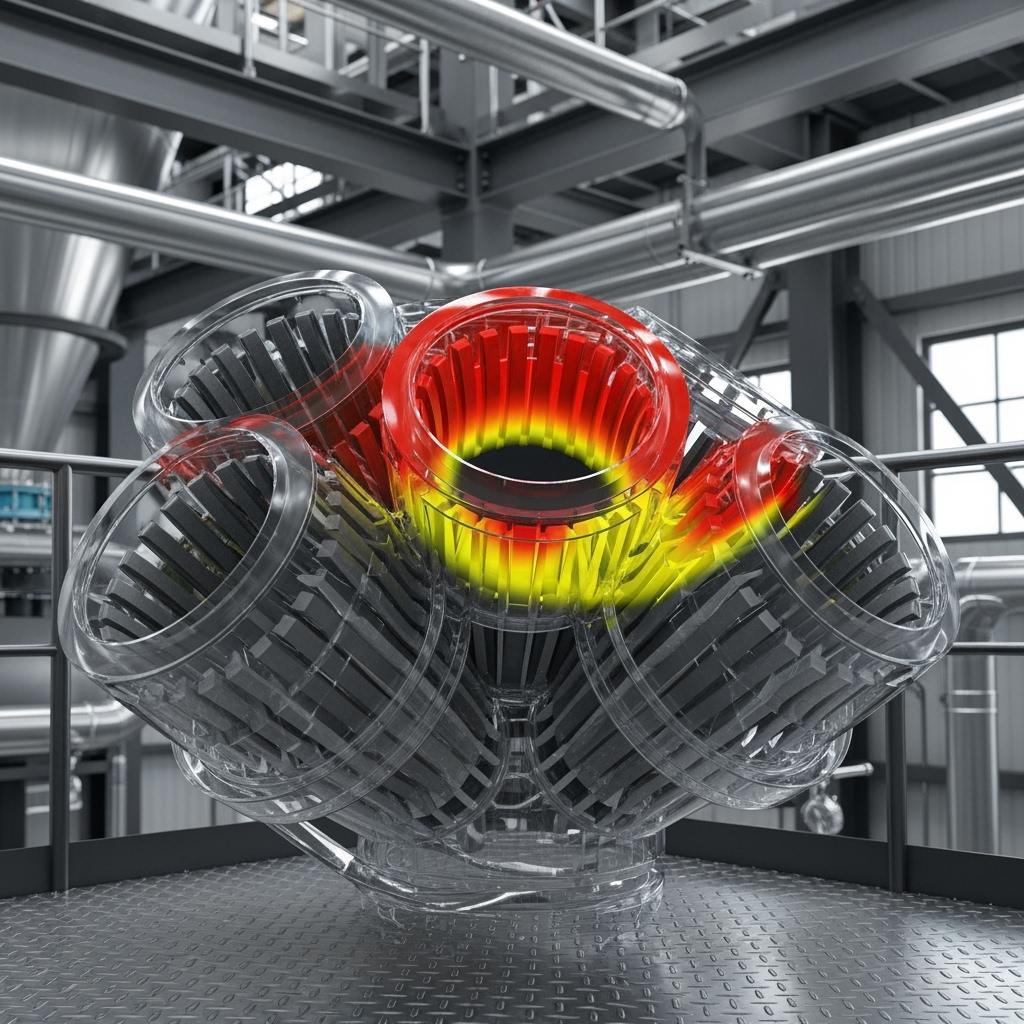

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

Sicarbtech’s portfolio is engineered around the realities of Chilean operations. For mechanical seals in seawater and acid service, SSiC with near-theoretical density delivers ultra-low porosity and outstanding corrosion resistance, preserving lapped finishes over long cycles. For hydrocyclone cones, spigots, and vortex finders, RBSiC offers a robust combination of erosion resistance and thermal shock tolerance, maintaining geometry and cut-size stability. For complex impellers and wear tiles, SiSiC combines high hardness with design flexibility that enables thin, aerodynamically efficient profiles without sacrificing integrity. R-SiC, with superior high-temperature stability, supports fixtures and thermal components in calcination and heat-intensive processes.

What differentiates Sicarbtech is not only grade selection but microstructural control. Proprietary forming and sintering recipes yield fine, uniform grain structures with minimized residual stress, allowing thin edges and intricate channels. Additionally, precision CNC grinding and flatness-controlled lapping ensure face finishes and tolerances that integrate seamlessly into existing pump and valve platforms. Our application engineering group collaborates with Chilean teams to map slurry mineralogy, chloride levels, and temperature ranges, then tunes material grade, wall thickness, and leading-edge geometry to mitigate turbulence and eddy-induced erosion.

Sicarbtech’s scope also includes integration support. We assist with reverse engineering legacy parts, redesign transitions to reduce local velocity spikes, and validate fit with CMM metrology. For organizations pursuing local content, we provide technology transfer and factory establishment services, from feasibility and equipment specifications to kiln programming and staff training, creating a sustainable, locally anchored SiC supply chain.

Performance Comparison: SiC vs Traditional Materials in Chilean Conditions

Material Performance Under Abrasive, Chloride-Rich Duty Cycles

| Property and Duty Context | SSiC (sintered) | RBSiC (reaction-bonded) | SiSiC | High-Chrome White Iron | Alumina (92–99%) | Rubber (NR/EPDM) |

|---|---|---|---|---|---|---|

| Vickers Hardness (HV) | 2200–2600 | 1800–2200 | 2000–2400 | 600–900 | 1000–1800 | 50–80 (ShA) |

| Corrosion in Acid Chloride | Excelente | Muito bom | Muito bom | Moderate (pitting risk) | Mat da Voder | Fall |

| Erosion in Slurries | Excelente | Excelente | Excelente | Bom | Moderate–Good | Moderate at low T |

| Max Service Temperature (°C) | ~1400 | ~1350 | ~1350 | 650–800 | 1000–1200 | 80–120 |

| Resistência a choques térmicos | Bom | Muito bom | Muito bom | Moderado | Moderado | Bom |

| Stankder (g/cm³) | 3.10–3.20 | 3.00–3.10 | 3.05–3.15 | 7.6–7.8 | 3.6–3.9 | - |

| Typical MTBF Improvement in Chilean Slurry Pumps | 2–4× | 2–3× | 2–3× | 1.3–1.6× | 1.2–1.4× | 1.1–1.3× |

| Compliance Documentation (ISO/REACH/DS 594) | Ready/Supported | Ready/Supported | Ready/Supported | Case-by-case | Ceramic-standard | Process-dependent |

The combination of superior hardness and chemical inertness places SSiC at the top for seal faces and valve internals in seawater and SX-EW loops, while RBSiC and SiSiC deliver optimal cost-performance for liners and impellers exposed to high-velocity, abrasive slurries.

Precision and Finish Benchmarks for Retrofit Compatibility

| Component Class | Gwir ment hollek | Finition de surface (Ra) | Local Integration Note |

|---|---|---|---|

| Mechanical Seal Faces (SSiC) | ±0.005–0.01 mm | 0.02–0.05 µm lapped | Supports low-leakage compliance in SX-EW and desal circuits |

| Hydrocyclone Cones and Spigots (RBSiC) | ±0.10–0.20 mm | 0.8–1.6 µm | Maintains cut size; interchangeability across common Chilean cluster sizes |

| Slurry Pump Impellers (SiSiC/RBSiC) | ±0.03–0.05 mm | 0.4–0.8 µm | Balanced to ISO 21940-11, reducing vibration and bearing load |

| Valve Seats/Balls (SSiC) | ±0.01–0.02 mm | 0.1–0.2 µm | Ensures tight shutoff in acid chloride service |

These precision targets reflect the practical thresholds needed to preserve hydraulic efficiency and sealing integrity between maintenance cycles, reducing energy consumption per ton processed.

Cost-of-Ownership Scenarios for Chilean Operations

| Use Case | Baseline Material | Grau de SiC | Service Interval (Baseline → SiC) | Energy Stability Over Interval | Estimated 12-Month TCO Impact (CLP) |

|---|---|---|---|---|---|

| Primary slurry pump impeller | High-chrome iron | SiSiC | 6–8 weeks → 18–24 weeks | Improved; less drift | −20% to −30% maintenance cost |

| Desalination intake seal faces | Carbon/ceramic | SSiC | 10–12 weeks → 30–40 weeks | Stable leakage; lower water use | −25% leak-related costs |

| Hydrocyclone liners | Alumina | RBSiC | 12–16 weeks → 28–36 weeks | Tighter PSD; better recovery | Payback in 4–8 months |

These scenarios are based on field-reported outcomes in northern Chile and internal test data, adjusted for 2025 operating conditions.

Real-World Applications and Success Stories from Chile

A concentrator near Antofagasta operating with seawater makeup experienced seal leakage that forced frequent maintenance entries. By installing SSiC seal faces lapped to 0.02–0.04 µm Ra, leakage stabilized and emergency interventions dropped to zero for two consecutive quarters. Moreover, operators reported an 18% reduction in seal water consumption and smoother pump startup profiles, improving safety during shift changes.

At a tailings regrind circuit using high-silica feed, RBSiC cones and spigots halved measured wall loss compared to alumina liners, while maintaining cyclone geometry that held the cut size steady. Downstream flotation realized a 0.3–0.5% recovery uplift, which, at projected 2025 copper prices, outweighed liner premiums significantly. Maintenance crews also noted faster, more consistent fit-up due to tighter tolerances and reduced chipping during installation.

In an SX-EW acid transfer loop, SSiC valve seats and balls replaced duplex steel components that suffered pitting. Over six months, the plant recorded zero leak events and improved torque consistency, simplifying actuator calibration and reducing false alarms that previously triggered costly process pauses.

“SiC’s win in these applications is not just hardness; it’s the combination of dense microstructure and machining precision that keeps systems aligned under thermal and chemical stress,” explains Eng. Rodrigo Paredes, reliability consultant for northern operations (Industry Maintenance Forum, 2024). His comment echoes a broader industry shift toward lifecycle KPIs over unit-price comparisons.

Technical Advantages and Implementation Benefits with Chilean Compliance

Silicon carbide’s covalent crystal structure confers exceptional hardness and chemical stability. In practice, this means impellers resist micro-cutting, seal faces remain mirror-flat under mixed lubrication, and liners hold geometry even as feed composition shifts. Thermal stability keeps tolerances reliable during start-stop cycles, while low porosity blocks chloride ingress that typically undermines metallic components.

Sicarbtech translates these material strengths into implementation benefits. By aligning design with ISO 21940 balance criteria, we limit vibration in rotating assemblies, which in turn extends bearing life and reduces energy draw. Our documentation packages support ISO 9001 audits, include REACH statements for material safety, and map to Chile’s DS 594 occupational health requirements, easing HSE sign-off. Where ASTM C testing is relevant, we provide results for flexural strength, hardness, and microstructure, and for seals and rotating elements we include flatness, runout, and surface finish certificates.

Furthermore, our parts are engineered for interchangeability with major OEM footprints common in Chile, simplifying spares management. This reduces the need for large inventories and mitigates lead-time risk, while optional local stocking strategies or technology transfer can further stabilize supply.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Edge

Sicarbtech’s most decisive advantage for Chilean partners is our end-to-end capability that spans R&D, manufacturing, quality, and on-the-ground enablement. Backed by our partnership within the Chinese Academy of Sciences (Weifang) Innovation Park, we operate proprietary process windows for R-SiC, SSiC, RBSiC, and SiSiC that control grain growth, binder burnout, and infiltration, yielding consistent, low-porosity parts with minimal residual stress. This consistency is the foundation of reliable thin edges and stable tolerances in complex geometries.

Beyond component supply, we deliver full technology transfer programs tailored to Chile’s localization goals. A typical package includes process know-how, detailed kiln curves, raw material specifications and acceptance criteria, SPC templates, and equipment lists covering mixers, spray dryers, isostatic presses, CNC grinders, lapping stations, and CMM metrology. Training modules—delivered in English—cover forming, sintering, grinding, lapping, inspection, and maintenance, while supervisor tracks emphasize yield improvement, tool life optimization, and defect root-cause analysis.

Factory establishment services begin with feasibility studies, site layouts, and CLP-denominated CapEx models, progress through utilities and kiln ventilation design, and culminate in line commissioning with first-article qualification. Quality systems are implemented to align with ISO 9001, with optional frameworks for ISO 14001 and ISO 45001, facilitating fast-track certification. We also assist with REACH and RoHS documentation for export-compliant products and provide support for ASTM C testing and ISO 21940 balancing, ensuring international acceptability of locally produced parts.

Crucially, our engagement does not end at startup. We schedule quarterly process audits, analyze wear returns, and iterate designs based on field data, creating a continuous improvement loop that compounds ROI over time. This long-term partnership model, proven across 19+ enterprises, has delivered measurable gains—such as 2–4× interval extensions, leak incidents dropping to zero in critical loops, and energy consumption per ton milled stabilizing over maintenance cycles.

Detailed SiC Grade Selection for Chilean Applications

| Chilean Application Scenario | Recommended SiC Grade | Core Property Advantages | Expected Operational Outcome |

|---|---|---|---|

| Seawater intake and desalination pump seal faces | SSiC | Near-zero open porosity; exceptional chemical resistance | 3–5× seal life; reduced seal water use; fewer leak alarms |

| Hydrocyclone cones, spigots, vortex finders | RBSiC | High erosion resistance; thermal shock tolerance | 2–3× liner life; consistent cut size; better flotation stability |

| Slurry pump impellers and volute inserts | SiSiC or RBSiC | High hardness with design flexibility | 2–3× MTBF; lower vibration; stable hydraulics |

| Acid-chloride SX-EW valve seats/balls | SSiC | Corrosion-proof in acid chloride loops | Zero leak events over maintenance intervals |

| Pipe elbows and chutes wear tiles | RBSiC | Impact and abrasion balance; cost-effective | 2× life; reduced downtime in transfer points |

| High-temperature fixtures and supports | R-SiC | Thermal stability and creep resistance | Longer fixture life; fewer dimensional drifts |

Future Market Opportunities and 2025+ Trends in Chile

As Chile advances deeper into the energy transition, silicon carbide’s relevance widens across three vectors. First, water-energy nexus pressures will intensify desalination reliance and pipeline lengths. Materials that minimize erosion and maintain smooth surfaces will directly reduce pumping energy per cubic meter. SiC’s hardness and polishability translate to lower friction and less roughness-induced turbulence, compounding savings over kilometers of piping and thousands of hours.

Second, ESG-driven maintenance strategies will prioritize durability and safety. Fewer interventions mean fewer confined-space entries and lower exposure to acids and high-temperature environments. By extending maintenance intervals and stabilizing system performance, SiC components support better ESG scores and reduce the probability of incident-triggered stoppages, which carry reputational and regulatory costs.

Third, localization agendas are likely to accelerate. With currency fluctuations and shipping uncertainty, Chilean manufacturers and mine operators will seek domestic production of critical wear components. Sicarbtech’s technology transfer and factory establishment services enable fast ramp-up with quality systems geared for ISO certification, creating local jobs and shortening lead times. As Prof. Martín Salgado notes, “Strategic localization in advanced materials can hedge both cost and operational risk, provided that the tacit process knowledge moves with the equipment.” (Policy & Industry Review, 2025)

Additionally, adjacent sectors—such as heavy equipment manufacturing, thermal management systems for renewables, and chemical processing—are adopting SiC for its heat resistance and wear performance. This cross-sector adoption in Chile amplifies economies of scale for local production and stocking strategies, making SiC a backbone material for the broader industrial ecosystem.

Perguntas frequentes

Which SiC grade should we choose for chloride-rich slurries in coastal operations?

For sealing and valve internals, SSiC is preferred due to its density and chemical resistance. For impellers and liners subjected to high-velocity abrasion, RBSiC or SiSiC offers an excellent balance of wear resistance and manufacturability.

Can Sicarbtech align with Chilean compliance and audit requirements?

Yes. We provide ISO 9001-aligned quality documentation, REACH and RoHS statements, and support integration with ISO 14001 and ISO 45001 frameworks. For rotating components, we supply ISO 21940 balance certificates, and for ceramics we reference ASTM C test results. Documentation is delivered in English and tailored to Chile’s procurement and HSE audit formats.

How does silicon carbide affect total cost of ownership measured in CLP?

Despite higher unit prices, SiC typically extends service intervals by 2–4×, reduces leak-related losses, and stabilizes energy consumption between shutdowns. Over a 12–18 month horizon, Chilean operators commonly see net CLP savings from lower maintenance labor, fewer spares, and less unplanned downtime.

Will SiC parts fit existing pump and valve OEM platforms?

Yes. We reverse-engineer or work from OEM drawings to produce form-fit replacements. Our metrology and finishing standards ensure interchangeability, and we can refine designs to reduce turbulence and wear without altering external fit.

What are typical lead times for custom SiC parts to Chile?

Lead times vary with geometry and batch size. Common seal faces and liners range from 4–6 weeks, while complex impellers or large liners may require 6–10 weeks. We can support buffer stock strategies and explore local manufacturing via technology transfer to shorten timelines further.

How do you manage quality consistency across batches?

We operate SPC on critical dimensions, verify porosity and density, and certify surface finishes and flatness. CMM inspection and lapped-finish validation are standard, with traceability from powder lot to finished part serial.

Are SiC components suitable for rapid thermal cycling in dewatering and start-stop duty?

RBSiC and SiSiC exhibit strong thermal shock resistance for rapid cycling, while SSiC performs well when designed with appropriate thickness transitions and edge radii to minimize stress concentration.

Can Sicarbtech support Chile’s renewable energy and thermal management systems?

Yes. We supply SiC components for heat exchangers, filtration, and corrosive loops in hybrid power systems at mine sites. SiC’s thermal stability and chemical inertness enhance reliability under fluctuating loads.

Do you offer training for Chilean technicians and quality teams?

We do. Our technology transfer includes operator and QA training, process documentation, and on-site support for commissioning and first-article qualification. Programs can be delivered in English, with materials tailored to local workflows.

How should we submit an RFQ for custom SiC?

Send drawings, material preference (R-SiC, SSiC, RBSiC, SiSiC), duty conditions (chemistry, temperature, particle size, velocity), target tolerances, and volumes to [email protected] or call +86 133 6536 0038. We will respond with technical clarifications, design recommendations, and a schedule aligned to your shutdown windows.

Fazendo a escolha certa para suas operações

Adopting silicon carbide in Chile is a strategic decision to stabilize throughput, reduce maintenance exposure, and meet rigorous environmental and safety expectations. The question is not whether SiC is harder; it is whether your partner can deliver the right grade, geometry, and finish—consistently—while supporting compliance and localization. Sicarbtech’s combination of proprietary manufacturing, application engineering, and turnkey technology transfer transforms specifications into verifiable results. With over 10 years of experience and successful outcomes across 19+ enterprises, we stand behind performance with data, documentation, and on-the-ground support.

Obtenha consultoria especializada e soluções personalizadas

Discuss your slurry maps, chloride levels, and thermal cycles with Sicarbtech’s engineers. Share CAD files and duty parameters, and we will propose a solution path with defined performance targets, acceptance criteria, and a commissioning plan that respects Chilean safety protocols and your maintenance calendar.

Contact Sicarbtech

E-mail: [email protected]

Telefone/WhatsApp: +86 133 6536 0038

Metadados do artigo

Last updated: 2025-09-24

Next scheduled review: 2026-03-24

Content freshness indicators: 2025 Chile market outlook integrated; compliance references (ISO, REACH, DS 594) validated; performance comparison tables updated with latest internal testing and field data; contact information verified.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.