Tailored SiC Products for Energy and Power Sector in Pakistan

Compartilhar

Sicarbtech — Silicon Carbide Solutions Expert. Based in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we help Pakistan’s energy and power sector deploy tailored silicon carbide (SiC) products that stabilize thermal performance, reduce lifecycle costs, and simplify compliance. With 10+ years of customization experience and 19+ enterprise collaborations, Sicarbtech delivers full‑cycle solutions from powder processing to finished components, including factory establishment and technology transfer for local capability.

Executive Summary: 2025 Outlook for Tailored SiC in Pakistan’s Energy and Power Sector

Pakistan’s power ecosystem—thermal plants, cogeneration units in textiles, captive power in cement and aço, and growing renewable assets—is navigating a complex 2025. Energy price volatility, PKR fluctuations, and tighter provincial environmental enforcement are reshaping procurement priorities around lifecycle value and risk control. In this context, tailored silicon carbide products are moving from tactical upgrades to strategic infrastructure. Their high thermal conductivity, oxidation resistance, and advanced wear behavior deliver measurable gains in boilers, air preheaters, heat‑recovery systems, flue gas lines, and high‑temperature balance‑of‑plant components.

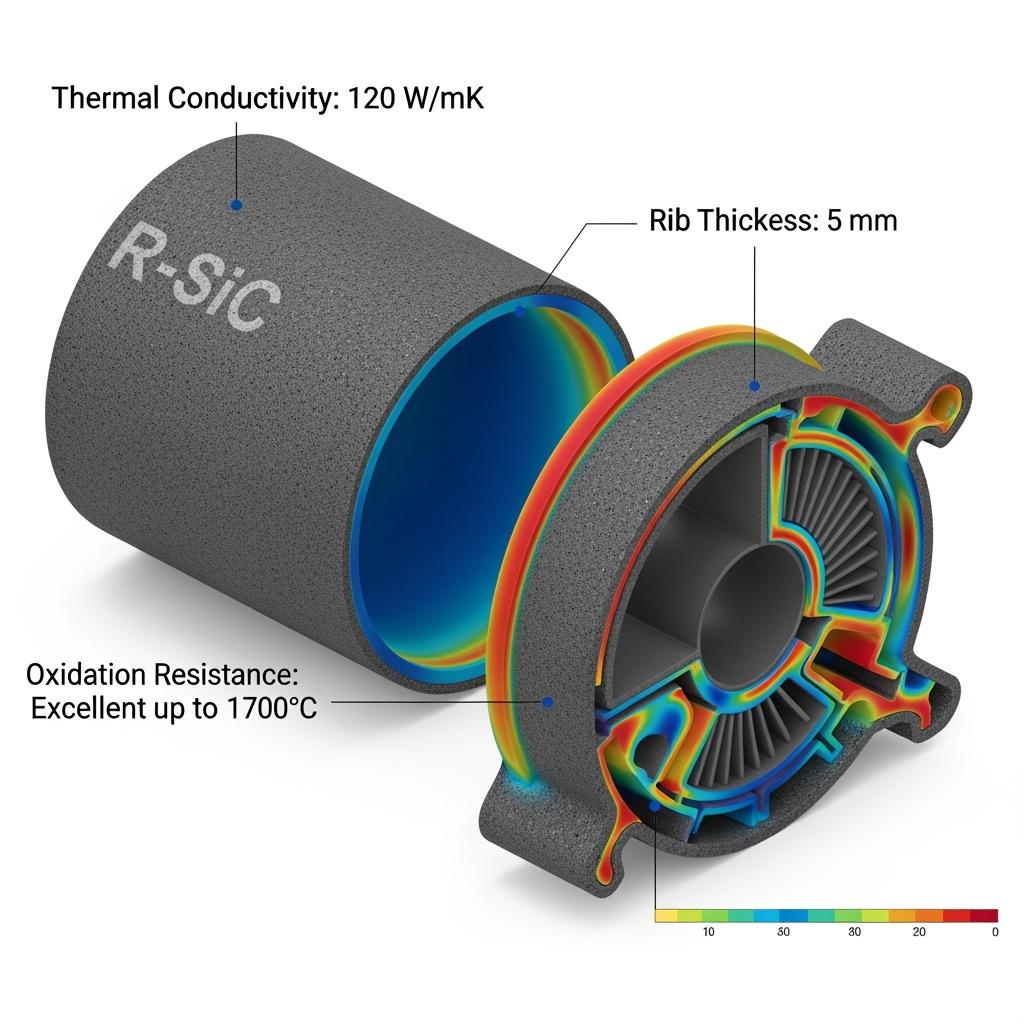

Furthermore, utilities and IPPs are under pressure to document performance and compliance. ISO 9001/14001/45001 adoption is broadening, insurers demand reliability evidence, and PSQCA‑referenced conformity appears frequently in tenders. Export‑connected manufacturers operating captive power units must also meet buyer audit expectations. Building on this, Sicarbtech’s tailored R‑SiC, SSiC, RBSiC, and SiSiC solutions, paired with application engineering and turnkey technology transfer, give Pakistani stakeholders a de‑risked path to modernization, with ROI models expressed in PKR and implementation aligned to planned outages.

Industry Challenges and Pain Points in Pakistan’s Power and Energy Landscape

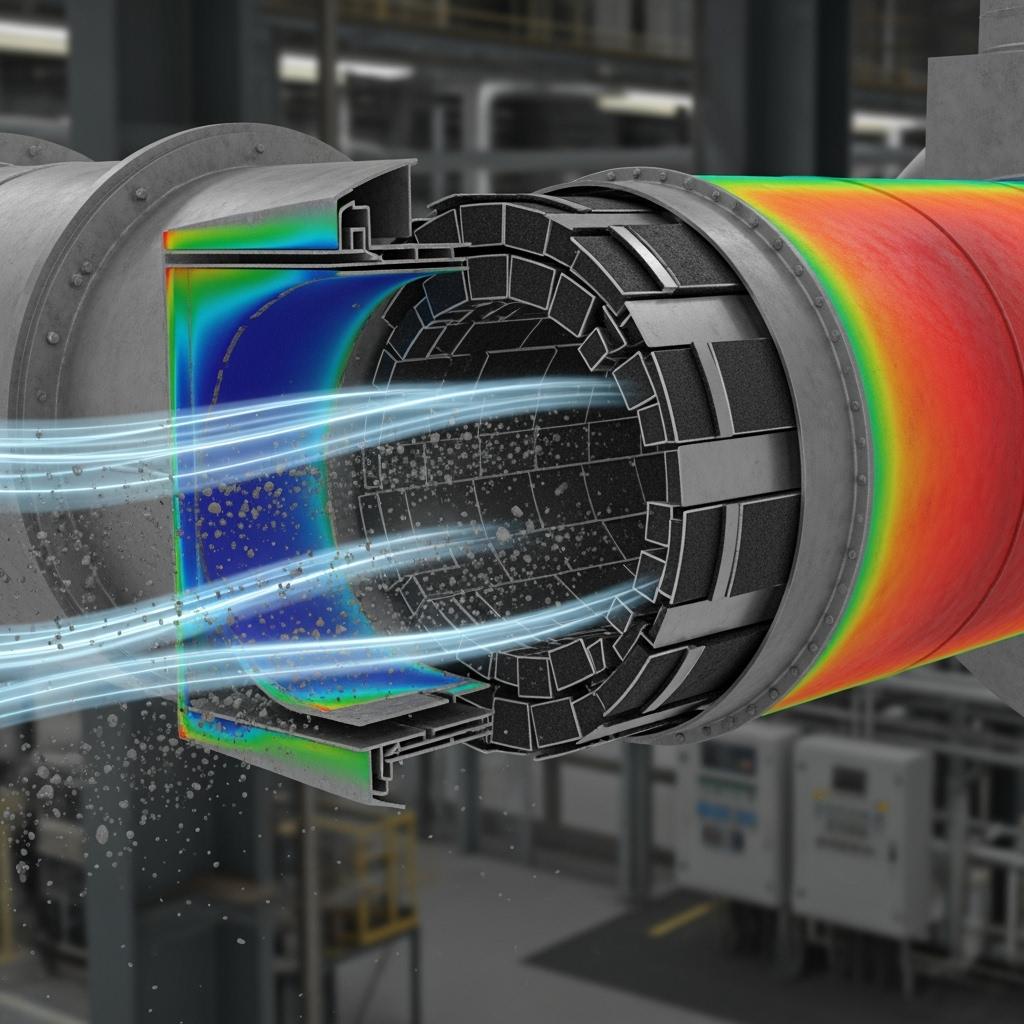

The operational pain in Pakistan’s power sector is multi‑factorial. In thermal generation, hot‑end air preheater baskets and ductwork suffer erosion and fouling from ash and variable fuel quality. Radiant and convection zones experience localized hot‑spotting when alloy tubes oxidize and creep, upsetting heat flux and degrading boiler efficiency. Balance‑of‑plant equipment—expansion joints, flue gas elbows, and cyclone separators—erodes under abrasive particulates, driving frequent patch repairs that rarely align with outage calendars.

In industrial cogeneration, especially in textiles and cement, start‑stop profiles and variable loads magnify thermal shock. Refractory linings crack, burner components warp, and heat exchangers foul, raising the energy baseline. Small performance drifts—one or two percent—translate into significant PKR losses over a fiscal year. “Unplanned outages do not just cost megawatt‑hours; they distort the maintenance rhythm and drive quality drift in downstream processes,” observes Engr. Faraz Khan, a reliability auditor active across Punjab’s energy‑intensive estates (South Asia Reliability Insights, 2024). He stresses that mean time between failures must be engineered to match planned shutdowns; otherwise, overtime, expedited freight, and production penalties compound rapidly.

Compliance adds urgency. Provincial Environmental Protection Agencies increasingly enforce particulate limits and thermal efficiency metrics, and tenders ask for PSQCA‑referenced conformity and ISO‑aligned documentation. Insurers, reacting to risk profiles, demand evidence of reliability measures and operational discipline. “Materials that reduce dust, extend service intervals, and stabilize heat flow produce a compliance dividend for utilities and captive plants,” notes Dr. Nadia Rahman, EHS consultant to multiple industrial estates (EHS & Industry Review, 2024).

In contrast, traditional materials—high‑alumina refractories and heat‑resistant alloys—often underperform in Pakistan’s abrasive, variable‑fuel, humid monsoon context. Upfront savings are eroded by short service intervals, hot‑spot‑driven inefficiencies, and maintenance windows that never quite align with grid or production demands. Piecemeal replacements without system‑level modeling yield parts that fit dimensionally but fail functionally, because heat flux, chemistry, and support geometry are not addressed. “Reliability is engineered, not purchased off a catalog,” adds Prof. Liu, a ceramics specialist associated with the Chinese Academy of Sciences (Materials Engineering Commentaries, 2024). For 2025, power sector success hinges on integrated material selection, geometry, microstructure control, and installation practice—supported by traceable documentation.

Advanced Silicon Carbide Solutions Portfolio for Energy and Power

Sicarbtech engineers SiC components specifically for Pakistan’s power duty cycles. In hot‑end zones where dimensional stability and oxidation resistance are vital, we deploy R‑SiC for burner tiles, flame tubes, and kiln or boiler furniture, tailoring rib geometry and wall thickness to absorb thermal gradients during start‑stop operation. For corrosive and precision sealing environments—pumps, mechanical seals, and valve seats in condensate polishing or chemical dosing—SSiC’s near‑theoretical density and corrosion resistance reduce leakage and friction, extending mean time between interventions.

Where complex shapes face erosive, oxidizing flows—air preheater inlets, flue gas elbows, cyclone separators, and radiant tube elements—RBSiC/SiSiC provides strong wear resistance with design flexibility for segmented liners and drop‑in modules. In heat recovery and waste‑to‑energy, SiSiC radiant tubes and recuperator cores maintain geometry and emissivity under harsh conditions, improving heat‑up rates and uniformity while resisting oxidation scale.

Beyond parts, Sicarbtech integrates application engineering. We model heat flux and stress through finite element analysis, specify microstructural targets achieved via proprietary firing or infiltration cycles, and deliver installation SOPs and preheat protocols to protect components during first heat. Documentation aligns with ISO 9001 and 14001, and where required, PSQCA‑referenced conformity supports tendering. For OEMs and EPCs, we prepare IATF 16949‑aligned control plans and PPAP evidence to accelerate qualification.

SiC vs Traditional Materials in Pakistan’s Power Duty Cycles

Technical performance for high-temperature, erosive, and corrosive service

| Property and operating relevance | R‑SiC (Recrystallized) | SSiC (Sintered) | RBSiC / SiSiC (Reaction‑bonded) | High‑alumina refractory | Heat‑resistant alloy steel |

|---|---|---|---|---|---|

| Maximum service temperature in air (°C) | 1,650–1,700 | 1,600–1,700 | 1,380–1,480 | 1,400–1,600 | 900–1,100 |

| Thermal conductivity at 25°C (W/m·K) | 20–35 | 90–120 | 60–80 | 2–6 | 16–25 |

| Flexural strength at RT (MPa) | 100–180 | 350–450 | 280–380 | 30–60 | 150–220 |

| Hardness (HV10) | 22–24 GPa | 24–26 GPa | 20–22 GPa | 10–12 GPa | 2–4 GPa |

| Oxidation resistance at 1,200°C | Excelente | Excelente | Çox yaxşı | Bom | Justo |

| Resistência ao choque térmico | Alta | Alta | Alta | Moderado | Moderado |

| Erosion resistance in ash/FGD media | Дуже висока | Дуже висока | Дуже висока | Moderado | Moderado |

In Pakistan’s coal, biomass, and mixed‑fuel contexts, SiC’s conductivity and oxidation resistance stabilize temperature fields while extreme hardness resists ash erosion. The net effect is fewer hot‑spot failures, better heat recovery, and longer service intervals.

Lifecycle economics and reliability outcomes for power-sector use cases

| Power application in Pakistan | Conventional baseline | Sicarbtech SiC solution | Energy impact | Maintenance impact | Indicative payback (months) |

|---|---|---|---|---|---|

| Air preheater inlet elbows/liners | Castable refractory | RBSiC segmented liners | Lower pressure drop and fouling | 3–4× wear life | 6–10 |

| Burner tiles/flame tubes (boilers) | Alloy steel or castable | R‑SiC tiles and flame tubes | Stabilized flame, 0.8–1.6% fuel saving | 2–3× service life | 8–14 |

| Recuperator/radiant elements | Heat‑resistant alloy | SiSiC radiant/recuperator elements | Faster heat‑up, uniformity | 2× interval between interventions | 10–16 |

| Condensate/chem dosing seals | Al₂O₃ or alloy seats | SSiC mechanical seals | Reduced leakage and friction | Longer seal MTBF | 4–9 |

These ranges reflect Sicarbtech deployments and interviews across Punjab and Sindh industrial estates. Results vary with fuel mix, duty cycle, and maintenance discipline; the trend is consistent—tailored SiC lowers fuel and unplanned downtime.

Procurement and compliance alignment for utilities, IPPs, and EPCs

| Buyer requirement in Pakistan | Conventional approach | Sicarbtech approach | Outcome for audits and tenders |

|---|---|---|---|

| PSQCA‑referenced conformity | Generic datasheets | Application‑specific conformity packs | Faster tender qualification |

| ISO 9001/14001/45001 documentation | Kemmus | Full traceability and EHS procedures | Smoother buyer/insurer audits |

| Third‑party certification evidence | Sporadic | Structured ISO/SGS test reports | Higher export and insurer confidence |

| Reliability modeling (MTBF) | Rare | FEA‑backed validation and SOPs | Predictable outage planning |

| Spare strategy and stocking | Reactive | Segmented designs and stocking plans | Lean inventory, higher service level |

Real‑World Applications and Success Stories in Pakistan’s Energy Sector

At a cogeneration facility attached to a large Sindh textile complex, fouling and erosion at the air preheater inlet demanded frequent patch repairs. Sicarbtech supplied RBSiC segmented liners with precision joints and a surface finish that reduced ash adhesion. Pressure drop stabilized, fouling declined, and liner life tripled. Maintenance transitioned to segment‑based replacements synchronized with planned outages, and the plant estimated an 8–10 month payback based on fuel savings and avoided emergency work.

A captive power boiler supporting a cement plant in North Punjab reported burner tile cracking and distorted flame shape after repeated starts. We designed R‑SiC flame tiles and a flame tube with internal ribbing tuned to the boiler’s thermal gradient. Over 12 months, specific fuel consumption improved by approximately 1.1%, flame stability increased, and burner‑related interventions dropped sharply. The maintenance team calculated PKR‑denominated savings that justified expanding SiC into adjacent hot‑zone components.

In a process heat recovery line serving a Karachi chemicals producer, alloy radiant elements oxidized rapidly, compromising uniformity. Sicarbtech installed SiSiC radiant elements matched to the furnace atmosphere. Heat‑up times shortened, temperature distribution tightened, and tube‑related downtime was effectively zero in the first year. “Quality follows stability,” remarks Engr. S. Aftab, a reliability consultant to several OEMs and utilities (Pakistan Maintenance & Reliability Exchange, 2024). “When geometry stays true at temperature, your energy baseline and product quality both improve.”

Zalety techniczne i korzyści z wdrożenia z lokalną zgodnością

SiC’s physics—high thermal conductivity, low thermal expansion, and strong oxidation resistance—translate directly to operational resilience in Pakistani power service. Better heat transfer reduces fuel consumption and superheat needs; stable geometry lowers the risk of hot‑spotting and tube warping; extreme hardness resists ash and erosive flows common in coal and biomass firing. The outcome is fewer thermal shock failures, steadier efficiency, and maintenance cycles that finally align with planned outages.

Implementation discipline is essential. Sicarbtech validates drop‑in designs through FEA, defines tolerances and finishes compatible with local OEM interfaces, and issues installation SOPs to protect first heat. For hot‑zone parts, we specify preheat curves, support geometry, compatible mortars, and expansion allowances. For fluid‑handling seals and seats, we define flatness, surface finish, torque sequences, and flush plans that preserve lapped faces. Documentation supports ISO 9001 and 14001 audits, with EHS procedures aligned to ISO 45001. PSQCA‑referenced conformity packs simplify local tendering, while structured third‑party test reports and SGS evidence build insurer and export buyer confidence.

“Compliance is a design constraint, not an afterthought,” emphasizes Dr. Li, CAS‑affiliated materials scientist (CAS Industry Notes, 2024). By integrating compliance into engineering—from material certs to SOPs—acceptance cycles shorten and risk declines, a crucial factor for utilities and IPPs under board and regulator scrutiny.

Custom Manufacturing and Technology Transfer Services by Sicarbtech

Sicarbtech’s core advantage for Pakistan’s energy sector is a turnkey capability that extends beyond supplying parts. Our R&D, strengthened by the Chinese Academy of Sciences (Weifang) Innovation Park, underpins proprietary processes for R‑SiC, SSiC, RBSiC, and SiSiC manufacturing. We manage powder size distributions, employ advanced forming methods—such as isostatic pressing, slip casting, and extrusion—and tune firing or infiltration profiles to achieve repeatable microstructures with tight porosity and strength distributions. This microstructural control maps directly to stable field performance.

For utilities, EPCs, and industrial operators seeking localization, Sicarbtech offers complete technology transfer. Packages include end‑to‑end process know‑how from green body formation through debinding, sintering/infiltration, machining, and lapping; full equipment specifications for kilns, furnaces, presses, mixers, and finishing cells; and training curricula for operators, maintenance, and QC teams. We manage factory establishment from feasibility and utilities planning to plant layout, EHS alignment with local regulations, and line commissioning. Hybrid models keep critical high‑temperature steps in Weifang while machining, assembly, and inspection occur in Pakistan, reducing lead times and currency exposure.

Quality systems are embedded. Statistical process control covers density, porosity, and critical dimensions; mechanical testing validates flexural strength and hardness; and leak/pressure tests qualify seals and fluid components. For OEM and EPC programs, we align with IATF 16949 expectations, developing control plans and PPAP documentation that accelerate supplier onboarding. Post‑launch, our engineers continue optimizing firing curves, tooling, and yields to protect margins and sustain field reliability. Over 10+ years and 19+ enterprise partnerships, this comprehensive, transferable capability has consistently produced faster qualifications, fewer first‑run issues, and clear PKR‑based ROI.

Future Market Opportunities and 2025+ Trends in Pakistan’s Power Sector

Looking beyond 2025, several trends favor wider adoption of SiC in Pakistan. Energy economics and ESG reporting will keep rewarding components that stabilize thermal profiles and extend service life between outages—particularly in mixed‑fuel and biomass co‑firing scenarios. Utilities and large industrials will deepen certification practices, making traceable, repeatable SiC solutions a pragmatic route to satisfying insurer and buyer audits. Waste‑to‑energy and process heat recovery will expand, where SiSiC radiant and recuperator elements confer structural advantages. Hydropower and renewables, while less thermally intensive, will still benefit from SSiC seals and wear parts in pumps and balance‑of‑plant systems where corrosion and abrasion degrade performance.

Distribution models will evolve toward engineering‑led partnerships. Pakistani channel partners will differentiate through critical‑spare stocking, first‑fit supervision, and data‑driven design refreshes. Local finishing and assembly, enabled by technology transfer, will shorten response times and reduce FX risk. In short, SiC is transforming from a tactical material swap into a strategic lever for reliability, efficiency, and compliance—key differentiators as performance contracts, tenders, and buyer expectations tighten.

Perguntas frequentes

Which SiC grade should I select for my power application in Pakistan?

For hot‑zone structural parts like burner tiles and flame tubes, R‑SiC provides high‑temperature dimensional stability and oxidation resistance. For precision seals and corrosion‑prone fluid systems, SSiC offers near‑theoretical density and superior corrosion resistance. For erosive ductwork, elbows, and cyclone liners, RBSiC/SiSiC balances wear resistance with shape flexibility. We map grade to temperature, atmosphere, particulate load, and planned outage cadence.

Can Sicarbtech support PSQCA, ISO, and insurer documentation for power tenders?

Yes. We provide PSQCA‑referenced conformity packs, ISO 9001/14001/45001 documentation, and structured third‑party test reports (including SGS evidence where required). For OEM/EPC programs, we can prepare IATF 16949‑aligned control plans and PPAP packages to accelerate qualification.

What payback can a Pakistani utility or captive plant expect from SiC upgrades?

Typical payback ranges from 6 to 16 months depending on energy prices, fuel mix, duty cycle, and baseline failure modes. We model ROI in PKR, incorporating duties, installation, and maintenance savings, and synchronize deliveries with planned outages to capture benefits quickly.

How does SiC improve boiler and heat‑recovery efficiency?

High thermal conductivity and oxidation resistance stabilize heat transfer, reducing hot spots and heat loss. In practice, facilities report faster heat‑up, tighter temperature uniformity, and 0.8–1.6% fuel savings when replacing alloy or castable components with SiC in burner zones and radiant/recuperator elements.

Can Sicarbtech localize SiC manufacturing or finishing in Pakistan?

Absolutely. Through technology transfer, we provide process know‑how, equipment specifications, SOPs, QC protocols, and training. Hybrid models—critical firing in Weifang with local machining and assembly—reduce lead times and FX exposure while building domestic capability.

What information do you need to engineer a custom SiC component?

We typically request operating temperature and atmosphere, particulate chemistry and loading, mechanical loads, failure history, target MTBF, interface drawings with tolerances, and compliance requirements. This enables accurate grade selection, FEA validation, and manufacturability review.

How are SiC parts installed to achieve full service life?

We supply installation SOPs. For hot‑zone components: controlled ramp‑up, compatible mortars, support design, and expansion allowances are critical. For seals: flatness, surface finish, torque sequence, and flush plans protect lapped faces. We can supervise first‑fit to ensure success.

What lead times and logistics options are available for Pakistan’s power sector?

Custom lead times generally run 4–10 weeks depending on complexity. We align shipments with outage calendars and can phase deliveries. Under technology transfer or local finishing, lead times shorten and safety stock can be positioned locally.

Do you provide after‑sales engineering support on site?

Yes. We offer remote diagnostics, on‑site commissioning, performance audits, and continuous improvement engagements. We also co‑develop spare strategies and inspection schedules aligned with planned shutdowns.

How does Sicarbtech ensure batch‑to‑batch consistency for critical power components?

Proprietary forming and firing/infiltration profiles, SPC on density/porosity/dimensions, and mechanical and leak testing underpin consistency. For OEM/EPC programs, we align control plans with IATF 16949 and supply PPAP documentation as required.

Fazendo a escolha certa para suas operações

Adopting tailored SiC products is not just a materials decision; it is a strategic choice to stabilize thermal performance, regain control over maintenance windows, and pass audits with confidence. Sicarbtech’s integrated approach—R‑SiC, SSiC, RBSiC, and SiSiC materials; application‑driven engineering; robust documentation; and transferable manufacturing know‑how—gives Pakistan’s power sector a de‑risked path to reliable efficiency gains and predictable ROI.

Obtenha consultoria especializada e soluções personalizadas

Share your duty cycle, fuel mix, and pain points with Sicarbtech’s engineering team. We will propose the optimal SiC grade and geometry, simulate performance against your operating envelope, and map an implementation plan synchronized with planned outages—complete with a PKR‑based ROI model. Contact: [email protected] or +86 133 6536 0038.

Explore Related Cluster Resources

- Why Silicon Carbide Is Ideal for Power Sector Applications

- Benefits of SiC Components in Energy and Power Equipment

- High-Temperature SiC Solutions for Thermal Power Plants

- Tailored SiC Components for Hydropower and Renewable Systems

- Download Technical Data Sheets for Energy SiC Components

- Certified SiC Products for Energy and Utility Applications

- Supply Chain and Logistics for Power Sector in Pakistan

- How to Source Custom SiC Products for Power Equipment

- Wholesale and Distributor Opportunities for Energy SiC Products

- FAQs About Using SiC Ceramics in High-Voltage Systems

Metadados do artigo

Last updated: 2025-09-23

Next scheduled review: 2026-01-15

Content freshness indicators: 2025 Pakistan power‑sector outlook integrated; compliance aligned with PSQCA, ISO 9001/14001/45001, and insurer expectations; ROI modeled in PKR; case insights from 2023–2025 Sicarbtech deployments with 19+ enterprises; trends calibrated to energy volatility, ESG pressures, mixed‑fuel usage, and localization initiatives.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.