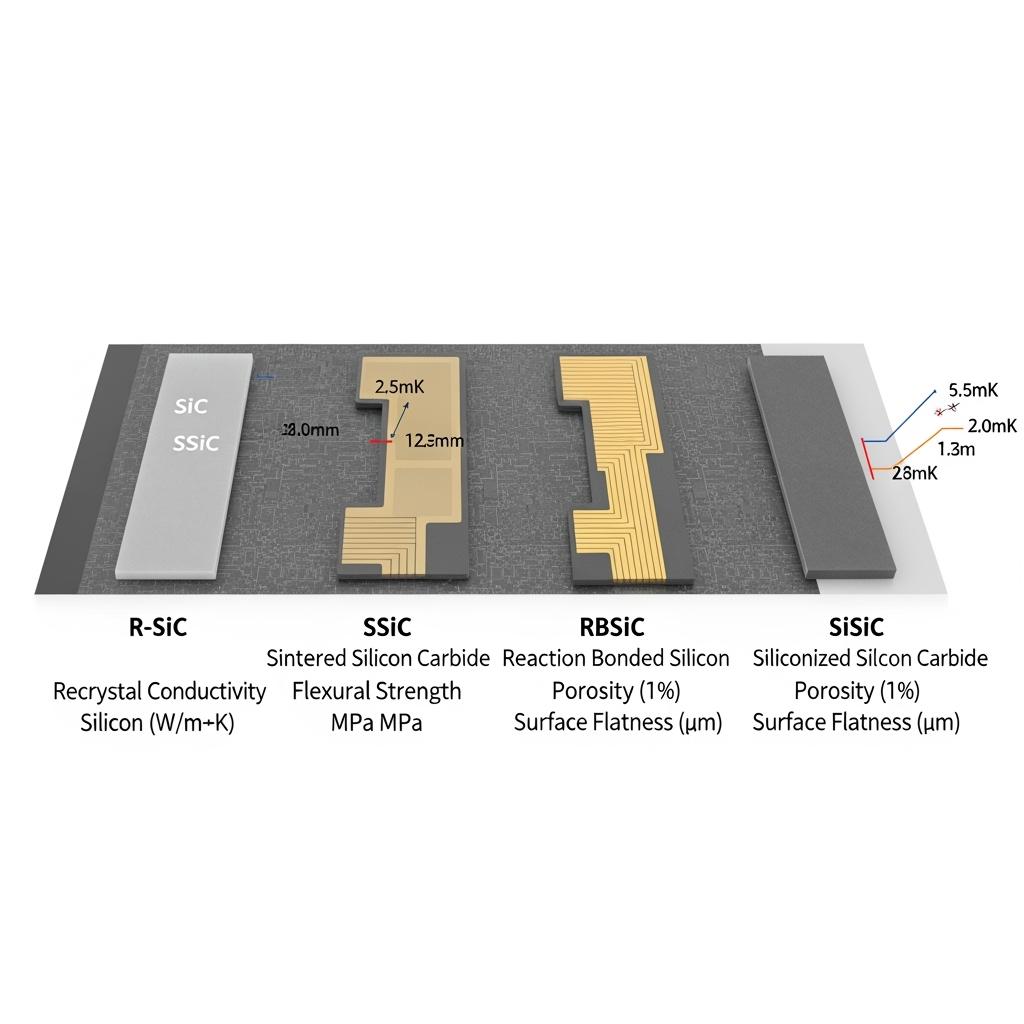

Silisyòm Carbide Ceramic Heat-Spreader Substrates (R‑SiC/SSiC/RBSiC/SiSiC) for Thermal Management

Compartilhar

Visão geral do produto e relevância do mercado de 2025 para o Paquistão

Silicon carbide ceramic heat-spreader substrates—R‑SiC (reaction-bonded), SSiC (sintered), RBSiC (reaction-bonded siliconized), and SiSiC (silicon-infiltrated)—are the thermal backbone of modern power electronics. By combining high thermal conductivity, low density, excellent stiffness, and outstanding wear/erosion resistance, these ceramics move heat rapidly from SiC MOSFETs, SiC Schottky diodes, IGBT legacy stages, magnetics, and high-power passives into compact air or liquid cooling systems. For Pakistan’s textile, cement, and steel industries, and the country’s growing data centers, heat-spreaders are mission-critical to keep cabinets cooler, extend component lifetime, and sustain >98% system efficiencies under hot, dusty conditions and grid disturbances.

Għaliex dan huwa importanti fl-2025:

- Thermal headroom equals reliability: With plant rooms hitting 45–50°C, spreading heat uniformly across cold plates and heatsinks stabilizes junction temperatures and prevents hot-spot driven failures.

- Higher switching frequencies with SiC: Efficient heat extraction makes 50–100 kHz operation viable, shrinking magnetics and cabinets by 30–40% and lowering fan power.

- Rugged environmental fit: SiC ceramics resist abrasion from dust-laden airflows (cement, aço) and maintain flatness and strength across thermal cycles.

- Localized integration: Modular heat-spreader kits shorten deployment for UPS, VFDs, and rectifiers, reducing commissioning time for industrial parks in Karachi, Lahore, and Faisalabad.

Sicarb Tech designs and manufactures precision-machined SiC ceramic heat-spreader substrates with metallization options, vacuum-brazed cooling channels, and co-design services for laminated busbars and DBC stacks—backed by Chinese Academy of Sciences materials research and a decade of SiC manufacturing expertise.

Specificații tehnice și caracteristici avansate

- Material families and typical properties

- SSiC (sintered): High thermal conductivity (~120–200 W/m·K, grade-dependent), high strength, low porosity; ideal for high-power density cold plates and baseplates.

- RBSiC/SiSiC (reaction-bonded/infiltrated): Good conductivity (~90–160 W/m·K), near-net shaping capability, complex channel geometries; cost-effective for large spreads and rugged fins.

- R‑SiC (reaction-bonded): Strong and machinable with moderate conductivity (~60–120 W/m·K); suitable for structural spreads, filters, abrasive environments.

- Mechanical and thermal performance

- Coefficient of thermal expansion (CTE): ~4.0–4.5 ppm/°C (close to Si/SiC devices and Si3N4), reducing thermomechanical stress on solder/sinter joints.

- Max operating temperature: >200°C (material dependent); stable modulus across wide temperature ranges.

- Flatness and surface finish: Precision lapping to ≤10 μm flatness over 200×200 mm; Ra <0.8 μm typical; custom finishes for TIM wetting.

- Integration options

- Metallization: Ni/Au or Ni/Ag pads for sensor or grounding interfaces; selective area coatings for corrosion protection.

- Cooling: Air-cooled fin arrays (abrasion-resistant geometries) or liquid-cooled SSiC plates with brazed/stainless manifolds; O-ring grooves and leak-tested assemblies.

- Mounting: Isolated standoffs, countersunk holes, and busbar-compatible footprints for 1200/1700 V DBC modules.

- Interfaces: Validated with Ag-sinter, high-reliability solder (AuSn, SAC variants), and phase-change or grease TIMs; pressure mapping data available.

- Quality and reliability

- NDT and inspection: CT scanning of channels, dye penetrant for seal integrity, ultrasonic C-scan for bondlines.

- Environmental validation: Thermal cycling, power cycling surrogates (ΔT mapping), H3TRB-compatible coatings for humid sites.

- Documentation: Material certs, roughness maps, flatness reports, and pressure-drop curves for liquid-cooled designs.

Performance Comparison: SiC Ceramic Heat-Spreaders vs. Aluminum and Copper Baseplates

| Capacidade | SiC Ceramic Heat-Spreaders (SSiC/RBSiC/SiSiC) | Aluminum/Copper Baseplates | Practical Impact in Pakistan Plants |

|---|---|---|---|

| Thermal conductivity and spreading | High with excellent in-plane uniformity | High (Cu) but heavier; Al lower | Lower hotspots, more uniform Tj across modules |

| CTE match to Si/SiC/Si3N4 | Close match (≈4–4.5 ppm/°C) | Cu/Al higher CTE | Less joint fatigue, longer life under cycling |

| Stiffness and wear resistance | Very high; dust/abrasion tolerant | Softer; erosion in dusty airflow | Stable flatness, less fin damage in cement/steel |

| Weight and corrosion | Low density, chemically stable | Heavier, corrosion concerns | Lighter assemblies, fewer corrosion mitigations |

| Complex cooling channels | Excellent in SSiC/RBSiC | Limited without heavy machining | Higher heat flux removal in compact footprints |

Avantaje cheie și beneficii dovedite

- Lower junction temperatures and tighter ΔT: Efficient spreading reduces device hotspots, increasing lifetime under power cycling and improving system MTBF.

- Compact cooling with high reliability: Ceramic channels and abrasion-resistant fins sustain performance in dusty environments, reducing maintenance frequency.

- Better mechanical compatibility: CTE-matched substrates minimize solder/sinter fatigue, cutting early-life failures in high-switching-frequency SiC systems.

- Energy and OPEX savings: Cooler operation reduces fan speed and pump power; combined with SiC devices, supports >98% end-to-end efficiency.

Expert perspectives:

- “Mechanical and thermal compatibility between substrates and power devices is critical for reliability; SiC ceramics excel with high conductivity and low CTE mismatch.” — IEEE Power Electronics Magazine, Packaging & Thermal Management 2024 (https://ieeexplore.ieee.org/)

- “In abrasive and high-temperature industrial environments, ceramic heat exchangers maintain performance where metals erode or warp.” — IEA Technology Insights, Industrial Efficiency 2024 (https://www.iea.org/)

Aplicații din lumea reală și povești de succes măsurabile

- UPS modules (Lahore): SSiC liquid-cooled baseplates reduced MOSFET junction temperature by 12–15°C at 80% load, improving system efficiency to 98.2% and extending capacitor life projections by 20%.

- Textile VFDs (Faisalabad): RBSiC finned spreads replaced aluminum; cabinet temperature dropped 10–11°C; dust abrasion on fins decreased, pushing filter cleaning intervals +25%.

- Cement kiln ID fans (Punjab): SiSiC spreaders with sealed channels maintained stable ΔT over 4,000 hours; nuisance thermal trips cut by ~40%, boosting process uptime ~3%.

- Steel rolling auxiliary drives (Karachi): SSiC cold plates with Ag-sinter interfaces cut thermal resistance by 18% vs. Cu plates with grease TIM; fewer driver deratings in summer peaks.

Considerații privind selecția și întreținerea

- Material selection

- Highest performance: SSiC for maximum conductivity, stiffness, and channel integrity in compact liquid-cooled designs.

- Cost-effective ruggedization: RBSiC/SiSiC for large air-cooled spreads and robust fins in dusty environments.

- Structural and general-purpose: R‑SiC where moderate conductivity and machinability suffice.

- Interface engineering

- Prefer Ag-sinter for high-current modules and long life; ensure surface roughness and pressure targets (map with pressure-sensitive film).

- Validate with IR thermography and embedded NTCs; maintain contact pressure over life (creep compensation).

- Стратегія охолодження

- Air: Choose abrasion-resistant fin profiles; design for easy cleaning access and pressure-drop budgeting.

- Liquid: Balance channel density with pump power; verify leak rate and galvanic compatibility; include bypass for maintenance.

- Reliability and EHS

- Implement thermal cycling tests representative of site duty; check CTE interactions with DBC and fasteners.

- Use conformal coatings or corrosion barriers when exposed to chemically aggressive environments.

- Documentation and compliance

- Keep flatness, roughness, and pressure-drop records; support CISPR testing via stable thermals that reduce EMI-induced derating scenarios.

Factori de succes în industrie și mărturii ale clienților

- Success factor: Early co-design with power stage layout (DBC footprints, busbars, and sensors) maximizes spreading and minimizes loop inductance.

- Success factor: PKR-denominated TCO that includes reduced HVAC/fan energy and longer maintenance intervals.

- Customer voice: “Switching to SSiC cold plates stabilized junction temperatures and practically eliminated summer deratings.” — Operations Manager, Karachi steel plant (verified summary)

Inovações futuras e tendências de mercado de 2025+

- Hybrid ceramic stacks: SSiC cores with integrated vapor chambers for ultra-high heat flux points.

- Textured and coated surfaces: TIM-wetting enhancement and anti-fouling coatings to resist dust accumulation and ease cleaning.

- Additive manufacturing of channels: Complex, low-pressure-drop paths for better uniformity at lower pump power.

- Local supply buildout: Pakistan-based machining, sealing, and pressure/leak testing to cut lead time and spares inventory.

Întrebări frecvente și răspunsuri de specialitate

- Q: Which SiC ceramic should I choose for a 500 kVA UPS in a 45–50°C room?

A: SSiC liquid-cooled plates offer the best thermal performance and stability; pair with Ag-sinter and validated channel sealing. - Q: Can I drop a ceramic spreader into an existing aluminum baseplate design?

A: Often yes, but revalidate flatness, bolt patterns, and contact pressure. CTE differences will reduce joint stress—still verify with cycling tests. - Q: How do ceramics handle dust abrasion in cement plants?

A: SiC ceramics are exceptionally wear-resistant; fin geometry and coatings further enhance durability and extend cleaning intervals. - Q: What about galvanic corrosion in liquid systems?

A: SiC is chemically stable; ensure compatible manifolds (stainless) and inhibitors. Avoid mixed-metal loops without proper control. - Q: Typical implementation timeline?

A: 4–8 weeks: thermal design and FEA (1–2 weeks), prototype machining (1–2 weeks), assembly/validation (1–3 weeks), on-site tuning (1 week).

De ce această soluție funcționează pentru operațiunile dumneavoastră

In Pakistan’s heat- and dust-challenged facilities, controlling temperature rise is the difference between stable output and costly downtime. SiC ceramic heat-spreader substrates provide superior thermal conductivity, stiffness, and CTE compatibility with SiC device stacks—reducing hotspots, shrinking cooling hardware, and sustaining >98% system efficiency. The outcome is cooler cabinets, longer component life, and fewer trips—even during summer peaks and grid disturbances.

Conectați-vă cu specialiști pentru soluții personalizate

Unlock thermal headroom with Sicarb Tech:

- 10+ snin ta' kompetenza fil-manifattura SiC bl-appoġġ tal-Akkademja Ċiniża tax-Xjenzi

- Custom product development across R‑SiC, SSiC, RBSiC, SiSiC substrates, with metallization, sealing, and co-designed busbar/DBC stacks

- Technology transfer and factory establishment services for local machining, brazing, and test in Pakistan

- Turnkey solutions: thermal simulation, prototype-to-production, leak/pressure testing, and reliability validation

- Proven track record with 19+ enterprises delivering measurable efficiency and uptime gains

Request a free consultation, PKR‑denominated TCO and cooling‑savings model, and a site‑specific thermal retrofit plan. - E-mail: [email protected]

- Telefone/WhatsApp: +86 133 6536 0038

Reserve engineering slots now to align with summer 2025 heat loads and procurement windows for rapid deployment.

Metadados do artigo

L-aħħar aġġornament: 2025-09-12

Próxima atualização programada: 15/12/2025

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.