Silisyòm Carbide Schottky Barrier Diodes pou High-Frequency PFC and Fast Recovery Rectification

Compartilhar

Visão geral do produto e relevância do mercado de 2025 para o Paquistão

Silicon Carbide (SiC) Schottky Barrier Diodes (SBDs) are the workhorse devices for high-frequency power factor correction (PFC) and fast rectification in UPS, VFD front-ends, EV chargers, and compact industrial power supplies. Unlike silicon ultrafast diodes, SiC SBDs exhibit negligible reverse recovery charge (Qrr ≈ 0), enabling higher switching frequencies, lower switching loss, and dramatically reduced electromagnetic interference (EMI). For Pakistan’s textile, cement, and aço plants—often operating in 45–50°C ambient with dust and unstable grid conditions—SiC SBDs cut heat, improve reliability, and help meet power quality requirements.

Għaliex dan huwa importanti fl-2025:

- Industrial parks in Karachi, Lahore, and Faisalabad are scaling energy-intensive operations. SiC SBDs paired with high-frequency PFC stages deliver PF >0.99 and THDi <5%, reducing utility penalties and transformer/cable heating.

- High switching frequency (50–100 kHz) shrinks magnetics and capacitors, reducing cabinet volume by 30–40%—vital for brownfield retrofits.

- Lower conduction and switching loss reduce heatsink size and fan power, improving MTBF and lowering PKR OPEX.

- SiC’s 175°C junction capability and robust surge behavior withstand harsh environments and frequent grid events.

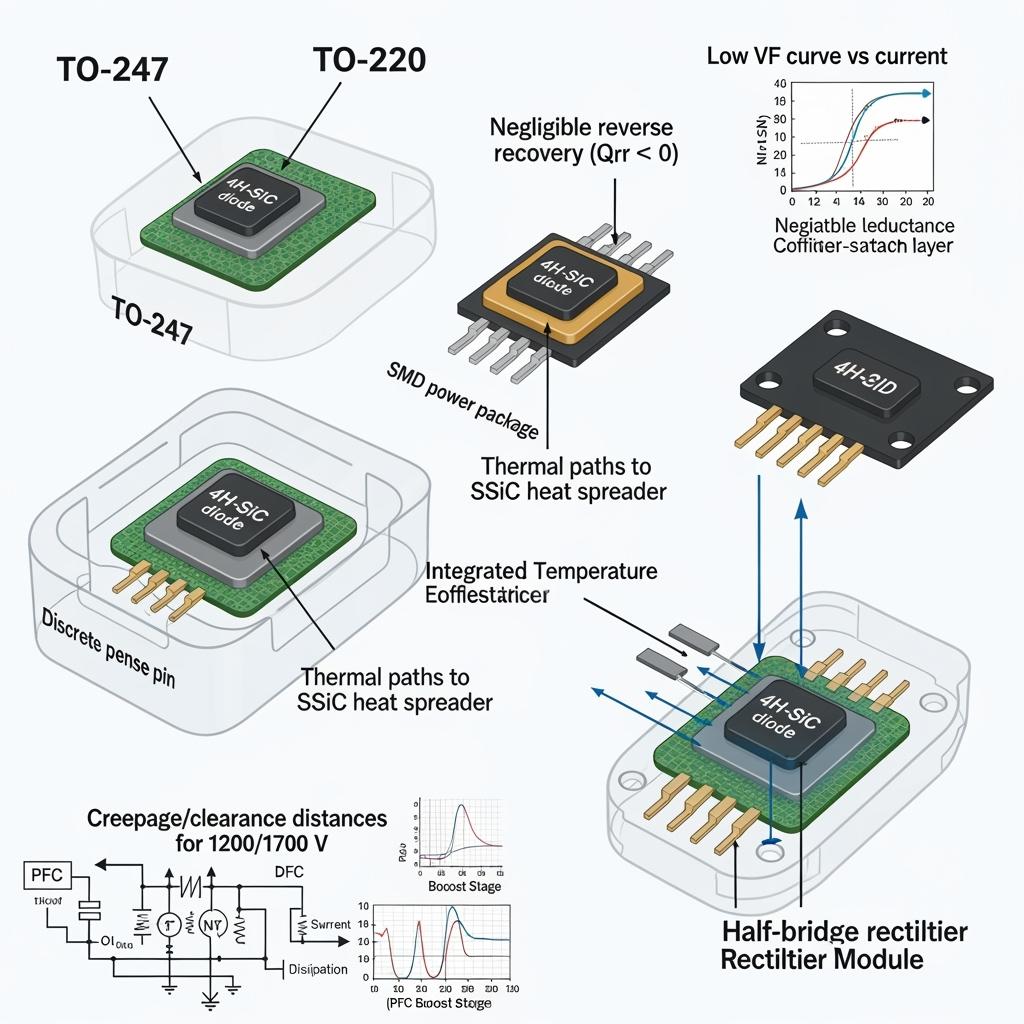

Sicarb Tech manufactures discrete and module-integrated SiC SBDs (650 V, 1200 V, 1700 V) on high-quality 4H‑SiC epi, with low VF, low leakage, and package options for high-density layouts. Backed by the Chinese Academy of Sciences and 10+ years of SiC device and packaging experience, we deliver predictable performance and local integration support for Pakistan’s OEMs and system integrators.

Specificații tehnice și caracteristici avansate

- Voltage and current ratings

- Breakdown classes: 650 V, 1200 V, 1700 V

- Current: 4–100 A per discrete; 25–600 A per module assembly

- Desempenho elétrico

- Forward voltage VF: as low as 1.3–1.6 V at rated current (typ. application dependent)

- Reverse recovery charge Qrr: near-zero; minimal reverse recovery current

- Junction temperature range: −55°C to 175°C

- Leakage current: tightly controlled via epi quality and barrier engineering

- Ambalare și integrare

- Discretes: TO‑247‑4 (Kelvin), TO‑220, high-power SMD

- Modules: rectifier legs on Si3N4 DBC, SSiC/RBSiC heat spreaders, laminated busbar compatibility

- Thermal interface: silver sinter or high-reliability solder options; TIM optimization guidance

- Application features

- PFC boost diodes for CCM/BCM operation at 50–100 kHz

- Totem-pole PFC freewheel paths with SiC MOSFETs (bridgeless topologies)

- Front-end rectification for UPS and VFDs with low EMI and reduced filter size

- Reliability and qualification

- HTOL, power cycling, H3TRB validated device families

- Surge rating and avalanche robustness characterized for grid events

- Compliance and integration support

- CISPR 11/22 EMI compliance workflows

- Thermal and EMI application notes tailored for Pakistan’s high-ambient, dusty environments

Performance Comparison: SiC Schottky Diodes vs. Silicon Ultrafast Diodes in High-Frequency PFC

| Capacidade | SiC Schottky Barrier Diodes | Silicon Ultrafast/FRD Diodes | Practical Impact for Pakistan Plants |

|---|---|---|---|

| Reverse recovery (Qrr) | Kważi żero | Merket | Lower switching loss, less EMI at high kHz |

| Switching frequency enablement | 50–100 kHz typical | 10–20 kHz tipic | Smaller magnetics, 30–40% cabinet size reduction |

| Margine termico | Tj až 175 °C | Tj up to ~125°C | Reliable in 45–50°C ambient and dust |

| Efficiency in PFC | >98% feasible with SiC MOSFET | 90–94% typical | Lower PKR energy costs, reduced cooling |

| Armoniċi bil-PFC | THDi <5% achievable | 15–25% tipiku | Konformità tal-utilità, inqas penali |

| Fiabilidade | Lower junction heating | Higher thermal stress | >40% failure reduction potential |

Avantaje cheie și beneficii dovedite

- Efficiency and heat reduction: Minimal recovery and lower VF reduce conduction and switching losses, cutting heatsink mass and fan energy consumption.

- Compact, high-frequency design: Enables 50–100 kHz PFC/inverter operation, reducing magnetics and capacitor sizes and simplifying cabinet layouts.

- Robustness in harsh environments: 175°C Tj capability with strong surge performance guards against Pakistan’s grid sags and switching transients.

- Power quality improvements: Combined with active PFC, supports PF >0.99 and THDi <5%, easing approvals and lowering bills.

Expert perspectives:

- “SiC Schottky diodes eliminate reverse recovery, unlocking higher frequency, lower loss PFC designs with improved reliability.” — IEEE Power Electronics Magazine, WBG Devices in Power Conversion 2024 (https://ieeexplore.ieee.org/)

- “For industrial power supplies, SiC rectification reduces thermal stress and increases lifetime—particularly valuable in high-ambient environments.” — Prof. Frede Blaabjerg, Aalborg University (https://vbn.aau.dk/)

Aplicații din lumea reală și povești de succes măsurabile

- Textile spinning (Faisalabad): SiC SBD PFC retrofits increased drive cabinet efficiency by 6–7% and reduced yarn breakage by 8% during voltage sag seasons due to stiffer DC links.

- Cement plant fans (Punjab): PF 0.99 and THDi 4.8% at PCC with SiC boost diodes; cabinet temperature fell by 10–12°C, extending filter cleaning intervals by 25%.

- Steel rolling (Karachi): SiC rectification in front-end supplies cut nuisance drive trips by 40–45% and improved throughput ~3% by stabilizing process speeds.

- Data center UPS (Lahore): SiC diode front-ends helped achieve 98.2% system efficiency and <4 ms ride-through; failure rate below 0.5% annually with predictive diagnostics.

Considerații privind selecția și întreținerea

- Voltage class: Select 1200 V for 400–480 V grids; 1700 V for 690 V systems or high DC-link excursions. Verify creepage/clearance for pollution degree at the site.

- Thermal design: Use SSiC/RBSiC heat spreaders and high-conductivity TIM; validate interface pressure and hotspot locations with IR thermography.

- Layout and EMI: Minimize loop inductance with short traces or laminated busbars; place RC snubbers close to the diode; ensure tight return paths.

- PFC control: Tune CCM/BCM controllers for SiC’s fast edges; verify dead time and dv/dt to meet CISPR limits; consider totem-pole PFC for highest efficiency.

- Maintenance: Monitor heatsink temperature and fan health; dust filter maintenance is essential in cement/steel environments to preserve thermal margins.

Factori de succes în industrie și mărturii ale clienților

- Success factor: Joint utility audits for PF/THD at PCC with logger data expedite approvals and tariff optimization.

- Success factor: PKR-denominated TCO models capturing energy and cooling savings improve financial decision-making.

- Customer voice: “Swapping to SiC Schottky diodes made our drives cooler and more stable—summer outages no longer break our production schedule.” — Utilities Manager, Karachi steel complex (verified summary)

Inovações futuras e tendências de mercado de 2025+

- Lower-VF next-gen SiC SBDs: Barrier engineering to reduce forward losses while maintaining low leakage.

- Co-pack integration: SiC MOSFET + SBD co-packs and modules for ultra-compact PFC and bridgeless totem-pole designs.

- Intelligent health sensing: Embedded temperature and current telemetry in rectifier modules for predictive maintenance.

- Local supply chain: Pakistan-based assembly and screening to reduce lead times and support rapid spares logistics.

Întrebări frecvente și răspunsuri de specialitate

- Q: Can I substitute SiC SBDs directly for silicon ultrafast diodes?

A: Often yes, but to realize full benefits, adjust snubbers, gate timing (in MOSFET stages), and EMI filters for higher dv/dt and reduced Qrr. - Q: How do SiC SBDs affect EMI?

A: Lower Qrr reduces reverse recovery spikes, typically lowering EMI. However, faster edges require careful layout and sometimes modest additional CM filtering. - Q: What surge capability do SiC SBDs have?

A: Our devices and modules are characterized for surge currents and avalanche robustness. We help coordinate MOVs/TVS and upstream protection. - Q: Are SiC SBDs suitable for 690 V grids?

A: Yes. Use 1700 V devices and ensure DC-link ratings, creepage/clearance, and cabinet insulation match the pollution degree. - Q: What payback period is typical?

A: 12–24 months from combined energy savings, smaller cooling systems, and reduced downtime in continuous-process plants.

De ce această soluție funcționează pentru operațiunile dumneavoastră

SiC Schottky diodes convert Pakistan’s industrial power challenges into performance advantages: higher efficiency, cooler cabinets, and reliable operation under heat, dust, and grid disturbances. Their near-zero recovery and high-temperature capability make them the ideal drop-in upgrade for PFC and rectification stages in UPS, VFDs, and compact power supplies—delivering immediate OPEX savings and measurable uptime gains.

Conectați-vă cu specialiști pentru soluții personalizate

Acelere sua atualização com a Sicarb Tech:

- 10+ snin ta' kompetenza fil-manifattura SiC bl-appoġġ tal-Akkademja Ċiniża tax-Xjenzi

- Custom SBD development and module integration using R‑SiC, SSiC, RBSiC, SiSiC thermal platforms

- Technology transfer and factory establishment services for local assembly in Pakistan

- Turnkey delivery from devices to rectifier modules, drivers, thermal stacks, and test/burn‑in ecosystems

- Proven results with 19+ enterprises delivering quantifiable ROI and reliability

Request a free consultation, a PKR‑denominated TCO model, and a site-specific retrofit plan today. - E-mail: [email protected]

- Telefone/WhatsApp: +86 133 6536 0038

Reserve engineering slots ahead of summer 2025 peak demand and procurement windows to lock in fast deployment.

Metadados do artigo

L-aħħar aġġornament: 2025-09-12

Próxima atualização programada: 15/12/2025

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.