Drivers de porta de alta frequência e alta temperatura otimizados para MOSFETs SiC (isolados, alta imunidade dv/dt)

Compartilhar

Earbsachd Drive Gate airson Tionndaidhean Àrd-èifeachdais Pakistan ann an 2025

Pákistánský textilní, cementářský a aço tha roinnean a’ luathachadh dealanachadh agus ùrachaidhean càileachd cumhachd fhad ‘s a tha comas ath-nuadhachail a’ leudachadh ann an Sindh agus Balochistan. Gus làn choileanadh a dhèanamh air èifeachdas agus astar Silicon Carbide (SiC) MOSFETs ann an SVG/STATCOM, APF, draibhearan àrd-tricead, UPS, agus solar cumhachd gnìomhachais, tha an draibhear geata riatanach airson misean. Bidh draibhearan geata àrd-tricead, àrd-teòthachd SiC-optimized le aonaranachd daingnichte agus dìonachd àrd dv/dt a’ cur casg air tionndadh meallta, a’ lughdachadh call tionndaidh, agus a’ dèanamh cinnteach à obrachadh seasmhach ann an teòthachd àrainneachd >45 ° C, duslach, agus taiseachd.

Bidh Sicarb Tech a’ dealbhadh agus a’ solar fuasglaidhean dràibhidh geata SiC-optimized le aonaranachd làidir, dìonachd gluasaid modh cumanta farsaing (CMTI), smachd Miller mionaideach, agus fiùran tionndaidh/tionndaidh prògramaichte. Le taic bho Acadamaidh Saidheansan Shìona, bidh na h-àrd-chabhsairean againn ag amalachadh gu sgiobalta a-steach do topologies ioma-ìre agus siostaman fo smachd IEC 61850, a’ giorrachadh cearcallan coimiseanaidh airson eadar-cheangal NTDC/NEPRA agus a’ leasachadh earbsachd fad-ùine.

Specificații tehnice și caracteristici avansate

- Aonaranachd agus dìonachd fuaim

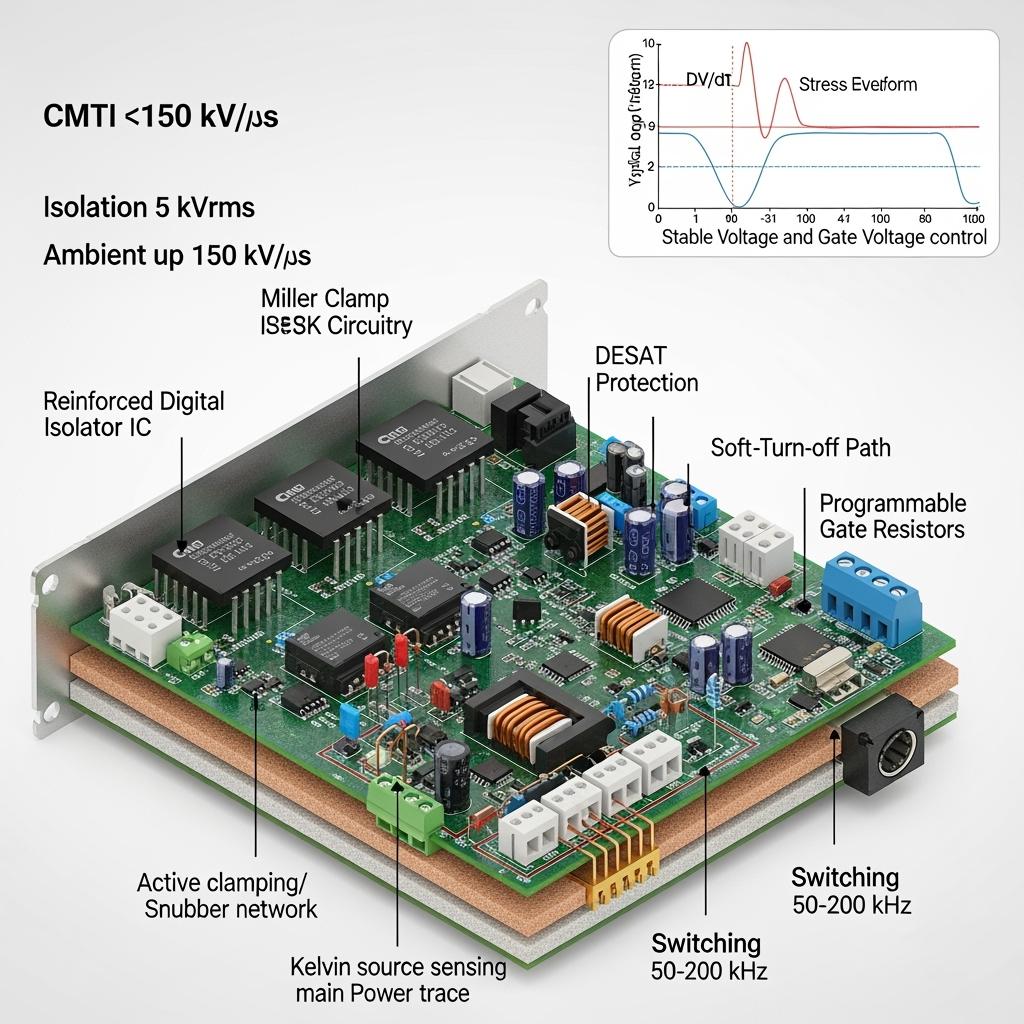

- Aonaranachd daingnichte suas ri 5 kVrms; creepage/fàs glan air a dhealbhadh gu IEC 60664-1

- CMTI ≥150 kV/µs gus fulang le oirean tionndaidh SiC luath gun truailleadh dàta

- Roghainnean ceangail fiber-optic no eadar-dhealaichte airson ruith càball fada fuaimneach ann an stèiseanan-fo agus muilnean

- Smachd geata agus dìon

- Luchd-aghaidh geata prògramaichte agus split RG (tionndadh/tionndadh) airson EMI agus smachd cus-losgadh

- Clamp Miller agus claonadh geata àicheil (me, +18 V / −3 gu −5 V) gus casg a chuir air tionndadh meallta

- Dìon DESAT overcurrent le tionndadh bog; co-òrdanachadh seasamh cuairt ghoirid

- Pròifilean smachd geata gnìomhach: cumadh di/dt agus dv/dt gus call agus EMI a chothromachadh

- Cumhachd agus teirmeach

- Solar claon iomallach ±18 V clas, 3–6 W gach seanal; Crìochan UVLO a rèir riatanasan SiC MOSFET

- Ag obair ann an àrainneachd suas ri 105 ° C; co-phàirtean air an rangachadh airson teòthachd eadar-aghaidh a rèir ìre gnìomhachais

- Cruth a tha air a bharrachadh le èifeachdas le inductance parasitic ìosal agus tilleadh stòr Kelvin

- Ùine agus diagnostics

- Sgaoileadh dàil <100 ns le maids seanal-gu-seanal ≤20 ns airson cruachan ioma-ìre

- Glasadh locht, stampadh ùine tachartais, agus sgrùdadh slàinte tro SPI/CAN/ceanglaichean optigeach

- Deiseil airson amalachadh a-steach do gheataichean IEC 61850 tro phrìomh bhòrd smachd (eadar-aghaidh aig ìre an t-siostaim)

- Gèilleadh agus earbsachd

- Air a dhealbhadh gus coinneachadh ri IEC 62477-1 (sàbhailteachd tionndaidh) agus riatanasan EMC gnìomhachais

- Roghainnean còmhdach conformal airson duslach saimeant agus taiseachd cladaich; tha dùnadh IP-rated ri fhaighinn aig ìre an t-siostaim

Carson a tha Draibhearan Geata SiC-Optimized nas fheàrr na draibhearan àbhaisteach ann an àrainneachdan cruaidh, àrd-tionndaidh

| Fòcas dealbhaidh | Draibhear geata iomallach SiC-optimized (am fuasgladh seo) | Draibhear àbhaisteach àm IGBT | Impact operațional în Pakistan |

|---|---|---|---|

| dv/dt agus CMTI | ≥150 kV/µs CMTI; làidir an aghaidh oirean luath | 25–50 kV/µs; buailteach a bhith a’ brosnachadh meallta | Seasmhachd ann an tachartasan griod lag agus stèiseanan-fo fuaimneach |

| Smachd geata | Split RG, clamp Miller, −Vge turn-off, smachd gnìomhach | RG stèidhichte, roghainnean clamp cuibhrichte | EMI nas ìsle, nas lugha de thursan mì-ghoireasach, èifeachdas nas fheàrr |

| Proteção | DESAT le tionndadh bog, freagairt cuairt ghoirid luath | Lorg OC nas slaodaiche; tionndadh nas cruaidhe | A’ dìon modalan SiC daor agus a’ lughdachadh ùine downtaim |

| Rangachadh teirmeach | Àrainneachd suas ri 105 ° C; co-phàirtean àrd-earbsachd | 70–85 ° C àbhaisteach | Earbsach ann an àrainneachd >45 ° C agus lusan dusty |

| Sioncronadh | Maids dàil teann airson topologies ioma-ìre | Maids sgaoilte | Tionndadh cothromach, sruthan cuairteachaidh nas lugha |

Avantaje cheie și beneficii dovedite

- Èifeachdas agus cothromachadh EMI aig tricead àrd (50–200 kHz): Bidh pròifilean geata prògramaichte a’ lughdachadh call tionndaidh gun a bhith a’ toirt buaidh air EMC.

- Earbsachd aig teòthachd: Bidh obrachadh seasmhach ann an àrainneachdan teth, dusty saimeant agus stàilinn a’ lughdachadh derating agus dùnadh.

- Dìon air a shuidheachadh airson SiC: Bidh DESAT luath agus tionndadh bog a’ lughdachadh cuideam inneal rè fàilligidhean agus tachartasan griod.

- Coimiseanadh nas luaithe: Bidh diagnostics aonaichte agus eadar-aghaidhean àbhaisteach a’ luathachadh gabhail ri FAT/SAT agus NTDC/NEPRA.

Citação de especialista:

“Gate drivers are the linchpin for realizing SiC’s promise—robust isolation, high CMTI, and precise gate shaping are essential to avoid EMI issues and unlock efficiency gains.” — Interpreted from IEEE Power Electronics Magazine perspectives on WBG gate driving (https://ieeexplore.ieee.org/xpl/RecentIssue.jsp?punumber=6161321)

Aplicații din lumea reală și povești de succes măsurabile

- SVG/STATCOM ann an tuathanas gaoithe Sindh (co-dhèanta): Dh’ ùraich draibhearan SiC-optimized freagairt ceum reactive gu <10 ms agus lughdaich iad call tionndaidh le ~12%, ag àrdachadh èifeachdas slabhraidh dìolaidh os cionn 98%.

- Ath-fhreagairt aghaidh VFD aodach ann am Faisalabad: Bha cumadh geata a’ gearradh thursan EMI-induced le 70% agus a’ leigeil le tricead àrdachadh bho 20 kHz gu 60 kHz, a’ crìonadh magnetics le ~25%.

- Steel APF ann an Karachi: Bha claonadh geata àicheil agus clamp Miller a’ cur às do thionndadh meallta aig àm gluasaid EAF; THD air a dhèanamh seasmhach taobh a-staigh crìochan IEEE 519 le nas lugha de ath-thionndadh sìoltachain.

- Auxiliaries plannt saimeant ann an KP: Chùm co-chruinneachaidhean draibhear geata còmhdaichte le conformal ùine obrachaidh tron t-seusan duslach le tachartasan fàilligeadh co-cheangailte ri draibhear <0.5% thar 12 mìosan.

Considerații privind selecția și întreținerea

- Co-chòrdalachd dealain

- Dèan maids air sruth toraidh draibhear (2–10 A aig a’ mhullach) gu cosgais geata inneal agus an astar tionndaidh a tha thu ag iarraidh

- Tagh ìre claonadh geata àicheil gus casg a chuir air tionndadh Miller gun a bhith a’ cur cus cuideam air ocsaid geata

- Dèan cinnteach gu bheil crìochan UVLO a rèir riatanasan MOSFET (+/− rèilichean)

- Aonaranachd agus cruth

- Tagh aonaranachd daingnichte airson cruachan MV; dearbhaich creepage/fàs glan airson ìre truailleadh ionadail

- Slighe tilleadh stòr Kelvin gus inductance parasitic agus mearachd tomhais a lughdachadh

- Proteção e detecção

- Suidheachadh stairsnich DESAT agus ùine falamh air a shuidheachadh gu feartan inneal agus topology (NPC/ANPC/MMC)

- Cuir a-steach mothachadh NTC/RTD faisg air bàsan airson pas teirmeach; dèan cinnteach gu bheil slighean sgaoilidh locht chun phrìomh rianadair

- Robustez ambiental

- Sònraich còmhdach conformal agus dùnadh le gasgaid ann an làraich dusty/humid

- Dèan dearbhadh air slighean sruth-adhair no fuarachadh leaghaidh timcheall air draibhearan agus luchd-aghaidh geata

- Cearcall-beatha agus pàirtean a bharrachd

- Cùm cùl-taic firmware/config; cùm pàirtean a bharrachd calibrated airson luchd-biadhaidh èiginneach

- Dealbhaich ath-sgrùdadh bliadhnail airson tuning parameter mar a bhios pròifilean obrachaidh a’ fàs

Factori de succes în industrie și mărturii ale clienților

- Co-dhealbhadh tràth le EPCs/integrators gus tricead tionndaidh, targaidean EMI, agus gèilleadh griod a cho-thaobhadh

- Oscillography air an làrach aig àm coimiseanaidh gus crìoch a chur air split RG, crìochan clamp, agus amannan falamh

- Trèanadh ionadail airson sgiobaidhean O&M gus diagnostics a mhìneachadh agus ionracas parameter a chumail suas

Vocea clientului (compus):

“Às deidh dhuinn draibhearan sònraichte SiC a ghabhail, rinn sinn oidhirp air tricead nas àirde gun pheanasan EMI agus chuir sinn às do thursan mì-ghoireasach aig àm tachartasan criathraich griod.” — Ceannard Cumail suas Dealain, Cluster Aodach, Punjab

Inovações futuras e tendências de mercado de 2025+

- Controladores integrados em módulos de potência SiC: Indutância de loop mais curta, detecção incorporada e proteção mais inteligente

- Controlo adaptativo da porta usando a temperatura e corrente do dispositivo em tempo real para minimizar dinamicamente a perda de comutação

- CMTI superior (>200 kV/µs) e isolamento digital com menor jitter para conversores utilitários baseados em MMC

- Canais de diagnóstico ciberseguros para alinhamento com a IEC 62443 para infraestruturas críticas

Întrebări frecvente și răspunsuri de specialitate

- Qual CMTI é recomendado para SiC com comutação de 50–100 kHz?

Recomenda-se ≥100–150 kV/µs; os nossos projetos visam ≥150 kV/µs para margem em ambientes de rede fraca e EAF. - A SiC MOSFET-ekhez szükségem van negatív kapufeszültségre?

Frequentemente sim, especialmente em topologias de comutação rápida ou alta dv/dt. A desativação de −3 a −5 V com grampo Miller reduz o risco de ativação falsa. - Como define o DESAT e o tempo de apagamento?

Calculamos com base na SOA do dispositivo, indutância parasita e topologia, depois validamos com capturas de osciloscópio durante FAT/SAT para garantir a desativação suave sem dissipação excessiva de energia. - Estes drivers podem integrar-se com sistemas IEC 61850?

Ao nível do sistema, o controlador principal agrega a telemetria do driver via SPI/CAN/óptico e publica via IEC 61850 MMS/GOOSE com carimbos de data/hora sincronizados. - E a operação em >45°C e poeira?

Especificamos componentes de nível industrial, revestimento de conformação e margens de projeto térmico; as caixas alcançam IP54–IP65 de acordo com os requisitos do local.

De ce această soluție funcționează pentru operațiunile dumneavoastră

Os drivers de porta SiC projetados para alta dv/dt e temperatura desbloqueiam o desempenho total dos MOSFETs SiC — maior eficiência, magnetismo menor e dinâmica estável — protegendo os dispositivos durante falhas. Nas condições adversas e interconexões de rede fraca do Paquistão, isso se traduz diretamente em menos disparos, aprovações mais rápidas e menor custo de vida útil.

Conectați-vă cu specialiști pentru soluții personalizate

Faça parceria com a Sicarb Tech para co-projetar a estratégia de acionamento de porta certa para seu SVG/STATCOM, APF, front-ends VFD e UPS:

- Mais de 10 anos de experiência em fabricação de SiC

- Pesquisa e desenvolvimento e validação apoiados pela Academia Chinesa de Ciências

- Desenvolvimento de produtos personalizados em materiais R‑SiC, SSiC, RBSiC, SiSiC e módulos de potência SiC

- Serviços de transferência de tecnologia e estabelecimento de fábrica - da viabilidade ao comissionamento

- Soluções completas desde o processamento de materiais e substratos até sistemas e controlos acabados

- Histórico comprovado com mais de 19 empresas que oferecem ganhos mensuráveis de eficiência e PQ

Obtenha uma consulta gratuita, revisão de projeto e plano de comissionamento no local.

Email: [email protected] | Phone/WhatsApp: +86 133 6536 0038

Metadados do artigo

- Última atualização: 11/09/2025

- Próxima atualização programada: 15/12/2025

- IEEE Transactions on Power Electronics e artigos da IEEE Spectrum sobre dispositivos SiC (fontes gerais da indústria)

- Referências: Revista IEEE Power Electronics sobre acionamento de porta WBG; IEC 62477-1; IEC 60664-1; IEEE 519; IEC 61000-3-6; práticas de interconexão NTDC/NEPRA

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.