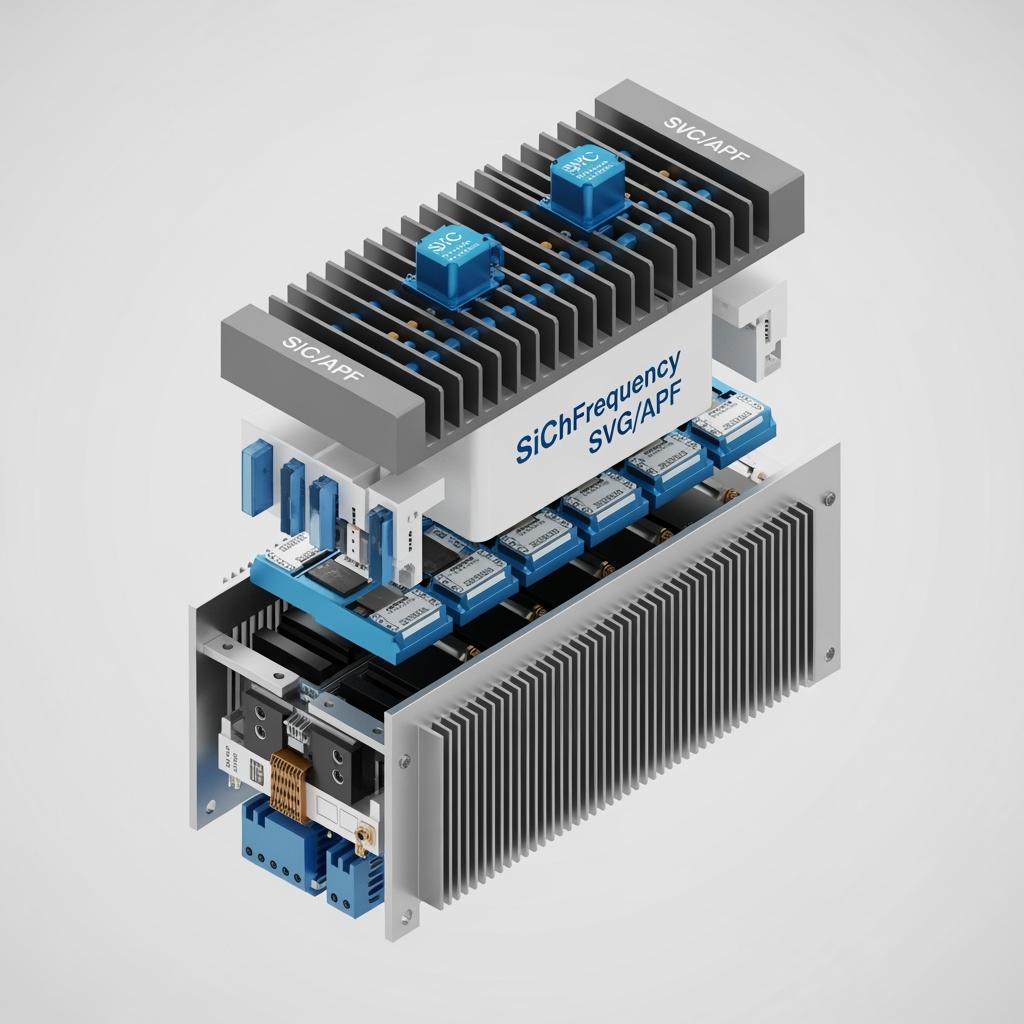

Módulos de energia de carboneto de silício de alta frequência para SVG/APF e acionamentos de média tensão

Compartilhar

Kvalita a účinnost energie pro průmyslový růst Pákistánu v roce 2025

Pákistánský textilní, cementářský a aço průmysl – spolu s rychle se rozvíjejícím větrným a solárním majetkem – vyžaduje robustní, kompaktní a účinnou konverzi energie. Vysokofrekvenční výkonové moduly z karbidu křemíku (SiC) poskytují >98% účinnost konverze a dynamickou odezvu pod 10 ms pro statické generátory VAR (SVG/STATCOM), aktivní výkonové filtry (APF) a pohony se středním napětím (MV). Tyto schopnosti pomáhají zařízením splňovat kritéria pro propojení NTDC/NEPRA, sladit se s harmonickými směrnicemi IEEE 519 a IEC 61000-3-6 a udržet výkon při vysokých okolních teplotách běžných v Sindhu a jižním Paňdžábu.

Sicarb Tech, se sídlem ve Weifang City (čínské centrum SiC) a podporovaný Čínskou akademií věd, poskytuje zakázkově navržené moduly SiC a komplexní transfer technologií. S více než 10 lety výroby SiC a více než 19 úspěšnými nasazeními naše moduly snižují ztráty, půdorys a údržbu a zároveň urychlují shodu a návratnost investic pro pákistánské závody a obnovitelné elektrárny.

Specificații tehnice și caracteristici avansate

- Jmenovité třídy napětí: zařízení 1200 V a 1700 V; stohy modulů přizpůsobené pro výstupní stupně MV prostřednictvím víceúrovňových topologií

- Spínací frekvence: 50–100 kHz pro SVG/APF a vysoce výkonné stupně střídače

- Účinnost systému: >98 % při jmenovitém zatížení; účinnost při částečném zatížení optimalizovaná pomocí adaptivní modulace

- Doba odezvy: <10 ms reaktivní kroková odezva pro dynamickou kompenzaci a zmírnění blikání

- Tepelná kapacita: Teplota přechodu -55 °C až 175 °C; ověřená tepelná cyklace a spolehlivost cyklace výkonu

- Hustota výkonu: >8 kW/l prostřednictvím pokročilého balení a konstrukce nízkoindukční sběrnice

- Integrované snímání: Hallovo/rogowského snímání proudu, přesná zpětná vazba napětí pro řízení s uzavřenou smyčkou

- Buzení brány: Odolnost proti vysokému dv/dt, svorka Miller, ochrana DESAT a izolovaný výkon pro vysokofrekvenční provoz

- EMC/EMI: Optimalizované uspořádání, stínění a RC tlumivky pro splnění průmyslových standardů EMC

- Odolnost vůči prostředí: Konformní povlak, možnosti integrace skříně IP55–IP65; zmírnění prachu a vlhkosti pro cementové/ocelové prostředí

Použitelné normy a integrace

- Harmonické a kvalita energie: IEEE 519, IEC 61000-3-6

- Bezpečnost výkonových elektronických měničů: IEC 62477-1

- PV/větrné připojení k síti: IEC 62109 (podle potřeby), místní kódy sítě NTDC/NEPRA

- Komunikace: IEC 61850, Modbus TCP, DNP3 pro integraci SCADA/DCS

Úvahy o výkonu a návrhu pro průmyslový Pákistán

- Odolnost vůči teplu a prachu pro lokality Karáčí, Faisalabad a Khyber Pakhtunkhwa

- Stabilizace slabé sítě ve větrných a PV uzlech v Sindhu a Balúčistánu

- Kompatibilita se stávajícími flotilami VFD a systémy UPS v textilních mlýnech a procesních závodech

- Snížená chladicí infrastruktura – nižší OPEX a menší elektrické místnosti

Deskriptivní srovnání: Moduly SiC vs. Tradiční křemík pro SVG/APF a pohony

| Oblast výkonu | Vysokofrekvenční moduly SiC (toto řešení) | Konvenční křemíkové moduly (na bázi IGBT) | Impact operațional în Pakistan |

|---|---|---|---|

| Dynamická odezva (SVG/APF) | <10 ms | 25–40 ms | Lepší řízení blikání pro spouštění EAF a náběhový proud motoru |

| Účinnost při jmenovitém zatížení | >98% | 92–95% | 5–7% úspora energie; nižší pokuty |

| Częstotliwość przełączania | 50–100 kHz | 10–20 kHz | Menší magnetika a skříně; tišší provoz |

| Margine termico | Tj až 175 °C | Tj až 125 °C | Menší snížení výkonu v okolí >45 °C |

| Densidade de potência | >8 kW/L | 3–5 kW/L | Redução de pegada de 25–35% |

| Potřeby chlazení | Nižší (kapalina/nucené proudění vzduchu) | Uheloc'h | Snížená klimatizace a údržba |

| Životnost (MTBF) | >15 let návrhový cíl | 8–10 anos | Méně generálních oprav, vyšší doba provozu |

Avantaje cheie și beneficii dovedite

- Připraveno na shodu: Rychlejší dynamika zajišťuje dodržování specifikací propojení NTDC/NEPRA; snadnější schválení

- Zisky v oblasti energie a kapacity: 5–7% zlepšení energetického systému; další rezerva pro rozšíření procesu

- Úspora prostoru a nákladů: O 25–35 % menší skříně; zjednodušené základy a vedení kabelů

- Spolehlivost: Prodloužená životnost a delší intervaly údržby v drsných prostředích

- Integrace: Bezproblémové připojení SCADA/DCS a modulární rozšíření pro fázové upgrady

Percepção do especialista:

„Vysokoteplotní provoz SiC a rychlé spínání výrazně zlepšují účinnost měniče a dynamický výkon, což je zásadní pro integraci obnovitelných zdrojů a stabilizaci průmyslových napáječů.“ – Perspektiva IEEE Power Electronics Society, syntetizováno ze zpráv IEEE Transactions on Power Electronics

Applikazzjonijiet tad-Dinja Reali u Suċċess li Jista' Jitkejjel

- Propojení větrné/PV sítě (Sindh): SVG na bázi SiC udržovaly kolísání napětí v rozsahu ±2 % a dosáhly 98,5 % účinnosti systému, což zlepšilo výsledky omezování a získalo souhlas provozovatele.

- Ocelářská válcovna (Karáčí): Moduly APF s SiC snížily celkové harmonické zkreslení na limity IEEE 519 a snížily spotřebu energie o 4,8 %; nežádoucí výlety se během rozběhu EAF výrazně snížily.

- Textilní komplex (Faisalabad): Moduly SiC v předních částech VFD stabilizovaly poklesy napětí, což snížilo události vypnutí tkalcovského stavu o 60 % a snížilo výkon chlazení o 15 %.

- Cementárna (KP): Vysokofrekvenční moduly SiC pohánějící ventilátory filtračních jednotek a pomocná zařízení pece dosáhly nižšího THD a prodloužily životnost ložisek a izolace díky plynulejším profilům točivého momentu.

Considerații privind selecția și întreținerea

- 电压等级和拓扑:选择 1200/1700 V 器件和适当的多电平拓扑结构(NPC、ANPC、MMC),以实现 MV 兼容性和减小滤波器尺寸

- 热路径:验证冷板或液体冷却的可用性、冷却液质量和流量;确保选择合适的热界面材料

- EMC 规划:机柜布局、接地和电缆屏蔽,以满足工厂的 EMC 要求

- 环境密封:为灰尘、湿度和腐蚀性环境选择 IP 等级和涂层策略

- 生命周期支持:计划备件、固件更新和远程诊断;与工厂停机窗口保持一致

Factori de succes în industrie și mărturii ale clienților

- 符合巴基斯坦的电网规范和工业园区要求

- 本地文档、培训和随叫随到的支持

- 最小化生产中断的分阶段改造策略

Vocea clientului (compus):

“在 SiC SVG/APF 升级后,我们的织造车间稳定性立即得到改善——跳闸次数减少,能源和冷却成本显着下降。” — 运营经理,旁遮普省纺织厂

Inovații viitoare și tendințe de piață (2025+)

- 中压 SiC MOSFET 和级联器件,可实现具有更少串联器件的更高电压堆栈

- 在可再生能源中心更广泛地采用模块化多电平转换器 (MMC) 用于公用事业规模的 SVG/STATCOM

- 增强 AI 的预测性维护,利用高频数据流进行早期故障检测

- 在巴基斯坦进行本地组装和技术转让,以缩短交货时间和降低外汇风险

Întrebări frecvente și răspunsuri de specialitate

- 这些模块是否符合巴基斯坦电网的要求?

是的,设计目标是 NTDC/NEPRA 互连规则和 IEEE 519/IEC 61000-3-6。集成支持 IEC 61850,用于所需的公用事业 SCADA。 - Qual é o período típico de retorno do investimento?

Quais certificações locais são necessárias? - Para sistemas conectados à rede: adesão aos códigos NTDC e aprovações de utilidade; para equipamentos industriais: conformidade com os padrões IEC e requisitos locais de EHS. Fornecemos documentação e relatórios de teste.

Você pode apoiar a fabricação ou montagem local no Paquistão? - Sim. Por meio de transferência de tecnologia, especificações de equipamentos e treinamento, ajudamos a configurar linhas de montagem locais para módulos de potência e componentes cerâmicos, reduzindo os prazos de entrega e os custos de importação.

Você oferece testes piloto? - Recomendamos implantações piloto com garantias de desempenho para validar a economia e a conformidade em seu ambiente específico.

Como os substratos cerâmicos SiC ajudam minha aplicação?

De ce această soluție funcționează pentru operațiunile dumneavoastră

Maior condutividade térmica e resistência mecânica reduzem os pontos quentes e prolongam a vida útil do módulo, especialmente em ciclos de trabalho pesados.

Conectați-vă cu specialiști pentru soluții personalizate

Quais considerações financeiras ou cambiais se aplicam?

- Estruturamos propostas com pagamentos faseados vinculados a marcos, oferecemos opções de indexação de preços para proteger o risco cambial e podemos trabalhar com EPCs e parceiros financeiros para o financiamento do projeto.

- Se sua usina visa maior tempo de atividade, custos de energia mais baixos e conformidade garantida, as soluções SiC oferecem um caminho robusto e à prova de futuro. A Sicarb Tech combina experiência em materiais avançados (R-SiC, SSiC, RBSiC, SiSiC), eletrônica de potência de alto desempenho e transferência de tecnologia turnkey para resolver os desafios industriais mais urgentes do Paquistão. Nosso histórico de mais de uma década e mais de 19 implantações bem-sucedidas ressaltam resultados mensuráveis: resposta mais rápida, maior eficiência e confiabilidade a longo prazo.

- Converse com nossos engenheiros de aplicação para uma avaliação personalizada, modelo de ROI e roteiro de conformidade para sua instalação, seja você um complexo têxtil em Faisalabad, uma usina de cimento em Khyber Pakhtunkhwa, uma usina siderúrgica em Karachi ou um local solar/eólico em Sindh.

- Transfè teknoloji ak etablisman faktori—soti nan posibilite pou komisyonin

- Localização: Cidade de Weifang, China (membro do Parque de Inovação da Academia Chinesa de Ciências)

- Autor: Equipe de Soluções Industriais da Sicarb Tech

Referências:

Email: [email protected] | Phone/WhatsApp: +86 133 6536 0038

Metadados do artigo

- Última atualização: 11/09/2025

- Próxima atualização programada: 15/12/2025

- IEEE Transactions on Power Electronics e artigos da IEEE Spectrum sobre dispositivos SiC (fontes gerais da indústria)

- Diretrizes padrão IEEE 519, IEC 61000-3-6, IEC 61850

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.