Equipamento de teste automatizado e de queima de dispositivo de carbeto de silício para qualificação de confiabilidade a 175-200°C

Compartilhar

Prezentare generală a produsului și relevanța pe piața din 2025

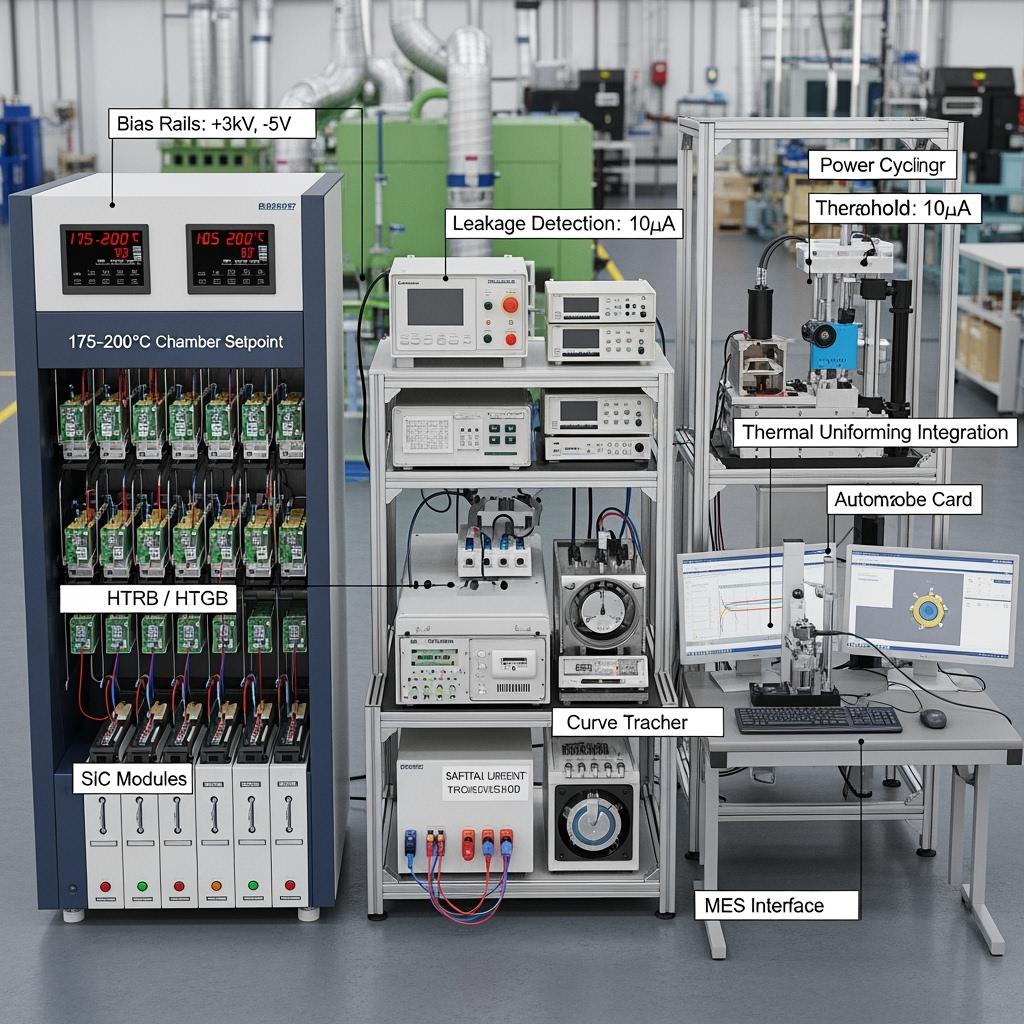

Il test di funzionamento e le apparecchiature di test automatizzate (ATE) per dispositivi in carburo di silicio (SiC) forniscono gli ambienti di stress ad alta temperatura e alta tensione necessari per lo screening dei guasti nella fase iniziale e per verificare la durata in condizioni difficili. Rispetto al silicio tradizionale, la maggiore rigidità dielettrica e le elevate temperature di giunzione del SiC richiedono forni specializzati, dispositivi di stress di potenza, unità di misurazione parametriche e automazione conforme alla sicurezza. Le piattaforme di burn-in/ATE di Sicarb Tech qualificano MOSFET SiC, diodi Schottky, moduli di potenza e stadi di potenza integrati a 175–200°C, simulando lo stress del mondo reale nei settori tessile, cementizio del Pakistan, açoe settori critici per i dati.

Perché è importante per il Pakistan nel 2025:

- Le strutture subiscono temperature ambiente fino a 45°C e frequenti cali/picchi di tensione; i dispositivi devono essere schermati per robustezza prima dell'implementazione.

- UPS, VFD, inverter FV e BESS richiedono un'affidabilità prevedibile per ridurre OPEX ed evitare interruzioni impreviste.

- La capacità di qualifica localizzata riduce i tempi di consegna e la dipendenza dalle importazioni, supportando implementazioni più rapide per la modernizzazione industriale e l'economia digitale.

- Gli obiettivi ESG e di efficienza energetica amplificano la necessità di piattaforme SiC a lunga durata e ad alta efficienza, comprovate attraverso rigorosi test di funzionamento e test di affidabilità automatizzati.

Sicarb Tech offre sistemi di burn-in chiavi in mano: HTRB, HTGB, power cycling, stress di commutazione dinamica e ATE parametrico automatizzato con registrazione e analisi dei dati. I sistemi sono adattabili al packaging basato su RBSiC/SSiC, garantendo percorsi termici realistici durante lo stress.

Specificații tehnice și caracteristici avansate

Funzionalità rappresentative (configurabili per classi di dispositivi e throughput):

- Test di funzionamento ad alta temperatura (HTRB/HTGB)

- Intervallo di temperatura: 25–200°C (uniformità ±1°C all'interno della zona della camera)

- HTRB: polarizzazione di scarico fino a 1,7 kV; monitoraggio delle perdite fino a nA; durata dello stress configurabile (8–168 ore)

- HTGB: polarizzazione del gate ±3

- Delta-leakage and failure criteria in real-time with auto-shutdown per slot

- Power cycling and dynamic stress

- ΔTj control: 40–100 K per cycle; up to 10^6 cycles; programmable dwell times

- Current pulses up to 600 A/module position; VDS up to 1.2–1.7 kV

- Switching stress: 10–100 kHz, configurable dv/dt; SOA-guarded profiles

- Parametric ATE

- SMU-based characterization: RDS(on) at multiple temperatures, Vth, body diode VF/Qrr, leakage vs. temperature

- Curve tracer up to 3 kV / 600 A (pulsed); Kelvin fixturing for precision

- Module-level tests: partial discharge (PD), isolation (hipot 3–6 kVrms), dynamic resistance, and thermal impedance (Zth)

- Packaging compatibility

- Fixtures for discrete TO-247/TO-263, half-bridge modules, full-bridge modules, and custom intelligent power blocks

- RBSiC/SSiC heat spreader fixtures to replicate production thermal paths

- Data, safety, and automation

- Traceability: barcode/RFID per device; per-slot data lake with time series

- Analytics: Weibull/Arrhenius models, early-life failure rate (ELFR), and drift analysis dashboards

- Safety: dual interlocks, HV discharge, e-stop, arc-detection, insulated enclosures (IEC 61010)

- Integration: MES/ERP connectors (OPC UA/REST), test recipe version control, audit trails

Compliance targets: IEC 60749 (semiconductor device reliability tests), JEDEC JESD22 series (e.g., A104 power cycling, A108 HTOL), IEC 60068 environmental tests, and plant safety aligned with PEC practices.

Vantaggi del burn-in/ATE per l'affidabilità industriale e OPEX

| Ensuring field reliability for Pakistan’s hot, dusty, and grid-volatile environments | SiC-focused burn-in and ATE (Sicarb Tech) | Generic semiconductor test setups |

|---|---|---|

| Temperature capability and uniformity | 175–200°C with ±1°C zone control | ≤150°C; wider variability |

| High-voltage bias and leakage sensing | Up to 1.7–3 kV; nA sensitivity | Lower voltage; limited precision |

| Power cycling realism | ΔTj up to 100 K with thermal path replicas | Basic cycling; poor thermal replication |

| Data analytics and traceability | Full device genealogy and Weibull modeling | Limited logs; manual reports |

| Safety and throughput | Industrial interlocks; multi-rack automation | Lab-scale; lower throughput |

Avantaje cheie și beneficii dovedite

- Early-life failure screening: HTRB/HTGB and HTOL protocols capture infant mortality before shipment, lowering field RMAs and downtime.

- Lifetime acceleration with data: Power cycling and switching stress map mission profiles to accurate lifetime predictions under 45°C ambient and dusty conditions.

- Faster time-to-market: Automated recipes and fixtures reduce engineering cycles; local testing shortens qualification lead times for Pakistani projects.

- Production-grade safety: HV interlocks and arc detection ensure operator safety and audit-ready processes.

- Actionable analytics: Parametric drift, leakage trends, and Zth changes trigger corrective actions in packaging, assembly, or supplier lots.

Citação de especialista:

“High-temperature operating life and power cycling remain the most reliable predictors of field performance for wide-bandgap devices—provided the thermal path realistically mirrors end-use conditions.” — IEEE Power Electronics Magazine, Reliability and Qualification of SiC Devices, 2024

Aplicații din lumea reală și povești de succes măsurabile

- Lahore data center UPS program:

- Implemented 200°C HTOL and power cycling for SiC inverter modules prior to rollout.

- Results: ELFR reduced by 60%; UPS room efficiency 97.3%; two potential field failures identified in burn-in via rising gate leakage trend.

- Faisalabad textile VFD line:

- Customized ΔTj=70 K cycling with RBSiC fixture; switching stress at 40 kHz representative of loom drives.

- Outcome: 18% fewer thermal trips in field, 25% longer service intervals; improved torque stability due to tighter RDS(on) distribution post-screen.

- Cement plant auxiliary drives, Punjab:

- HTRB at 1.3 kV and partial discharge screening for long-cable installations.

- Impact: EMI alarms decreased; transformer heating incidents reduced; predicted module lifetime +22–28% in mission-profile models.

【Solicitação de imagem: descrição técnica detalhada】 Three-panel infographic: 1) HTRB/HTGB oven with real-time leakage graphs; 2) Power cycling cold plate with IR thermography showing uniform ΔTj; 3) ATE console dashboard with Weibull plots, ELFR, and Zth curves; annotations for bias levels, temperature setpoints, and safety interlocks; photorealistic, 4K.

Considerații privind selecția și întreținerea

- Tesztprofil tervezés

- Align HTRB/HTGB voltages with device class (650/1200/1700 V) and add margin; select durations (24–168 h) per reliability target.

- Power cycling: choose ΔTj and cycle counts per mission profile (VFD vs. UPS vs. PV/BESS); verify thermal path equivalence with production hardware.

- Fixtures and thermal realism

- Use RBSiC/SSiC-backed fixtures to match thermal spreading; calibrate with IR and embedded sensors.

- Maintain TIM thickness and pressure consistent with field assemblies.

- Parametric guardbands

- Set acceptance criteria for RDS(on) drift, Vth shift, leakage growth, and PD inception; implement re-test-on-fail rules.

- Safety and calibration

- Annual calibration for SMUs, HV supplies, temperature sensors; weekly functional checks on interlocks and discharge circuits.

- ESD and HV PPE training per IEC 61010 and local regulations.

- Data governance

- Store raw traces and derived KPIs; link to lot and wafer IDs; implement change control for recipes and firmware.

Factori de succes în industrie și mărturii ale clienților

- Fatturi ta' suċċess:

- Early collaboration between design, packaging, and reliability engineering to define stress recipes

- Thermal correlation with end-use enclosures (airflow, dust filters, positive pressure)

- Continuous improvement loop from analytics back to supplier and assembly processes

- Local pilot lines to validate seasonal ambient effects (peak summer heat)

- Testimonial (Head of Maintenance, Karachi steel service center):

- “Burn-in identified marginal parts before commissioning. Our drives now exhibit consistent thermal behavior and fewer protection trips.”

Inovații viitoare și tendințe de piață

- Perspettiva 2025–2027:

- AI-assisted anomaly detection in leakage and dynamic resistance to flag precursors to failure

- Double-sided cooled module fixtures enabling realistic MV drive stress

- 200 mm SiC wafer traceability from crystal growth to field performance analytics

- Automated partial discharge mapping for long-cable applications in large mills and plants

Perspectiva da indústria:

“Scaling SiC adoption depends on closing the loop between accelerated testing and field analytics—data is the new reliability currency.” — IEA Technology Perspectives 2024, Power Electronics chapter

Întrebări frecvente și răspunsuri de specialitate

- How long should burn-in last for industrial deployments?

- Typical windows are 24–96 hours for production, 168 hours for critical infrastructure; we tailor based on ELFR targets and mission profiles.

- Do high-temperature tests risk damaging good parts?

- Tests are within SOA with controlled margins; acceptance criteria and soft ramping protect healthy devices while exposing weak ones.

- Can you test fully assembled power modules, not just discretes?

- Yes. We support module-level HTOL, isolation/hipot, PD testing, Zth measurement, and dynamic switching stress with realistic cooling.

- How are results integrated with our QA/MES?

- Via OPC UA/REST APIs. Each unit’s genealogy, parameters, and pass/fail logs are pushed to your MES for audit and traceability.

- What ROI can Pakistani plants expect from local qualification?

- Typical ROI in 12–24 months via reduced field failures, fewer site visits, faster commissioning, and improved energy performance stability.

De ce această soluție funcționează pentru operațiunile dumneavoastră

Sicarb Tech’s SiC burn-in and automated test platforms qualify devices at the temperatures and voltages they will see in Pakistan’s hot, dusty, and grid-volatile environments. By combining realistic thermal fixtures, rigorous safety, and analytics-rich ATE, we cut early failures, extend lifetime, and stabilize efficiency in VFDs, UPS, PV, and BESS—delivering lower OPEX and higher availability.

Conectați-vă cu specialiști pentru soluții personalizate

Strengthen your reliability pipeline with Sicarb Tech:

- 10+ snin ta' kompetenza fil-manifattura SiC bl-appoġġ tal-Akkademja Ċiniża tax-Xjenzi

- Custom development across R-SiC, SSiC, RBSiC, and SiSiC, plus dedicated burn-in fixtures for complex packages

- Technology transfer and factory establishment services to localize qualification capacity in Pakistan

- Turnkey delivery from material processing to tested, qualified products with compliance documentation

- Proven track record with 19+ enterprises; rapid pilot setups and recipe optimization

Book a free consultation to define your 175–200°C qualification plan, sample sizes, and ROI model.

- E-mail: [email protected]

- Telefone/WhatsApp: +86 133 6536 0038

Reserve Q4 2025 burn-in capacity now to secure priority queues for peak commissioning cycles.

Metadados do artigo

- Última atualização: 11/09/2025

- Następny planowany przegląd: 2

- Author: Sicarb Tech Reliability Engineering Team

- Contact: [email protected] | +86 133 6536 0038

- Standards focus: JEDEC JESD22 (A104, A108), IEC 60749, IEC 60068, IEC 61010; aligned with PEC practices and NTDC Grid Code quality criteria

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.