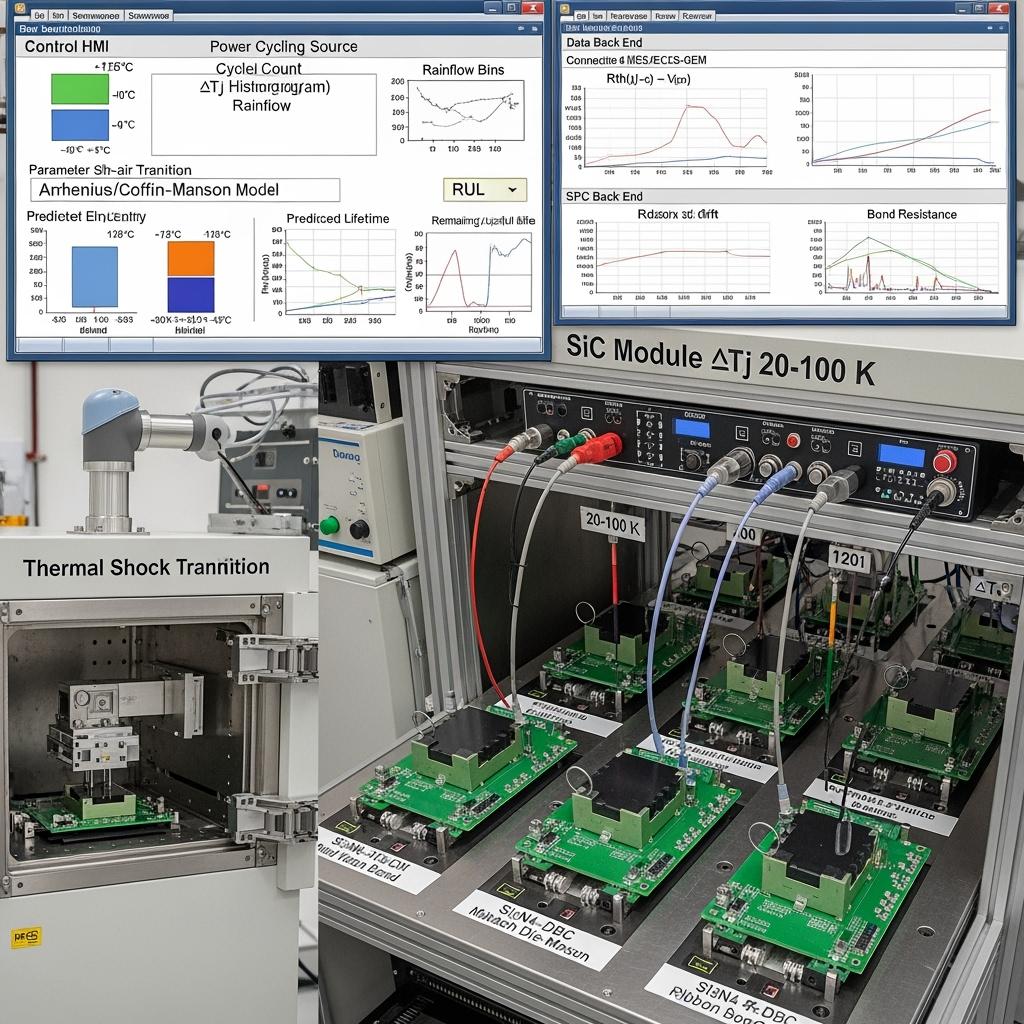

Plataformas de teste de ciclo de energia e de vida útil de choque térmico para módulos de SiC com controle de ΔTj e modelagem Arrhenius/Coffin-Manson

Compartilhar

Prezentare generală a produsului și relevanța pe piața din 2025

A teljesítményciklusos és termikus sokk élettartam-vizsgáló platformok elengedhetetlenek a szilícium-karbid (SiC) modulok minősítéséhez és a kockázatok csökkentéséhez, amelyeket az akkumulátoros energiatároló rendszer (BESS) PCS-ben és MV-inverterekben használnak. Pakisztán textil-, cement-, açoés feltörekvő ipari szektoraiban – ahol a környezeti hőmérséklet eléri a 45–50°C-ot, és a por korlátozza a légáramlást – a csomagolás megbízhatósága a legfontosabb. Ezek a platformok szabályozott csatlakozási hőmérséklet-ingadozásokat (ΔTj) és gyors termikus átmeneteket alkalmaznak a valós küldetéses profilok reprodukálására, majd a degradációt a meghibásodás fizikai modelljeivel (Arrhenius a termikusan aktivált mechanizmusokhoz és Coffin–Manson a fáradáshoz) elemzik.

Miért fontosak 2025-ben:

- A nagyfrekvenciás SiC kapcsolás (50–200 kHz) és a kompakt termikus stackek (Si3N4/AlN + Ag-sinter) növelik az összeköttetéseken, a chip rögzítésén és a kötőhuzalokon/szalagokon a ciklikus termikus feszültségeket.

- Az MV összeköttetési követelmények (FRT, reaktív teljesítmény támogatás) olyan átalakítókat igényelnek, amelyek megbízhatóak maradnak a hálózati események során, amelyek átmeneti termikus terheléseket rónak ki.

- A lokalizációs prioritások ösztönzik az országon belüli minősítési képességet a fejlesztési ciklusok lerövidítéséhez, a pályázatok támogatásához és az értékesítés utáni kötelezettségvállalások megerősítéséhez.

A Sicarb Tech automatizált platformjai pontos ΔTj-szabályozást, gyors termikus sokk szekvenciákat, in-situ elektromos/termikus monitorozást és integrált élettartam-modellezést biztosítanak – kvantitatív bizalmat nyújtva a MTBF-célokhoz, amelyek közel 200 000 óra a pakisztáni zord ipari környezetben.

Specificații tehnice și caracteristici avansate

- Teljesítményciklusos képességek

- ΔTj szabályozási tartomány: 20–100 K (programozható) a terhelési áram vagy az aljzathűtés révén; tartózkodási és rámpázási alakítás a küldetéses profilokhoz

- Elektromos feszültség: akár több kiloamperes impulzusok a nagy modulokhoz; gyors emelkedési idők biztonságos di/dt-vel; konfigurálható kitöltési tényezők

- Mérés: in-situ Vce(on)/Rdson, termikus impedancia Zth extrakció, kötési ellenállás (Kelvin) és szivárgás monitorozás

- Termikus sokk és környezet

- Levegő-levegő vagy folyadék-segített kamrák: -40°C és +175°C között, akár 30–50 K/perc rámpázási sebességgel

- Páratartalom/THB opciók: 85°C/85% relatív páratartalom profilok; sóköd a korróziós értékelésekhez (opcionális)

- Érzékelés és analitika

- Csatlakozási hőmérséklet becslése: Vce,on/TSEP kalibrálás; beágyazott NTC/RTD naplózás; IR termográfia igazítás

- Degradációs metrikák: Rth növekedési küszöb, Vce(on) sodródás, huzal/szalag kötési ellenállás növekedése, szinterező rögzítés nyírási korreláció

- Modellezés és jelentéskészítés

- Arrhenius gyorsulási modellezés a hőmérsékletfüggő mechanizmusokhoz (aktiválási energia bemenet)

- Coffin–Manson fáradtsági modellezés esőfolyamat-számlálással a ΔTj ciklusokon; Miner-szabály károsodási összegzés

- Automatizált jelentések: élettartam-becslések terepi körülmények között, konfidencia intervallumok és ajánlott leértékelési stratégiák

- Automatizálás és nyomon követhetőség

- Receptvezérlés paraméter verziókezeléssel; vonalkód/QR tételkövetés

- Adat API-k digitális ikrekhez és megbízhatósági műszerfalakhoz; exportálás CSV/JSON/PDF formátumban

- Segurança e conformidade

- Reteszelések nagy áramhoz, hőmérséklethez és ajtóhozzáféréshez; ESD védelem; ívhibák érzékelése a készülék meghibásodásához

Összehasonlítás: Fejlett ΔTj-szabályozott teljesítményciklusos tesztelés a Basic Burn-In/Soak teszteléssel szemben

| Criteriu | ΔTj-szabályozott teljesítményciklusos + termikus sokk platform | Alapvető beégetési/áztatási tesztelés |

|---|---|---|

| Meghibásodási mechanizmus lefedettsége | A szinter, a kötések és az aljzat fáradása; termikusan aktivált elhasználódás | Korai élettartamú csecsemőhalandóság; korlátozott fáradtsági betekintés |

| Korreláció a terepi feladathoz | Magas a küldetéses profil ΔTj-vel és esőfolyamattal | Alacsony; csak egyenletes állapotú előfeszítés |

| Modelado de vivdaŭro | Arrhenius + Coffin–Manson károsodási összegzéssel | Minimális; nincs fizikaalapú előrejelzés |

| Paraméter monitorozás | In-situ Rth, Vce(on), Rdson, szivárgás, kötési ellenállás | Korlátozott; jellemzően csak átment/nem ment át |

| Döntés hatása | Lehetővé teszi a tervezés/leértékelés optimalizálását és a garancia meghatározását | Csak a durva hibákat szűri |

Vantaggi chiave e benefici comprovati con citazione di esperti

- Prediktív megbízhatóság: A fizikaalapú modellek a gyorsított teszteredményeket pakisztáni specifikus küldetéses profilok szerinti terepi élettartammá alakítják.

- Gyorsabb fejlesztés és tanúsítás: A helyszíni minősítés lerövidíti az iterációs hurkokat, támogatja a közüzemi dokumentációt és csökkenti a pályázatok kockázatát.

- Alacsonyabb életciklus költség: A gyenge stackek (pl. forrasztás vs. Ag-szinter, AlN vs. Si3N4) korai felismerése csökkenti a terepi meghibásodásokat, a teherautókat és a garanciális kitettséget.

Perspectiva do especialista:

“Thermal cycling with accurate ΔTj control, coupled with Coffin–Manson and Arrhenius modeling, is fundamental to predicting lifetime in wide bandgap power modules operated at high temperatures and switching speeds.” — IEEE Power Electronics Magazine, module reliability methodologies (https://ieeexplore.ieee.org)

Aplicații din lumea reală și povești de succes măsurabile

- Punjab BESS PCS (2 MW/4 MWh): A ΔTj = 60 K teljesítményciklusos tesztelés a kötőszalag forró pontjait tárta fel; az újratervezés a szélesebb szalagokra és az Ag-szinterezésre javította a becsült élettartamot ~2,1×-szeresére. A terepi adatok kevesebb termikus riasztást és 0,6–0,8%-kal jobb hatásfokot igazoltak az alacsonyabb Rth miatt.

- Sindh textil hajtások: A termikus sokk és a páratartalom tesztelés korróziós kockázatot azonosított a terminálokon; a konform bevonatok és a tömítésfrissítések több mint 30%-kal csökkentették a meghibásodási incidenseket a monszun szezonban.

- MV inverter Dél-Pakisztánban: A ΔTj ciklussal végzett Si3N4-DBC vs. AlN összehasonlítás 1,5–1,8× fáradtsági élettartam-javulást mutatott a Si3N4-gyel a változó terheléses profilok mellett; a közüzemi elfogadást a leértékelési változások nélkül érték el.

Considerații privind selecția și întreținerea

- Tesztprofil tervezés

- Tükrözze a küldetéses profilokat: tartalmazzon csúcsborotválási ciklusokat, FRT eseményeket és magas környezeti leértékeléseket. Használjon esőfolyamat-számlálást a mért ΔTj-n.

- A minta előkészítése

- Műszeres modulok Kelvin csapokkal és NTC-kkel; biztosítsa a síkságot és az egyenletes TIM-et az ismételhetőség érdekében.

- Meghibásodási kritériumok és végpontok

- Határozza meg az Rth növekedési küszöbértékeit (pl. +10–20%), a Vce(on)/Rdson sodródást és a kötési ellenállás növekedését, mint a leállítási pontokat.

- Adat hűség

- Kalibrálja a Vce,on-to-Tj leképezést; érvényesítse az IR emissziót; végezzen időszakos érzékelő kalibrálást.

- Biztonság és EHS

- Implementáljon ívhiba reteszeléseket, termikus runaway érzékelést és árnyékolt tesztkamrákat; tartson naplót az auditokhoz.

Factori de succes în industrie și mărturii ale clienților

- A csomagolási, termikus és vezérlőcsoportok közötti funkciók közötti összehangolás biztosítja, hogy az élettartam-előrejelzések a valós leértékelési és vezérlési stratégiákat tájékoztassák.

- A terepről érkező folyamatos telemetria frissíti a digitális ikreket és finomítja az élettartam-becsléseket.

Feedback de la clienți:

„A ΔTj platform feltárta a valós gyenge láncszemünket – a kötési fáradást a süllyedési események során. Az újratervezés után stabil működést értünk el a nyári csúcsidőszakban.” – Megbízhatósági mened

Inovații viitoare și tendințe de piață

- تقدير درجة حرارة الوصلة في الوقت الفعلي عبر القياس عن بعد لمحرك البوابة والنماذج المستنيرة بالفيزياء

- نماذج تراكم الضرر بمساعدة الذكاء الاصطناعي التي تدمج بيانات المختبر والميدان لتقديرات RUL المتداولة

- الجمع بين الدوران الميكانيكي والكهربائي لمحاكاة أعطال الشبكة مع اندفاعات التيار

- التوطين: إنشاء مختبرات موثوقية في باكستان لدعم مصنعي المعدات الأصلية والمرافق من خلال الشهادات السريعة

Întrebări frecvente și răspunsuri de specialitate

- ما هو ΔTj الذي يجب أن نختبره لظروف باكستان؟

تستخدم ملفات التعريف بشكل شائع 40–80 كلفن لتغطية الدوران العدواني؛ يعتمد ΔTj الدقيق على استراتيجية التبريد وتردد التبديل والتخفيض المحيط. - كم عدد الدورات التي تكفي؟

قم بالتشغيل حتى الفشل أو نقاط النهاية المحددة مسبقًا. استخدم ΔTj الميداني الذي تم حسابه بالأمطار لتحويل دورات المختبر إلى سنوات خدمة عبر Coffin–Manson مع قاعدة Miner. - هل يمكن الجمع بين Arrhenius وCoffin–Manson؟

نعم. قم بتطبيق Arrhenius للآليات المنشطة بدرجة الحرارة (على سبيل المثال، الانتشار، التآكل) وCoffin–Manson للإجهاد. تعكس النماذج المجمعة بشكل أفضل الضغوط المختلطة. - كيف نضمن دقة Tj؟

قم بمعايرة Vce(on)/Rdson مقابل درجة الحرارة لكل جهاز؛ تحقق باستخدام التصوير الحراري بالأشعة تحت الحمراء وأجهزة الاستشعار المضمنة؛ أعد الفحص بعد تغييرات التصميم الكبيرة. - هل يفوز Ag-sinter دائمًا على اللحام؟

بالنسبة لـ ΔTj العالي، يُظهر Ag-sinter عادةً مقاومة إجهاد فائقة وانحراف Rth أقل؛ تحقق من مجموعتك وملف تعريف مهمتك.

De ce această soluție funcționează pentru operațiunile dumneavoastră

تتطلب البيئات الحارة والمتربة والمتقلبة في باكستان أكثر من مواصفات المكونات - فهي تتطلب عمرًا مثبتًا في ظل ΔTj والصدمات الحرارية الواقعية. تعمل منصات دورة الطاقة والصدمات الحرارية المتقدمة على تحديد الإجهاد، وتوجيه اختيارات المواد والتغليف (Si3N4/AlN، Ag-sinter/شرائط)، وإنتاج نماذج عمر قابلة للدفاع عنها. والنتيجة هي زيادة وقت التشغيل، ومفاجآت أقل في التشغيل، وكفاءة PCS مستدامة ≥98% بتصميمات مدمجة وموثوقة.

Conectați-vă cu specialiști pentru soluții personalizate

قم بتقوية برنامج الموثوقية الخاص بك باستخدام Sicarb Tech:

- 10+ سنوات من هندسة تصنيع وموثوقية SiC

- مد

- Zhvillim i personalizuar në R-SiC, SSiC, RBSiC, SiSiC; kualifikimi i pajisjes, modulit dhe grumbullit termik

- Transferimi i teknologjisë dhe shërbimet e krijimit të fabrikave për të ndërtuar laboratorë testimi lokalë dhe linja kualifikimi në Pakistan

- Zgjidhje të gatshme nga materialet dhe pajisjet deri te testimet e besueshmërisë, binjakët dixhitalë dhe dokumentacioni i pajtueshmërisë

- Sukses i provuar me 19+ ndërmarrje që përmirësojnë MTBF, efikasitetin dhe kohën e daljes në treg

Kërkoni një konsultim falas për të përcaktuar profilet ΔTj, planet e testimit dhe modelet e jetëgjatësisë të përshtatura për kushtet e misionit të Pakistanit:

- E-mail: [email protected]

- Telefone/WhatsApp: +86 133 6536 0038

Siguroni kapacitetin e laboratorit për 2025–2026 dhe vendet e transferimit të proceseve për të ulur rreziqet e vendosjeve dhe për të fituar tenderë kritikë në tregun e ruajtjes së energjisë në Pakistan.

Metadados do artigo

Ultima actualizare: 2025-09-10

Următoarea actualizare programată: 2026-01-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.