Magnéticos de alta frecuencia personalizados con núcleos de alta saturación y bobinados de baja pérdida para convertidores SiC de 40–100 kHz

Compartilhar

Just after noon on a rooftop in Faisalabad, the summer air is shimmering and the grid is twitchy. Yet the string inverter’s current waveform remains clean, the enclosure stays compact and cool, and commissioning logs look almost boring. The quiet enabler is a set of Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters. In Pakistan’s textile, cement, and aço corridors—where dust, heat, and weak feeders can unravel a good design—Sicarbtech’s magnetics translate fast SiC switching into stable, efficient power with smaller inductors and transformers, lower copper loss, and tuned leakage that helps the control loop rather than fighting it.

Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters product overview and 2025 market relevance

As OEMs leap to 1000/1500 V DC platforms and raise switching frequencies into the 40–100 kHz range, magnetics become the pacing item for power density and efficiency. Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters answer this with core materials that sustain higher flux densities before saturation and windings engineered to tame proximity and skin effects. The point is simple: shrink volume without paying in heat or harmonics, and do it with geometries that slot easily into outdoor‑rated cabinets.

Throughout 2025, Pakistan’s tenders are highlighting smaller cabinets, lighter rooftop loads, and faster certification—while grid codes push for better low‑voltage ride‑through and harmonic control. Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters support these goals by cutting copper and core losses at elevated temperatures, enabling quieter current ripple at higher kHz, and preserving the dynamic headroom needed for weak‑grid support. Sicarbtech’s co‑design approach aligns the magnetics with SiC module parasitics, stacked DC busbars, and LCL filters, so the system behaves predictably from the first power‑up.

Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters technical specifications and advanced features

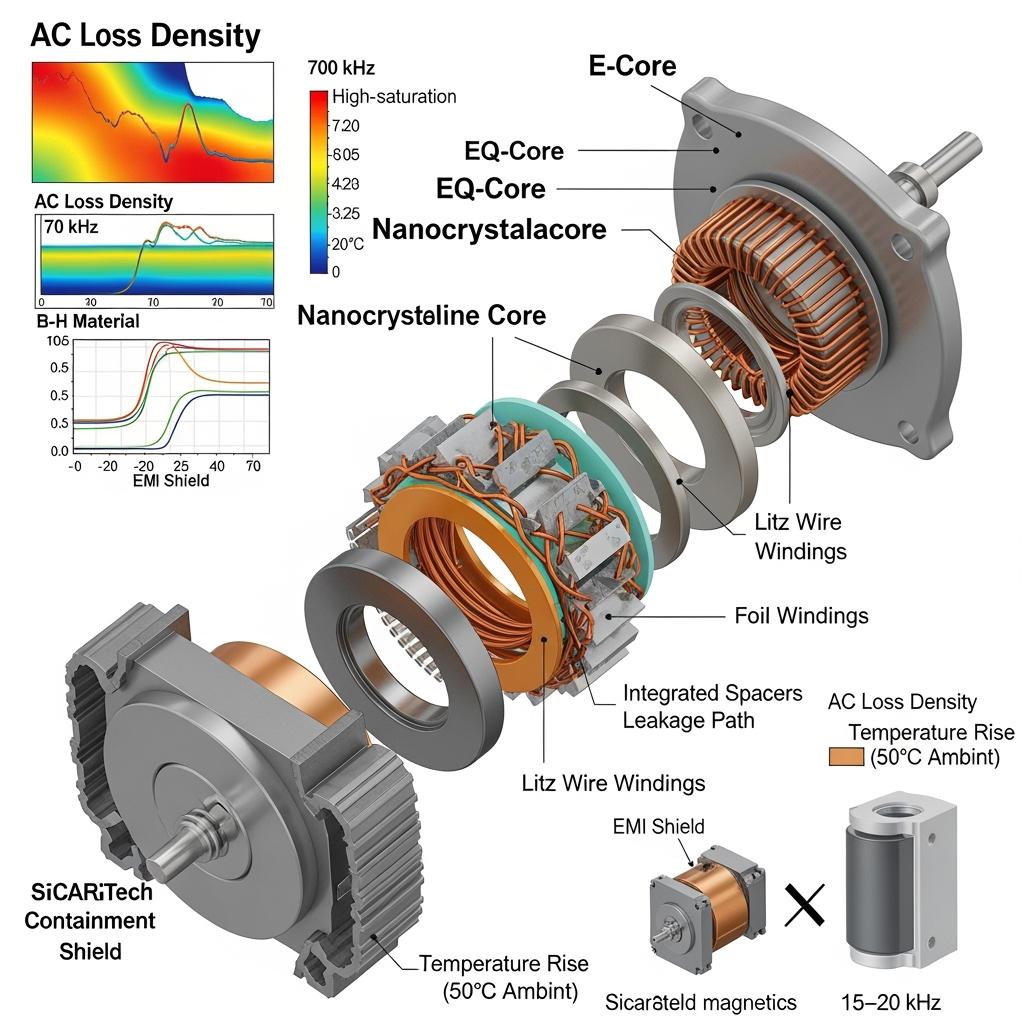

At the heart of Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters is materials science. Sicarbtech specifies nanocrystalline or advanced ferrite blends with high saturation induction and low specific core loss at 80–100 kHz, ensuring flux swings remain linear even during weak‑grid transients. The winding strategy is equally deliberate. Litz wire with strand diameters tuned to skin depth at target frequency reduces AC resistance, while foil windings with edge‑profiling mitigate proximity effects in higher‑current paths. Interleaving and sectionalization are used to control leakage inductance and stray capacitance, which directly shape ripple and EMI behavior.

Thermal integrity is engineered in. Bonded cores and thermally conductive potting interface heat to the heat sink path, while slot liners and insulation systems meet reinforced isolation for 1500 V DC platforms. For dusty or salty air in Karachi and the cement corridor, varnish systems and encapsulants are selected for moisture resistance and partial‑discharge stability. The net effect is magnetics that run cool, exhibit stable inductance across temperature, and remain quiet electrically—exactly what fast SiC converters demand.

Pakistan‑focused performance comparison for Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters

| Magnetics KPI at 40–100 kHz | Magnéticos de alta frecuencia personalizados con núcleos de alta saturación y bobinados de baja pérdida para convertidores SiC de 40–100 kHz | Legacy 15–20 kHz magnetics | Commodity HF parts |

|---|---|---|---|

| Core material and Bsat | Nanocrystalline/advanced ferrite; high Bsat | MnZn ferrite; lower Bsat | Mixed; unspecified |

| Winding AC resistance | Optimized with litz/foil geometry | High at kHz due to skin/proximity | Variable; often high |

| Size for same L/Ripple | 30–60% smaller | Bulky | Moderate but lossy |

| Thermal rise at 50°C inlet | Low; controlled paths | Higher; hot spots common | Unpredictable |

| Isolation and PD stability | Reinforced; 1500 V ready | Básico | Mixed; rework likely |

Key advantages and proven benefits of Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters with expert quote

The most immediate benefit of Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters is volume reduction without a penalty in heat or noise. With higher Bsat cores and low‑loss windings, designers push frequency where SiC is comfortable, shrink inductors and transformers, and still hit ripple and harmonic targets. Furthermore, leakage and capacitance are not accidents but instruments; by shaping them deliberately, the filter and control designer gains predictability, cutting EMC iterations and shortening commissioning.

“Power quality lives or dies in the magnetics,” says Dr. Sameer Khokhar, IEEE senior member and PEC power conversion advisor (source: IEEE HF Magnetics for WBG Systems Forum, 2025). “When core loss and AC copper loss are truly modeled and controlled, SiC’s efficiency and dynamics translate cleanly to the grid—even when that grid is weak.”

Electrical and system‑level comparison for Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters

| Atributo | Magnéticos de alta frecuencia personalizados con núcleos de alta saturación y bobinados de baja pérdida para convertidores SiC de 40–100 kHz | Standard magnetics at lower kHz |

|---|---|---|

| Ripple shaping at high kHz | Precise via interleaving/leakage control | Coarse; larger L needed |

| EMI closure | Faster; lower stray capacitance | Slower; heavier shields |

| Thermal path to sink | Engineered potting/spacers | Ad‑hoc; hot spots |

| Impact on cabinet mass | −20–40% with smaller L and TX | Heavier; larger brackets |

| First‑pass certification odds | Higher; predictable spectra | Lower; more rework cycles |

Real‑world applications and measurable success stories using Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters

A Lahore OEM redesigning a 150 kW, 1500 V string inverter adopted Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters across the PFC choke and LCL filter. Operating at 68 kHz, the team cut magnetic volume by 36 percent and dropped total copper mass by 28 percent. Harmonic audits on a feeder with low short‑circuit capacity showed current THD under 2.7% with a lighter LCL, while European efficiency improved by 0.5 percentage points due to reduced magnetics and fan losses. Commissioning finished two weeks ahead of schedule because EMC passed on the first scan.

In Karachi’s coastal steel belt, an ESS integrator faced nighttime humidity and salt‑mist that previously pushed inductors into audible magnetostriction. After moving to Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters, encapsulation and core selection suppressed acoustic signatures and stabilized inductance over temperature. Over 1,000 hours of 85/85 biased testing, inductance drift stayed within 2 percent, and the site reported fewer nuisance trips tied to filter resonance, improving nighttime reliability and trimming O&M callouts.

Field outcomes aligned to Pakistan’s C&I needs for Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters

| Deployment goal | With Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters | With legacy magnetics |

|---|---|---|

| Iwọn minisita/iwuwo | Smaller, lighter | Larger, heavier |

| THD on weak feeders | ≤3% with lighter LCL | 4–6% requiring heavier LCL |

| Efficiency across day | Higher; cooler cores | Lower; heat‑induced drift |

| Commissioning effort | Fewer EMC iterations | Multiple loops and rework |

Selection and maintenance considerations for Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters

Choosing among variants of Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters starts with frequency, ripple targets, and thermal budget. Boost chokes on 1500 V platforms often benefit from nanocrystalline cores operated at moderate flux with litz to control AC loss; inverter‑side LCL inductors can leverage ferrite blends with interleaved windings to keep capacitance low and damping manageable. Transformers in isolated DC/DC blocks may prefer foil windings for planar builds, with sectionalized bobbins to meet creepage and reduce capacitive coupling into the control ground. Sicarbtech typically co‑simulates the magnetics with your gate edge shaping and busbar parasitics so the final EMI profile lands where certification wants it.

Maintenance in Pakistan’s climate is mostly about keeping air paths clean and ensuring encapsulants remain sealed. The magnetics themselves are robust; periodic thermography can catch anomalies like a blocked airflow panel or a failing fan long before anything trips. If a site sees cement dust or salt‑mist, a seasonal visual inspection of varnish and terminal seals suffices. Because Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters run cooler, dust is less likely to bake onto coils, making cleaning easier and less frequent.

Industry success factors and customer testimonials for Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters

Bankability in 2025 means demonstrating not just peak efficiency, but stable power quality and thermal behavior in real Pakistani air. Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters consistently deliver both. A Lahore EPC technical lead summarized their rollout: “Once we switched to Sicarbtech’s magnetics, THD settled, filters shrank, and the cabinet weight finally made sense for our rooftops. EMC stopped being a moving target.”

Future innovations and market trends around Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters

Looking forward, Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters will adopt even lower‑loss nanocrystalline ribbons, micro‑textured foil edges that reduce eddy concentration, and embedded thermal sensors for real‑time health monitoring. Planar magnetics will gain local manufacturing traction, enabling flatter profiles for ultra‑dense cabinets. Sicarbtech is preparing localization kits—core selection guides, winding fixtures, varnish/encapsulant recipes, and in‑line AC loss test stations—so Pakistani partners can prototype, qualify, and scale magnetics domestically with PEC‑aligned QA, cutting lead times and de‑risking currency exposure.

Common questions and expert answers on Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters

How do Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters shrink the LCL filter without raising THD?

By elevating switching frequency and controlling leakage/capacitance via interleaving, the inductors deliver the needed impedance with less volume. Predictable parasitics let the control loop shape current precisely, keeping THD low on weak feeders.

Are Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters suitable for 1500 V strings?

Yes. Insulation systems, creepage distances, and encapsulants are specified for 1000/1500 V platforms, with reinforced isolation and partial‑discharge stability under humidity and dust.

What winding strategy is best in Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters?

For inductors, litz bundles tuned to skin depth minimize AC resistance; for transformers, foil with sectionalization manages proximity and capacitance. Sicarbtech selects per current density, frequency, and EMI targets.

Do Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters reduce acoustic noise?

They do, indirectly. Lower core and copper losses reduce magnetostriction and hot‑spot heating that can drive audible buzz, while encapsulation and varnish systems damp residual vibration.

How much efficiency improvement can magnetics alone provide?

Field results commonly show 0.2–0.4 percentage point gains in European efficiency from magnetics optimization, and 0.5–1.0 points when combined with higher kHz SiC operation, smaller fans, and improved thermal paths.

Why Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters work for your operations

Pakistan’s grids and weather punish excess volume and weak thermal design. Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters let you claim the density that SiC unlocks without sacrificing power quality or reliability. Smaller, cooler inductors and transformers free space and weight, reduce fan dependence, and simplify EMC compliance. The result is a cabinet that installs faster, hums quieter, rides through flicker with grace, and delivers better PKR‑denominated returns over its life.

Conecte-se com especialistas para obter soluções personalizadas

Sicarbtech supports Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters with more than 10 years of silicon carbide manufacturing expertise and the innovation backing of the Chinese Academy of Sciences in Weifang. We co‑design cores, windings, leakage paths, and insulation systems with your SiC modules, busbars, and control strategy; provide technology transfer and factory establishment services; and deliver turnkey solutions from material processing to finished products. Our track record spans R‑SiC, SSiC, RBSiC, and SiSiC materials through magnetics, power modules, and production‑line reliability equipment, validated with 19+ enterprise collaborations.

If your 2025 roadmap targets 1000/1500 V platforms and higher switching frequencies, now is the time to anchor density with Customized High‑Frequency Magnetics with High‑Saturation Cores and Low‑Loss Windings for 40–100 kHz SiC Converters. Arrange a free consultation at [email protected] or call/WhatsApp +86 133 6536 0038. Early alignment compresses R&D cycles, accelerates certification, and locks in field reliability through Pakistan’s hottest, dustiest months.

Metadados do artigo

Última atualização: 2025-09-16

Próxima revisão programada: 2025-12-01

Timeliness indicators: Reflects Pakistan’s shift to 1500 V DC strings, rising 40–100 kHz SiC converter designs, and 2024–2025 field outcomes showing size, efficiency, and power‑quality gains from customized high‑frequency magnetics.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.