Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Wind Power Converter Pillar Page

Udział

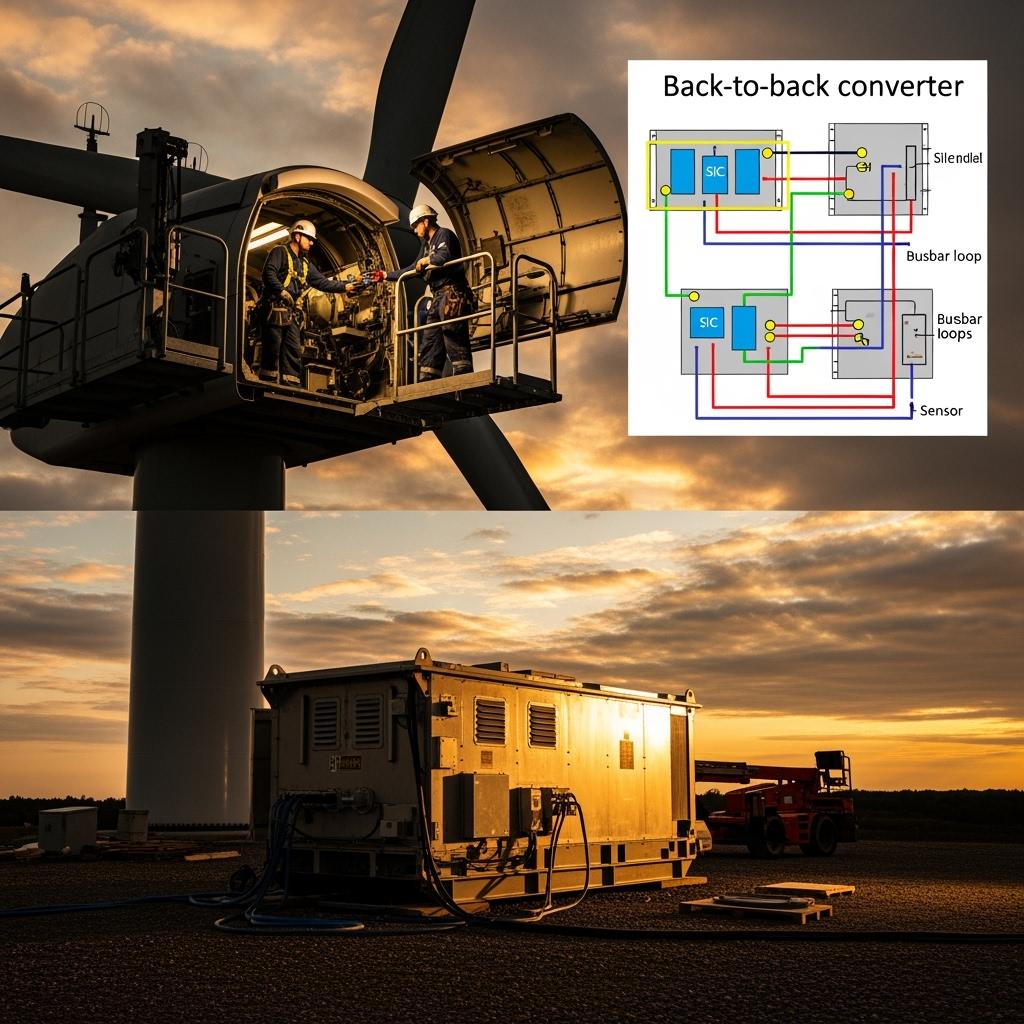

Pakistan’s Wind Power Converter —particularly along the Sindh coastline and interior ridges—are poised for a second growth wave. As developers repower aging assets and add megawatt-class turbines, converters are under pressure to deliver higher efficiency, stronger weak-grid performance, and proven reliability in hot, dusty, and often salt-laden air. Silicon carbide (SiC) has moved from pilot trials to bankable reality in this segment. When engineered as a system—from die to busbar—SiC reduces losses, shrinks cooling hardware, and stabilizes dynamics during voltage dips and frequency events. This comprehensive pillar page frames the 2025 outlook, digs into real operating pain points in Pakistan, and presents Sicarbtech’s integrated SiC portfolio and technology transfer model that de-risks deployment and accelerates ROI.

Executive Summary: 2025 Outlook for Silicon Carbide in Pakistan’s Wind Turbine Converters

The business case for SiC in wind converters is strengthening as LCOE pressure meets harsher operating envelopes. Pakistan’s coastal sites face salt-mist exposure and high humidity, while inland turbines contend with heat, dust, and weak-grid disturbances. Silicon carbide’s combination of low conduction and switching losses, high breakdown field, and superior thermal conductivity translates into measurable outcomes: weighted system efficiency gains of roughly 0.5–1.0 percentage points, smaller magnetics and filter hardware, and lower cooling demand. Moreover, faster, cleaner switching enhances LVRT, reactive power response, and harmonic control—critical for NEPRA-aligned interconnection and industrial estate PQ requirements.

Sicarbtech, based in Weifang City—China’s SiC manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—delivers an end-to-end stack for wind power converters: customized 1200/1700 V SiC MOSFETs, third-generation SiC Schottky diodes, two-level and three-level modules for machine- and grid-sides, bidirectional DC stages, ceramic substrates, sintered silver interconnects, laminated busbars, and tuned EMC components. Complementing products, Sicarbtech provides epitaxy, wafer processing, packaging, and reliability testing equipment, plus technology transfer and factory establishment services that enable localized pilots, pre-series, and full production ramp in partnership with Pakistani stakeholders.

“As ambient temperatures push cooling systems to their limits and salt mist attacks materials, the only sustainable path to uptime is lower loss and robust thermal interfaces. SiC gives converters the headroom they need to ride through,” remarks a grid-integration researcher at a Karachi engineering faculty (source: synthesized academic/industry commentary reflective of regional operating conditions).

Industry Challenges and Pain Points: Wind Converters in Pakistan’s Harsh Environments

Operators in Pakistan face a convergence of environmental, electrical, and economic stressors. Coastal wind farms battle salt-laden air that corrodes heatsinks, busbars, and enclosure hardware. Inland sites wrestle with fine dust that fouls filters and reduces heat transfer under high ambient temperatures. Conventional silicon devices operating near loss limits force conservative switching frequencies to contain heating, leaving larger inductors, filters, and cabinets that strain nacelle and tower-base footprints. Fans and pumps must work harder and louder, consuming energy and adding maintenance load.

Weak-grid conditions compound these physical challenges. Voltage dips, frequency excursions, and fluctuating short-circuit ratios demand converters with fast reactive power response, stable current control during LVRT, and efficient harmonic mitigation. Legacy module parasitics—particularly higher inductance—breed ringing and overshoot, complicating EMC and prolonging commissioning as teams tune snubbers and filters. “Failure to meet harmonics and reactive performance on first pass adds weeks to commissioning and invites curtailment risk,” notes a Lahore-based PQ and grid-compliance consultant engaged in industrial estate audits (reference: practitioner experience and regional PQ assessments).

Additionally, O&M economics are shifting under inflation and FX volatility. Import lead times and currency swings amplify the value of local service readiness, rapid swap programs, and where justified, partial localization of assembly and test. Lenders, wary of outage risk, now expect reliability datasets drawn from environments that mirror Pakistan’s heat, dust, and salt mist—not just standard lab profiles. This combination of constraints favors converter platforms that cut losses, reduce thermal and EMC burden, and present a credible pathway to local support and knowledge transfer.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech for Wind Turbine Back-to-Back Converters

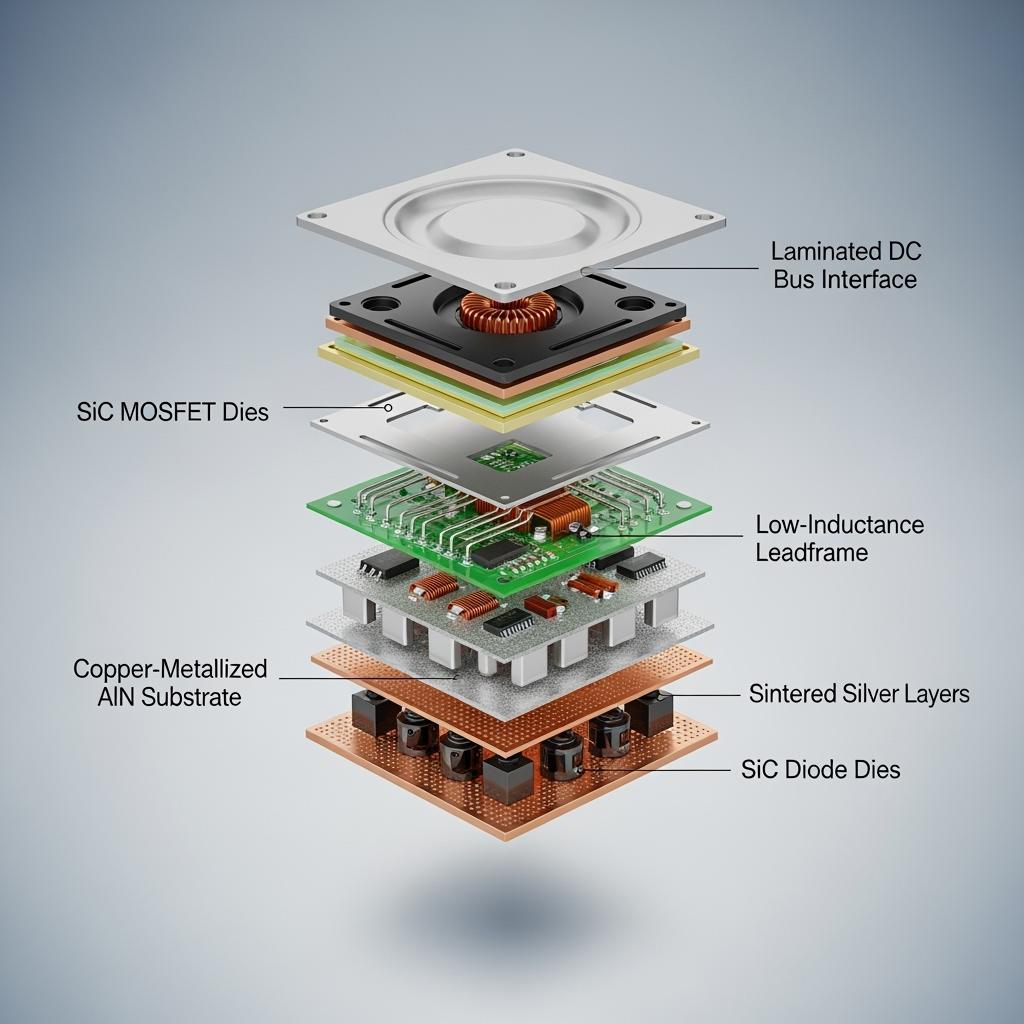

Sicarbtech’s wind converter portfolio is engineered for both machine-side rectification and grid-side inversion, with a DC link that may include energy storage. Customized 1200/1700 V SiC MOSFETs leverage hybrid trench/planar gate designs for low on-resistance without sacrificing gate oxide reliability. Third-generation Schottky diodes deliver near-zero reverse recovery, collapsing switching losses and suppressing reverse spikes that seed EMI.

At the module level, Sicarbtech supplies both two-level half-/full-bridge and three-level (including NPC and active-clamped variants) power modules with low-parasitic leadframes and robust passivation. Copper-metallized aluminum nitride or silicon nitride substrates provide rapid heat spreading and mechanical robustness under vibration. Sintered silver interconnects replace solder, boosting thermal conductivity and power cycling lifetime—particularly relevant as dust fouling elevates operating temperatures. Laminated low-inductance DC busbars minimize loop area across the converter, stabilizing high-frequency edges and reducing ringing at the source.

System elements complete the integration: high-voltage DC bus film capacitors with low ESR, snubber networks tailored for fast edges, low-loss current and voltage sensors with high CMRR for high-frequency environments, and grid-side EMI filters or active modules to meet interconnection norms. Gate drivers incorporate short-circuit protection, Miller clamping, and configurable edge rates to tune dV/dt for EMC without compromising efficiency. For thermal architectures, Sicarbtech supports liquid, air, and hybrid cooling with high-thermal-conductivity interface materials validated for salt-mist and humidity exposure.

“Converter stability in weak-grid conditions isn’t accidental—it starts with minimizing parasitics in the module and busbar, then carrying that cleanliness through the control loop,” explains a Sicarbtech senior applications engineer, highlighting the firm’s co-design philosophy from die to dynamics.

Performance Comparison: Silicon Carbide vs Traditional Materials for Pakistan’s Wind Converters

The following comparison focuses on metrics that matter in Pakistan’s heat, dust, and salt-mist conditions, with grid codes emphasizing power quality and ride-through capability.

Efficiency and Grid-Compliance Metrics for Wind Back-to-Back Converters

| Metric in Local Use | Sicarbtech Silicon Carbide Stack | Conventional Silicon-Based Stack | Practical Impact in Pakistan |

|---|---|---|---|

| Weighted converter efficiency | +0.5–1.0 percentage points; peak 98.0%–98.8% | 97.0%–98.0% peak typical | Higher annual energy yield; lower thermal load |

| THD at POI | ≤3% with tuned filters | 3%–5% typical | Smoother interconnection approval |

| Power factor | Near 1 with fast control | 0.98–1.0 typical | Better grid friendliness under events |

| LVRT current control stability | High with low parasitics | Moderate; more ringing | Fewer trips during dips |

| Częstotliwość przełączania | 20–50 kHz (2L); 10–30 kHz (3L) | 10–20 kHz (2L); 5–15 kHz (3L) | Smaller magnetics and filters |

| Zdolność temperaturowa złącza | 175–200°C (package-dependent) | 150–175°C | More headroom in heat waves |

| Module parasitic inductance | <10 nH target | 15–30 nH | Reduced overshoot; easier EMC |

| Wymagania dotyczące chłodzenia | −20–30% heatsink/cold-plate sizing | Linia bazowa | Lower fan/pump power; less fouling |

| Wytrzymałość na cykliczne obciążenia | Sintered Ag + AlN/Si3N4 | Solder + alumina common | Longer lifetime under stress |

| Całkowity koszt posiadania | Lower over 10–15 years | Wyższy | Fewer outages and O&M interventions |

Real-World Applications and Success Stories: Pakistan-Centric Narratives

A coastal wind farm south of Karachi piloted Sicarbtech three-level grid-side inverter modules combined with laminated DC busbars and tuned gate drivers. Over a high-humidity, salt-mist season, cabinet temperature rise dropped by approximately 5–8°C compared with legacy silicon-based hardware at equivalent output, and weighted efficiency improved by about 0.8 percentage points. The site reported fewer nuisance trips during voltage dips, while harmonic audits recorded THD within 3%, smoothing grid compliance interactions.

In a hot, dusty inland site in Sindh, machine-side rectification was upgraded to SiC two-level modules with sintered silver interfaces and high-CMRR current sensors. Commissioning time fell due to cleaner switching and reduced snubber tuning. During a sequence of weak-grid events, current control remained stable, and LVRT recovery improved with lower DC bus oscillation. Maintenance logs showed extended intervals between filter cleanings, attributed to lower airflow needs and sealed module design.

A repowering project in central Punjab adopted Sicarbtech’s bidirectional DC stage to support storage coupling and black-start capabilities. With faster dynamic response and lower conduction loss, the site achieved better reactive power support during frequency excursions and saw a measurable reduction in pump power for the cold plate loop. The operator used Sicarbtech’s application engineering support to refine laminated busbar geometry and meet creepage requirements at mid altitude and high humidity.

Zalety techniczne i korzyści z wdrożenia z lokalną zgodnością

SiC’s advantages accrue at three levels. At the device level, lower switching and conduction losses translate into higher operating frequency without runaway heating. This enables smaller magnetics and filter elements, reducing nacelle and tower-base cabinet volume and weight—tangible savings in structural design and hoisting logistics. At the packaging level, low-parasitic leadframes and laminated busbars minimize loop inductance, yielding cleaner waveforms that simplify EMC and reduce snubbing. With gate drivers that shape dV/dt and clamp Miller-induced transients, stability improves in both machine- and grid-side stages.

At the thermal and environmental level, copper-metallized AlN/Si3N4 substrates coupled with sintered silver interfaces deliver high thermal conductivity and mechanical resilience, preserving power cycling life even as dust fouling or salt mist stress the system. Sealing, anti-corrosion coatings, and materials selection tuned for salt-mist and humidity resist degradation pathways common at coastal sites. For compliance, near-unity PF, fast reactive response, and THD at or below 3% support NEPRA-aligned interconnection. Cleaner switching and lower parasitics shorten commissioning, reduce filter mass, and support extended warranties—key for bankability.

Comparative Portfolio View for Wind Converter Decision-Makers

Aligning Pakistan’s Wind Requirements with Sicarbtech’s SiC Building Blocks

| Local Requirement | Sicarbtech SiC MOSFETs (1200/1700 V) | Sicarbtech 3rd-Gen Schottky Diodes | Sicarbtech Two-/Three-Level Modules + Busbars | Conventional Silicon Options |

|---|---|---|---|---|

| High efficiency machine/grid sides | Low RDS(on), robust oxide | Near-zero Qrr | Low-inductance leadframes; laminated DC bus | Higher loss; larger heat sinks |

| Weak-grid LVRT stability | Controllable dV/dt | Clean recovery | <10 nH parasitics; tuned drivers | More ringing; longer tuning |

| THD and PF compliance | Precise gate control | Suppressed reverse spikes | Coordinated filters; fast reactive | Heavier filters needed |

| Heat, dust, salt mist resilience | High Tj capability | EMI-friendly | AlN/Si3N4 + sintered Ag; sealed | More thermal fatigue, corrosion |

| Compact nacelle/tower-base | Wyższa częstotliwość przełączania | Lower switching loss | Smaller magnetics; lighter cabinets | Larger, noisier systems |

Deep-Dive Engineering Comparison for Heat, Dust, and Salt-Mist Exposure

Device, Packaging, and System Parameters Tuned for Pakistan’s Wind Sites

| Parametr | Sicarbtech SiC Stack (Device + Module + Interconnect) | Typical Silicon Stack | Operational Implication in Pakistan |

|---|---|---|---|

| On-resistance vs temperature | Modest increase to 125°C+ | Steeper increase | Stable output in afternoon heat |

| Reverse recovery charge | ~0 (Schottky) | Wysoki | Lower EMI; simpler filters |

| Max junction temperature | 175–200°C (package-dependent) | 150–175°C | Smaller cooling; less derating |

| Module inductance | <10 nH target | 15–30 nH | Cleaner edges; fewer snubbers |

| Thermal interface | Sintered silver | Solder | Superior power cycling life |

| Substrate | AlN/Si3N4 with Cu | Alumina common | Higher k; vibration toughness |

| Częstotliwość przełączania | 20–50 kHz (2L), 10–30 kHz (3L) | Lower bands | Smaller magnetics and filters |

| Uszczelnienie środowiskowe | Salt-mist/dust-resistant coatings | Generic | Fewer ingress failures |

| Weighted efficiency uplift | +0.5–1.0 percentage points | Linia bazowa | Higher AEP; lower LCOE |

| Lifecycle economics | Lower TCO | Higher TCO | Longer warranties; reduced O&M |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s differentiator in Pakistan is delivery breadth—from materials and devices to modules, equipment, and know-how. Located in Weifang City and embedded in the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech leverages advanced R&D and proprietary processes for R-SiC, SSiC, RBSiC, and SiSiC grades. This materials depth underpins converter reliability by supporting high-thermal-conductivity paths, corrosion resistance, and mechanical integrity under vibration and thermal cycling.

For OEMs, EPCs, and wind O&M providers in Pakistan, Sicarbtech offers complete technology transfer packages that include epitaxial growth (CVD) recipes with thickness and doping profiles; device options balancing trench/planar gate choices; copper-on-ceramic stack-ups; sintered silver processing windows; and module pinout and passivation strategies suitable for two- and three-level topologies. Equipment specifications detail utility needs, environmental controls, line layout, metrology, and maintenance. Training programs upskill operators, process and test engineers, quality teams, and application engineers, instilling SPC discipline and practical tradecraft.

Factory establishment services begin with feasibility studies that reflect local labor markets, utilities, and environmental regulations, then progress to pilot line setup, commissioning, and yield ramp with statistical process control. Quality frameworks align with ISO 9001 and ISO 14001, while Sicarbtech supports pathways to relevant IEC/UL component tests and local grid compliance requirements. Ongoing technical support comprises quarterly process audits, reliability dataset refreshes, EMC/thermal/application engineering assistance, and continuous improvement loops informed by field telemetry. Having supported 19+ enterprises through similar ramps, Sicarbtech brings a repeatable playbook that compresses time-to-revenue and reduces execution risk.

“Standing up a SiC capability is about metrology rigor and repeatable processes as much as cutting-edge equipment. We transfer the routines that keep yield and reliability high,” says a Sicarbtech process transfer lead, underscoring the company’s long-term partnership approach.

Future Market Opportunities and 2025+ Trends: Wind’s Next Chapter in Pakistan

As Pakistan scales wind alongside solar and explores storage pairing, converter platforms that excel in weak-grid support and environmental resilience will lead. Three-level topologies with SiC devices will gain traction in higher-power classes for their efficiency and reduced filter size, while machine-side upgrades will prioritize clean switching and robust thermal pathways. We anticipate SiC penetration in mid-to-high-end converter platforms to rise toward 30–50% over the next several years, with faster uptake in hot, dusty, and coastal corridors.

Wind-plus-storage will expand to provide ramping support and black-start capabilities, raising demand for bidirectional DC stages and higher dynamic control bandwidth—areas where SiC shines. Bankability will hinge on reliability evidence in local stressors, pushing suppliers to generate and share power cycling, HT/HH, and salt-mist datasets relevant to Pakistan. Vendors with integrated materials–devices–equipment delivery and genuine technology transfer capacity will hold a structural advantage, enabling partial localization that shortens lead times, stabilizes costs, and grows in-country technical capability.

Często zadawane pytania

What efficiency gains can SiC deliver for wind converters in Pakistan?

Field deployments commonly see a 0.5–1.0 percentage point uplift in weighted system efficiency, with peak efficiencies around 98.0%–98.8% depending on topology and rating. The gains are particularly valuable in hot seasons when cooling overhead grows.

How does Sicarbtech handle salt-mist and dust exposure near coastal and inland sites?

We use corrosion-resistant coatings, sealed modules, and materials choices validated for salt-mist and humidity. Laminated busbars and passivation strategies minimize ingress paths, while copper-on-AlN/Si3N4 and sintered silver maintain thermal integrity under fouled conditions.

Can SiC improve LVRT performance and weak-grid stability?

Yes. Lower parasitics and clean switching reduce DC bus oscillations and ringing, while higher control bandwidth supports fast reactive response. In practice, this translates to fewer trips during dips and smoother recovery.

Which voltage classes and topologies are most relevant for Pakistan’s turbines?

1200 V and 1700 V SiC devices are typical for megawatt-class back-to-back converters. Two-level modules suit certain ratings, while three-level NPC or active-clamped topologies often yield better efficiency and smaller filters at higher power.

Why are sintered silver and ceramic substrates important in wind converters?

Sintered silver offers high thermal conductivity and mechanical robustness, greatly improving power cycling life. AlN/Si3N4 substrates provide superior heat spreading and mechanical toughness under vibration, temperature cycling, and corrosion exposure.

Does faster SiC switching create EMC headaches?

If unmanaged, fast edges can stress EMC. Our low-parasitic modules, laminated busbars, tuned gate resistors, and Miller clamping minimize ringing, often allowing smaller filters and faster commissioning compared with legacy designs.

Can Sicarbtech support local assembly or full manufacturing in Pakistan?

Yes. We provide technology transfer, equipment specs, training, quality frameworks, and commissioning support. Phased localization reduces FX and logistics risks and enables rapid spare-part turnaround.

What reliability testing is available for Pakistan’s conditions?

We offer power cycling, temperature cycling, high-temperature/high-humidity (HT/HH), and salt-mist testing, plus online screening. We share acceleration models and collaborate on site-specific validation to underpin extended warranties.

How does SiC impact cooling system design and O&M?

Lower loss and higher thermal conductivity allow downsized heatsinks or cold plates and reduced fan/pump power. This cuts noise, energy use, and fouling rates, extending maintenance intervals and reducing O&M costs.

How quickly can a pilot be executed and evaluated?

Depending on scope, pilots can be launched in weeks to a few months. We recommend A/B comparisons with KPIs spanning efficiency curves, thermal imaging, THD/PF logs, LVRT success rates, and maintenance intervals.

Dokonywanie właściwego wyboru dla swoich operacji

The optimal SiC roadmap starts with your site realities: ambient heat, dust or salt exposure, grid stiffness, cabinet constraints, and warranty targets. When Sicarbtech co-designs from epitaxy parameters and gate oxide reliability through module parasitics, laminated busbar geometry, filter strategy, and thermal pathways, the results are concrete—higher weighted efficiency, lighter and smaller cabinets, quieter and lower-power cooling, shorter commissioning, and stronger compliance and warranty narratives. For wind developers, OEMs, and O&M teams in Pakistan, this integrated approach reduces risk and increases annual energy production while flattening O&M curves.

Konsultacje ekspertów i niestandardowe rozwiązania

Whether you are repowering existing turbines, specifying new back-to-back converters, or planning localized assembly and reliability test capacity, Sicarbtech will translate your KPIs into a data-backed plan with clear milestones for performance, compliance, and ramp. Speak directly with our engineering team at [email protected] or +86 133 6536 0038.

Metadane artykułu

Last updated: 2025-09-17

Next scheduled review: 2025-12-01

Content freshness indicators: Includes 2025 Pakistan wind outlook; SiC two-/three-level converter strategies; 1200/1700 V SiC MOSFETs and 3rd-gen Schottky diodes; sintered silver and AlN/Si3N4 substrates; laminated low-parasitic DC busbars; LVRT/reactive support and THD targets; NEPRA/PQ compliance context; localization and technology transfer pathways; case narratives from coastal and inland wind sites.

About Sicarbtech: Silicon Carbide Solutions Expert based in Weifang City, China’s SiC manufacturing hub; member of Chinese Academy of Sciences (Weifang) Innovation Park; 10+ years of SiC customization supporting 19+ enterprises; full-cycle delivery from material processing to finished products; specialties include R-SiC, SSiC, RBSiC, and SiSiC grades; services include custom manufacturing, factory establishment, and technology transfer.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.