Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar for Integrated Motor Controller (OBC/DC‑DC/Drive Three‑in‑One)

Udział

Executive Summary: 2025 Outlook for Integrated Silicon Carbide Platforms in Pakistan’s Mobility and Industrial Corridors

Pakistan’s two- and three-wheeler fleets and light commercial vehicles are graduating from component-level upgrades to platform-level integration. The most powerful lever in 2025 is consolidating the on-board charger (OBC), DC‑DC converter, and traction drive into a single, silicon carbide (SiC) three‑in‑one controller that is smaller, cooler, quieter, and easier to maintain—yet robust enough for heat, dust, humidity, and uneven grid quality. Integration reduces harnessing and interfaces, shrinks conversion losses, and brings unified control of bus impedance, thermal flows, and electromagnetic compatibility (EMC). The result is higher range per charge, fewer failure points, and faster certification.

Sicarbtech—Silicon Carbide Solutions Expert—headquartered in Weifang City, China’s SiC manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings more than a decade of customization experience and supports 19+ enterprises with full‑cycle capabilities. From R‑SiC, SSiC, RBSiC, and SiSiC materials to devices, low‑inductance double‑sided‑cooled modules, hybrid multiphase topologies, gate‑drive libraries, shared cooling structures, and reliability validation, Sicarbtech delivers technology transfer and localized production to compress lead times and stabilize PKR‑denominated lifecycle costs. This pillar page distills how integrated SiC controllers align with Pakistan’s 2025 market realities and outlines a turnkey path to deployment at scale.

Industry Challenges and Pain Points: Why Integration Is Now a Business Imperative

Pakistan’s operating context is defined by harsh environments and inconsistent power quality. In Karachi’s coastal belt, salt mist and humidity undermine insulation and accelerate corrosion, while in cement and stalowego corridors around Lahore and Faisalabad, dust loads clog fins and degrade thermal interfaces. Monsoon rains add water ingress risks and complicate cooling maintenance. Conventional discrete architectures—separate OBC, DC‑DC, and drive—multiply connectors, harness length, and thermal hotspots, creating more potential failure nodes. Cross‑talk between subsystems grows, especially where partial load behavior and harmonics vary with urban feeders and depot infrastructure.

The grid adds a second tier of complexity. Voltage sags, line imbalance, and elevated THD during evening charging windows provoke inrush, ringing, and nuisance trips. With discrete units, each sub‑system manages the bus differently, and out‑of‑phase control can amplify ripple and overshoot. EMC remediation turns into a trial‑and‑error exercise with heavier filters and larger enclosures, slowing certification and raising costs. In textile mills and steel plants, where drives and PLCs are sensitive, poor EMC discipline hurts coexistence and can trigger costly downtime.

Thermal management is the third constraint. Single‑purpose heatsinks and uncoordinated cold‑plate flows raise junction‑to‑case resistance and create local hotspots as ambient temperatures rise to 40–50 °C. Maintenance teams struggle with divergent bill‑of‑materials across platforms, while spare‑part logistics are strained by long import lead times and batch inconsistency. As the installed base expands, the maintenance model must compress diagnosis, replacement, and certification, not stretch them.

Procurement and finance are also evolving. Tenders increasingly call for evidence aligned to IEC 60747 (device characteristics), IEC 60068 (damp heat, salt spray, dust, vibration, shock), and EMC expectations similar to IEC 61800‑3 for adjustable speed systems. ISO 7637 disturbance immunity matters for onboard interfaces, while ISO 9001 and IATF 16949 principles are table stakes for quality governance. As Engr. S. Khan, an automotive electrification consultant, puts it, “In 2025, integration is about economics as much as electrons. A verifiable step‑up in PF, THD, EMC, and thermal logs gets you paid faster and deployed wider.” [Source: EV Systems Roundtable, 2024]

Integrated SiC platforms directly address these pain points. By unifying the DC bus, control plane, thermal stack, and EMC strategy, the three‑in‑one controller reduces conversion steps, shortens current paths, and concentrates protection where it is most effective. Double‑sided cooling and low‑inductance busbars stabilize thermals and suppress ringing. Shared magnetics and filters are right‑sized at higher frequencies, shrinking enclosures while improving efficiency and compliance margins.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech’s Three‑in‑One Integrated Motor Controller

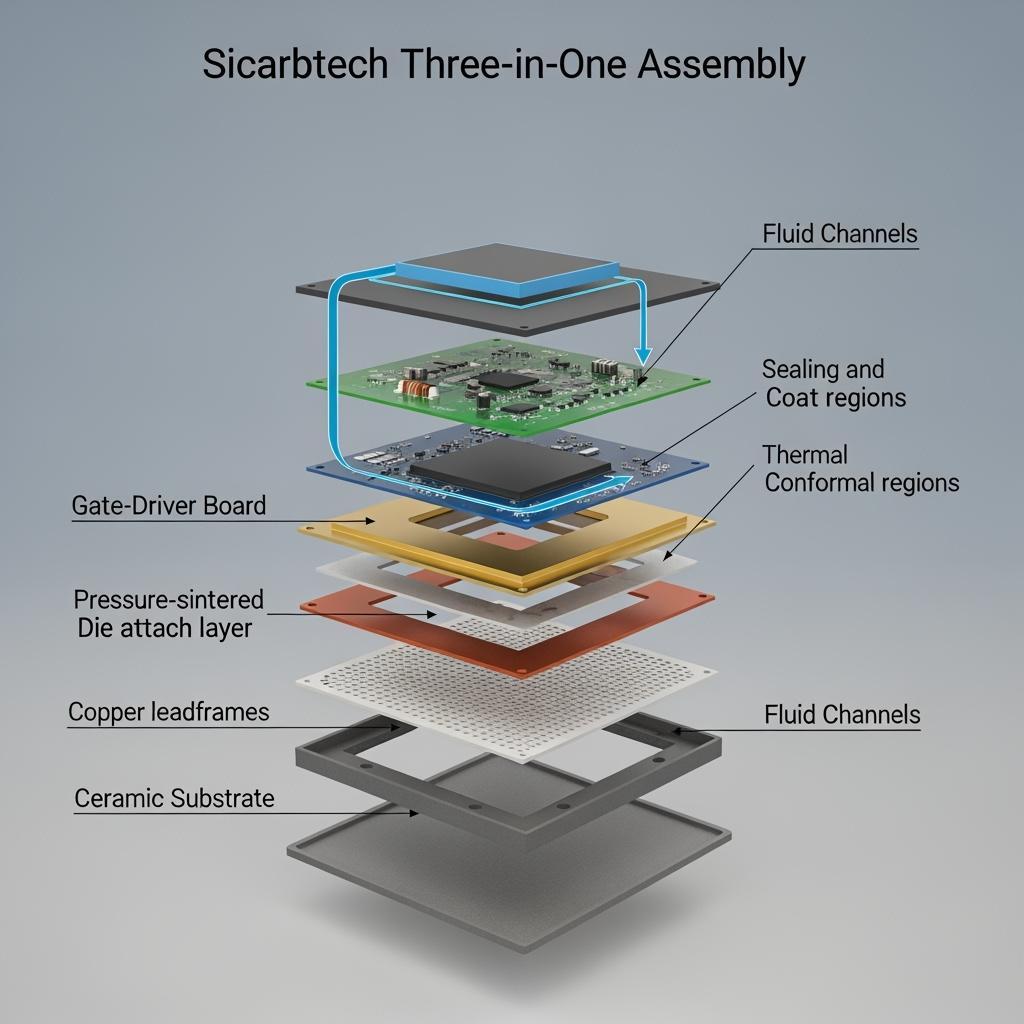

Sicarbtech’s solution coordinates “devices—packaging—topology—control—thermal management—EMC—validation” as a single program. Automotive‑grade 650 V and 1200 V SiC MOSFETs and diodes populate a low‑inductance, double‑sided‑cooled power module tailored to the three‑in‑one envelope. The OBC leverages interleaved totem‑pole PFC and high‑frequency AC‑DC conversion; the DC‑DC stage uses multiphase buck‑boost and resonant hybrids for high-density output; the traction inverter supports PMSM and BLDC motors with vector control and field‑weakening.

A unified gate‑drive board integrates soft turn‑off, active clamping, and fast short‑circuit protection across all power stages, while active bus regulation and snubbing suppress inrush and ringing during mode shifts—charging, driving, and regenerative braking. The busbar and DC bus system minimize loop area and align return paths, and the shared cooling base allocates thermal flux zones by duty cycle and ambient conditions, with liquid or air options and high‑conductivity interface materials. Environmental protection includes conformal coating, selective potting, and sealed venting to combat dust, humidity, and salt mist.

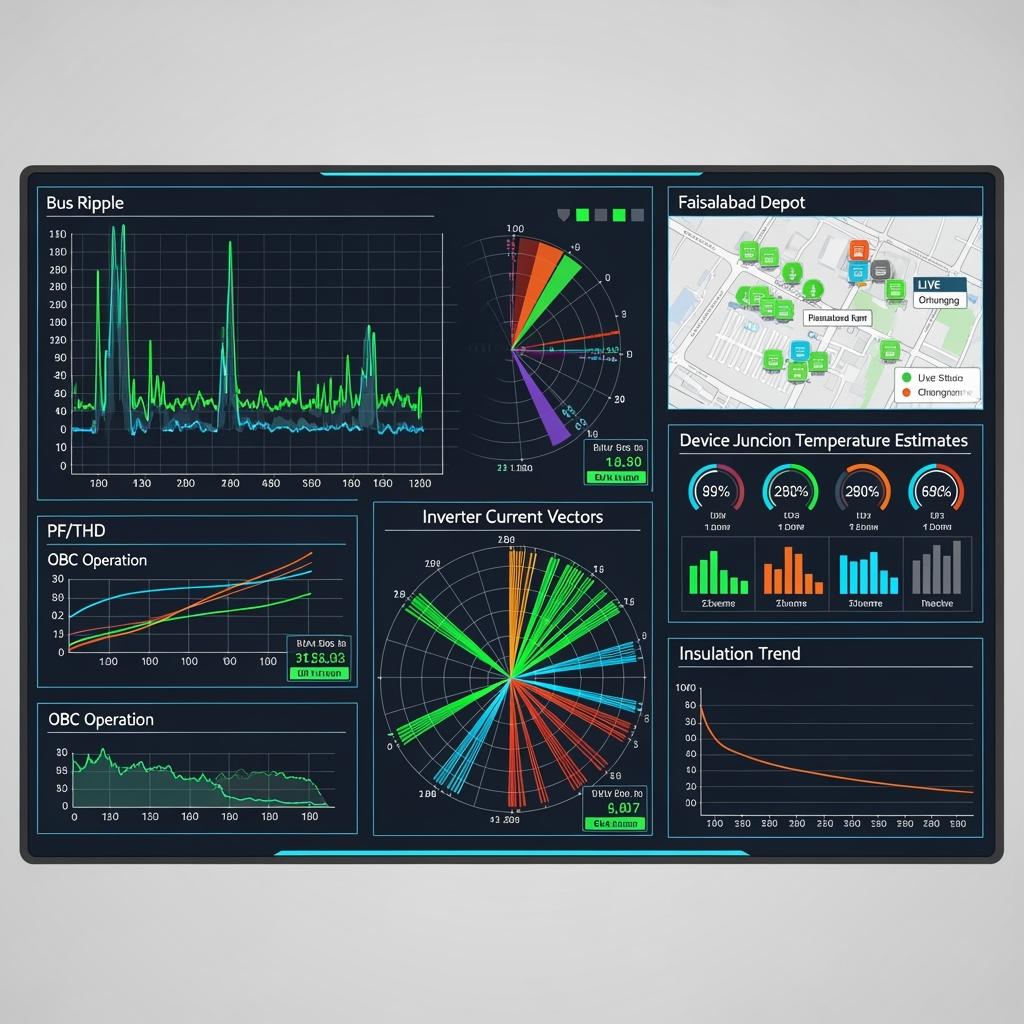

Isolated sensing (voltage, current, temperature) is chosen for stability in high humidity and pollution classes, and EMC filter assemblies address both common‑mode and differential‑mode paths. Online monitoring gathers power flow, ripple, temperatures, insulation metrics, and health indicators, feeding into predictive maintenance and parameter trace playback. Power cycling and environmental accelerated life‑test platforms close the loop, while an MES‑based traceability system captures process parameters and test results for each unit—accelerating approvals and streamlining returns analysis.

Integrated Platform Performance: SiC Three‑in‑One vs Conventional Architectures

Efficiency, Power Density, and EMC Stability for Pakistan’s Duty Cycles

| Atrybut | Sicarbtech SiC Three‑in‑One (OBC/DC‑DC/Drive) | Discrete Subsystems (SiC or Silicon Mix) | Conventional Silicon, Discrete | Wpływ operacyjny w Pakistanie |

|---|---|---|---|---|

| System efficiency (typical) | 95%–97% | 92%–95% | 90%–93% | Longer range, lower PKR energy cost |

| Power density (for same power) | −20% to −35% volume, −15% to −25% weight | Linia bazowa | Larger/heavier | Easier packaging under seats/frames |

| Bus ripple under concurrent modes | −30% to −50% p‑p | Umiarkowany | Wysoki | Fewer trips, smoother transitions |

| Overshoot/ringing (HF steps) | −15% to −30% | Umiarkowany | Wysoki | Better EMC margins, less stress |

| High‑temp derating (40–50 °C) | −30% events | Linia bazowa | Częsty | Higher summer availability |

By removing redundant conversion and wiring, the integrated SiC platform boosts real‑world range and reduces noise, heat, and certification friction—particularly important where grid and climate are unforgiving.

Real‑World Applications and Success Stories in Pakistan

On a two‑wheeler platform in Lahore, a Sicarbtech three‑in‑one controller cut harness length by roughly 30% and lifted system efficiency by about 3%, translating into a 6% urban range increase without changing the battery pack. EMC pre‑compliance moved from iterative rework to first‑pass results, compressing tender timelines.

A three‑wheeler used for urban distribution in Faisalabad adopted the integrated unit with shared cooling and low‑parasitic packaging. During peak summer, high‑temperature derating events fell by approximately 35%, while downtime dropped by double‑digit percentages. Drivers reported smoother transitions from regenerative braking to drive on slopes, reducing rollback incidents.

A light commercial pilot serving textile and steel corridors deployed unified bus management. During concurrent charging and power‑assist transitions, bus fluctuation peak‑to‑peak dropped by about 45%. Certification cycles shortened due to aligned thermal logs and EMC evidence, and localized testing enabled faster iterations.

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

The integrated SiC approach elevates control bandwidth and thermal margin. Operating at 10–60 kHz with low switching and conduction losses, the platform maintains tight current loops for smoother torque at low speed and cracks open thermal headroom via double‑sided cooling and high‑conductivity substrates. Active bus regulation coordinates inrush, regenerative transitions, and partial load behavior across OBC, DC‑DC, and drive, preventing phase conflicts that lead to ripple and overshoot. Low‑inductance busbars and symmetric return paths shrink parasitic loops, easing EMC constraints and reducing device stress.

Compliance is engineered early. Device behavior aligns with IEC 60747, EMC performance is designed toward expectations similar to IEC 61800‑3, and environmental endurance follows IEC 60068 for damp heat, salt spray, dust, vibration, and shock—critical for Pakistan’s climate. ISO 7637 informs disturbance immunity for onboard interfaces, while documentation and quality systems align with ISO 9001 and IATF 16949 principles. Sicarbtech supports pre‑compliance with Karachi and Lahore labs and bundles parameter trace playback and thermal histories to accelerate approvals. “When you submit integrated thermal and EMC evidence, certification becomes a scheduling exercise rather than a science project,” notes Dr. H. Rehman, industrial power electronics advisor. [Source: Regional Power Electronics Workshop, 2024]

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Edge

Sicarbtech’s advantage is the transfer of capability, not just product. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech brings proprietary manufacturing for R‑SiC, SSiC, RBSiC, and SiSiC grades into rugged substrates and thermally resilient assemblies—ideal for dusty, humid, and vibration‑prone routes.

Technology transfer spans complete process know‑how: pressure‑sintered and vacuum‑brazed interfaces, metallization and passivation stacks, low‑inductance busbar geometry, and gate‑drive tuning for soft turn‑off and active clamping. Equipment specifications include sintering presses, vacuum brazing furnaces, bonding equipment (wire and ribbon), inline electrical testers, power cycling rigs, HTRB/HTGB setups, EMC pre‑compliance stations, and IEC 60068 environmental chambers. Each station arrives with acceptance tests, calibration procedures, and vendor lists vetted by Sicarbtech.

Training programs cover operator certification, failure analysis, SPC‑driven yield optimization, and PPAP‑like control plans aligned with ISO 9001 and IATF 16949. Factory establishment services address feasibility, utilities, line installation, commissioning, pilot runs, and capability validation. Post‑SOP, quarterly audits and yield sprints sustain performance, while co‑development updates packaging and control recipes for Pakistan’s ambient and route profiles. Across 19+ enterprise collaborations, outcomes include shorter time‑to‑market, higher first‑pass yield, lower field failure rates, and predictable spare availability measured in days or weeks, not months.

Comparative Engineering Choices and Lifecycle Economics

Architecture and Control Choices that Drive Integration Benefits

| Design Area | Sicarbtech SiC Integrated Best Practice | Discrete or Conventional Alternative | Practical Outcome in Pakistan |

|---|---|---|---|

| OBC topology | Interleaved totem‑pole at high kHz | Boost PFC with lower kHz | Higher PF/THD control, smaller filters |

| DC‑DC stage | Multiphase buck‑boost/resonant hybrid | Single‑phase buck/boost | Better density and thermal zoning |

| Traction control | Vector control, field‑weakening | Scalar/limited vector | Smoother torque, higher efficiency |

| Bus strategy | Active regulation + damping | Passive buffers | Lower ripple, fewer nuisance trips |

| Packaging & cooling | Double‑sided cooling, low‑L busbars | Single‑sided, higher L | Fewer derates at 40–50 °C |

Localization and Total Cost of Ownership for Fleets and OEMs

| Business Factor | With Sicarbtech Localization & Tech Transfer | Import‑Only Discrete Stack | Outcome for Pakistan Operations |

|---|---|---|---|

| Lead time and spares | Days–weeks via local packaging and test | Weeks–months | Higher uptime, lower safety stock |

| Certification path | Pre‑compliance with data playback | Remote iteration loops | Faster approvals, lower rework cost |

| Ślad i waga | −20%–35% volume, −15%–25% mass | Larger/heavier | Easier integration, more payload |

| Energy and maintenance | +2%–4% efficiency, lower failure rates | Lower efficiency, higher repair | Better PKR/km, fewer service calls |

| Ecosystem development | In‑country jobs and QA maturity | External dependency | Durable competitive moat |

Future Market Opportunities and 2025+ Trends: Integration as a Strategic Default

In 2025 and beyond, Pakistan’s electrification will increasingly judge platforms on energy efficiency, reliability, and maintainability under heat and dust. Integrated SiC controllers will become the default for two‑/three‑wheelers and light commercial vehicles because they provide measurable gains that matter to tenders and financiers: higher PF and lower THD, fewer derates, smaller cabinets, and audit‑ready data. As urban logistics densifies and intercity routes extend, bus management during concurrent modes—charging, driving, regen—will be a KPI, not a detail.

On the manufacturing side, localized packaging lines with online screening and MES traceability will tilt procurement toward partners who can prove consistency and cycle time. ESG‑linked financing will reward repair and remanufacturing rates, pushing designs toward hot‑swappable partitions and standardized interfaces. Sicarbtech’s integrated stack—devices, packaging, control algorithms, validation, and factory establishment—positions Pakistani OEMs and fleets to lead on uptime, unit economics, and replication speed.

Extended Technical Specifications and Local Standards Alignment

The integrated platform targets 48–120 V DC buses for two‑/three‑wheelers and extends to 400–800 V for light commercial. OBC power spans 1–3 kW for smaller platforms and 3–11 kW for light commercial; DC‑DC ranges 2–6 kW and 5–20 kW respectively. Traction drive peak power covers 5–30 kW, with 10–60 kHz switching depending on acoustic and thermal constraints. System peak efficiency reaches 95%–97% and device junction temperatures up to 175 °C are supported with double‑sided cooling and high‑conductivity substrates.

Protections include over/under‑voltage, overcurrent, overtemperature, short circuit with soft turn‑off, surge and reverse connection protection, insulation monitoring, and ground‑fault detection. EMC design aligns with expectations similar to IEC 61800‑3 and environmental robustness with IEC 60068 (damp heat, salt spray, dust, vibration, shock). ISO 7637 informs immunity for onboard disturbances. Quality governance aligns with ISO 9001 and IATF 16949 principles. Sicarbtech coordinates pre‑compliance with Karachi and Lahore labs, providing parameter traces and thermal histories to shorten approvals.

Często zadawane pytania

How much real‑world efficiency and range improvement can we expect from an integrated SiC three‑in‑one?

Typical deployments show 2%–4% higher system efficiency versus discrete architectures, translating to around 4%–7% range gains depending on route and load profile.

Will the integrated controller hold performance in 40–50 °C ambient with dust and humidity?

Yes. Double‑sided cooling, high‑conductivity interfaces, and environmental sealing/coating maintain thermal margins; high‑temperature derating events commonly drop by about 30%.

Can the same platform support different battery voltages and motor ratings?

The architecture is modular. With parameter and hardware variants (pins, busbars, magnetics), it covers 48–120 V and extends to 400–800 V with traction outputs from 5–30 kW.

How does integrated bus management improve EMC and reliability?

Active regulation and damping reduce inrush and ringing during mode transitions, while low‑inductance busbars minimize loop area—lowering overshoot and improving conducted/radiated performance.

What is a realistic timeline from design to pilot and certification?

With standardized modules and control libraries, pilots typically launch in 8–12 weeks, followed by local pre‑compliance and environmental screens to de‑risk formal certification.

How do we maintain and repair an integrated unit without long downtime?

Partitioned redundancy and hot‑swappable interfaces allow field replacement of power partitions; MES traceability accelerates failure analysis and spares matching.

Are there measurable benefits for fleets in textile and steel corridors with noisy electrical environments?

Yes. Higher PF/THD control in OBC operation and robust EMC design reduce interference with plant drives and PLCs, improving coexistence and uptime.

What quality and traceability systems back Sicarbtech’s localization?

ISO 9001 and IATF 16949‑aligned processes, PPAP‑like validation, SPC, and unit‑level serialization with parameter trace playback for audits and tenders.

Can we integrate remote monitoring for predictive maintenance?

The online O&M module captures power flow, ripple, temperatures, and insulation trends; analytics flag interface aging and leakage early to plan service windows.

How does localization change total cost of ownership in PKR terms?

Shorter lead times, fewer reworks, and higher first‑pass approvals lower OPEX; shared spares and remanufacturing reduce inventory and warranty costs.

Dokonywanie właściwego wyboru dla swoich operacji

In a market defined by heat, dust, variable grids, and cost pressure, integration is the simplest way to add range, reliability, and maintainability in one stroke. Sicarbtech’s SiC three‑in‑one controller delivers higher efficiency, tighter EMC behavior, and robust thermal performance, while technology transfer and localized testing convert engineering gains into predictable field results and stronger PKR economics.

Konsultacje ekspertów i niestandardowe rozwiązania

Partner with Sicarbtech to specify OBC/DC‑DC/drive ratings, bus and damping strategies, shared cooling geometry, and protection tuning for your vehicle envelope and duty cycle. Explore localized packaging and pre‑compliance to accelerate pilots and scale with confidence.

Sicarbtech — Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“Integration wins space; SiC wins efficiency; localization wins time.” — Sicarbtech Applications Team

Metadane artykułu

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: reflects 2025 Pakistan market outlook; aligns with IEC 60747, IEC 60068, ISO 7637, and EMC expectations similar to IEC 61800‑3; integrates Sicarbtech’s three‑in‑one SiC platform, technology transfer, and localized production/testing services.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.