Moduły konwerterów UPS online z węglika krzemu dla centrów danych i maszynowni finansowych

Udział

Przegląd produktów i znaczenie dla rynku w 2025 r.

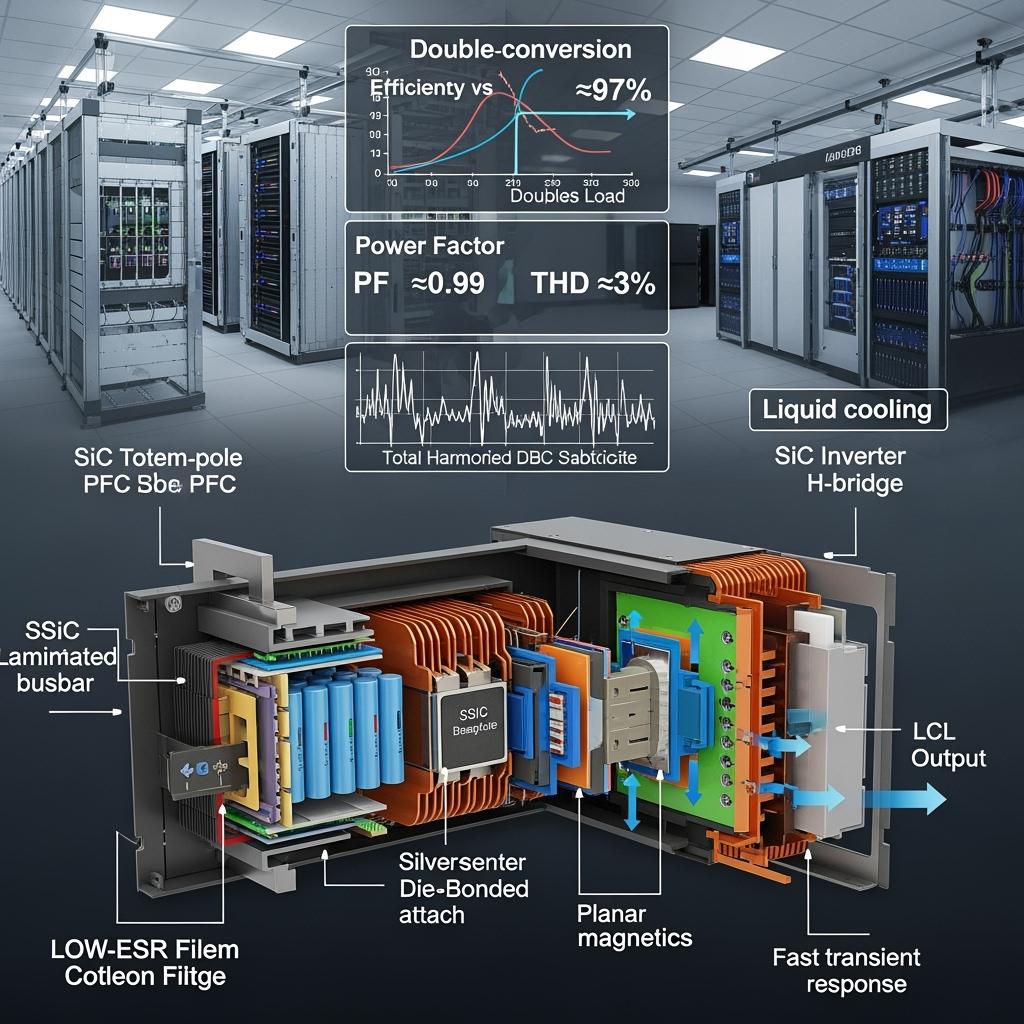

Moduły konwerterów UPS online z węglika krzzemu (SiC) to wstępnie zaprojektowane stopnie mocy, które integrują tranzystory MOSFET/diody SiC, magnetykę o dużej gęstości, sterowanie cyfrowe i zaawansowane zarządzanie termiczne, aby zapewnić ciągłą, podwójną konwersję dla obciążeń o krytycznym znaczeniu. W porównaniu z konstrukcjami UPS opartymi na krzemie, moduły SiC osiągają wyższą wydajność zarówno przy pełnym, jak i lekkim obciążeniu, szybszą reakcję przejściową i niższe naprężenia termiczne — kluczowe dla pakistańskich centrów danych i pomieszczeń maszyn finansowych, które borykają się z wysokimi temperaturami otoczenia, zapylonym środowiskiem i niestabilną siecią.

Dlaczego rok 2025 ma znaczenie dla Pakistanu:

- Presja na energię i niezawodność: Operatorzy centrów danych i banki wymagają podwójnej konwersji o sprawności 97% + i prawie zerowego czasu przestoju, aby kontrolować koszty operacyjne i chronić usługi.

- Zmienność sieci: Częste zapady, przepięcia i harmoniczne wymagają solidnej wydajności prostownika/falownika z niskim THD i wysokim PF.

- Ograniczenia przestrzenne i chłodzenia: Wyższa gęstość mocy i niższa emisja ciepła zmniejszają pomieszczenia UPS i obniżają koszty HVAC, umożliwiając większą pojemność szaf IT na tej samej powierzchni.

- ESG i zgodność: Poprawiona wydajność wspiera cele zrównoważonego rozwoju i jest zgodna z oczekiwaniami dotyczącymi jakości energii w kodzie sieci NTDC.

Moduły konwerterów UPS online SiC firmy Sicarb Tech obejmują zakres 10–300 kW na ramę (możliwość równoległego łączenia do wielu MW), z przednimi końcami totem-pole lub Vienna PFC oraz stopniami DC/DC + falownika o wysokiej częstotliwości. Zawierają ochronę, telemetrię i mechanikę z możliwością wymiany podczas pracy w celu szybkiego wdrożenia i konserwacji.

Specyfikacje techniczne i zaawansowane funkcje

Konfigurowalne opcje (specyficzne dla projektu):

- Parametry elektryczne

- Wejście: 3-fazowe 380/400/415 VAC, 50 Hz; PF ≥0,99; wejściowe THD ≤3% z aktywnym PFC

- Wyjście: 208/230/400 VAC konfigurowalne; 50/60 Hz; regulacja napięcia ±1% statyczna; reakcja przejściowa <2 ms dla 50% skoków obciążenia

- Zakres mocy: 10–300 kW na moduł; skalowalność równoległa N+1 do >2 MW

- Interfejs akumulatora: 384–800 Vdc Li-ion/VRLA; dwukierunkowy DC/DC z łagodnym rozruchem i aktywnym balansowaniem

- Wydajność i jakość zasilania

- Tryb podwójnej konwersji: typowo 96,5–97,8% przy obciążeniu 25–100%

- Tryby ECO/oszczędzania energii opcjonalne z monitorowaniem jakości sieci

- Wyjściowe THD: ≤2% obciążenia liniowe; ≤3% obciążenia nieliniowe

- Przełączanie i magnetyka

- Stopień PFC: totem-pole lub Vienna, 45–120 kHz

- DC/DC i falownik: 40–100 kHz z magnetyką planarną i rdzeniami o niskich stratach

- Termiczne i mechaniczne

- Rozpraszacze ciepła SSiC/RBSiC; mocowanie matrycy z lutem srebrowym; AlN/Si3N4 DBC

- Chłodzone powietrzem do 100–150 kW (w zależności od otoczenia); opcje chłodzenia cieczą dla większej gęstości

- Modułowe, wymienne podczas pracy szuflady zasilania ze złączami blind-mate

- Sterowanie i zabezpieczenia

- Sterowanie cyfrowe (MCU/FPGA) ze sterowaniem predykcyjnym lub średnim prądem

- Zabezpieczenia: OCP, OVP/UVP, OTP, zwarcie z DESAT i łagodnym wyłączaniem, odporność na przepięcia zgodnie z serią IEC 61000-4

- Strategie podtrzymania i podtrzymania przy niskim napięciu (LVRT); szybkie przełączanie obejściowe (przełącznik statyczny)

- Monitorowanie i interfejsy

- SNMP, Modbus-RTU/TCP, CAN; styki bezpotencjałowe dla alarmów; zdalne monitorowanie z włączonym cyberbezpieczeństwem

- Analityka konserwacji predykcyjnej: trend ESR kondensatora, stan wentylatora/łożyska, dryft termiczny, SOH/SOC akumulatora

- Normy i zgodność

- IEC/EN 62040 (UPS), IEC 62477-1 (konwertery mocy), IEC 61000-6-2/6-4 (EMC), IEC 61000-3-2/3-12 (harmoniczne)

- Zgodne z praktykami PEC i zaleceniami dotyczącymi jakości energii w kodzie sieci NTDC

Opcje modułów Sicarb Tech:

- Zestawy przednie: moduły SiC PFC dostosowane do zniekształceń sieci w Pakistanie

- Stopnie falownika: wyjścia filtrowane LCL, o niskim THD z dynamicznym wsparciem mocy biernej

- Akumulator DC/DC: dwukierunkowy przepływ mocy z możliwością rozruchu i przycinania szczytów

Wyższa wydajność i jakość zasilania dla obiektów o krytycznym znaczeniu

| Wydajność podwójnej konwersji UPS w środowiskach danych/finansowych w Pakistanie | Moduł konwertera UPS online SiC (Sicarb Tech) | Moduły UPS oparte na krzemie |

|---|---|---|

| Sprawność podwójnej konwersji | 96,5–97,8% przy obciążeniu 25–100% | Typowo 91–94% |

| Wejściowy PF i THD | PF ≥0,99, THD ≤3% | PF 0,95–0,98, THD 5–10% |

| Gęstość mocy | >10 kW/L do osiągnięcia | Typowo 4–6 kW/L |

| Zapotrzebowanie na chłodzenie i hałas | Zmniejszona moc wentylatora; chłodniejsze szafy | Większe radiatory; wyższa wydajność wentylatora |

| Interwały konserwacyjne | Rozszerzone dzięki mniejszemu obciążeniu termicznemu | Częstsze ze względu na zużycie związane z ciepłem |

Kluczowe zalety i sprawdzone korzyści

- Mierzalne oszczędności operacyjne: Niższe straty przełączania/przewodzenia i zmniejszona energia wentylatora/HVAC obniżają roczne koszty energii elektrycznej w obiektach działających 24/7.

- Najwyższa jakość zasilania: Bliski jedności PF i niski THD zmniejszają nagrzewanie transformatora/kabla w górę, poprawiając stabilność i zgodność w miejscu instalacji.

- Wysoka gęstość mocy: Mniejsza magnetyka, filtry i radiatory umożliwiają kompaktowe ramy i zwiększoną pojemność IT na tej samej powierzchni.

- Niezawodność w wysokiej temperaturze i pyle: Ceramiczne ścieżki termiczne, powłoki konformalne i uszczelnione lub dodatnio ciśnieniowe obudowy wytrzymują temperatury otoczenia 40–45°C i cząstki stałe.

Cytat eksperta:

„Konwertery UPS z obsługą SiC utrzymują wysoką wydajność w szerokim zakresie obciążeń, jednocześnie poprawiając jakość zasilania — krytyczne dla nowoczesnych centrów danych i obiektów finansowych”. — IEEE Power Electronics Magazine, Data-Center Power Conversion, 2024

Zastosowania w świecie rzeczywistym i wymierne historie sukcesu

- Modernizacja centrum danych w Lahore:

- Wdrożono moduły UPS online SiC o mocy 200 kW (N+1) z totem-pole PFC i stopniami falownika chłodzonymi cieczą.

- Wyniki: 97,3% sprawności podwójnej konwersji; energia chłodzenia pomieszczenia zmniejszona o ~12,6% w pierwszym roku; PF utrzymywany ≥0,99; powierzchnia zmniejszona o 35%, umożliwiając dodanie dwóch dodatkowych szaf IT.

- Pomieszczenie maszyn bankowych w Karaczi:

- 80 kW chłodzony powietrzem UPS SiC z analityką konserwacji predykcyjnej.

- Wyniki: Wejściowe THD obniżone z 7,1% do 2,6%; zdarzenia transferu uciążliwości zmniejszone o 60%; prędkość wentylatora zmniejszona o 25% przy typowych obciążeniach.

- Obiekt brzegowy w Fajsalabad (telekomunikacja + usługi finansowe):

- Modułowe ramy 40 kW równolegle z szufladami wymiennymi podczas pracy.

- Wydajność: Średni czas do naprawy (MTTR) <30 minut; wzrost dostępności do „pięciu dziewiątek”; hałas słyszalny zmniejszony o 4–6 dBA.

【Podpowiedź dotycząca obrazu: szczegółowy opis techniczny】 Trzypanelowa infografika porównawcza: 1) Krzywa wydajności w funkcji obciążenia (tryb podwójnej konwersji) podkreślająca plateau 97%; 2) Przebieg i widmo prądu wejściowego pokazujące THD ≤3% i PF ≥0,99; 3) Mapa termiczna porównująca moduł krzemowy i SiC w temperaturze otoczenia 45°C z wektorami przepływu powietrza i płytą podstawy SSiC. Fotorealistyczne, 4K.

Rozważania dotyczące wyboru i konserwacji

- Dobór rozmiaru i redundancja

- Wybierz N+1 lub N+2 w oparciu o SLA; sprawdź pojemność transformatora i zasilacza przy PF 0,99 i zmniejszonym THD.

- Sprawdź koordynację zwarciową i prądu rozruchowego z zabezpieczeniem w górę.

- Strategia termiczna

- Chłodzone powietrzem dla ≤100–150 kW na ramę w przestrzeniach ≤35–40°C; rozważ chłodzenie cieczą dla gęstych pomieszczeń lub modułów o mocy >150 kW.

- Zapewnij czystość filtrów; zastosuj obudowy z dodatnim ciśnieniem w zapylonych miejscach.

- Akumulator i łącze DC

- Dopasuj chemię i napięcie Li-ion do dwukierunkowego DC/DC; użyj integracji BMS do telemetrii SOH/SOC.

- Wdróż okresową kalibrację czujników napięcia/prądu.

- Zgodność z EMC i siecią

- Dostrój filtry LCL do lokalnych impedancji sieci; sprawdź emisje/odporność zgodnie z IEC 61000 in-situ.

- Skonfiguruj parametry podtrzymania zapadów/przepięć zgodnie z lokalnymi profilami zasilania.

- Serwis i analityka

- Włącz pulpity konserwacji predykcyjnej; zaplanuj kwartalne inspekcje złączy, uszczelek i wentylatorów/pomp.

- Używaj aktualizacji oprogramowania układowego, aby udoskonalić kompensację harmonicznych w miarę ewolucji warunków sieci.

Czynniki sukcesu w branży i referencje klientów

- Czynniki sukcesu:

- Wczesna analiza miejsca pod kątem harmonicznych, obciążenia transformatora i wydajności HVAC

- Modelowanie termiczne na szczyt lata; projektowanie przepływu powietrza/kanałów w ciasnych pomieszczeniach

- Integracja z DCIM/SCADA dla alarmów i KPI

- Szkolenie zespołów obiektowych w zakresie wymiany podczas pracy, obejścia i przepływów pracy oprogramowania układowego

- Rekomendacja (Kierownik ds. Operacji Centrum Danych, Lahore):

- „Moduły SiC ustabilizowały nasz PF i THD, jednocześnie zmniejszając obciążenia chłodzenia. Odzyskaliśmy przestrzeń na podłodze i poprawiliśmy czas pracy podczas zakłóceń w sieci”.

Przyszłe innowacje i trendy rynkowe

- Perspektywy na lata 2025–2027:

- Dwukierunkowy UPS + BESS z usługami sieciowymi (przycinanie szczytów, wsparcie VAR, rozruch)

- Współopakowane sterowniki i czujniki dla niższych pasożytów i wyższego CMTI

- Dojrzałość wafli SiC o średnicy 200 mm zmniejszająca koszty; regionalny montaż/testowanie dla krótszych czasów realizacji

- Wykrywanie anomalii wspomagane przez sztuczną inteligencję w zakresie PF/THD i dryftu termicznego w celu zapobiegania awariom

Perspektywa branżowa:

„Półprzewodniki o szerokiej przerwie energetycznej na nowo definiują architektury UPS, umożliwiając sprawność podwójnej konwersji, która kiedyś była zarezerwowana dla trybów ekologicznych — bez poświęcania jakości zasilania”. — IEA Technology Perspectives 2024, rozdział dotyczący elektroniki mocy

Najczęściej zadawane pytania i odpowiedzi ekspertów

- Czy UPS SiC może utrzymać wysoką wydajność przy częściowych obciążeniach?

- Tak. Nasze konstrukcje utrzymują 96,5–97,5% przy obciążeniu 25–100% z zoptymalizowanym czasem bramkowania, magnetyką i sterowaniem PFC.

- Czy niski THD utrzyma się na zniekształconych pakistańskich sieciach?

- Dzięki adaptacyjnej kompensacji harmonicznych i solidnej kontroli prądu osiągamy ≤3% THD w typowych profilach zniekształceń.

- Czy chłodzenie cieczą jest konieczne?

- Nie zawsze. Ramy chłodzone powietrzem do ~100–150 kW są możliwe; chłodzenie cieczą zwiększa gęstość i redukuje hałas w przypadku większych modułów lub gorących pomieszczeń.

- Jak szybkie jest przełączanie/obejście?

- Przejścia przełącznika statycznego występują w ciągu milisekund; topologia podwójnej konwersji zapewnia zerowy czas transferu do obciążenia krytycznego.

- Jaki jest oczekiwany zwrot z inwestycji?

- Zazwyczaj 12–24 miesiące dzięki oszczędnościom energii i klimatyzacji, z dodatkową wartością wynikającą ze zmniejszenia przestojów i wezwań serwisowych.

Dlaczego to rozwiązanie działa w Twoich operacjach

Moduły konwertera UPS online SiC firmy Sicarb Tech łączą wysokowydajne urządzenia SiC z zaawansowanym sterowaniem, niskim THD na wejściu i solidnym opakowaniem termicznym, aby prosperować w gorących, zapylonych i niestabilnych środowiskach sieciowych w Pakistanie. Rezultatem jest czystsza moc, mniejsze pomieszczenia, cichsza praca i wyższa dostępność — bezpośrednio poprawiająca całkowity koszt posiadania i ciągłość usług dla centrów danych i instytucji finansowych.

Połącz się ze specjalistami, aby uzyskać niestandardowe rozwiązania

Zwiększ wydajność swojego UPS dzięki Sicarb Tech:

- Ponad 10 lat doświadczenia w produkcji SiC, wspierane przez Chińską Akademię Nauk

- Niestandardowy rozwój produktów w zakresie R-SiC, SSiC, RBSiC i SiSiC dla optymalizacji termicznej i mechanicznej

- Usługi transferu technologii i zakładania fabryk w celu lokalizacji montażu, testowania i serwisu

- Kompleksowe rozwiązania od materiałów po gotowe moduły UPS, w tym dokumentacja zgodności i wsparcie przy uruchomieniu

- Sprawdzony dorobek z ponad 19 przedsiębiorstwami; szybkie prototypowanie, testy terenowe i modelowanie ROI

Zarezerwuj bezpłatną ocenę wejścia UPS i badanie ROI dla konkretnej lokalizacji.

- Email: [email protected]

- Telefon/WhatsApp: +86 133 6536 0038

Zabezpiecz teraz miejsca inżynieryjne i produkcyjne na Q4 2025, aby zagwarantować dostawę przed szczytowymi oknami uruchomień.

Metadane artykułu

- Ostatnia aktualizacja: 2025-09-11

- Następny zaplanowany przegląd: 2025-12-15

- Autor: Zespół inżynierii zastosowań Sicarb Tech

- Contact: [email protected] | +86 133 6536 0038

- Skupienie na standardach: IEC/EN 62040, IEC 62477-1, IEC 61000-3-2/3-12, IEC 61000-6-2/6-4; zgodne z praktykami PEC i kryteriami jakości NTDC Grid Code

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.