Moduły z węglika krzemu dla ramion mostka falownika zoptymalizowane pod kątem niskich harmonicznych i wysokiej wydajności w warunkach słabej sieci

Udział

Late afternoon in Multan, the grid sags as industrial motors upstream gulp reactive power. Yet the rooftop PV keeps feeding smooth current into the feeder, holding THD low and VAR support steady. Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions are doing the quiet heavy lifting. In Pakistan’s textile, cement, and steel clusters—where 50–250 kW string inverters face 1500 V DC rails, hot dusty air, and voltage flicker—Sicarbtech’s bridge‑arm modules convert SiC’s raw switching speed into clean, bankable power. By co‑optimizing low‑inductance packaging, dv/dt shaping, and sensing‑ready interfaces, these modules help controllers sculpt current harmonics precisely while preserving exceptional efficiency.

Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions product overview and 2025 market relevance

Across 2025 tenders, Pakistan’s EPCs ask for smaller cabinets, faster commissioning, and first‑pass EMC compliance—even on weak feeders. Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions meet that brief by integrating high‑speed 1200/1700 V SiC switches into low‑parasitic bridge arms that are friendly to LCL filters and weak‑grid dynamics. The packaging targets sub‑10 nH commutation loops, enabling 40–100 kHz operation with lower overshoot and tamer spectra. When paired with digital control that exploits the modules’ predictable edges, string inverters achieve lower current THD and maintain LVRT and reactive power support through feeder events that would rattle legacy silicon stacks.

Moreover, Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions align with rooftop realities: lighter magnetics, smaller heat sinks, and fewer fans. This is essential on textile sheds where acoustic caps and structural limits converge. For cement‑adjacent and coastal stalowego environments, coatings and passivation stacks safeguard insulation and leakage stability, ensuring that low harmonics and high efficiency persist through dust, humidity, and salt‑mist.

Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions technical specifications and advanced features

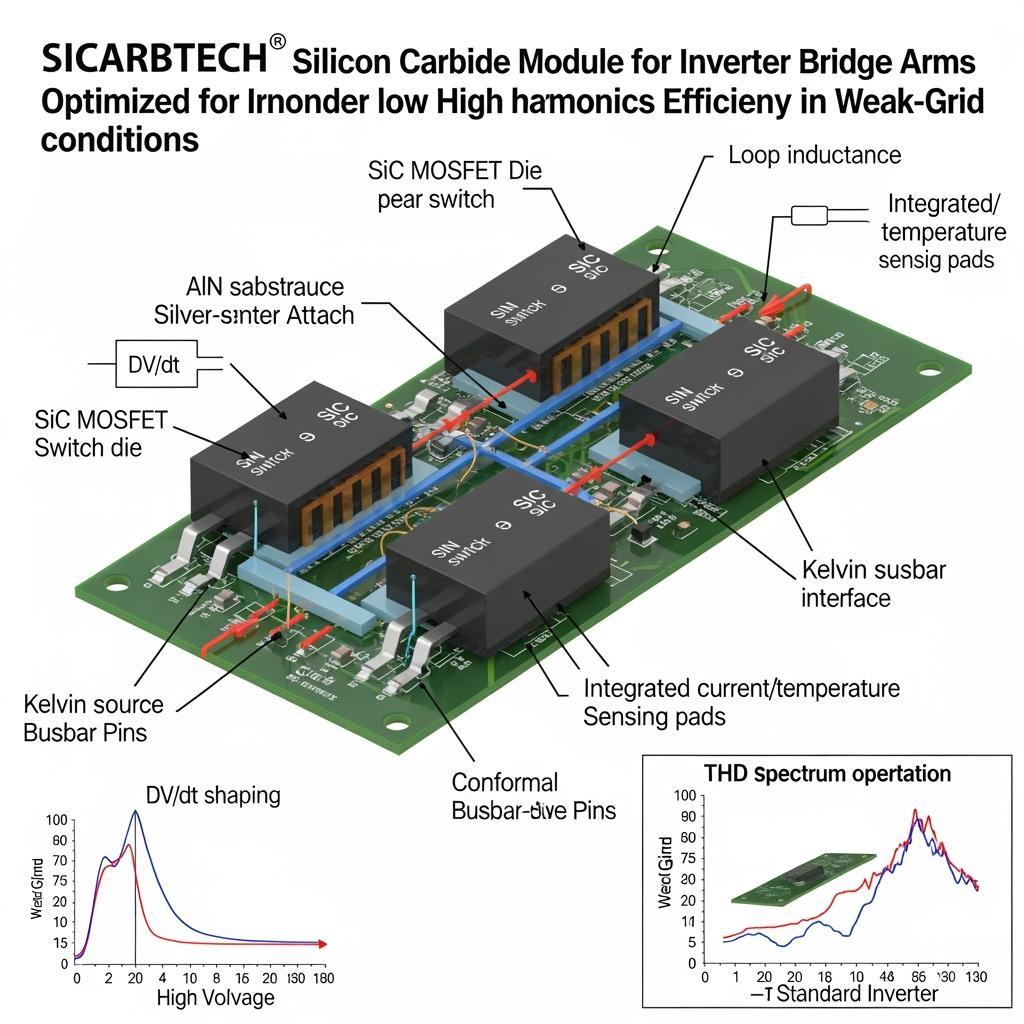

The core of Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions is field‑proven geometry that brings commutation paths as close as physics allows. Sicarbtech employs silver‑sinter die attach over aluminum nitride substrates for low thermal resistance and robust power cycling life. The bridge‑arm layout couples naturally to stacked DC busbars so that current loops are compact, ringing is damped, and switching edges are repeatable—key to predictive digital current control on weak grids. Kelvin source pins decouple power and gate returns, stabilizing desat behavior and enabling precise dv/dt tuning without false triggers.

A sensing‑ready interface is optional yet popular. Temperature pins map near‑junction thermal conditions for dynamic derating only when truly needed, while current pins enable tighter phase current control and phase‑to‑phase balancing in paralleled bridges. Around terminal perimeters, Sicarbtech’s high‑voltage terminal passivation and surface treatments raise partial discharge inception voltage at 85% RH, protecting leakage margins in Karachi‑type humidity. Coatings and sealed interfaces are chosen to resist dust and alkaline particulates from cement corridors, so harmonic performance remains consistent across seasons.

Pakistan‑focused performance comparison for Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions

| Inverter KPI at 1000/1500 V | Moduły z węglika krzemu dla ramion mostka falownika zoptymalizowane pod kątem niskich harmonicznych i wysokiej wydajności w warunkach słabej sieci | Discrete SiC bridge on PCB | Silicon IGBT bridge module |

|---|---|---|---|

| Zakres częstotliwości przełączania | 40–100 kHz stable | 20–60 kHz; layout‑limited | 8–20 kHz typical |

| DC‑link loop inductance | <10 nH with stacked busbars | 20–60 nH | 30–80 nH |

| Current THD on weak feeders | 2–3% achievable with lighter LCL | 3–4% with heavier LCL | 4–6% with large LCL |

| Peak/Euro efficiency uplift | +0.5–1.0 / +0.3–0.8 pts | +0.3–0.6 / +0.2–0.5 pts | Linia bazowa |

| Heat sink volume and fans | −30–50%; halved fan duty possible | −15–25% | Larger sinks; higher duty |

Key advantages and proven benefits of Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions with expert quote

The immediate advantage of Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions is the control headroom it grants. Clean, consistent edges translate into predictable plant models for the DSP, which can then run higher switching frequencies and smarter modulation to drive down harmonics even as feeder impedance wobbles. The modules’ thermal path and sensing options keep junctions honest; if a dust‑clogged filter slows airflow, the controller sees it early and reacts gracefully rather than tripping.

“Harmonic performance is as much about repeatable switching physics as it is about control code,” comments Prof. Nida Arshad, IEEE senior member and PEC‑affiliated power quality specialist (source: PEC Power Quality Workshop, 2025). “When the bridge arm is low‑inductance and observable, weak‑grid THD targets stop being a gamble and become a guarantee.”

Architecture and grid behavior comparison for Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions

| Atrybut | Moduły z węglika krzemu dla ramion mostka falownika zoptymalizowane pod kątem niskich harmonicznych i wysokiej wydajności w warunkach słabej sieci | Generic SiC module | Silicon IGBT stack |

|---|---|---|---|

| dv/dt control with Kelvin paths | Fine, low EMI | Umiarkowany | Limited |

| Reactive power agility | Fast; sensing‑assisted | Umiarkowany | Slow response |

| PDIV and humidity robustness | Elevated with passivation | Standard | Standard |

| EMC iteration count | Fewer loops | Umiarkowany | More loops, heavier filters |

| Rooftop acoustics | Quieter; lower fan duty | Średni | Loud; higher airflow |

Real‑world applications and measurable success stories using Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions

In Faisalabad, a 200 kW rooftop inverter program replaced a discrete bridge with Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions. By co‑designing stacked DC busbars and adopting sensing‑enabled modules, the team pushed switching frequency to 70 kHz and trimmed LCL filter mass by 30 percent. On a feeder with volatile short‑circuit capacity, grid‑tied current THD stayed under 2.5% while maintaining full reactive power support during flicker tests. Across the first summer, SCADA reported zero midday derates at 50°C inlet, and rooftop acoustics improved markedly due to lower fan duty.

In southern Punjab, an industrial park microgrid deployed containerized ESS inverters using the same Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions. Current pins tightened phase balancing across paralleled bridges, reducing circulating losses. Harmonic audits showed a 35 percent reduction in 7th and 11th components compared to the prior silicon design, allowing a lighter harmonic filter and smaller cabinet footprint. Maintenance logs showed extended filter cleaning intervals as fan speeds dropped, a secondary benefit of improved efficiency and thermal behavior.

Field outcomes aligned to Pakistan’s weak‑grid conditions for Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions

| Deployment goal | With Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions | Legacy bridge approach |

|---|---|---|

| Current THD at low SCR | ≤3% with lighter LCL | 4–6% requiring heavier LCL |

| LVRT stability | Sustained VAR support; no nuisance trips | Trips or derates during flicker |

| Cabinet mass | −20–40% from magnetics + sinks | Heavier; logistics burden |

| Czas uruchomienia | Short; first‑pass EMC likely | Longer; multiple reworks |

Selection and maintenance considerations for Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions

Selecting the right variant of Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions hinges on voltage class, switching frequency, and filter philosophy. For 1500 V platforms, many Pakistani sites prefer 1700 V devices to cushion altitude and surge variations; at 1000 V, 1200 V devices may minimize conduction loss. Coordinate dv/dt shaping with your LCL filter design; faster edges cut switching loss but can shift harmonic spectra if uncontrolled. Sicarbtech typically tunes gate resistance and Kelvin returns to produce edges your control loop can model precisely, enabling lower THD without oversized filters.

On maintenance, the modules themselves are largely hands‑off. The sensing pins become your early‑warning system: rising temperature at constant load can indicate airflow degradation, while subtle current imbalance points to connector or busbar issues. In dusty or coastal sites, periodic inspection of coating integrity and terminal seals preserves partial discharge margins. Pairing with high‑protection‑level enclosure thermal management keeps fins clean and flow laminar, sustaining the harmonic and efficiency gains over years.

Industry success factors and customer testimonials for Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions

Bankability in Pakistan increasingly depends on power quality under stress. Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions have turned several difficult feeders into routine commissioning stories. A Karachi EPC technical manager reflected, “With Sicarbtech’s bridge‑arm modules, our THD and VAR specs stopped being moving targets. EMC closed on the first pass, and we shaved days off rooftop work because the cabinets were lighter.”

Future innovations and market trends around Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions

Looking forward, Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions will integrate smarter telemetry and materials. Expect digital temperature sensors with tighter calibration, on‑module current sensing with broader bandwidth, and substrate advances that pull thermal resistance even lower. Field‑grading and passivation stacks will evolve to repel both moisture and industrial oils, sustaining PDIV in harsher pollution degrees. Localization will deepen as Sicarbtech transfers packaging, sintering, and PD screening to Pakistani partners, enabling domestic build and qualification with PEC‑aligned QA frameworks.

Common questions and expert answers on Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions

How do Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions reduce THD on weak feeders?

By minimizing loop inductance and stabilizing dv/dt with Kelvin paths, switching edges become highly predictable. The controller can then apply higher switching frequency and advanced modulation to shape current precisely, achieving low THD with lighter LCL filters.

Are Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions suitable for 1500 V rooftops?

Yes. Offered in 1200 V and 1700 V classes with creepage/clearance and coatings tailored for 1500 V DC, the modules maintain reliability in heat, dust, and humidity typical of Pakistan’s rooftops.

What impact do Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions have on cabinet size?

Higher switching frequencies and cleaner edges allow smaller magnetics and heat sinks. Projects commonly see 20–40 percent reductions in cabinet mass and significant fan duty cuts, easing installation and acoustic compliance.

Do Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions help with EMC?

They do. Lower parasitics reduce ringing and high‑frequency energy, shrinking filter requirements and increasing the likelihood of first‑pass EMC compliance even at higher switching frequencies.

How do sensing options in Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions affect reliability?

Temperature and current pins provide early visibility into thermal and electrical drift, enabling predictive maintenance and gentler fault handling, which lowers warranty risk and improves uptime.

Why Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions work for your operations

Pakistan’s grids are demanding teachers. Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions pass the course by uniting low parasitics, controllable edges, and observability. Controllers can act with precision rather than caution, keeping THD low, efficiency high, and LVRT stable through hot, dusty afternoons and humid nights. The benefits compound: lighter filters, smaller heat sinks, quieter rooftops, faster certifications, and stronger PKR‑denominated returns.

Połącz się ze specjalistami, aby uzyskać niestandardowe rozwiązania

Sicarbtech backs Silicon Carbide Modules for Inverter Bridge Arms Optimized for Low Harmonics and High Efficiency in Weak‑Grid Conditions with over 10 years of SiC manufacturing expertise and the innovation backing of the Chinese Academy of Sciences in Weifang. We customize die selection, module geometry, passivation stacks, and sensing options; co‑design stacked DC busbars and cooling paths; and deliver technology transfer and factory establishment services for localized production. Our turnkey capability spans R‑SiC, SSiC, RBSiC, and SiSiC materials through finished modules, high‑frequency magnetics, and production‑line reliability equipment, validated with 19+ enterprise collaborations.

If your 2025 roadmap targets 1000/1500 V platforms and weak‑grid deployments, now is the time to anchor low harmonics and high efficiency at the bridge arm. Arrange a free consultation at [email protected] or call/WhatsApp +86 133 6536 0038. Early alignment secures certification timelines, trims O&M, and positions your bids to win Pakistan’s toughest tenders.

Metadane artykułu

Last updated: 2025‑09‑16

Next scheduled review: 2025‑12‑01

Timeliness indicators: Incorporates Pakistan’s move to 1500 V DC platforms, NEPRA/IEC/PEC expectations, and 2024–2025 results from low‑inductance SiC bridge‑arm modules driving low THD and high efficiency under weak‑grid conditions.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.