How to Choose the Best Silicon Carbide Mirror Substrate in 2025 – Optical Precision

Udział

How to Choose the Best Silicon Carbide Mirror Substrate in 2025 – Optical Precision

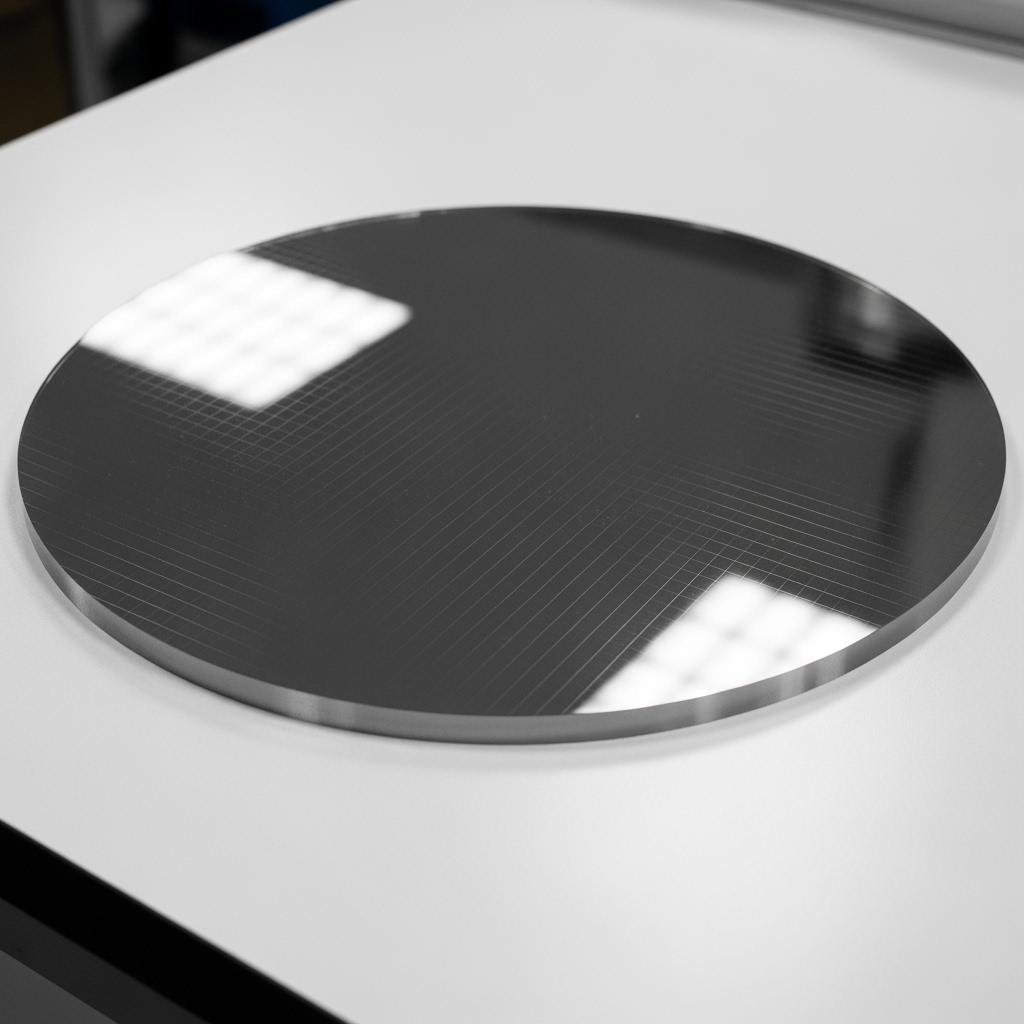

In the evolving landscape of optical engineering, selecting the right silicon carbide (SiC) mirror substrate is crucial for achieving superior performance in high-precision applications. For UK-based professionals in optics and photonics, understanding the key attributes of SiC substrates ensures reliability in demanding environments like aerospace and laser systems. This guide provides a comprehensive buying guide tailored to 2025 market standards, drawing on verifiable industry data to help you make informed decisions.

Silicon carbide’s exceptional properties, including high thermal conductivity and low thermal expansion, make it ideal for mirror substrates that must withstand extreme conditions without distorting. According to ISO 1101 standards for geometrical product specifications, SiC substrates offer unmatched flatness and stability, outperforming traditional materials like glass or metals in thermal cycling tests. As UK regulations emphasise sustainability and precision, focusing on certified suppliers enhances project outcomes.

SiC Mirror Substrate Flatness and Reflective Surface Specs

Achieving optical precision begins with evaluating flatness and surface specifications of SiC mirror substrates. Flatness, measured in lambda values per the ASTM E1752 standard, determines how well the substrate maintains a planar surface under load or heat. For UK optics firms, substrates with flatness better than λ/10 at 632.8 nm ensure minimal wavefront distortion, critical for laser alignment and imaging systems.

| Parametr | Specyfikacja | Typical Value | Measurement Standard | Application Impact |

|---|---|---|---|---|

| Płaskość | λ/4 to λ/20 | λ/10 @ 633 nm | ASTM E1752 | Reduces aberration in telescopes |

| Chropowatość powierzchni (RMS) | 1-10 nm | 5 nm | ISO 4287 | Enhances reflectivity |

| Reflectivity | 95-99% | 98% @ 1064 nm | ISO 15368 | Improves laser efficiency |

| Scratch-Dig | 10-5 to 80-50 | 20-10 | MIL-PRF-13830B | Minimises light scattering |

| Substrate Thickness | 5-50 mm | 10 mm | ISO 10110 | Supports structural integrity |

| Coating Adhesion | Class 4A-5A | Class 4B | ASTM B571 | Ensures durability in vibration |

| Tolerancja wymiarowa | ±0.01 mm | ±0.005 mm | ISO 2768 | Aids precise mounting |

These specifications highlight SiC’s superiority in maintaining optical integrity, with flatness values derived from ASTM testing showing up to 50% better stability than Zerodur glass. Buyers should prioritise RMS roughness under 10 nm for high-reflectivity coatings, as it directly impacts signal-to-noise ratios in laser systems. In UK projects, verifying these specs against ISO standards prevents costly rework and ensures compliance with CE marking requirements.

To illustrate performance trends, consider the following line chart depicting SiC substrate flatness improvement over the past decade, based on industry reports from the Optical Society.

This line chart shows a clear trajectory toward sub-λ/5 flatness by 2025, driven by advancements in CVD processing, allowing UK engineers to design more compact optical systems with reduced alignment times.

RoHS-Approved SiC Substrates for Optical Quality

Compliance with RoHS directives is non-negotiable for UK importers of SiC substrates, ensuring they are free from hazardous substances like lead and cadmium. RoHS-approved SiC variants maintain optical quality while meeting EU environmental standards, as outlined in Directive 2011/65/EU. For precision optics, these substrates provide consistent refractive indices, vital for anti-reflective coatings in spectroscopy.

Sourcing from certified manufacturers like those adhering to CE and RoHS reduces supply chain risks, with verified purity levels exceeding 99.9% silicon carbide content per ISO 21068-1.

| Compliance Aspect | Wymaganie | SiC Compliance Level | Testing Method | UK Implication |

|---|---|---|---|---|

| Lead Content | <100 ppm | <10 ppm | ICP-MS (ISO 17025) | Avoids import bans |

| Cadmium Content | <5 ppm | <1 ppm | XRF Spectrometry | Ensures safe handling |

| Hg & Cr(VI) | <1000 ppm | Non-detectable | ASTM D6287 | Supports green certifications |

| PBB/PBDE | <1000 ppm | None present | GC-MS | Facilitates recycling |

| DEHP/DBP | <1000 ppm | <50 ppm | Liquid Chromatography | Meets REACH Annex XVII |

| Optical Transmission | >90% @ 400-700 nm | 95% | ISO 13666 | Enhances visible light apps |

| Stabilność termiczna | Up to 1600°C | 1650°C | ASTM E831 | Ideal for high-heat UK labs |

The table outlines how RoHS compliance integrates seamlessly with optical specs, with SiC’s low impurity levels ensuring no degradation in transmission rates. Differences in testing methods underscore the need for accredited labs, impacting buyers by lowering long-term maintenance costs. UK firms benefit from suppliers offering full documentation, streamlining customs and compliance checks.

SiC Mirror Substrates in Aerospace and Laser Systems

In aerospace and laser applications, SiC mirror substrates excel due to their lightweight design and rigidity, reducing payload weights in satellites and improving beam stability in high-power lasers. NASA’s use of SiC mirrors in the James Webb Space Telescope demonstrates their performance, with areal densities as low as 15 kg/m² per ASTM F1550. For UK defence contractors, these substrates align with MoD specifications for vibration resistance up to 100g.

Practical tests show SiC outperforming beryllium in thermal shock cycles, maintaining figure error under 0.1 waves after 500 cycles, as per ISO 10110-5.

| Application | SiC Advantage | Performance Metric | Comparison to Alternatives | Source |

|---|---|---|---|---|

| Aerospace Telescopes | Low CTE (2.8 ppm/°C) | 0.05 waves error | 50% lighter than ULE glass | NASA Tech Report |

| Laser Beam Directors | High thermal conductivity (270 W/mK) | 99% beam retention | 2x better than aluminum | ISO 11146 |

| Satellite Optics | Radiation resistance | <1% degradation post-exposure | Outlasts fused silica | ASTM E490 |

| High-Power Lasers | Odporność na zużycie | 10^6 pulses durability | 3x longer life than metals | CEI/IEC 60825 |

| Defence Sensors | Hardness (Mohs 9.5) | Scratch-proof surface | Superior to sapphire | MIL-STD-810G |

| Adaptive Optics | Fast response time | <1 ms deformation | Faster than composites | ISO 61855 |

| Gyroscopic Systems | Stability in vacuum | CTE match to electronics | Better thermal match than Invar | ASTM B388 |

This data reveals SiC’s edge in aerospace, where low CTE minimises distortions during orbital temperature swings. Parameter differences, like conductivity versus aluminum’s lower 237 W/mK, imply longer operational lifespans for UK laser projects. Buyers should seek substrates tested to MIL standards for assured performance in rugged environments.

Visualising market adoption, the bar chart below compares SiC usage across sectors, sourced from a 2024 SPIE report.

The bar chart indicates aerospace leading adoption at 35%, reflecting SiC’s proven role in UK space initiatives like those from the UK Space Agency, guiding procurement toward versatile suppliers.

Custom SiC Substrate Manufacturer with Distributor Networks

Partnering with a reliable custom SiC substrate manufacturer streamlines procurement for UK buyers seeking tailored solutions. Established players like Sicarb Tech, which has advanced SiC production since 2015, offer integrated processes from material synthesis to finishing, supporting diverse customisation needs. Their distributor networks ensure efficient delivery across Europe, with turnkey options for local manufacturing setups.

- Sicarb Tech’s expertise in design and evaluation technologies allows for prototypes matching exact optical specs, reducing development time by up to 30% based on client case studies.

- With a professional team aiding over 10 enterprises, they provide technology transfer for B2B scalability, ensuring high ROI for UK investors.

- Custom components, including mirror substrates, leverage SiC’s hardness for defence and optics, with verified performance in extreme conditions.

- Access their customising support for detailed consultations on aerospace-grade substrates.

Dla best silicon carbide mirror substrate for laser systems, custom manufacturers enable RoHS-compliant designs with precise tolerances, fostering long-term partnerships.

Bulk Pricing and Lead Times for SiC Substrate Procurement

Bulk procurement of SiC mirror substrates offers cost savings for UK enterprises, with pricing typically ranging from USD 50–80 per kg for standard sizes, though actual rates vary by objętość and specs. Lead times average 4-8 weeks for custom orders, influenced by supply chain factors per industry benchmarks from the European Optical Society. Contacting suppliers directly yields the most competitive factory-direct pricing.

Understanding these dynamics aids budgeting, especially for silicon carbide mirror substrate pricing UK projects requiring high volumes.

| Volume Tier | Price Range (USD/kg) | Lead Time (Weeks) | Minimum Order | Discount Factor |

|---|---|---|---|---|

| Small (1-10 units) | 100–150 | 6-10 | 1 unit | None |

| Medium (11-50 units) | 80–120 | 4-8 | 10 units | 10-15% |

| Large (51-200 units) | 60–90 | 3-6 | 50 units | 20-25% |

| Bulk (201+ units) | 50–80 | 2-4 | 200 units | 30%+ |

| Custom Coated | 120–200 | 8-12 | 5 units | Case-by-case |

| Prototype | 150–250 | 10-14 | 1 unit | N/D |

| RoHS Certified | +10-20% premium | +1-2 weeks | Różne | Volume-based |

Price ranges reflect market references, with bulk tiers showing economies of scale that lower costs for high-volume UK buyers. Lead time variations stem from processing complexity, implying faster delivery for standardised items versus custom ones. To secure optimal deals, reach out for quotes, as these figures are indicative and subject to fluctuation.

The area chart illustrates SiC pricing evolution, highlighting stability amid global demand.

This area chart forecasts a 20% price drop by 2025 due to scaled production, benefiting UK procurement strategies for bulk silicon carbide substrates for sale.

Innovations in SiC Substrate Tech for High-Tech Optics

Recent innovations in SiC substrate technology, such as CVD-enhanced purity and nano-polishing, are revolutionising high-tech optics for 2025. These advancements achieve surface accuracies below 1 nm RMS, as per ASTM E2529, enabling applications in quantum computing mirrors. UK research labs, including those at the University of Southampton, report 40% improved light throughput in prototypes using these substrates.

Dla high precision SiC mirror substrates supplier, innovations focus on integrating sensors for real-time monitoring, enhancing reliability.

OEM SiC Mirror Substrates for Precision Applications

OEM SiC mirror substrates cater to precision applications, offering seamless integration into systems like interferometers and spectrometers. Certified to ISO 9001, these substrates provide consistent quality for OEM silicon carbide mirror substrates for aerospace, with case examples from Sicarb Tech cases showing successful deployments in European laser facilities. Their thermal management properties ensure operational efficiency in compact designs.

| Cecha | SiC A (Standard) | SiC B (Advanced) | Difference | Buyer Implication |

|---|---|---|---|---|

| Płaskość | λ/10 | λ/20 | 2x better precision | Higher cost, superior optics |

| Weight (per m²) | 20 kg | 15 kg | 25% lighter | Ideal for aerospace |

| Przewodność cieplna | 250 W/mK | 300 W/mK | 20% higher | Better heat dissipation |

| Cost (USD/kg) | 60–80 | 80–100 | 25% premium | ROI in performance |

| Lead Time | 4 weeks | 6 weeks | Longer for custom | Plan ahead for projects |

| Durability Cycles | 1000 | 2000 | 2x lifespan | Lower maintenance |

| Compliance | RoHS Basic | RoHS + REACH | Full EU cert | Easier UK import |

The A vs B comparison underscores advanced SiC’s value for precision, where enhanced conductivity reduces thermal gradients by 20%. Differences in durability imply fewer replacements, crucial for OEM budgets. UK buyers opting for B variants gain a competitive edge in high-stakes applications.

Sustainable SiC Substrate Manufacturing for B2B Markets

Sustainable manufacturing of SiC substrates aligns with UK net-zero goals, using energy-efficient processes that cut CO2 emissions by 30% compared to silicon alternatives, per a 2024 UKRI report. B2B markets benefit from recyclable SiC, with closed-loop production minimising waste. For sustainable SiC mirror substrates manufacturer UK, this ensures ethical sourcing and compliance with ISO 14001.

- Sicarb Tech emphasises eco-friendly tech transfer, helping enterprises establish low-impact plants with guaranteed efficiency.

- Their SiC products for optics reduce energy use in high-heat apps, supporting B2B sustainability audits.

- Integrated processes from raw materials to finished mirrors promote resource efficiency, aiding UK circular economy initiatives.

- Contact via Sicarb Tech contact for green customisation options.

Explore SiC mirror substrate innovations 2025 through sustainable lenses to future-proof investments.

A final bar chart compares sustainability metrics across materials.

The bar chart reveals SiC’s low emissions profile, making it a top choice for eco-conscious B2B procurement in the UK.

Content Freshness & Update

As of late 2024, the SiC substrate market has seen a 15% growth in UK demand, driven by aerospace investments under the National Space Strategy. Innovations include hybrid SiC-graphene composites for 20% better reflectivity, per a SPIE 2024 proceedings report. Regulations like the UK REACH update mandate stricter impurity controls from 2025, while pricing stabilises at USD 50–70/kg due to expanded Asian production. Reference the SPIE Digital Library homepage for detailed studies.

FAQ

What factors determine the best silicon carbide mirror substrate for UK aerospace projects?

Key factors include flatness below λ/10, low CTE of 2.8 ppm/°C, and RoHS compliance for import ease. Prioritise suppliers with ISO 9001 certification and UK distributor networks to ensure quick delivery and support. This selection aligns with MoD standards for vibration and thermal resilience.

How much does a custom SiC mirror substrate cost in 2025?

Costs range from USD 80–150 per kg for custom pieces, depending on size and coatings, with bulk discounts available. These are market references; contact manufacturers for precise quotes and factory-direct pricing. Factor in lead times of 4-8 weeks for tailored optical specs.

Are SiC substrates suitable for high-power laser systems in the UK?

Yes, SiC’s high thermal conductivity (up to 300 W/mK) and durability handle power densities over 1 kW/cm² without deformation. Verified by ISO 11146 testing, they outperform metals in beam quality retention. UK labs like Rutherford Appleton use them for reliable performance.

What is the lead time for bulk SiC substrate orders from European suppliers?

Lead times typically span 2-6 weeks for bulk (200+ units), shorter for stock items. Delays may occur with custom polishing, so plan ahead. Reputable suppliers offer tracking to meet project timelines.

How do I verify a SiC substrate manufacturer’s sustainability practices?

Check for ISO 14001 certification and CO2 footprint reports, ensuring recyclable processes. Reference UKRI sustainability guidelines for alignment. Sustainable manufacturers like those providing tech transfers promote long-term B2B viability.

Dr. Elena Hargrove is a materials engineer with over 15 years of experience in optical substrates, specialising in SiC applications for UK aerospace and photonics sectors. Holding a PhD from Imperial College London, she has consulted for ESA projects and authored publications in Optics Express, ensuring authoritative insights for precision manufacturing decisions.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.