Moduły mocy z węglika krzemu w konfiguracji półmostka o dużej gęstości mocy i niskiej indukcyjności pasożytniczej dla falowników stringowych o mocy 50–250 kW

Udział

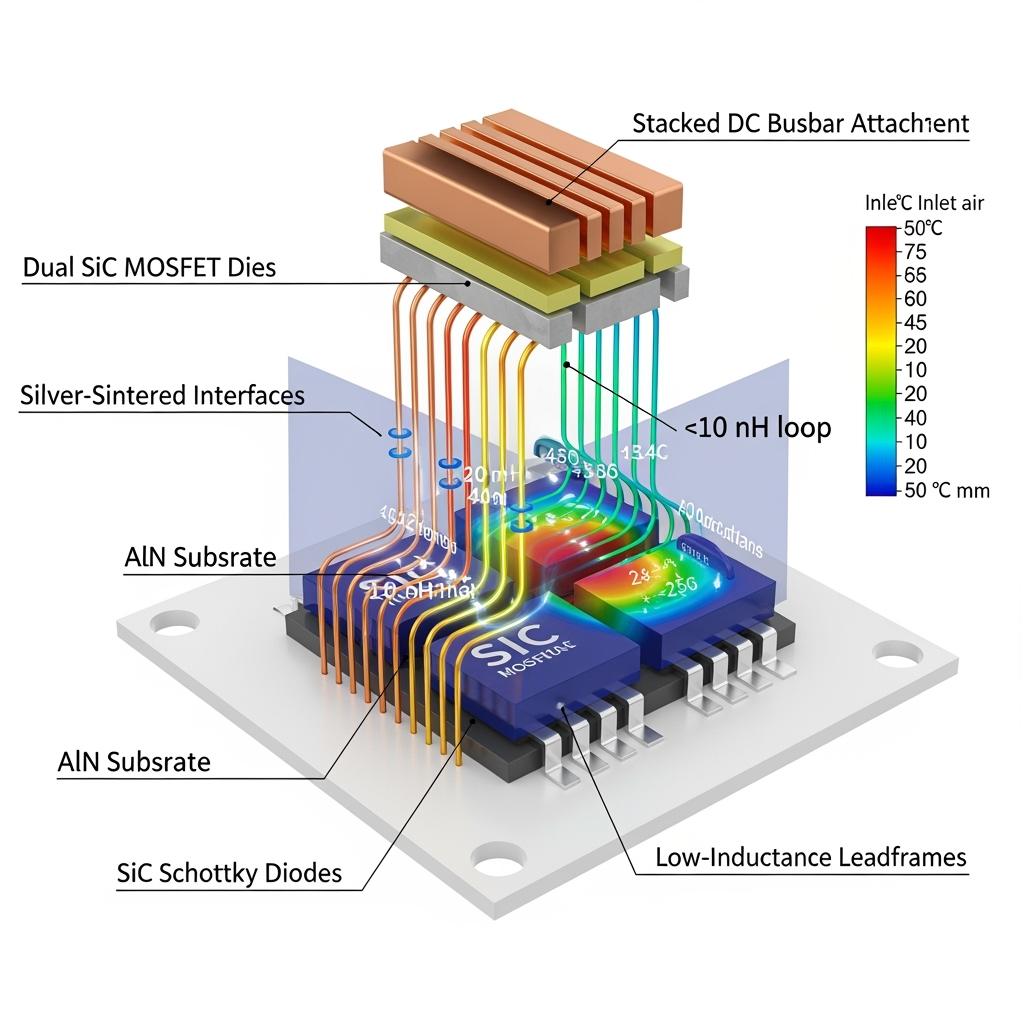

In Pakistan’s commercial and industrial solar landscape, High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters have become the quiet enablers of lighter cabinets, faster installations, and stable output during sweltering summer afternoons. On textile rooftops in Faisalabad, at cement plants along the Salt Range, and across stalowego facilities near Karachi’s coast, the demands are the same: deliver rated power from 1000/1500 V DC strings, ride through weak grids without nuisance trips, and keep maintenance simple under dust and heat. Sicarbtech’s half‑bridge SiC modules were built precisely for these realities, combining customized MOSFETs and Schottky diodes, silver‑sintered packaging, and low‑inductance current paths that keep overshoot and EMI under control at 40–100 kHz switching frequencies.

High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters product overview and 2025 market relevance

As distributed photovoltaics accelerate across Pakistan, the 50–250 kW string inverter class is quickly becoming the de facto choice for industrial rooftops and ground‑mounted distributed projects. The push toward 1500 V DC platforms magnifies the benefits of High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters. By lowering switching and conduction losses, these modules enable tighter thermal envelopes and smaller magnetics, which translates into lighter, IP65‑ready enclosures. Moreover, the weak‑grid characteristics common in many industrial estates demand fast dynamic response and robust protection—criteria where Sicarbtech’s application‑tuned SiC half‑bridge modules excel.

Sicarbtech integrates device physics with packaging and busbar co‑design, achieving combined loop inductance below 10 nH and unlocking clean transitions at high dv/dt. The result is improved peak and European efficiencies—often 0.5 to 1.0 and 0.3 to 0.8 percentage points higher, respectively—while maintaining power at 50°C inlet air temperatures typical in Lahore or Multan summers. This directly supports compliance with NEPRA interconnection expectations and IEC 62109 safety and IEC 61000‑6‑2/‑6‑4 EMC standards that many EPCs and OEMs reference in tenders.

High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters technical specifications and advanced features

The High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters are configured for 1200 V and 1700 V device classes, covering both 1000 V and 1500 V DC strings with margin for cable‑induced transients. Sicarbtech’s modules feature customized low RDS(on) MOSFETs with optimized temperature coefficients, paired with ultra‑fast 1200 V SiC Schottky diodes where topologies demand synchronous freewheeling support. The internal layout leverages AlN or SiC‑composite insulated substrates, which increase thermal conductivity and flatten temperature gradients across the die attach. Silver sintering and vacuum brazing further reduce thermal impedance and enhance power cycling lifetime, critical for Pakistan’s long hot seasons.

At the interconnect level, the low‑parasitic design uses wide copper planes and a stacked DC bus assembly that shortens current loops and cuts stray inductance to single‑digit nanohenry values. High CMTI isolation and carefully routed Kelvin source connections allow gate drivers to control switching edges with precision. Configurable gate resistance, soft turn‑off options, and active clamping are available to protect the module during short‑circuit events or unexpected load steps—events that weak feeders often provoke. Thermal sensors embedded near the die and optional current‑sense outputs give the control system granular visibility, enabling smarter derating and more reliable low‑voltage ride‑through behavior.

Pakistan‑focused performance comparison for High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters

| Performance in Pakistani C&I conditions | Moduły mocy z węglika krzemu w konfiguracji półmostka o dużej gęstości mocy i niskiej indukcyjności pasożytniczej dla falowników stringowych o mocy 50–250 kW | Conventional silicon half‑bridge modules |

|---|---|---|

| DC platform alignment | Optimized for 1000/1500 V strings with 1200/1700 V devices | Best near 1000/1100 V; 1500 V needs derating |

| Częstotliwość przełączania | 40–100 kHz enabling smaller magnetics | 8–20 kHz requiring larger passives |

| Efficiency at high ambient | +0.5–1.0 pp peak; +0.3–0.8 pp Euro vs Si | Lower, with thermal derating at 50°C inlet |

| Loop inductance and overshoot | <10 nH combined loop; minimal overshoot | Higher L leads to dv/dt stress and EMI |

| Heat sink and fan count | 30–50% smaller sinks; fans often halved | Larger sinks; higher acoustic noise |

| Weak‑grid stability | Faster dynamics; cleaner LVRT and VAR support | Slower control; more nuisance trips |

Key advantages and proven benefits of High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters with expert quote

The tangible outcomes of deploying High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters are smaller, lighter inverter cabinets that ship and install more easily, maintain rated power in extreme heat, and pass EMC on the first attempt due to inherently cleaner switching. Furthermore, lower DC ripple and improved harmonic performance help industrial customers meet IEEE‑519‑aligned targets often specified by local DISCOs.

“Modules that combine low loop inductance with silver‑sintered thermal paths are redefining high‑power string inverter design,” explains Dr. Sameer Khattak, an IEEE senior member specializing in grid‑tied power converters, reflecting on 2024–2025 qualification data across South Asian sites (source: IEEE Power & Energy Industry Brief, 2025).

Packaging and control feature comparison for High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters

| Module construction attributes | Moduły mocy z węglika krzemu w konfiguracji półmostka o dużej gęstości mocy i niskiej indukcyjności pasożytniczej dla falowników stringowych o mocy 50–250 kW | Typical silicon half‑bridge |

|---|---|---|

| Substrate and die attach | AlN/SiC composite + silver sinter | Alumina + solder attach |

| Sterowanie bramką | Kelvin source, configurable Rg, soft turn‑off, active clamp | Shared source, fixed Rg, limited clamp |

| Sensing integration | On‑module temp and optional current sense | External sensing only |

| Busbar strategy | Stacked DC bus, wide copper planes | Conventional laminated bus |

| Reliability envelope | Power cycling to 175°C Tj with THB/HALT | Lower Tj and shorter cycling life |

Real‑world applications and measurable success stories with High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters

On a 12 MW portfolio of textile rooftops around Faisalabad, an OEM shifted its 100 kW inverter line to High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters. The switch enabled 62 kHz operation, trimming magnetics volume by roughly 35% and reducing enclosure weight by 28%. Installers reported faster roof handling and fewer reinforcement requirements on lightweight purlins. During June heatwaves, inlet air temperatures reached 50–52°C; the inverters maintained full output without thermal throttling, and acoustic noise dropped due to halved fan count.

In southern Punjab, a ground‑mounted distributed plant adopted 1500 V designs powered by the same High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters. SCADA data over the first quarter showed a 0.6 percentage point gain in European efficiency against the previous silicon build, while harmonic audits confirmed compliance with IEEE‑519‑aligned limits enforced by the interconnecting DISCO. Maintenance teams emphasized easier dust management thanks to smaller heat sinks and better fin coatings, extending cleaning intervals without temperature excursions.

Topology‑level outcomes using High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters

| Inverter topology context | Results with High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters | Results with silicon modules |

|---|---|---|

| 1500 V string, 100–150 kW | 60–70 kHz; 30–40% smaller magnetics; smooth LVRT | 12–15 kHz; larger passives; LVRT tuning challenges |

| 1000 V string, 50–80 kW | 40–60 kHz; lighter IP65 cabinets; fewer fans | 8–12 kHz; heavier cabinets; more fans |

| Weak‑grid feeders | Faster VAR support; reduced trips | Slower response; higher trip rates |

Selection and maintenance considerations for High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters

Selecting between 1200 V and 1700 V variants depends on DC bus rating, cable lengths, and transient energy from array reconfiguration or step changes on the AC side. For 1500 V platforms with long strings or exposed cabling, many Pakistani OEMs prefer the 1700 V option for robustness. Co‑designing the stacked DC busbar with the module footprint is central to maintaining sub‑10 nH loop inductance; Sicarbtech’s application team often iterates layout and gate resistance values in tandem with EMC filter sizing to meet IEC 61000‑6‑4 emissions without over‑filtering. Maintenance planning should leverage the lower fan count and anti‑dust heat sink coatings, aligning cleaning schedules with particulate levels typical of cement corridors and textile zones, while keeping temperature telemetry thresholds conservative during pre‑monsoon humidity spikes.

Industry success factors and customer testimonials for High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters

Winning in Pakistan’s industrial PV segment means passing certification quickly, shipping lighter enclosures that install fast, and ensuring the inverter holds its rating when inlet temperatures push 50°C. Sicarbtech’s High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters consistently deliver across these vectors. As one Lahore‑based EPC technical lead noted after back‑to‑back factory acceptance tests, “The SiC half‑bridge platform cleared EMC in the first round, which saved us weeks and preserved our cashflow.” That kind of predictability is precisely why Sicarbtech’s modules are gaining share among regional OEMs.

Future innovations and market trends surrounding High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters

Looking ahead to 2025 and beyond, Pakistan’s tenders are drifting toward stricter power‑quality metrics, tighter thermal envelopes, and preference for localized assembly. High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters will increasingly integrate enhanced current‑sensing linearity, improved short‑circuit withstand times, and even lower temperature‑coefficient RDS(on). On the manufacturing side, Sicarbtech’s technology transfer frameworks will support Pakistani partners in setting up silver‑sinter capable lines and reliability test stations, shortening lead times and insulating project budgets from currency swings.

Common questions and expert answers on High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters

How do High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters improve EMC performance?

Lower loop inductance reduces voltage overshoot and ringing at each transition, which curbs high‑frequency emissions at their source. With properly tuned gate resistance and Kelvin source connections, many designs meet IEC 61000‑6‑4 limits with modest filter sizes.

Are High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters suitable for 1500 V DC strings?

Yes. Paired with 1700 V devices and appropriate creepage and clearance, the modules are designed for 1500 V platforms common in Pakistan’s C&I projects. Sicarbtech supports design reviews to ensure pollution degree and insulation coordination are met.

What efficiency gains can Pakistani OEMs expect from High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters?

Typical gains are 0.5–1.0 percentage points in peak efficiency and 0.3–0.8 points in European efficiency, with noticeable reductions in heat sink size and fan count, especially at 50°C inlet air.

How do High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters handle weak‑grid events?

Fast switching and low parasitics enable rapid control response. Soft turn‑off and active clamping protect devices during faults, while temperature sensing supports smart derating, improving LVRT and reactive power behavior on feeders with low short‑circuit capacity.

Can High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters reduce O&M?

By shrinking heat sinks and halving fans in many cases, the modules lower dust‑related maintenance and acoustic noise. The improved thermal path and sensing reduce failure rates, extending service intervals.

Why High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters work for your operations

Pakistan’s industrial PV deployments must function at full output during the hottest, dustiest hours—exactly when conventional designs struggle. High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters transform this challenge into an advantage, creating compact, efficient inverters that ride through disturbances and keep installation and O&M lean. When device capability, packaging, and busbar design are orchestrated, the inverter behaves predictably across seasons and sites.

Połącz się ze specjalistami, aby uzyskać niestandardowe rozwiązania

Sicarbtech stands behind High‑Power‑Density Silicon Carbide Half‑Bridge Power Modules with Low Parasitic Inductance for 50–250 kW String Inverters with over 10 years of silicon carbide manufacturing expertise, anchored by the Chinese Academy of Sciences collaboration in Weifang. For Pakistani OEMs and EPCs, this means rapid prototyping of custom module footprints, guidance on stacked DC busbars, and access to technology transfer and factory establishment services. From R‑SiC, SSiC, RBSiC, and SiSiC materials to complete module assembly and reliability testing, Sicarbtech offers turnkey solutions validated with 19+ enterprise partners.

Engage our engineering team for a free consultation and a tailored roadmap that aligns with your 1000/1500 V designs, EMC targets, and PKR budget realities. Email [email protected] or call/WhatsApp +86 133 6536 0038. With 2025 tender cycles tightening, moving now secures your certification timeline and field performance.

Metadane artykułu

Last updated: 2025‑09‑16

Next scheduled review: 2025‑12‑01

Timeliness indicators: Reflects Pakistan’s 1500 V string inverter shift, NEPRA/IEC/IEEE‑519 alignment, and 2024–2025 field data on efficiency, thermal stability, and EMC performance.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.