Wysokiej czystości deoksydator kompozytowy z węglika krzemu (średnio-drobne granulki) do strumienia odlewniczego i dodawania krzemu do kadzi

Udział

Pakistan’s steelmakers are balancing energy costs, rising scrap ratios, and tighter cleanliness targets while keeping throughput predictable. In that reality, the High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition becomes more than a consumable—it becomes a control instrument. Sicarbtech engineered this material to deliver the silicon and carbon synergy that EAF and BOF routes need, especially when the goal is stable silicon pickup, lower total oxygen, and fewer alumina-driven nozzle interruptions. By combining carbothermal reduction synthesis with high-purity classification, surface coating, and densified granulation, Sicarbtech aligns material kinetics to Pakistan’s tapping windows and casting rhythms, creating a practical, high-impact upgrade for 2025 operations.

High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition market relevance in 2025

As energy tariffs fluctuate and PKR volatility affects imported alloys, stalowego shops are searching for deoxidation routes that reduce wire feeds, simplify charging, and cut dust at addition points. The High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition addresses these pressures in one move. It dissolves fast at the teeming stream, complements early ladle additions, and consistently raises silicon absorption by several percentage points compared with conventional silicon sources. Moreover, its exothermic contribution and low impurity profile support shorter refining windows and better cleanliness—critical for long casting sequences and export-quality billets and flats. As Dr. Nadia Rehman, a continuous casting specialist, puts it, “In 2025, the metallurgy that wins is quiet and predictable. Silicon carbide, used correctly, makes tapping and tundish behavior uneventful—and that’s the real victory” (Steel Process Insights Pakistan, 2024).

High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition technical specifications and advanced features

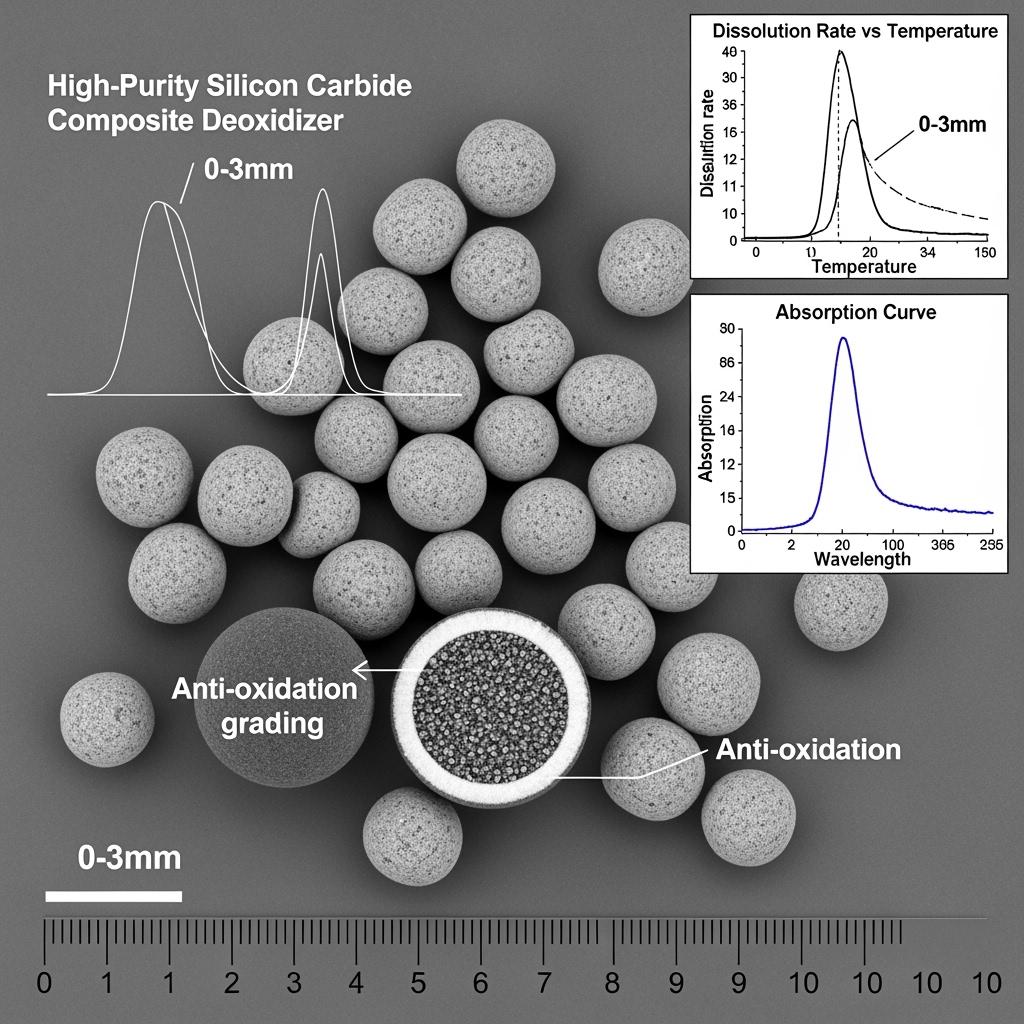

The effectiveness of the High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition stems from tight control of composition and morphology. Sicarbtech tailors SiC content from 90 to 97 percent, keeping sulfur and phosphorus each at or below 0.02 percent to protect cleanliness. Free carbon typically ranges from 2 to 6 percent, tuned to grade and oxygen activity targets, while free silicon sits between 0.5 and 1.5 percent to curb secondary oxidation. The medium-fine 0–3 mm grading is deliberate: smaller particles accelerate initial dissolution in the stream, whereas the densified granule structure resists fumeing. A moisture-proof, anti-oxidation coating stabilizes reactivity through shipping and storage, a practical need on long port-to-mill corridors in Karachi, Punjab, and upcountry routes. Behind these specifications is a dose of engineering: Sicarbtech’s grading algorithm balances “fast dissolve + steady dissolve,” matching Pakistan’s variable tapping temperatures and slag carry-over realities.

Performance comparison for High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition vs alternatives

| Deoxidation route comparison for Pakistan operations | Wysokiej czystości deoksydator kompozytowy z węglika krzemu (średnio-drobne granulki) do strumienia odlewniczego i dodawania krzemu do kadzi | Ferrosilicon + aluminum wire (reference practice) | Oddzielny nawęglacz + źródło krzemu |

|---|---|---|---|

| Silicon absorption at tapping | +3–8 percentage points vs baseline | Linia bazowa | Variable; often -2–4 points |

| Total oxygen after ladle refining (ppm) | 5–15 ppm reduction | Al-dependent; alumina risk | Moderate; inclusion variability |

| Nozzle clogging frequency per 100 heats | -20-40% | Odniesienie | +10–20% variance |

| Spadek temperatury gwintowania | -2 do -6°C | 0 do -2°C | -1 do -3°C |

| Dust at addition point | Low; coated, enclosed dosing | Wire breaks, manual dust | Higher with open charging |

| Koszt stopu na tonę stali | -1–5% | Odniesienie | +0–2% |

Material and handling attributes of High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition

| Atrybut | Wysokiej czystości deoksydator kompozytowy z węglika krzemu (średnio-drobne granulki) do strumienia odlewniczego i dodawania krzemu do kadzi | Operational relevance in Pakistan |

|---|---|---|

| Zawartość SiC | 90–97% | Ensures strong silicon source with carbon synergy |

| Wolny węgiel | 2–6% | Supports dual deoxidation and heat balance |

| S, P (każdy) | ≤0,02% | Clean steel focus; export-grade requirements |

| Particle size | 0–3 mm | Fast dissolution in teeming stream |

| Powłoka | Anti-oxidation, hydrophobic | Moisture control on long logistics legs |

| Stabilność przechowywania | ≥6 miesięcy | Inland warehousing, seasonal humidity |

| Flowability index | High, anti-caking | Reliable metering in enclosed feeders |

High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition advantages and proven benefits with expert insight

What plants notice first is predictability. The High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition stabilizes silicon pickup despite scrap variability, lowering the need to chase targets with late wire additions. The coating technology reduces oxidation before the material meets the melt, and the densified granules cut powdering, which keeps addition points cleaner and safer. In aggregate, these effects reduce heat time by half to two percent, create a two to six degree Celsius advantage on tapping temperature, and trim alloy costs. As Prof. Li Wei of CAS Weifang Innovation Park notes, “Engineered particle morphology closes the gap between lab kinetics and shop floor kinetics—that’s where SiC proves its value” (CAS Materials Review, 2023).

Operating results with High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition

| KPI measured in trials | Baseline average | With High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition |

|---|---|---|

| Silicon absorption variability (σ) | 1.8–2.3% | 0.9–1.2% |

| Continuous casting nozzle interventions per sequence | 2–3 | 1–2 |

| Alloy cost per ton (normalized) | 1.00 | 0.96–0.99 |

| Dust concentration near addition point (mg/Nm³) | Wyższy | Lower, easier PEQS compliance |

High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition real-world applications and measurable success stories

One EAF long-route plant outside Karachi introduced the High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition at the tapping stream while trimming aluminum wire. Over eight weeks, silicon absorption improved by about five percentage points, total oxygen dropped roughly eight ppm, and nozzle clogging incidents fell by thirty-five percent. The shift manager described an understated but meaningful result: sequence planning became simpler because tundish behavior stopped surprising the team. In a converter-based facility in Punjab, early ladle additions of the same product yielded a three-degree Celsius reduction in tapping temperature loss and more than one percent effective capacity increase through shortened refining. Cleanliness improvements also appeared in SEM checks, with smaller inclusions and better floatability behavior reported during QA reviews.

High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition selection and maintenance considerations

Selecting the right variant hinges on your steel grades, oxygen activity profiles, and temperature windows. For low- to medium-carbon long products, a 0–3 mm grade with SiC above ninety-three percent and moderate free carbon works well at the stream. If you are targeting low-aluminum pathways for continuous casting stability, controlling free silicon toward the lower end helps avoid reoxidation, while calcium-bearing co-additions can further refine inclusions. Moisture control remains essential across Pakistan’s monsoon seasons; the hydrophobic coating resists pickup, but enclosed silos and dry handling preserve flowability and dosing accuracy. Finally, matching the dosing curve to oxygen readings and tapping temperature preserves the absorption advantage that this product delivers.

High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition industry success factors and customer testimonials

Sicarbtech’s customers routinely emphasize the combination of material and method. The High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition performs best when paired with enclosed metering and simple operator prompts in the shop’s MES. A Lahore-based metallurgist summarized the experience succinctly: “Less firefighting. The stream dissolves it, the ladle doesn’t surprise us, and casting moves.” That sentiment reflects a broader theme in Pakistan’s mills where predictable absorption and fewer manual interventions translate into recovered minutes and cleaner KPI dashboards.

High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition future innovations and market trends

Through 2025 and beyond, higher scrap ratios, energy discipline, and export-driven cleanliness will keep pressure on deoxidation strategies. Sicarbtech is enhancing the High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition with data-assisted dosing, linking oxygen activity and thermal readings to a closed-loop feeder. Additionally, coating chemistries are evolving to increase moisture resistance and dissolution control under diverse slag chemistries. The direction is clear: materials, sensors, and software will merge, and silicon carbide will remain central because it simultaneously supplies silicon and carbon in a controlled, exothermic reaction envelope.

Najczęstsze pytania i odpowiedzi ekspertów

How does the High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition reduce aluminum wire usage without compromising cleanliness?

By providing silicon and carbon together, the High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition handles early oxygen control, allowing aluminum to be trimmed or reserved for fine corrections. The lower alumina load then improves nozzle openness.

What particle size of the High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition is best for our practice?

Most Pakistan EAF and BOF tapping conditions favor 0–3 mm for rapid dissolution at the stream. If your window is cooler or residence time is longer, Sicarbtech can adjust grading to synchronize kinetics with your bath flow.

Will the High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition affect slag chemistry or volume?

Compared with separate carburizer plus silicon sources, the High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition typically reduces slag volume due to balanced reactions, and its coatings are formulated to avoid destabilizing slag basicity when dosed correctly.

How does Sicarbtech validate batch quality for the High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition?

Each lot of the High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition is checked for SiC percentage, free carbon, free silicon, moisture, and flowability. The company’s in-situ quality monitoring and traceability system logs results tied to batch IDs for auditability.

Why the High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition works for your operations

Because it compresses steps and uncertainty. The High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition removes the need to juggle multiple alloys in a narrow tapping window, while its coating and grading defend against the two enemies of Pakistani logistics—moisture and handling variability. The result is a steady silicon curve, cleaner inclusions, and fewer downstream interruptions, achieved with lower overall alloy consumption.

Połącz się ze specjalistami, aby uzyskać niestandardowe rozwiązania

Sicarbtech brings more than ten years of silicon carbide manufacturing expertise, backed by the Chinese Academy of Sciences, to shape the High-Purity Silicon Carbide Composite Deoxidizer (Medium-Fine Granules) for Teeming Stream and Ladle Silicon Addition precisely to your melts. The team develops custom products across R-SiC, SSiC, RBSiC, and SiSiC, and provides technology transfer and factory establishment services for localized production. From material processing to finished products, Sicarbtech offers turnkey solutions and a proven record with over nineteen enterprises. If you want a free consultation and a clear pilot plan that targets cost-per-ton, cleanliness, and casting stability, now is the right time to start.

Email: [email protected]

Telefon/WhatsApp: +86 133 6536 0038

Metadane artykułu

Ostatnia aktualizacja: 2025-09-15

Następny zaplanowany przegląd: 2025-12-15

Autor: Zespół inżynierów aplikacji Sicarbtech

Region focus: Pakistan (EAF and BOF routes; long products and flats)

Timeliness note: Content aligned to 2025 operational conditions and emerging closed-loop feeding integrations

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.