Porous Silicon Carbide Thermal-Insulation Solutions for High-Temperature Equipment: Sicarbtech’s 2025 Pillar Guide for Pakistan

Udział

Pakistan’s stalowego, cement, glass, and adjacent sectors are entering 2025 with a common agenda: reduce fuel intensity, stabilize temperatures, and accelerate decarbonization—without sacrificing uptime. The insulation system is where these goals converge. Conventional lightweight bricks and fiber products have carried plants for decades, yet they struggle in dust-laden, alkali–sulfur atmospheres and under rapid start–stop cycles. Porous silicon carbide (SiC), engineered with controllable pore architecture, functionally graded layers, anti-fouling surfaces, and edge sealing, offers a credible, field-proven step change. Sicarbtech—based in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—has spent over a decade turning advanced SiC into auditable capability. For Pakistani plants, that means energy savings, lower shell temperatures, faster heat-up, and fewer rebuilds—supported by localizable equipment and ISO/PSQCA-aligned quality systems.

Executive Summary: 2025 Outlook and Why Porous SiC Insulation Matters in Pakistan

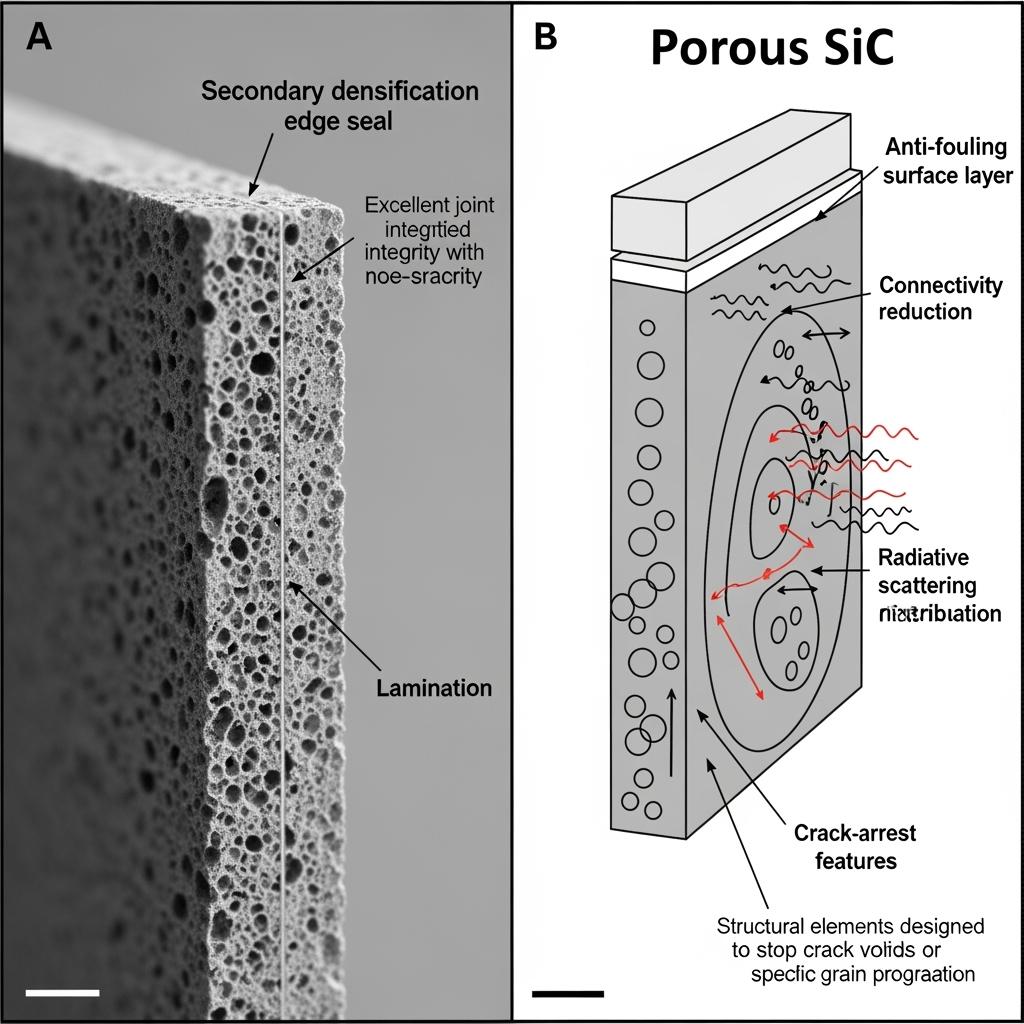

Energy and emissions targets are sharpening capital priorities across Pakistan’s high-temperature assets—from reheating and annealing furnaces to rotary kilns, preheaters, waste-heat boilers, and hot flues. Insulation retrofits are delivering some of the fastest paybacks on the table, especially where shell temperatures and heat losses remain stubborn. Porous SiC brings the physics that matter: low thermal conductivity via optimized pore-size distributions and radiation scattering; low bulk density with high specific strength; and a chemically resilient SiC skeleton that resists alkali dust, chlorides, sulfides, and steam. When combined with functionally graded layers, anti-dust/anti-wetting surfaces, secondary densification edge sealing, and quick-install modules, porous SiC cuts conductive and radiative losses, lowers shell temperature, shortens heat-up, and survives cycling far better than conventional insulators. Sicarbtech connects these materials with production discipline—multi-zone reaction sintering/carburation, controllable atmospheres, pore-former dispersion, and digital QA—so Pakistani plants can bank on measurable, auditable improvement.

Industry Challenges and Pain Points: The Insulation Reality on Pakistani Lines

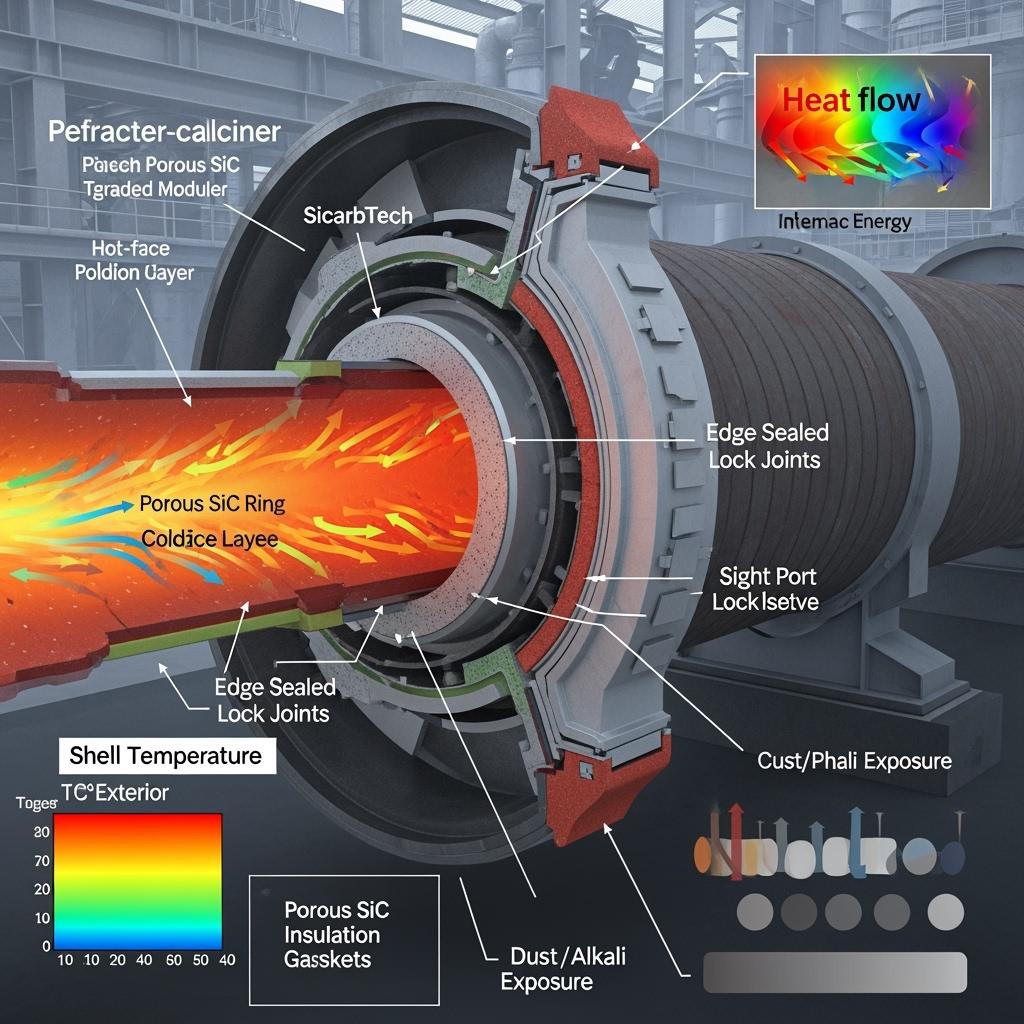

Walk the flank of a rotary kiln during a summer afternoon and you can feel the inefficiency. Hot shell temperatures radiate away fuel value, while hotspots betray missing or degraded insulation. In preheaters and risers, dust-laden, alkali-bearing gases attack conventional lightweight bricks and fibers, accelerating shrinkage, chalking, and fiber drop. Moisture and dust uptake raise effective conductivity over months, erasing early gains. In roller-hearth and annealing furnaces, frequent start–stop cycles and rapid ramps inflict thermal shock on backup layers; an unnoticed spall or gap becomes a cold spot, inviting leaks and infiltration that destabilize temperature uniformity and increase fuel demand.

Pakistan’s operating realities amplify these stresses. Alternative fuels and raw mix variability change gas chemistry and dust morphology, challenging materials calibrated for steadier atmospheres. Monsoon humidity and cooling nights complicate installation and cure behavior; rushed windows lead to residual moisture, which spikes conductivity and undermines adhesion. Maintenance budgets chase recurring insulation failures, while FX volatility and lead-time uncertainty push teams to compromise on material choice or installation thoroughness. “We turned down the burner curve to hit efficiency targets, then the shell temperature crept back up,” a Lahore-based kiln reliability engineer recalled in 2024. “Dust and alkali attacked our lightweight layer faster than planned; we were fighting a losing slope.”

Regulators and customers are also changing the conversation. Procurement frameworks in 2025 are explicitly valuing thermal conductivity, strength-to-weight, shell-temperature control, and corrosion life—backed by ISO 9001 documentation, PSQCA conformity, and ISO 14001-aligned environmental records. Energy audits now ask for demonstrable reductions in shell temperature and modeled fuel savings tied to verified thermal properties. As a regional energy efficiency advisor put it: “You cannot manage what you cannot prove. Thermal conductivity, moisture resistance, and alkali-dust survivability need data, not promises.” In this context, porous SiC insulation becomes less a commodity and more a system—materials, surfaces, edge sealing, joints, and installation playbooks—designed to perform under Pakistan’s specific constraints.

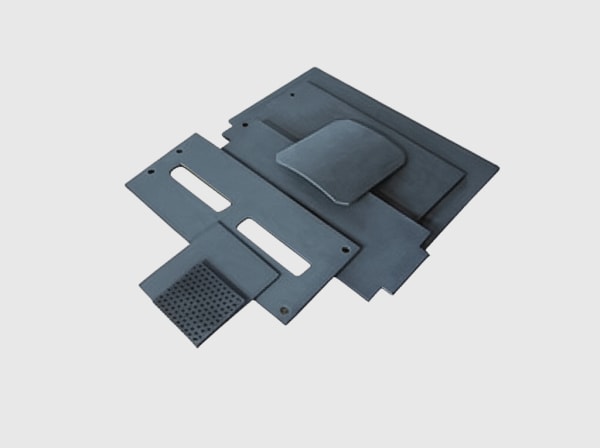

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

Sicarbtech’s porous SiC portfolio is architected to attack heat loss and degradation at their roots. Low-thermal-conductivity porous SiC insulation plates serve as robust backup layers behind hot-face refractories, pairing low k-values with dimensional stability. Functionally graded laminated modules put corrosion-resistant, radiation-scattering hot-face layers over strengthened cold-face layers to balance insulation with load-bearing. High-strength lightweight bricks, tuned for hot-air ducts and flues, deliver stiffness at low mass where vibration and mechanical loads matter.

In alkali-heavy zones, porous SiC blocks with anti-dust and anti-corrosion surfaces resist chemical attack and prevent chalking. Burner-area rings made from thermal-shock-resistant porous SiC tolerate rapid ramps, while sight-port plugs and door sleeves reduce heat leakage and survive repeated handling. On equipment interfaces, porous SiC insulation gaskets for flanges and expansion joints combine sealing with low thermal bridging. Interlayers for waste-heat boilers and flue ducts add low k-values without collapsing under dust abrasion. For sensitive zones, porous SiC around thermocouple sheaths minimizes conduction and environmental ingress, stabilizing readings.

Surface engineering and edge sealing extend life. Anti-wetting, anti-fouling treatments cut dust adhesion and moisture uptake, preserving low conductivity; secondary densification edge sealing suppresses chalking and protects joints. For complex geometries, custom curved and ring-shaped specials match rotary kiln arcs and transitions, while porous SiC honeycomb/ribbed structures raise specific stiffness. Quick-install lock-type modules shave days off retrofits and simplify future replacements.

This materials stack is powered by a complete manufacturing toolkit: multi-zone reaction sintering/carburation with controllable atmospheres (oxygen/nitrogen/carbon-source/steam), cold isostatic and die-press forming for porous green bodies, intelligent mixing and pore-former dispersion for pore architecture control, impregnation densification and edge-sealing equipment, precision cutting and curved-surface machining lines, and online thermal-physical property testing—conductivity, specific heat, dilatometry—backed by NDT and dimensional metrology.

Comparative Insulation Performance for High-Temperature Retrofits

| Performance profile in insulation and energy-saving retrofits | Sicarbtech Porous SiC (graded + anti-fouling + edge-sealed) | Lightweight Clay/High-Alumina Brick | Ceramic Fiber Blanket/Board | Calcium Silicate Board |

|---|---|---|---|---|

| Thermal conductivity at RT (W/m·K) | 0.25–2.0 (by density) | 0.6–1.8 | 0.04–0.15 (initial) | 0.06–0.2 |

| Thermal conductivity at 800–1200°C (W/m·K) | 0.45–2.8 | 1.0–3.0 | 0.12–0.35 (rises with dust/moisture) | 0.2–0.5 |

| Bulk density (g/cm³) | 0.60–1.45 | 0.8–1.6 | 0.08–0.2 | 0.2–0.5 |

| Thermal-shock stability (cycles, 1000°C quench) | 40–120 | 10–40 | 20–60 | 10–30 |

| Alkali–sulfur corrosion resistance | Wysoki | Umiarkowany | Niski-umiarkowany | Niski-umiarkowany |

| Dimensional stability at high T | Wysoki | Umiarkowany | Lower (shrink/chalking risk) | Umiarkowany |

| Moisture/dust uptake | Low with surface engineering | Umiarkowany | Wysoki | Umiarkowany |

| Installation speed (modular systems) | High (lock-type modules) | Umiarkowany | High (but fragile at high T) | Umiarkowany |

For Pakistan’s alkali-laden, dust-heavy, cyclic environments, porous SiC anchors a durable, low-conductivity backbone that keeps k-values low over time rather than only on day one.

Real-World Applications and Success Stories in Pakistan

A cement plant in northern Punjab targeted lower shell temperatures at a preheater riser–calciner junction notorious for alkali dust attack. The retrofit combined functionally graded porous SiC laminated modules, an anti-fouling hot-face, and edge-sealed lock modules tailored to expansion and joint geometry. Quick-install procedures compressed the window, and IR thermography baselines were captured before and after. Over twelve months, shell temperature fell by roughly 22°C, equivalent thermal conductivity dropped by about 31%, heat-up time shortened by approximately 18%, alkali-atmosphere mass-loss rates fell by around 44%, annual fuel per ton decreased by about 2.9%, and unplanned insulation-related downtime declined by roughly 27%. “We expected better k-values,” the energy manager said. “The real win was how the numbers stayed stable through monsoon and dust spikes.”

At a steel annealing furnace near Karachi, porous SiC door and sight-port sleeves cut leakage and survived repeated cycles. Operators reported fewer hot spots at seals and improved safety around access points. In a glass plant on the outskirts of Lahore, porous SiC interlayers in flue ducts reduced temperature gradients and enabled tighter control of waste-heat boiler inlet conditions, supporting a more consistent electricity export profile.

Zalety techniczne i korzyści z wdrożenia z lokalną zgodnością

Porous SiC’s advantage starts with heat-transfer physics. Conductive losses fall with low solid pathways, while radiative transfer is damped by scattering along controlled pores—both preserved by anti-fouling surfaces that resist moisture and dust. The SiC skeleton’s low CTE and high thermal conductivity help bleed localized spikes and survive thermal shock, while chemical resilience handles alkali and sulfur exposure that undermines conventional insulators. Functionally graded layers and edge sealing stabilize joints and corners, where failures often begin. Together, these properties lower shell temperature and heat loss, shorten heat-up, and deliver longer intervals between interventions.

Compliance follows naturally. Lower fuel and fewer emergency repairs align with ISO 14001 goals; Sicarbtech’s QA packs—pore architecture, conductivity vs temperature, strength, thermal shock, moisture uptake, corrosion mass loss, dimensional checks—align with ISO 9001 and support PSQCA submissions. Safety improves as lock-type modules shorten time at heat and as door/sight-port sleeves reduce leakage and personnel exposure. The result is an insulation upgrade that performs technically and audits credibly.

Pakistan-Focused Technical Specifications and QA Guidance

| Specification ranges for porous SiC insulation | Typical Sicarbtech Targets | Local QA and testing guidance |

|---|---|---|

| Bulk density (g/cm³) | 0.60–1.45 | Density mapping by module; SPC |

| Open porosity (%) | 45–80 (controlled connectivity) | MIP/Archimedes; pore-size analysis |

| Pore-size distribution (μm) | 5–500 (single/multi-peak) | Image analysis; PSD certificates |

| Thermal conductivity RT (W/m·K) | 0.25–2.0 | Guarded hot plate/laser flash |

| Thermal conductivity at 800–1200°C (W/m·K) | 0.45–2.8 | High-temp LFA; trend vs dusting |

| Flexural strength (MPa) | 4–18 | 3/4-point bend; retained samples |

| Cold crushing strength (MPa) | 12–65 | Standard blocks per batch |

| CTE (×10⁻⁶/K) | 3.8–4.6 | Dilatometry; joint design input |

| Thermal shock (cycles, 1000°C quench) | 40–120 | Cross-check with ramp schedule |

| Water absorption (%) | ≤ 5–18 (lower after surface engineering) | Gravimetric; humidity exposure |

| Surface roughness Ra (μm) | ≤ 1.6 (≤ 0.8 optional) | Stylus/optical profilometry |

| Alkali–dust mass loss (%) | −30–60 vs reference | Lab corrosion tests; field logs |

Operational Outcomes Comparison That Shift Energy, Uptime, and Safety

| Outcome essential to Pakistani heat-intensive lines | Sicarbtech Porous SiC (graded, anti-fouling, edge-sealed) | Lightweight Brick/Fiber/Calcium Silicate |

|---|---|---|

| Shell temperature reduction | 15–40°C typical | Lower and less stable over time |

| Heat-up time | −10–25% | Variable; slows as materials age |

| Thermal-shock spall risk | Much lower | Higher under start–stop |

| Corrosion/alkali aging | Resistant; slower k drift | Faster degradation |

| Interwał konserwacji | 1.5–3.0× longer | Short; frequent patching |

| Nieplanowane przestoje | −20–40% | Higher; gap/leak repairs |

| Safety exposure at heat | Reduced via quick-install | Higher; longer hot work |

| Energy per ton | −2–5% | Flat or worsening with age |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s competitive edge is converting porous SiC from specification to local capability. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, we offer proprietary routes for R-SiC, SSiC, RBSiC, and SiSiC porous bodies and transfer them through complete, auditable packages.

We begin with feasibility and design. Pore architecture—porosity, pore-size distribution, and connectivity—is mapped to temperature zones, atmospheres, dust loads, and mechanical requirements. Functionally graded laminations define hot-face/cold-face roles; anti-fouling surfaces and edge sealing are configured by chemistry and joint geometry. Equipment specifications include multi-zone reaction sintering/carburation kilns with controllable atmospheres (oxygen/nitrogen/carbon-source/steam), cold isostatic and die-press forming lines for porous green bodies, intelligent powder mixing and pore-former dispersion systems, impregnation densification and edge-sealing units, precision cutting/curved-surface machining for specials, and online thermal-physical testing (conductivity, specific heat, dilatometry).

Quality systems are embedded from day one. We implement ISO 9001-aligned QC plans with SPC on pore architecture, conductivity vs temperature, mechanicals, thermal shock, moisture uptake, corrosion mass loss, and geometry; ISO 14001 environmental practices; and safety SOPs aligned with ISO 45001. Training programs cover substrate preparation, moisture control, module numbering and joint sealing, lock-module installation, bake-out and equalization curves, IR thermography baselining, and inspection routines. Commissioning uses DOE trials to confirm conductivity under humidity/dust exposure, verify joint durability under cycling, and optimize bake-out curves to prevent shock.

Factory establishment services tie together layout, utilities (gas handling, off-gas, power, cooling), and safety systems (interlocks, detection, purge protocols). Quarterly audits track k-value drift, shell and IR maps, and maintenance intervals; corrective actions include touch-up anti-fouling coatings and re-densification at edges. Across 19+ enterprise collaborations, this “materials + equipment + process + training” methodology has delivered durable energy savings, fewer hot repairs, and stable properties across monsoon seasons—outcomes that procurement teams can price and auditors can verify.

“Insulation performance is not declared—it is measured and preserved,” a Sicarbtech technical director said. “Control the pores, protect the edges, stabilize the surface, and prove it with data. That is the difference between a promise and a program.”

Comparative Design Elements That Turn Specs into Lasting Insulation Gains

| Design and execution element | Sicarbtech Porous SiC System | Conventional Insulation Approach |

|---|---|---|

| Pore architecture | Controlled PSD and connectivity for low k and scattering | Coarse control; aging-sensitive |

| Layering | Functionally graded hot/cold-face laminations | Single layer; generic |

| Surface behavior | Anti-fouling, anti-moisture coatings | Uncoated; k drifts upward |

| Edge and joint design | Secondary densification edge sealing; lock modules | Simple butt joints; gaps |

| Geometry | Curved/ring specials; honeycomb/ribbed stiffness | Flat stock; field cuts |

| Installation | Quick-install lock modules; numbered kits | Time-consuming fit-up |

| Digital QA | Conductivity/LFA, MIP/PSD, dilatometry, IR baselines | Visual checks; limited tests |

Innovation That Matters: Pore Control, Edge Sealing, and Surface Stability

Sicarbtech’s R&D focuses on three levers with the highest lifecycle impact. First, controllable pore architecture reduces both conductive and radiative components of heat transfer and keeps them low over time. Second, edge sealing through secondary densification stabilizes joints and prevents chalking, the most common failure origin. Third, anti-wetting, anti-fouling surfaces preserve low k by resisting moisture and dust, especially through monsoon swings and alkali-laden conditions. These are reinforced by functionally graded laminations and lightweight ribbed structures that deliver stiffness at low density, turning insulation into a structural asset, not a consumable.

Future Market Opportunities and 2025+ Trends in Pakistan

Three trends will accelerate adoption. Energy and carbon mandates are pushing measurable, auditable retrofits; porous SiC’s stable k-values and shell-temperature reductions offer defensible ROI. Waste-heat utilization and thermal networks are expanding across cement and steel, raising the bar for corrosion-resistant, low-degradation insulators. Finally, localization is becoming a procurement criterion; providers that transfer not just materials but also pore control, edge sealing, surface engineering, and digital QA will win on both performance and availability.

In scale terms, a 3,000–7,000 t/d clinker line or a medium-to-large reheating/annealing line typically needs 200–1200 m² of porous SiC components annually (about 10–80 tons), depending on duty and retrofit depth. Nationally, new builds and energy retrofits imply several hundred to over a thousand tons per year; adding design, machining, installation, and inspection services, the addressable market sits in the tens to hundreds of millions of Pakistani Rupees. Sicarbtech’s integrated platform—materials, equipment, process, and QA—positions Pakistani operators to capture these gains predictably.

As a regional energy-efficiency specialist remarked at a 2025 seminar, “When the k-value holds through the rainy season and the shell stops glowing, you know your fuel and your schedule are finally on the same side.”

Często zadawane pytania

Which porous SiC components should we prioritize for the biggest energy impact?

Start with functionally graded porous SiC backup modules in the hottest, most alkali-exposed zones—preheater risers, calciner junctions, burner surrounds, and rotary kiln transitions. Add edge-sealed lock modules at complex joints and porous SiC sleeves at doors and sight ports to stop leakage.

How much energy saving and shell-temperature reduction are realistic?

Typical retrofits deliver 15–40°C shell-temperature reductions and 2–5% fuel-per-ton savings, with 10–25% shorter heat-up times. Plants with severe alkali dust or moisture issues often see larger, more durable gains thanks to anti-fouling surfaces and edge sealing.

Can Sicarbtech localize porous SiC production and finishing in Pakistan?

Yes. We provide equipment specifications and process know-how for pore-former dispersion, porous forming, multi-zone sintering/carburation with atmosphere control, edge sealing, and surface engineering. Many partners start with cutting/curved machining and installation, then phase into sintering and impregnation as volumes grow.

How do porous SiC modules handle monsoon humidity and dust?

Anti-wetting coatings and sealed pore connectivity reduce moisture uptake, limiting k-value drift. Installation SOPs include moisture checks, controlled bake-out, and IR baselining. Anti-fouling surfaces resist dust adhesion, keeping conductivity low between cleanings.

What installation practices avoid gaps, chalking, and early failure?

Prepare clean, dry substrates; follow numbered module layouts; apply joint sealants and mechanical stops; use lock-type modules and edge sealing at transitions; and run staged heat-up and equalization curves. Record IR maps and shell temperatures for post-install benchmarks.

Which KPIs should we track to validate and sustain benefits?

Track shell temperature and IR hotspot maps, effective k-value estimates, fuel per ton, heat-up times, moisture and dust uptake indicators, corrosion mass-loss tests, and maintenance intervals. Link these to batch QA—pore architecture, conductivity, strength—and installation records.

Are porous SiC gaskets and joints compatible with our flanges and expansion joints?

Yes. We adapt thickness, density, and compressive strength to your loads and temperatures, with CTE compatibility checks. Sealing faces are machined for flatness, and torque specs are provided for reliable, low-leak joints.

How often should anti-fouling and edge-sealing treatments be refreshed?

Intervals depend on atmosphere and dust chemistry. We recommend inspection during planned outages; refresh anti-fouling surfaces and re-densify edges where contact angle and surface integrity drift beyond thresholds.

What documentation supports Pakistani tenders and audits?

We supply ISO 9001-aligned QC packs—pore architecture (PSD/connectivity), conductivity vs temperature, CCS/MOR, thermal shock, CTE, moisture uptake, alkali-dust mass loss, and dimensional certificates—alongside PSQCA conformity support and ISO 14001 environmental records.

What is a pragmatic roadmap to full capability?

Phase 1: deploy porous SiC modules with local installation training and digital QA. Phase 2: localize cutting/curved machining, edge sealing, and surface treatments. Phase 3: commission porous forming and sintering/carburation lines with atmosphere control, backed by operator training and SPC analytics.

Dokonywanie właściwego wyboru dla swoich operacji

If shell temperatures keep glowing, if IR maps trace the same hotspots after every outage, and if insulation failures are writing your maintenance calendar, it is time to change the material and the method. Porous silicon carbide—engineered with controlled pores, graded layers, anti-fouling surfaces, and edge sealing—reduces heat loss and survives the chemistry and cycling that defeat conventional options. With Sicarbtech, you are not just buying panels; you are adopting a documented, trainable capability that converts energy targets into operating reality.

Konsultacje ekspertów i niestandardowe rozwiązania

Share your operating envelope—temperature profiles, fuel and flue-gas chemistry, dust load and velocity, start–stop cadence, shell-temperature and IR maps, geometry and joint details—and Sicarbtech will design a tailored porous SiC system. We will specify pore architecture and grading, surface and edge treatments, module geometry and lock design, installation and bake-out curves, and a monitoring plan. If localization is your aim, we will map a phased technology transfer—from finishing and edge sealing to full porous forming and sintering—aligned with your CAPEX and schedule.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

Email: [email protected]

Telefon/WhatsApp: +86 133 6536 0038

Metadane artykułu

Last updated: 2025-09-19

Następna planowana aktualizacja: 2026-01-15

Content freshness indicators: 2025 Pakistan insulation retrofit outlook validated; porous SiC technical ranges aligned with current deployments; PSQCA/ISO alignment reviewed; contact details verified for Pakistan engagements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.