Stopnie mocy z węglika krzemu dla systemów prostowania elektrolitycznego o sprawności >98% i wysokiej gęstości prądu

Udział

Przegląd produktów i znaczenie dla rynku w 2025 r.

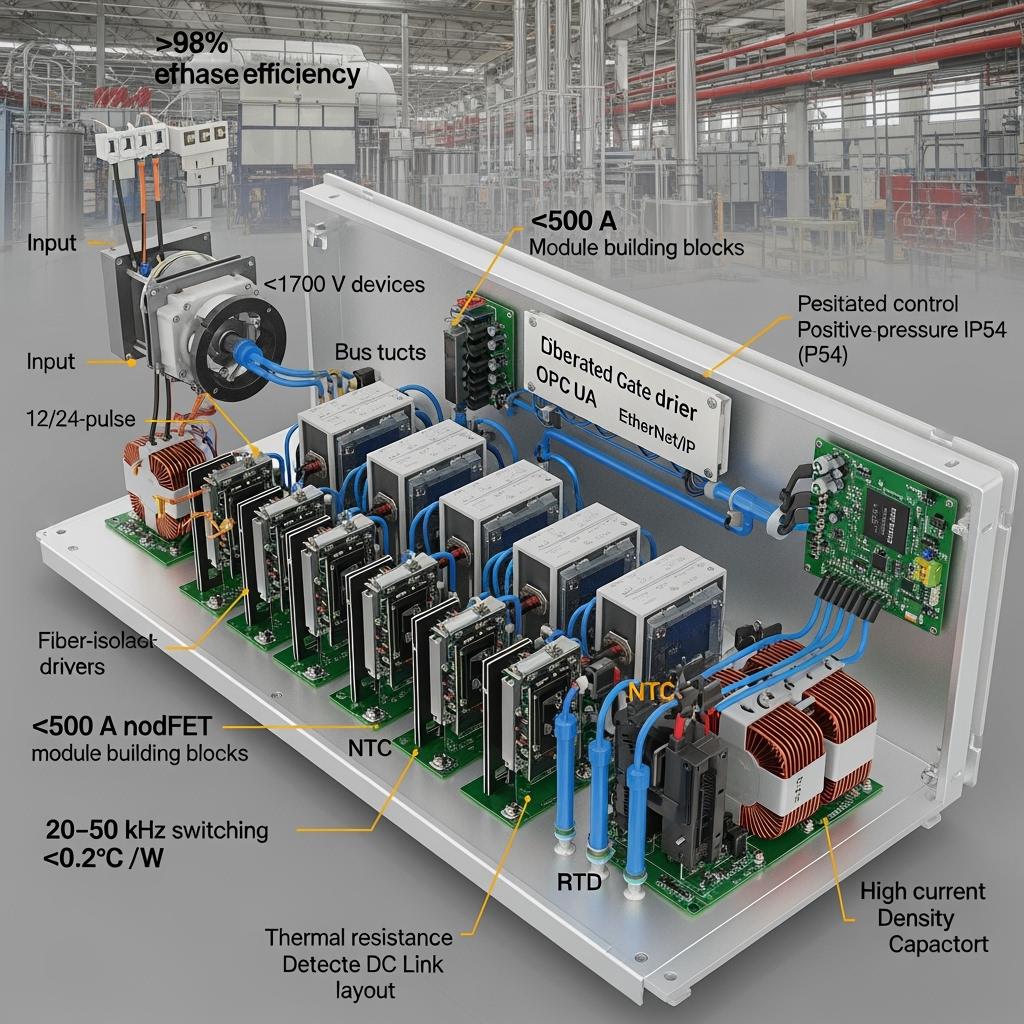

Silicon carbide (SiC) power stages engineered for electrolytic rectification deliver >98% efficiency, high current density, and robust thermal margins for Pakistan’s textile, cement, stalowego, and emerging industrial sectors. These power stages integrate SiC high-power Schottky diodes, SiC MOSFET bridges or active front ends (AFE), high-thermal-conductivity ceramic substrates, and modular cooling systems to support continuous heavy-duty operation with minimal downtime.

In 2025, producers in Punjab and Sindh face grid volatility, rising electricity tariffs, and aging rectifier assets. SiC power stages address these constraints by enabling 20–50 kHz operation, stable performance at junction temperatures up to 175°C, and compact thermal designs that reduce cooling infrastructure by 30%–40%. Plants report 10%–15% annual energy savings and >50% reduction in failure rates, while maintaining power quality and meeting compliance requirements. Documentation aligns with IEC 62477-1 (safety), IEC 61000 (EMC), and IEC 60747 (semiconductor devices), and data integration supports ISO 50001 energy and ISO 14001 environmental programs. Power stages are delivered as modular building blocks for electrolytic aluminum, electroplating, electrowinning, DC drives, and furnace rectifiers, with options for multi-pulse architectures and AFE-based harmonic mitigation.

Specyfikacje techniczne i zaawansowane funkcje

- Parametry elektryczne i topologia

- Input: 400–690 VAC three-phase, compatible with multi-pulse transformer secondaries

- Output: High-current DC rails for electrolytic cells and furnace supplies

- Device classes: SiC MOSFETs and high-power SiC Schottky diodes, ≥1700 V

- Current capability: ≥500 A per module; scalable in parallel to kA-class outputs with current sharing

- Rectification strategies: 6/12/24-pulse passive reduction; optional AFE for low THDi and near-unity power factor

- Przełączanie i sterowanie

- Frequency: 20–50 kHz to minimize ripple and reduce passive size

- Control features: Soft-start/pre-charge, sag/swell ride-through, current balancing, and ripple optimization for electrolytic stability

- Interfaces: MODBUS TCP, PROFINET, EtherNet/IP, DNP3, OPC UA with structured data models for SCADA/MES/CMMS

- Konstrukcja termiczna i mechaniczna

- Junction temperature range: -55°C to 175°C device capability

- Module-level thermal resistance: <0.2°C/W using AlN/Si3N4 substrates and optimized baseplates

- Cooling: Liquid cooling or sealed high-efficiency forced-air; positive-pressure IP54 cabinet designs for dust-prone sites

- Layout: Laminated busbars and low-inductance loops for reduced EMI; vibration-resistant mounts

- Ochrona i diagnostyka

- Fast desaturation/short-circuit protection (AFE), surge suppression, DC link crowbar options

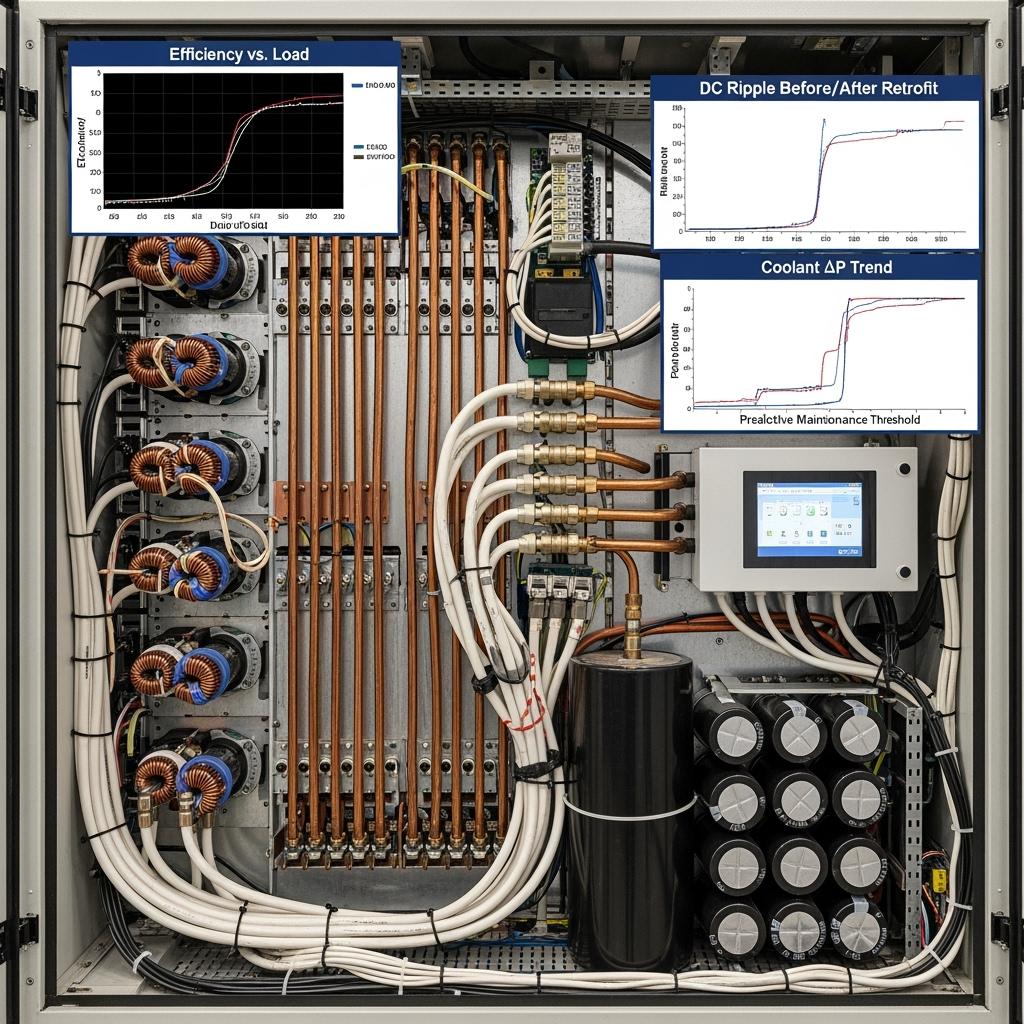

- Sensor suite: NTC/RTD temperature, DC ripple, input harmonics, coolant flow and differential pressure

- Analytics: Leakage and Vf tracking, dynamic Rds(on), capacitor ESR trending, thermal impedance monitoring for predictive maintenance

- Compliance and documentation

- Standards: IEC 62477-1, IEC 61000 series, IEC 60747 device data

- Programs: KPI logging for ISO 50001 and ISO 14001; audit-ready test and calibration records

Performance Advantages for Electrolytic Rectification and High Current Density

| Operations outcome | SiC Power Stages for Electrolytic Rectification | Conventional Silicon Rectifier Stages |

|---|---|---|

| Rectification efficiency | >98% across wide load range | Typowo 90%–94% |

| Current density and footprint | Higher density enabling >8 kW/L and smaller cabinets | Lower density, large footprint |

| Zarządzanie termiczne | 30%–40% smaller cooling systems; stable 175°C junction capability | Larger cooling hardware; derating at elevated temps |

| Reliability and uptime | >50% failure-rate reduction; 24-month maintenance intervals | Higher failure rates; semi-annual maintenance |

| Jakość energii elektrycznej | Low ripple and optional AFE for low THDi and high PF | Higher ripple; power factor correction required |

| Oś czasu zwrotu | 2–3 lata dzięki oszczędnościom energii i OPEX | Longer due to higher losses and maintenance |

Kluczowe zalety i sprawdzone korzyści z wglądem ekspertów

- High-efficiency conversion: Negligible reverse recovery from SiC diodes and low switching loss from SiC MOSFETs sustain >98% efficiency, directly lowering OPEX.

- High current density: Optimized ceramic substrates and laminated busbars enable compact, kA-class outputs with controlled thermal gradients.

- Electrolytic process stability: Reduced ripple and fast dynamic response improve product quality and cell life in electrowinning and plating.

- Harsh-environment resilience: IP-rated enclosures, conformal-coated boards, and robust cooling guard performance against dust and heat.

Cytat eksperta:

“SiC power stages cut losses and improve thermal headroom, enabling stable high-current electrochemical processes while shrinking system size.” — IEEE Power Electronics Magazine, Wide Bandgap for Industrial DC Conversion (2023)

Odniesienie do organu:

“By 2025, the economics of SiC in high-current rectification are compelling, with system-level energy savings and reliability gains driving adoption.” — Yole Group, Power SiC Market Monitor (2024)

Zastosowania w świecie rzeczywistym i wymierne historie sukcesu

- Electrolytic process hall upgrade (cement-associated metals recovery)

- Result: Overall rectification efficiency raised from 92.3% to 98.1%; kA-class output stabilized with lower ripple; cooling skid footprint reduced by ~35%; electricity savings exceeded 120,000 USD annually; continuous operation increased to 8,760 hours in a Karachi facility.

- Steel plant furnace DC supply

- Result: SiC AFE improved power factor and reduced THDi; fewer transformer hot spots; maintenance intervals extended to 24 months.

- Textile auxiliary plating lines and SMPS front ends

- Result: Higher frequency operation (20–30 kHz) reduced passive components; cabinet temperatures dropped; improved uptime under dusty conditions.

Rozważania dotyczące wyboru i konserwacji

- Core design choices

- Pulse strategy: 12/24-pulse for passive harmonic reduction; add AFE if near-unity power factor or regenerative capability is needed.

- Device selection: ≥1700 V SiC MOSFETs and Schottky diodes sized for surge, ripple, and thermal headroom; ensure proper SOA and short-circuit coordination.

- Thermal engineering

- Use high-thermal-conductivity ceramics (AlN/Si3N4) and validated TIMs; model coolant flow to maintain ΔT within targets; consider liquid cooling near furnaces/kilns.

- EMC i okablowanie

- Apply low-inductance busbars, dv/dt filters, shielded control harnesses, and compliant grounding/earthing to meet IEC 61000 limits.

- Service plan (24 months)

- Inspect/retorque busbar joints, verify capacitor ESR, check coolant chemistry/filters, recalibrate sensors, and update firmware; trend thermal impedance and Rds(on) for early warnings.

Czynniki sukcesu w branży i referencje klientów

- Success factors: Power-quality assessment, transformer vector group alignment, thermal and EMI co-design, rigorous factory acceptance testing, and operator training.

- Customer voice: “The SiC power stage stabilized our high-current rectifiers, cut cooling energy, and simplified compliance reporting.” — Electrical Manager, integrated steel producer in Punjab.

Przyszłe innowacje i trendy rynkowe 2025+

- Higher-voltage pathways: 3.3 kV SiC devices to simplify series stacking and reduce insulation complexity in medium-voltage rectifiers.

- Co-packaged power stages: Tighter integration of MOSFET/diode dies and gate drivers to reduce parasitics and improve current sharing.

- Embedded intelligence: On-module sensors and health analytics for continuous lifetime estimation and predictive maintenance.

- Localization: Technology transfer for local assembly, testing, and service in Pakistan to reduce lead times and adapt to site conditions.

Perspektywy branżowe:

“Front-end DC conversion efficiency and reliability are critical levers for industrial decarbonization, with SiC at the core of next-generation rectifiers.” — International Energy Agency, Technology Perspectives (2024)

Najczęściej zadawane pytania i odpowiedzi ekspertów

- How do SiC power stages achieve >98% efficiency?

- Low switching and conduction losses from SiC MOSFETs and Schottky diodes, coupled with optimized magnetics and high-thermal-conductivity substrates, minimize total losses.

- What current levels can be supported?

- Modules rated ≥500 A can be paralleled with equalization strategies to reach kA-class outputs for electrolytic cells and furnaces.

- Do I need an AFE or is multi-pulse enough?

- 12/24-pulse often meets THD targets; select AFE for stricter THDi limits, near-unity power factor, or regenerative operation.

- What is the typical deployment timeline?

- Standard builds: 6–10 weeks; custom ratings/enclosures: 10–14 weeks; commissioning and acceptance testing typically within 1–2 weeks on site.

- How is reliability ensured in dust and heat?

- IP54+ enclosures, positive-pressure filtration, conformal coating, liquid cooling, and predictive diagnostics preserve thermal margins and uptime.

Dlaczego to rozwiązanie działa w Twoich operacjach

SiC power stages provide the efficiency, current density, and ruggedness required for electrolytic rectification in Pakistan’s heavy industries. They enable >98% efficiency, reduce cooling infrastructure by 30%–40%, cut failure rates by more than 50%, and support stable, continuous operation at elevated temperatures. With modular integration, power quality compliance, and predictive maintenance, these stages shorten payback to 2–3 years and future-proof rectifier fleets.

Połącz się ze specjalistami, aby uzyskać niestandardowe rozwiązania

Scale your electrolytic rectification performance with end-to-end SiC expertise and turnkey delivery.

- Ponad 10 lat doświadczenia w produkcji SiC

- Wsparcie i innowacje Chińskiej Akademii Nauk

- Niestandardowy rozwój produktów w R-SiC, SSiC, RBSiC i SiSiC

- Transfer technologii i usługi zakładania fabryk

- Rozwiązania pod klucz od przetwarzania materiałów po gotowe produkty

- Historia współpracy z ponad 19 przedsiębiorstwami

Request a free consultation, detailed thermal/electrical design review, and a plant-specific ROI model. Reserve engineering capacity for harmonic studies, thermal simulation, and pilot deployment.

- Email: [email protected]

- Telefon/WhatsApp: +86 133 6536 0038

Recommended next steps: Share single-line diagrams, transformer vector groups, electrolytic cell duty profiles, cooling constraints, and harmonic limits; schedule a power-quality audit; plan a pilot power stage with measurable KPIs.

Metadane artykułu

- Ostatnia aktualizacja: 2025-09-12

- Następna zaplanowana aktualizacja: 2026-03-31

- References: IEEE Power Electronics Magazine (2023) Wide Bandgap for Industrial DC Conversion; Yole Group Power SiC Market Monitor (2024); International Energy Agency Technology Perspectives (2024)

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.