Inteligentne zintegrowane systemy modułów zasilania SiC z diagnostyką w czasie rzeczywistym i modułową skalowalnością

Udział

Przegląd produktów i znaczenie dla rynku w 2025 r.

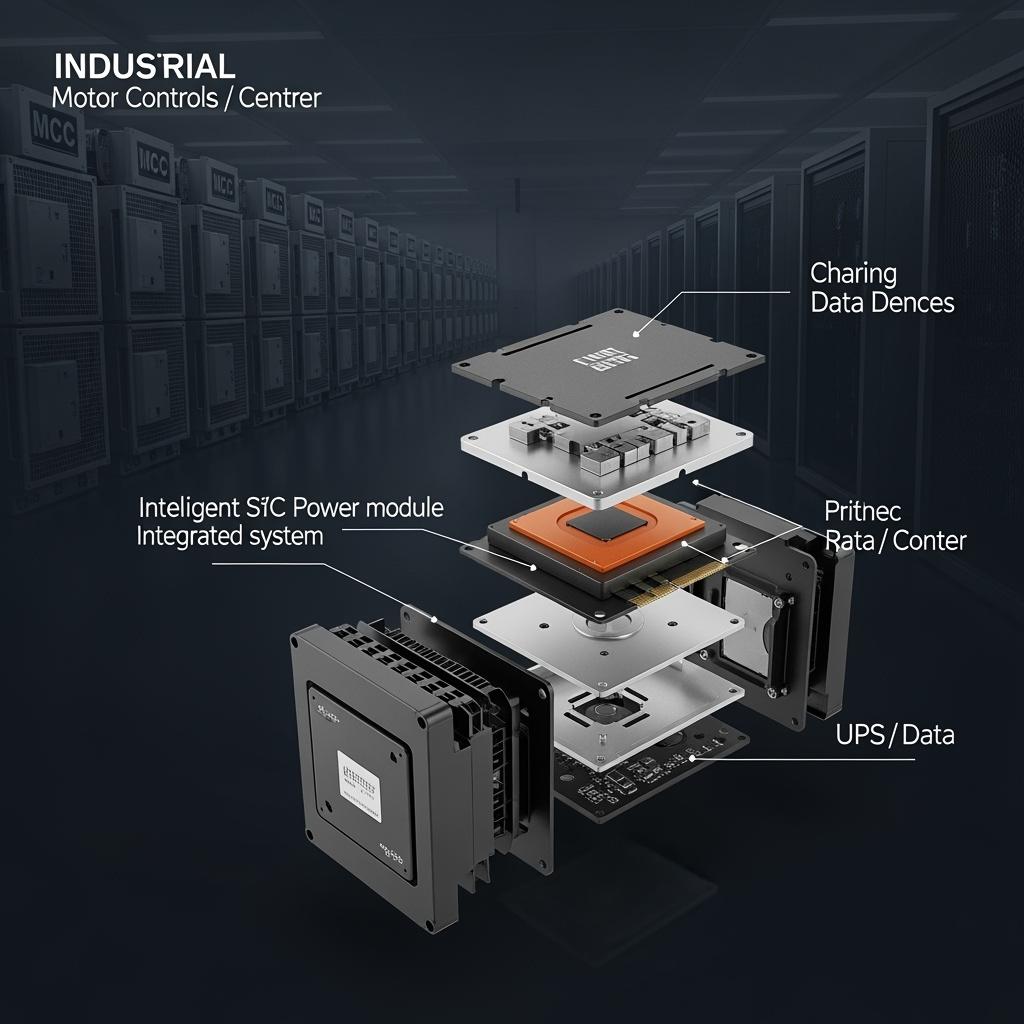

Zintegrowane systemy modułów mocy z węglika krzemu (SiC) łączą wysokowydajne stopnie mocy SiC MOSFET/dioda z wbudowanym wykrywaniem, analizą brzegową i znormalizowanymi interfejsami mechanicznymi/elektrycznymi. W przeciwieństwie do modułów dyskretnych, te zintegrowane systemy są dostarczane jako gotowe do wdrożenia bloki konstrukcyjne — wraz ze sterownikami bramek, szynami zbiorczymi o niskiej indukcyjności, kondensatorami łącza DC, zabezpieczeniami i diagnostyką cyfrową — umożliwiając szybkie skalowanie od dziesiątek kilowatów do platform o mocy kilkuset kilowatów.

Dla pakistańskiego przemysłu tekstylnego, cementowego, stalowego, i wschodzące sektory cyfrowe w 2025 r., inteligentne systemy SiC odpowiadają na krytyczne potrzeby:

- Zmienne napięcie sieciowe i wysokie temperatury otoczenia (40–45°C) wymagają solidnej ochrony, zapasu termicznego i konserwacji predykcyjnej.

- Presja OPEX i cele transformacji energetycznej wymuszają przyjęcie konwerterów o wysokiej częstotliwości i dużej gęstości dla falowników VFD, UPS, energii słonecznej i BESS.

- Ograniczone przestrzenie w pomieszczeniach MCC i halach danych wymagają kompaktowych, modułowych bloków, aby uprościć wdrażanie i rozbudowę etapową.

- Lokalne możliwości konserwacji korzystają z wbudowanej diagnostyki, zdalnego monitorowania i dzienników zdarzeń w celu szybszej analizy przyczyn źródłowych.

Zintegrowane systemy SiC firmy Sicarb Tech zapewniają >97% sprawności konwersji w całym zakresie obciążenia, zmniejszają THD w połączeniu z SiC PFC i obejmują bezpieczną telemetrię do konserwacji opartej na stanie. Skalowalność modułowa umożliwia wdrażanie w szafach lub na płozach dostosowane do dystrybucji energii przemysłowej w Pakistanie i oczekiwań Grid Code.

Specyfikacje techniczne i zaawansowane funkcje

Reprezentatywne specyfikacje (konfigurowalne dla danej aplikacji):

- Elektryczne i topologia

- Klasy napięcia: 650 V / 1200 V / 1700 V

- Zakres mocy na blok: 20–250 kW; możliwość równoległego łączenia do >1 MW

- Topologie: 2-poziomowe, 3-poziomowe NPC/TNPC/ANPC; dwukierunkowe dla UPS/BESS; opcjonalny przeplatany front-end PFC

- Częstotliwość przełączania: do 100 kHz; typowo 20–80 kHz

- Sprawność: szczytowa >98%; pełne obciążenie >97% (w zależności od zastosowania)

- Stopień mocy i ochrona

- Moduły SiC MOSFET ze źródłem Kelvina; współpakowane diody SiC, jeśli dotyczy

- Wykrywanie zwarcia DESAT (<2 µs), miękkie wyłączanie, UVLO, OCP/OVP/OTP

- Zarządzanie termiczne oparte na NTC z dynamicznym obniżaniem parametrów

- Diagnostyka i łączność

- Pomiary w czasie rzeczywistym: prądy fazowe, napięcie/tętnienia magistrali DC, temperatura obudowy modułu, wskaźniki wentylatora/chłodziwa

- Analiza brzegowa: szacowanie marginesu SOA, model żywotności kondensatorów/wentylatorów (oparty na Arrhenius/HALM)

- Komunikacja: izolowany CAN, RS485/Modbus, Ethernet; opcjonalna brama w chmurze

- Rejestrowanie zdarzeń: znaczniki czasu błędów, zdarzenia w sieci (zanik/wzrost), przekroczenia temperatury

- Mechaniczne i termiczne

- Chłodzenie: stosy żeber chłodzących chłodzone powietrzem lub płyta chłodząca cieczą; opcje rozpraszacza ciepła SSiC/RBSiC

- Obudowy: płytki drukowane pokryte powłoką konformalną; warianty z klasą IP; opcje nadciśnienia dla pyłu cementowego/tekstylnego

- Kompaktowy format szafy/płozy ze złączami zasilania/danych typu blind-mate do szybkiej wymiany w terenie

- Cele zgodności

- IEC 61800 (VFD), IEC 62040 (UPS), IEC 62109 (PV), IEC 62477-1 (konwertery mocy), IEC 61000 EMC

- Praktyki zgodne z bezpieczeństwem PEC i wymaganiami jakości NTDC Grid Code

Inteligentne funkcje Sicarb Tech:

- Modułowe oprogramowanie układowe sterowania z adaptacyjnym dv/dt i strategią przełączania na profil obciążenia

- Pulpity konserwacji predykcyjnej z progami dostosowanymi do lokalnych wzorców otoczenia/sezonowych

- Bezpieczne aktualizacje zdalne i migawki konfiguracji dla szybszej obsługi

Mierzalne korzyści z zintegrowanej inteligencji i wydajności SiC

| Kompaktowe, bogate w diagnostykę bloki mocy dla trudnych lokalizacji w Pakistanie | Inteligentne zintegrowane systemy SiC | Konwencjonalne zespoły oparte na krzemie |

|---|---|---|

| Sprawność konwersji (ważona) | >97% w całym zakresie obciążenia | Typowo 91–94% |

| Gęstość mocy i powierzchnia | >10 kW/L; 30–35% mniejsze szafy | Średnia gęstość; większe szafy |

| Niezawodność i ochrona | Szybki DESAT, miękkie wyłączanie, predykcyjne logi | Podstawowe wyzwalania; ograniczone rejestrowanie |

| THD i PF (z PFC) | THD <3%, PF >0,99 osiągalne | Wyższy THD; wymagana korekcja PF |

| Model konserwacji | Oparty na stanie, zdalna diagnostyka | Oparty na czasie, rozwiązywanie problemów na miejscu |

Kluczowe zalety i sprawdzone korzyści

- Wyższa sprawność i niższe koszty eksploatacji: 5–8% oszczędności energii w porównaniu z krzemem; zmniejszone zużycie HVAC ze względu na mniejsze wydzielanie ciepła.

- Szybsze wdrażanie i skalowanie: Wstępnie zaprojektowane bloki ze złączami typu blind-mate skracają czas instalacji o 30–40%.

- Czas sprawności dzięki inteligencji: Diagnostyka w czasie rzeczywistym i analiza trendów ograniczają nieplanowane przestoje i przyspieszają analizę przyczyn źródłowych.

- Odporność termiczna i środowiskowa: Stabilna w wysokich Tj i w pomieszczeniach 45°C z konstrukcjami chronionymi przed kurzem.

- Zgodność i przyjazność dla sieci: Czystsze przebiegi i skoordynowany PFC pomagają spełnić cele THD i PF zgodnie z NTDC Grid Code.

Cytat eksperta:

„Inteligentne moduły mocy, które integrują wykrywanie, ochronę i analizę, są niezbędne do uzyskania wydajności SiC przy jednoczesnym zachowaniu niezawodności przy wysokich prędkościach przełączania.” — IEEE Power Electronics Magazine, Market Watch 2024 (wgląd w integrację przemysłową)

Zastosowania w świecie rzeczywistym i wymierne historie sukcesu

- Modernizacja UPS w centrum danych w Lahore:

- Inteligentne zintegrowane bloki prostownika/falownika zastąpiły starsze ramy.

- Wyniki: 97,3% sprawności UPS; ~35% redukcja powierzchni pomieszczenia; koszty energii w pierwszym roku spadły o ~12,6%; alarmy predykcyjne zapobiegły dwóm potencjalnym przestojom związanym z degradacją wentylatora chłodzącego.

- Modernizacja falownika VFD w przemyśle tekstylnym w Fajsalabad:

- 45 kW inteligentne bloki falownika SiC z adaptacyjnym dv/dt i monitorowaniem stanu.

- Wyniki: 5,5% oszczędności energii; 18% niższa temperatura szafy; o 20% mniej wyzwoleń podczas zaników zasilania; konserwacja przeniesiona z kwartalnej na opartą na stanie.

- Wentylatory nagrzewnicy/ID w cementowni w Pendżabie:

- 3-poziomowe zintegrowane systemy ANPC z obudowami odpornymi na kurz i chłodzeniem nadciśnieniowym.

- Wydajność: <3% THD z etapem PFC, ~7% redukcja mocy wentylatora; wydłużone interwały wymiany filtrów; mniej alarmów związanych z EMI.

【Podpowiedź dotycząca obrazu: szczegółowy opis techniczny】 Podział sceny: 1) Szafa inteligentnych modułów SiC z diodami LED diagnostyki Ethernet/CAN; 2) Nakładka interfejsu użytkownika pulpitu nawigacyjnego pokazująca prąd, temperaturę, THD, PF, margines SOA; 3) Technik wykonujący wymianę modułu typu blind-mate; dołącz adnotacje dotyczące gęstości mocy, krzywej sprawności i alertów konserwacji predykcyjnej; fotorealistyczne, 4K.

Rozważania dotyczące wyboru i konserwacji

- Dobór rozmiaru i topologia

- Wybierz napięcie/prąd z 20–30% zapasem dla zaników/wzrostów i przeciążeń.

- Wybierz 2-poziomowy dla prostoty lub 3-poziomowy NPC/ANPC dla mniejszego obciążenia przełączaniem i lepszej sprawności w ramach o większej mocy.

- Termika i środowisko

- Sprawdź chłodzenie dla otoczenia 40–45°C; rozważ chłodzenie cieczą powyżej ~250 kW lub na dużych wysokościach.

- W zapylonych zakładach należy zastosować obudowy nadciśnieniowe lub z klasą IP oraz płytki pokryte powłoką konformalną.

- EMC i okablowanie

- Używaj laminowanych szyn zbiorczych i krótkich pętli; postępuj zgodnie z normą IEC 61000-6-4 dla emisji i 6-2 dla odporności.

- Długie kable silnikowe mogą wymagać filtrów dV/dt lub sinusoidalnych.

- Integracja diagnostyczna

- Połączenie CAN/Ethernet z systemem SCADA w miejscu instalacji; konfiguracja progów dla wskaźników żywotności wentylatorów/kondensatorów.

- Konfiguracja zdalnego przepływu aktualizacji oprogramowania układowego i archiwizacji dziennika zdarzeń.

- Praktyka serwisowa

- Utrzymanie momentu obrotowego na zaciskach; kontrola złączy podczas przestojów.

- Wykorzystanie analiz do planowania wymiany wentylatorów i filtrów, minimalizując wpływ na produkcję.

Czynniki sukcesu w branży i referencje klientów

- Czynniki sukcesu:

- Wstępne badanie harmonicznych i przegląd obciążenia transformatora

- Testy pilotażowe w warunkach szczytowego lata w celu walidacji marginesów termicznych

- Szkolenie personelu w zakresie paneli kontrolnych i interpretacji alarmów

- Strategia modułów zapasowych dla szybkiej wymiany na gorąco i minimalnych przestojów

- Rekomendacja (Kierownik ds. Operacyjnych, systemy pomocnicze Karachi Steel):

- „Modułowe bloki SiC i diagnostyka w czasie rzeczywistym pozwalają nam zidentyfikować problemy, zanim wstrzymają produkcję. Wymiana modułu zajmuje minuty, a nie godziny.”

Przyszłe innowacje i trendy rynkowe

- Perspektywy na lata 2025–2027:

- Głęboka fuzja czujników i sztuczna inteligencja na brzegu sieci do wykrywania anomalii i modelowania żywotności

- Szersze zastosowanie SiC 1700 V dla napędów wielopoziomowych średniego napięcia w cementowniach/stalowniach

- Redukcja kosztów dzięki płytkom SiC 200 mm i regionalnym partnerstwom montażowym

- Znormalizowane ekosystemy modułowe z gotowymi do użycia stosami sterowania i bliźniakami cyfrowymi

Perspektywa branżowa:

„Cyfryzacja i modułowa konwersja mocy zbliżają się do półprzewodników o szerokiej przerwie energetycznej, aby zapewnić niespotykaną dotąd wydajność i łatwość serwisowania.” — IEA Technology Perspectives 2024, sekcja Elektronika mocy

Najczęściej zadawane pytania i odpowiedzi ekspertów

- Czy inteligentne moduły mogą integrować się z istniejącymi systemami SCADA/EMS?

- Tak. Obsługujemy Modbus/RS485, CAN i Ethernet z udokumentowanymi rejestrami i bezpiecznymi bramami do integracji.

- Jak działają alerty konserwacji predykcyjnej?

- Wbudowane modele śledzą cykle temperatury, obroty wentylatora, ESR kondensatora i obciążenia przełączające, aby przewidzieć pozostały okres użytkowania i uruchomić alerty.

- Jaki THD i PF można osiągnąć?

- Z opcją SiC PFC: THD <3% i PF ≥0,99 w szerokim zakresie obciążeń, wspierając cele jakościowe NTDC Grid Code.

- Czy systemy nadają się do pracy przy napięciu 220/400 V, 50 Hz i w zapylonym środowisku?

- Całkowicie. Dostosowujemy pełzanie/prześwit, powłoki i ciśnienie w obudowie do lokalnych warunków i praktyk PEC.

- Jaki jest typowy zwrot z inwestycji (ROI)?

- 18–30 miesięcy dzięki oszczędnościom energii i chłodzenia, zmniejszonym przestojom i niższym kosztom konserwacji – szybciej w przypadku pracy 24/7.

Dlaczego to rozwiązanie działa w Twoich operacjach

Inteligentne zintegrowane systemy modułów mocy SiC łączą najlepszą w swojej klasie wydajność z przydatną diagnostyką i modułową skalowalnością. W gorącym, zapylonym i zmiennym pod względem sieci przemysłowym krajobrazie Pakistanu zapewniają niższe koszty eksploatacji, wyższy czas sprawności i szybsze wdrażanie – wspierając stabilność procesów tekstylnych, niezawodność wentylatorów cementowych, sterowanie pomocnicze w stalowniach oraz krytyczne operacje UPS/centrów danych.

Połącz się ze specjalistami, aby uzyskać niestandardowe rozwiązania

Przyspiesz swoją drogę do inteligentnej, wysoce wydajnej konwersji mocy z Sicarb Tech:

- Ponad 10 lat doświadczenia w produkcji SiC, wspartego przez Chińską Akademię Nauk

- Niestandardowy rozwój w zakresie R-SiC, SSiC, RBSiC i SiSiC oraz zaawansowane pakowanie inteligentnych modułów

- Usługi transferu technologii i zakładania fabryk w celu tworzenia lokalnej wartości

- Kompleksowe rozwiązania od przetwarzania materiałów po gotowe, inteligentne moduły z inżynierią zastosowań

- Sprawdzona historia z ponad 19 przedsiębiorstwami w wymagających środowiskach; szybkie prototypowanie i testy pilotażowe

Uzyskaj bezpłatną konsultację, audyt miejsca instalacji i model ROI dostosowany do Twojej fabryki lub obiektu danych.

- Email: [email protected]

- Telefon/WhatsApp: +86 133 6536 0038

Zarezerwuj teraz miejsca produkcyjne na Q4 2025, aby zabezpieczyć czas realizacji i zmaksymalizować oszczędności energii w sezonie szczytowym.

Metadane artykułu

- Ostatnia aktualizacja: 2025-09-11

- Następny zaplanowany przegląd: 2025-12-15

- Autor: Zespół inżynierii zastosowań Sicarb Tech

- Contact: [email protected] | +86 133 6536 0038

- Skupienie na standardach: IEC 61800, IEC 62040, IEC 62109, IEC 62477-1, IEC 61000; zgodne z praktykami PEC i kryteriami jakości NTDC Grid Code

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.