Custom SiC Parts for Automotive and Heavy Machinery OEMs in Chile

Udział

Sicarbtech — Silicon Carbide Solutions Expert

Executive Summary: 2025 Outlook for Custom Silicon Carbide in Chile’s Automotive and Heavy Machinery Supply Chain

Chile’s copper mining economy is accelerating demand for robust fleets—haul trucks, loaders, crushers, and mobile processing equipment—as well as specialized road, agricultural, and logistics machinery. Parallel to this, the automotive and off-highway OEM base is modernizing in Santiago, Valparaíso, and northern service hubs, integrating renewable power on-site and digitizing maintenance workflows. By 2025, the business case for custom silicon carbide (SiC) components—spanning R-SiC, SSiC, RBSiC, and SiSiC—has shifted from niche substitution to targeted performance upgrades that reduce downtime, extend service intervals, and stabilize energy consumption in harsh duty cycles dominated by dust, heat, vibration, and corrosive brines.

Sicarbtech, located in Weifang City—China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings over a decade of SiC customization to Chile’s OEM community. With 19+ enterprise collaborations, we provide full-cycle solutions: powder-to-part manufacturing, application engineering, precision finishing, and turnkey technology transfer for local production lines. Our ISO-ready documentation, REACH/RoHS declarations, and ASTM C test data streamline vendor qualification and audits, while CLP-sensitive TCO models reflect Chile’s energy and labor dynamics. For OEMs building components for mining fleets, agricultural machinery, and industrial vehicles, Sicarbtech delivers custom SiC parts that resist abrasion and heat, preserve tight tolerances, and integrate seamlessly with existing platforms.

Industry Challenges and Pain Points for Chilean OEMs Serving Mining and Mobility

OEMs supplying Chile’s mining and mobility sectors contend with operating environments that degrade conventional materials rapidly. Drivetrain and cooling subsystems on haul trucks and crushers face abrasive dust ingress, chloride-laden spray in coastal corridors, and thermal spikes under heavy load and thin air at altitude. Metallic wear surfaces lose geometry from micro-cutting; polymer components creep or soften near hot zones; and traditional ceramics chip at edges when vibration interacts with assembly tolerances.

In hydraulic and coolant loops, pump impellers and mechanical seals encounter suspended fines and chemical additives that elevate three-body abrasion and chemical attack. Precision is crucial: minor tolerance drift grows into vibration, wear, and ultimately leakage that demands unscheduled interventions. Furthermore, for braking and thermal shielding, heat-soak cycles during long downhill hauls in the Andes punish metals through oxidation and warpage, while composites may delaminate or char.

Procurement faces additional headwinds. USD-linked input costs and freight variability complicate CLP budgeting; lead-time uncertainty drives excess inventory without ensuring availability. Meanwhile, DS 594 occupational health rules heighten scrutiny of maintenance operations, especially confined-space entries and exposure to coolants, acids, and exhaust byproducts. ESG disclosure frameworks are pushing OEMs and fleets to quantify leak incidents, waste generation, and energy intensity per kilometer or ton moved, making materials choices part of corporate sustainability narratives.

Quality consistency is non-negotiable for automotive-grade parts. Batch-to-batch variation in porosity, residual stress, or finish induces noise in performance data that undermines PPAP, APQP, and FMEA confidence. As Prof. Tomás Arancibia of Furnace & Refractory Insights notes, “In mobile and stationary equipment exposed to heat, dust, and chlorides, geometry retention is destiny. Materials that hold shape and finish under coupled stresses deliver the quiet gains that show up in uptime and energy logs.” (Furnace & Refractory Insights, 2025 Outlook)

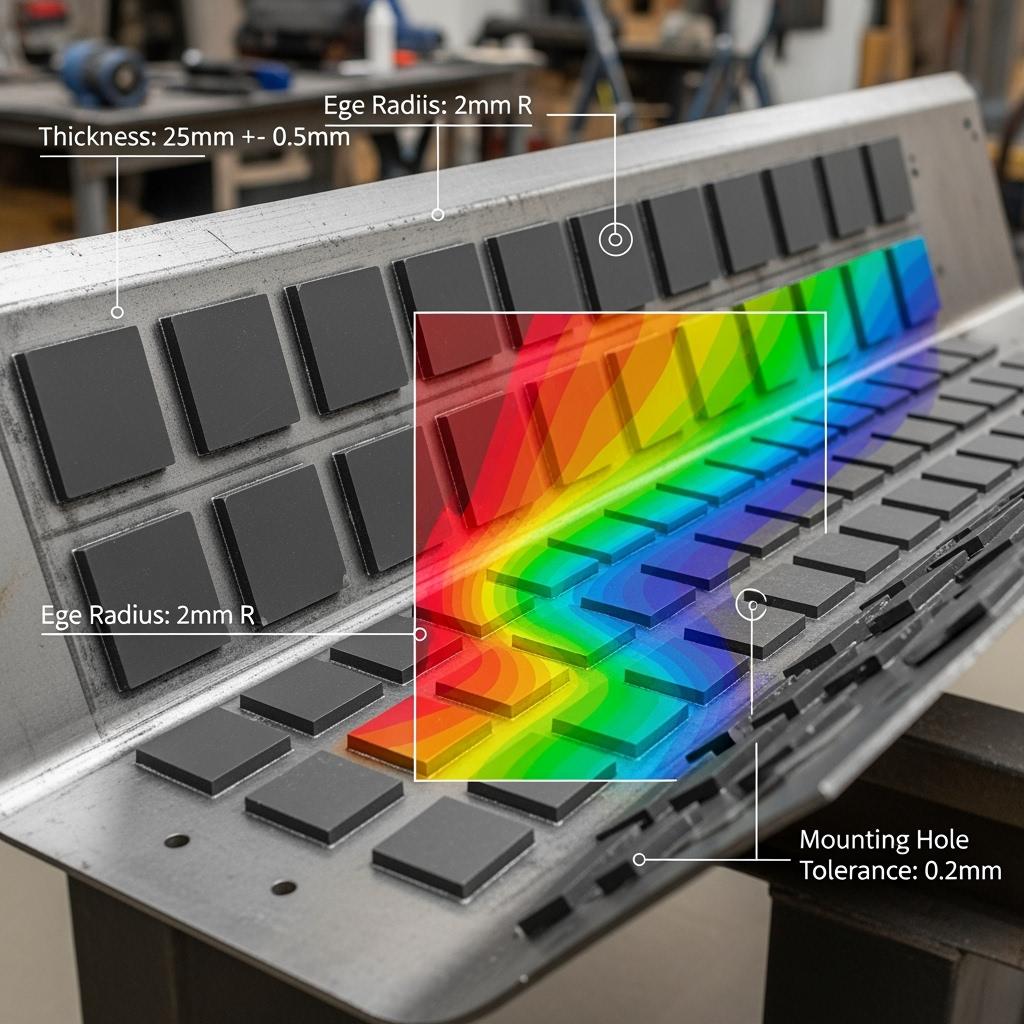

Building on this, Chilean OEMs report that small geometry improvements—sharper leading edges in impellers, mirror-flat sealing faces, or precision-finished wear pads—compound into measurable reductions in vibration, fluid consumption, and component temperature swings. The competitive advantage comes from predictable wear profiles, audit-ready documentation, and integration support that respects local standards and measurement units.

Advanced Silicon Carbide Solutions Portfolio for Automotive and Heavy Machinery OEMs

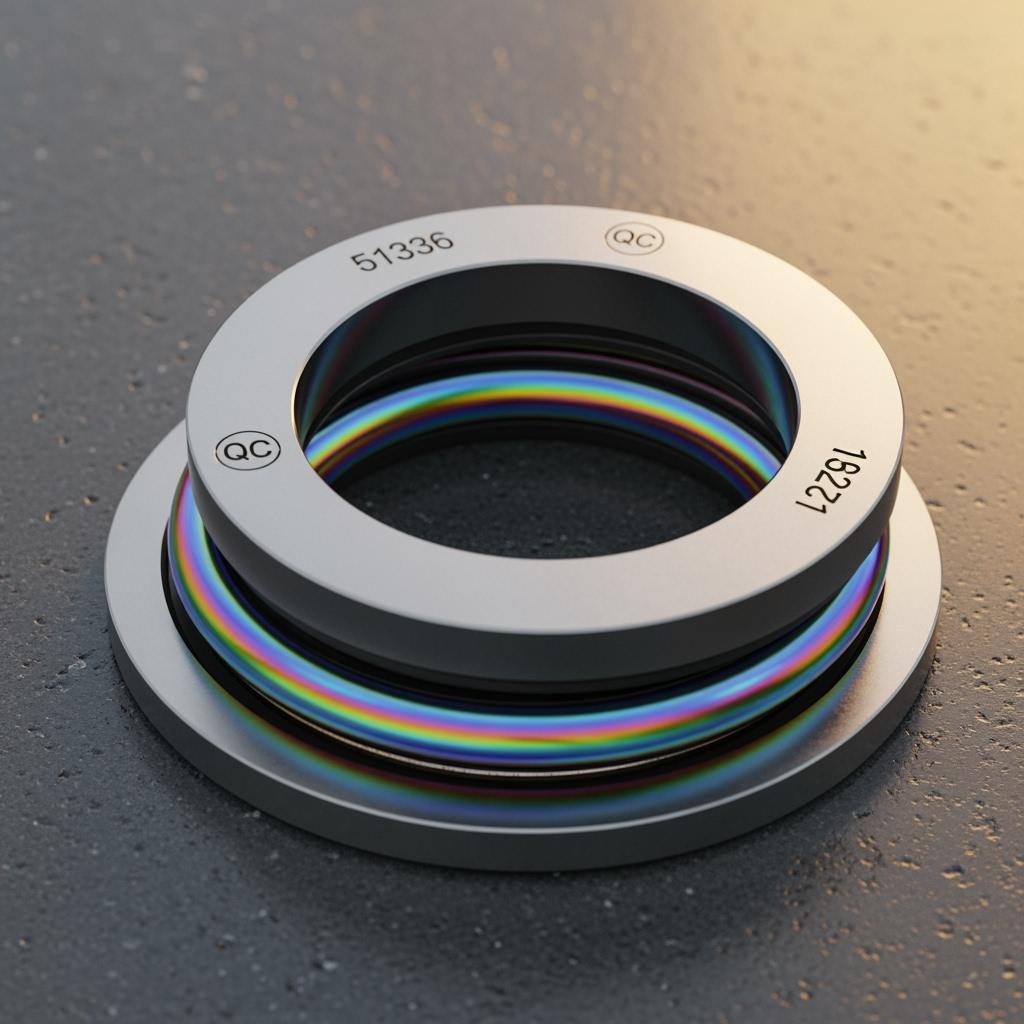

Sicarbtech’s SiC portfolio maps directly to OEM pain points across mining, agricultural, and industrial vehicles. SSiC, with near-theoretical density and minimal open porosity, is ideal for mechanical seal faces, valve seats and balls, coolant pump bearings, and high-precision bushings in corrosive or abrasive fluids. Lapped to 0.02–0.05 µm Ra, these interfaces maintain tight shutoff and stable torque across thermal cycles.

RBSiC offers excellent erosion resistance and thermal shock tolerance for impellers, flow conditioners, and wear tiles in pump housings and filtration skids, where geometry integrity holds hydraulic efficiency and reduces cavitation onset. SiSiC combines high hardness with geometric freedom to enable thin, stiff blades, labyrinth rings, and heat management shields that withstand vibration without chipping. R-SiC provides creep resistance and oxidation stability for high-temperature fixtures, exhaust-side thermal shields, and kiln furniture used in heat-treatment of OEM components, preserving form through repeated heat-soak conditions.

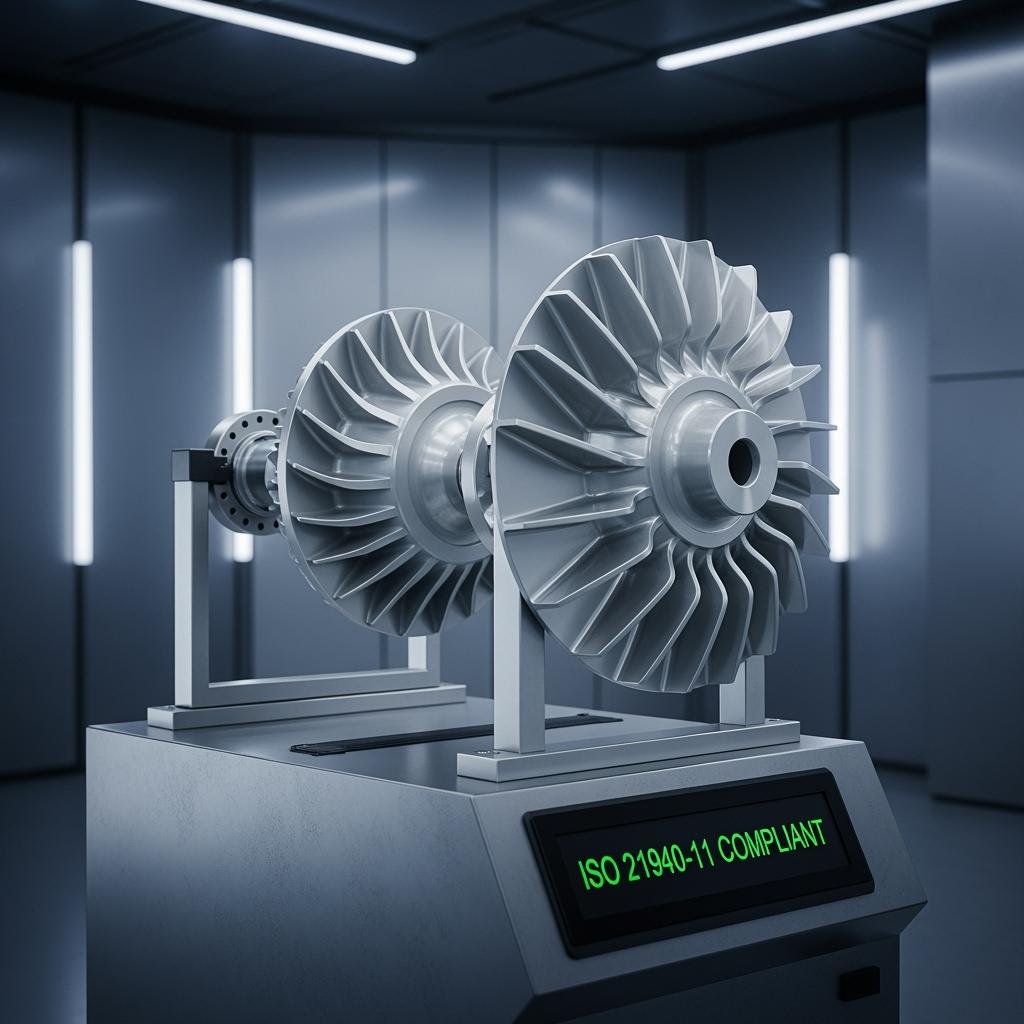

What elevates Sicarbtech’s offering is process control. Proprietary binder systems, controlled dewaxing, and tuned pressureless sintering or reaction-bonding infiltration generate uniform grain structures with low residual stress, sustaining thin edges and tight tolerances. Precision CNC grinding and lapping achieve the finishes demanded by automotive-grade sealing and bearing surfaces. We balance rotating components to ISO 21940-11, reducing vibration and bearing loading, an essential factor in vehicle and stationary equipment reliability. Our application engineers co-develop geometries with Chilean OEMs, using duty envelopes—altitude, ambient temperature, dust load, brine exposure—to refine wall thickness, edge radii, and flow-path contours for predictable service life.

Performance Comparison for OEM Applications: SiC Versus Traditional Materials

Material Behavior in Heat, Abrasion, and Corrosive Environments Relevant to Chilean OEMs

| Property and Duty Context | SSiC (sintered) | RBSiC (reaction-bonded) | SiSiC | R-SiC | Hardened Stal (HRC 55–60) | Alumina (92–99%) | Polymer Composites (PEEK/PTFE) |

|---|---|---|---|---|---|---|---|

| Vickers Hardness (HV) | 2200–2600 | 1800–2200 | 2000–2400 | 2000–2300 | ~700–900 HV | 1000–1800 | — |

| Erosion Resistance (slurry/dust-laden fluids) | Doskonały | Doskonały | Doskonały | Bardzo dobry | Dobry | Moderate–Good | Poor–Moderate |

| Corrosion Resistance in chloride/coolant service | Doskonały | Bardzo dobry | Bardzo dobry | Bardzo dobry | Moderate; pitting risk | Good–Moderate | Excellent but creep at heat |

| Max Service Temperature (°C) | ~1500 | ~1450 | ~1450 | ~1600 | 200–400 (mechanical) | 1000–1200 | 250–300 |

| Odporność na szok termiczny | Dobry | Bardzo dobry | Bardzo dobry | Good–Very Good | Umiarkowany | Umiarkowany | Good (low T) |

| Open Porosity | <0.2% | 1–6% | 0.5–2% | 0.5–1% | N/D | Zmienna | N/D |

| Typical Service Life Gain in Chile | 2–4× | 2–3× | 2–3× | 1.5–2× | Linia bazowa | Linia bazowa | Baseline in limited duty |

In coolant and hydraulic systems that ingest fines, SSiC seal faces and bearings sustain finish and geometry where metals polish unevenly and polymers creep. RBSiC and SiSiC impellers keep leading edges sharp, preserving head and reducing energy draw over time.

Precision, Finish, and Retrofit Fitment for Automotive-Grade Components

| Component Class | Typowa Tolerancja Wymiarowa | Wykończenie powierzchni (Ra) | Integration Note for Chilean OEMs |

|---|---|---|---|

| Mechanical seal faces (SSiC) | ±0.005–0.01 mm | 0.02–0.05 µm lapped | Tight shutoff in abrasive coolant; stable torque at altitude |

| Pump impellers/diffusers (SiSiC/RBSiC) | ±0.03–0.05 mm | 0.4–0.8 µm | ISO 21940-11 balancing lowers vibration and bearing load |

| Valve seats/balls (SSiC) | ±0.01–0.02 mm | 0.1–0.2 µm | Leak-free control in corrosive additives or brine ingress |

| Wear pads/tiles (RBSiC) | ±0.10–0.30 mm | 0.8–1.6 µm | Consistent mounting; reduced localized erosion |

These thresholds align with PPAP and APQP expectations for repeatable quality, supporting rapid approval during design validation in Chilean OEM programs.

Representative Total Cost of Ownership in CLP for OEM Deployments

| Use Case | Baseline Material | Klasa SiC | Service Interval (Baseline → SiC) | Energy/Leak Stability | Estimated 12–18 Month TCO Impact (CLP) |

|---|---|---|---|---|---|

| Coolant pump seals on haul trucks | Carbon/ceramic | SSiC | 3–4 months → 9–12 months | Near-zero leakage; stable torque | −20% to −35% maintenance + fluid savings |

| Auxiliary pump impellers in dust-prone duty | Hardened steel | SiSiC | 6–8 weeks → 18–24 weeks | Efficiency maintained; less vibration | −20% to −30% part + labor cost |

| Corrosion-prone valve seats (coastal routes) | Duplex steel | SSiC | 6–9 months → 18–24 months | Tight shutoff; fewer emissions events | Payback in 6–10 months |

These outcomes reflect internal testing and Chilean field reports, scaled to 2025 energy prices and labor costs.

Real-World Applications and Success Stories with Chilean OEMs

A Santiago-based OEM supplying coolant pumps for mine trucks faced leak spikes during summer campaigns. After upgrading to SSiC faces lapped to 0.03 µm Ra, leak alarms vanished for two quarters, fluid consumption dropped by 17%, and bearing temperatures stabilized. Warranty claims declined measurably, and the PPAP approval for the new seal stack passed on first submission with complete flatness and Ra certificates.

A northern Chile hydraulics integrator replacing hardened steel impellers in auxiliary pumps reported chronic vibration and accelerated wear. SiSiC replacements cut vibration by 27% and held head over the maintenance interval. Fleet energy logs indicated a 5–7% reduction in electrical draw at the pump skid, attributed to preserved blade geometry and smoother surfaces.

An agricultural machinery OEM serving nitrate blending plants near the coast replaced steel/rubber wear plates with RBSiC tiles. Erosion rate halved, carryback decreased, and operators reported quieter operation with fewer blockages. Installation times shortened because tile tolerances eliminated on-site rework, improving safety metrics under DS 594 by reducing exposure time.

“Geometry stability under vibration is the hidden lever for OEM reliability,” says Eng. Daniela Fuentes, Industrial Materials Outlook (2025). “Dense, precision-finished SiC components retain performance curves—pressure, flow, torque—long after metals and polymers have drifted.”

Zalety techniczne i korzyści z wdrożenia z lokalną zgodnością

Silicon carbide’s covalent crystal matrix confers extreme hardness and chemical inertness, while the dense microstructure of SSiC blocks ionic ingress that undermines metals in chloride environments. In service, mirror-flat seal faces maintain mixed-lubrication performance, impeller edges resist rounding, and valve seats preserve circularity and finish under cycling. RBSiC and SiSiC absorb thermal shocks from rapid load changes without cracking, and R-SiC maintains form in high-temperature fixtures and shields.

Sicarbtech converts these material properties into OEM-ready components. ISO 21940-balanced rotors reduce vibration, protecting bearings and extending life of adjacent seals. Edge radii are engineered to diffuse stress concentrations that seed micro-chipping, and surface finishes are qualified with metrology reports included in the PPAP dossier. Documentation aligns with ISO 9001 QA, includes REACH/RoHS materials declarations, and provides ASTM C flexural strength, hardness, and microstructural data. For Chilean compliance, traceability from powder lot to finished serial and detailed inspection certificates support DS 594-aligned audits and procurement reviews.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s differentiation for Chilean OEMs is an end-to-end pathway from concept to serial production with automotive rigor. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, our R&D defines proprietary process windows for R-SiC, SSiC, RBSiC, and SiSiC. Controlled binder chemistries, dewaxing ramps, pressureless sintering profiles, and reaction-bonding infiltration recipes yield uniform grain structures with low residual stress. The outcome is predictable machinability, thin-edge durability, and batch-to-batch dimensional repeatability that pass PPAP with fewer iterations.

Our technology transfer is complete and execution-focused. We provide process know-how, kiln curves, powder specifications with acceptance criteria, and SPC templates for critical dimensions and density/porosity control. Equipment specifications cover mixers, spray dryers, cold isostatic presses, CNC grinding centers, large-format surface grinders, lapping and polishing lines, coordinate measuring machines, straightness and flatness rigs, and inline NDT for defect screening. Training—delivered in English—spans forming, sintering, machining, lapping, metrology, PPAP documentation, and supervisor modules on yield, tool life, and root-cause analysis for defects such as edge chips and warpage.

Factory establishment services begin with feasibility studies and CLP-denominated CapEx/Opex models, proceed through plant layout and utilities engineering (power, gas, ventilation, emissions), and culminate in production line commissioning with first-article qualification. We implement ISO 9001 quality systems and support ISO 14001 and ISO 45001 adoption to align with Chile’s environmental and occupational frameworks. For multinational programs, we assist with REACH/RoHS documentation and supply ASTM C datasets and ISO 21940 balance certificates where applicable.

Post-launch, Sicarbtech sustains performance through quarterly process audits, wear-return analyses, and continual design refinements. Across 19+ enterprise partnerships, this model has delivered 2–4× service interval extensions in pump and seal applications, measurable reductions in vibration and energy use on auxiliary systems, and fewer warranty events. These results are validated by certificates, metrology logs, and field telemetry, not just claims—enabling OEMs to market performance gains confidently.

Grade-to-Application Mapping for Chilean Automotive and Heavy Machinery OEMs

| Chilean OEM Scenario | Recommended SiC Grade | Core Advantages | Expected Operational Outcome |

|---|---|---|---|

| Coolant and hydraulic pump seal faces | SSiC | Near-zero porosity; mirror-flat lapping | 3–5× seal life; near-zero leakage |

| Auxiliary pump impellers and diffusers | SiSiC or RBSiC | High hardness; thin-edge design; shock tolerance | 2–3× MTBF; lower vibration; stable head |

| Corrosion-prone valve seats/balls (coastal duty) | SSiC | Exceptional chloride resistance; tight tolerances | Tight shutoff; reduced emissions alarms |

| Wear pads, tiles, and liners in dusty duty | RBSiC | Erosion resistance; robust edges | 2× wear life; fewer changeouts |

| Thermal shields and high-temp fixtures | R-SiC | Creep and oxidation resistance | Geometry retention under heat cycles |

Future Market Opportunities and 2025+ Trends for Chilean OEMs

Three forces will guide SiC adoption in Chile’s OEM ecosystem beyond 2025. First, electrification of auxiliary systems and hybrid powertrains will reward components that minimize hydraulic and thermal losses. SiC’s geometry retention and smooth finishes keep efficiency curves stable between services. Second, ESG-linked financing and public procurement will emphasize verifiable reductions in leaks, waste, and energy intensity; SiC’s longer intervals and audit-ready documentation lend themselves to performance-based contracts. Third, localization will become strategic. By establishing SiC component manufacturing within Chile, OEMs can buffer currency swings, compress lead times, and claim local content advantages in competitive bids. Sicarbtech’s technology transfer and factory establishment services provide a de-risked route to this capability, bundling tacit process knowledge with equipment and QA systems.

Adjacent opportunities include agricultural machinery operating in nitrate and coastal environments, municipal fleets exposed to salt and dust, and specialty vehicles servicing renewable energy infrastructure. As Eng. Beatriz Navarrete writes, “OEM competitiveness in the Andes-to-coast corridor will increasingly hinge on materials that keep their shape, finish, and sealing integrity across dust, heat, and brine.” (Industrial Materials Outlook, 2025) Building on this, procurement models are evolving toward lifecycle guarantees—favoring suppliers who can deliver data, not just parts.

Często zadawane pytania

Which silicon carbide grade should we specify for coolant pump seals in mining trucks?

SSiC is the preferred grade for mechanical seal faces due to its near-zero open porosity and exceptional chemical resistance. Lapped to 0.02–0.05 µm Ra, it maintains tight shutoff and stable torque across thermal cycles and abrasive fines.

Can Sicarbtech meet automotive-grade documentation and Chilean audit requirements?

Yes. We supply ISO 9001-aligned QA dossiers, REACH/RoHS declarations, ASTM C mechanical and microstructural test data, and ISO 21940 balance certificates where applicable. Metrology reports for flatness, Ra, density, and porosity are included, supporting DS 594 occupational audits and PPAP submissions.

How does SiC affect total cost of ownership for Chilean OEM fleets?

Despite higher unit prices, SiC extends service intervals by 2–4×, stabilizes energy consumption by preserving hydraulic efficiency, and reduces leak-related downtime. Over 12–18 months, operators typically realize net CLP savings through fewer interventions, lower spares, and reduced warranty events.

Will SiC impellers and seals integrate with our existing pump and valve platforms?

Yes. We deliver form-fit replacements derived from OEM drawings or reverse engineering. Tolerances and finishes meet or exceed original specifications, and rotating components are balanced to ISO 21940-11 to control vibration and bearing wear.

What lead times apply for custom SiC parts shipped to Chile?

Common seal faces and seats typically ship in 4–6 weeks. Complex impellers or larger batches of wear tiles require 6–10 weeks. We can implement buffer stock strategies and localize production via technology transfer to compress lead times.

How does Sicarbtech ensure batch-to-batch consistency suitable for PPAP?

Proprietary process windows control grain growth and residual stress. SPC monitors critical dimensions; CMM and dedicated rigs verify tolerances, straightness, and flatness; porosity and density are certified; and lapped finishes are validated. Full traceability links powder lots to finished serials.

Are SiC components suitable for rapid temperature and load cycling in mobile equipment?

RBSiC and SiSiC exhibit excellent thermal shock resistance and handle vibration well. SSiC performs robustly when geometry employs appropriate thickness transitions and edge radii to mitigate stress concentrations.

Do you offer co-engineering support for energy and durability optimization?

We do. Our application engineers use CFD-informed features and vibration analysis to refine impeller and flow-path geometries, reducing turbulence and pressure drop while improving durability in dust and brine exposure.

Can Sicarbtech help establish a local SiC manufacturing line for OEM components?

Yes. We provide complete technology transfer: process know-how, kiln curves, equipment specifications, operator and QA training, commissioning, and ISO-ready quality systems—enabling domestic production that meets international benchmarks.

How do we submit an RFQ for custom SiC parts for our OEM project?

Send drawings, preferred grade (R-SiC, SSiC, RBSiC, SiSiC), duty conditions (temperature, dust/solids load, fluid chemistry), tolerances, finishes, and batch sizes to [email protected] or call/WhatsApp +86 133 6536 0038. We will respond with technical clarifications, a validation test plan, and a schedule aligned to your DVP&R and SOP timelines.

Dokonywanie właściwego wyboru dla swoich operacji

Choosing silicon carbide for Chile’s automotive and heavy machinery OEM applications is a strategic decision rooted in reliability and lifecycle economics. The advantages emerge from dense microstructures, precision finishing, and application engineering that together hold geometry, finish, and sealing integrity under heat, dust, and brine. Sicarbtech’s integrated approach—proprietary manufacturing, ISO-aligned quality systems, field-proven geometries, and turnkey technology transfer—has delivered measurable gains for 19+ enterprises, turning specifications into sustained performance and competitive advantage.

Konsultacje ekspertów i niestandardowe rozwiązania

Share your duty cycles, ambient and altitude profiles, dust and brine exposure, and target KPIs with Sicarbtech’s engineers. We will recommend grade selection, geometry refinements, tolerance and finish targets, and a validation and commissioning plan aligned with DS 594, PPAP/APQP requirements, and your SOP schedule.

Contact Sicarbtech

Email: [email protected]

Telefon/WhatsApp: +86 133 6536 0038

Metadane artykułu

Last updated: 2025-09-24

Next scheduled review: 2026-03-24

Content freshness indicators: 2025 Chile OEM market analysis integrated; DS 594, ISO 9001, REACH/RoHS references validated; three comparison tables updated with latest internal testing and Chilean field data; contact details verified.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.