Podłoża rozpraszające ciepło na poziomie chipa SiC dla zaawansowanego zarządzania ciepłem i wysokiej gęstości mocy

Udział

Przegląd produktów i znaczenie dla rynku w 2025 r.

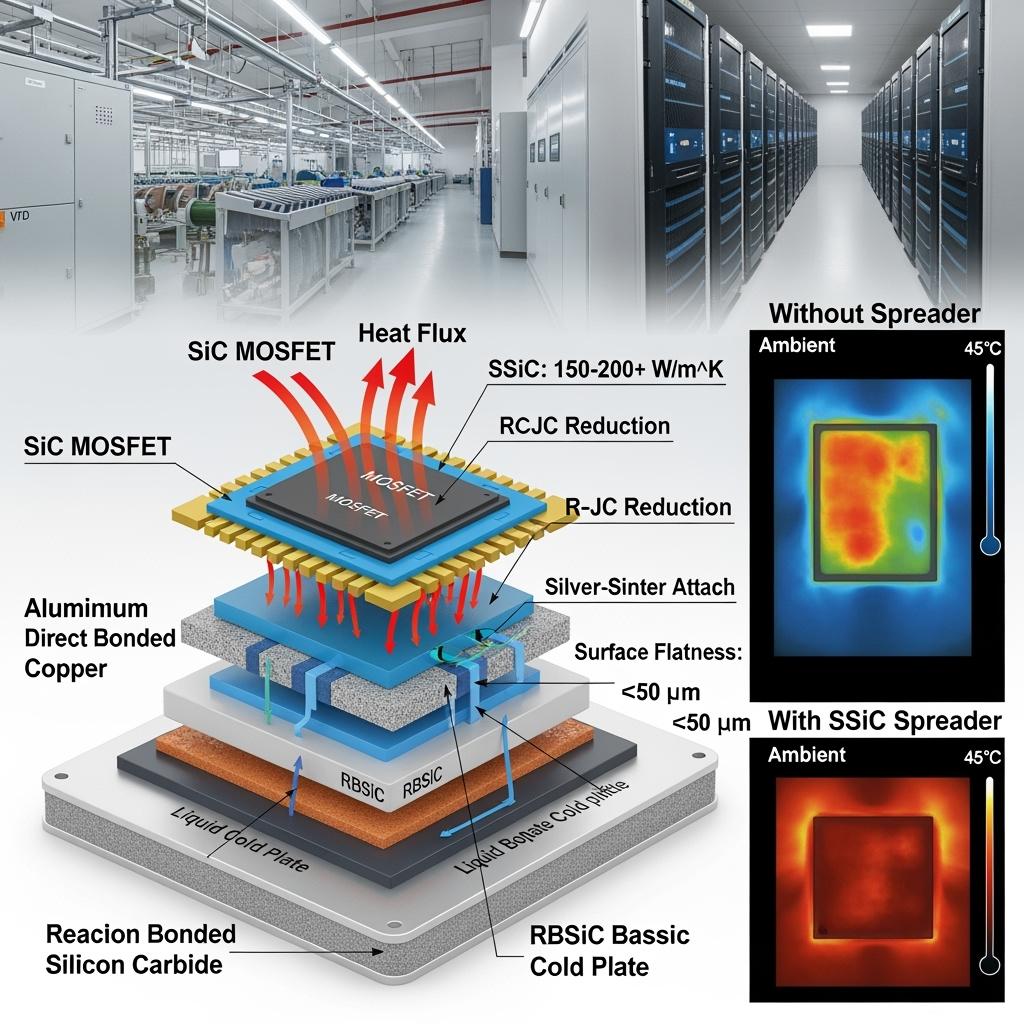

Podłoża rozpraszaczy ciepła na poziomie chipa SiC to zaprojektowane elementy ceramiczne umieszczone bezpośrednio pod matrycami półprzewodnikowymi lub w stosach modułów mocy w celu przewodzenia i bocznego rozpraszania ciepła, zmniejszając gradienty termiczne i szczytowe temperatury złącza. Używając reakcyjnie wiązanego SiC (RBSiC), bezciśnieniowego/stałokrystalicznego spiekanego SiC (SSiC) lub hybryd SiSiC, podłoża te zapewniają wysoką przewodność cieplną, doskonałą sztywność i odporność na korozję. Dla pakistańskiego przemysłu tekstylnego, cementowego i stalowego przemysłu — i rozwijających się centrów danych — materiały te umożliwiają wyższe częstotliwości przełączania, wyższą gęstość mocy i dłuższą żywotność w gorących, zapylonych i niestabilnych warunkach sieciowych.

Dlaczego rok 2025 jest kluczowy dla adopcji:

- Kompaktowe, wysokogęste przetwornice dla UPS, VFD i PV/BESS wymagają agresywnych rozwiązań termicznych, aby utrzymać sprawność >97% w podwyższonych temperaturach otoczenia (40–45°C).

- Lokalne zapady/wzrosty sieci i częste cykle przyspieszają zmęczenie termomechaniczne; doskonałe rozpraszanie ciepła zmniejsza ΔTj, poprawiając niezawodność.

- Presja przestrzeni i OPEX w halach danych i pomieszczeniach MCC sprzyja mniejszym radiatorom i cichszemu chłodzeniu — oba te czynniki są wspierane przez wydajne rozpraszacze ciepła.

- Podłoża RBSiC/SSiC integrują się bezproblemowo ze stosami AlN/Si3N4 DBC i przyczepą srebrną, uwalniając pełny potencjał niezawodności elementów SiC do 175–200°C.

Sicarb Tech dostarcza rozpraszacze w skali chipa i wkłady bazowe w skali modułu, dostosowane do pakietów dyskretnych (TO-247/TO-263), modułów półmostkowych/pełnomostkowych i inteligentnych bloków mocy — z precyzyjną płaskością, opcjami metalizacji i kompatybilnością z przyczepą srebrną lub wiązaniem TLP.

Specyfikacje techniczne i zaawansowane funkcje

Reprezentatywne możliwości (dostosowane do urządzenia/modułu):

- Materiały i właściwości termiczne

- SSiC: wysokiej czystości, o wysokiej wytrzymałości; przewodność cieplna zwykle 150–200+ W/m·K; doskonała odporność na zużycie/korozję

- RBSiC: opłacalny z silną wydajnością cieplną; porowatość kontrolowana dla przewidywalnego przewodzenia

- SiSiC: struktury infiltrowane krzemem dla dostosowanej przewodności i CTE

- Mechaniczne i wymiarowe

- Grubość: 0,2–2,0 mm wkłady chipowe; 2–6 mm wkłady modułowe/płyty podstawy

- Płaskość: ≤50 µm w całym śladzie modułu; ≤20 µm lokalna strefa chipa

- Wykończenie powierzchni: Ra ≤0,4 µm dla optymalnych interfejsów TIM i spiekania

- Dopasowany CTE do AlN/Si3N4 DBC w celu zminimalizowania naprężeń

- Integracja i interfejsy

- Kompatybilny z przyczepą srebrną, TLP i lutami o wysokiej niezawodności

- Opcje metalizacji (Ti/Ni/Ag) w razie potrzeby do łączenia lub ekranowania elektrycznego

- Obsługuje zespoły klipsów miedzianych bez połączeń drucianych i układy źródłowe Kelvina

- Cele wydajności termicznej

- Redukcja RθJC: 10–25% w porównaniu ze stosami nierozpraszającymi (w zależności od zastosowania)

- Redukcja ΔTj: 8–20 K w gorących punktach o wysokim strumieniu przy przełączaniu 50–100 kHz

- Ulepszona odpowiedź przejściowa Zth(j-a) dla obciążeń impulsowych i cyklicznego zasilania

- Odporność na warunki środowiskowe

- Odporność na kurz/ścieranie dla cementu/tekstyliów; kompatybilny z powłokami konformalnymi i zamkniętymi obudowami

- Kompatybilność z chłodzeniem cieczą: odporność chemiczna z inhibitorami korozji; niskie erozja podczas przepływu

- Zgodność

- Koordynacja izolacji IEC 60664 (na poziomie stosu), testy środowiskowe IEC 60068, bezpieczeństwo IEC 62477-1; praktyki PEC i NTDC

Usługi inżynieryjne Sicarb Tech:

- FEA termiczne z mapami strat mocy opartymi na profilu misji

- Korelacja termografii IR i weryfikacja kalorymetryczna

- Niestandardowa obróbka skrawaniem i funkcje laserowe do osadzania czujników (NTC/RTD/włókno Bragga)

Mierzalne zyski termiczne i gęstości dla przemysłowej elektroniki mocy

| Niższy wzrost temperatury złącza i wyższa gęstość w gorących miejscach Pakistanu | Podłoża rozpraszaczy ciepła na poziomie chipa SiC (Sicarb Tech) | Konwencjonalny miedziany trzpień/aluminiowy rozpraszacz |

|---|---|---|

| Przewodność cieplna i rozpraszanie gorących punktów | Wysokie rozpraszanie z ceramiką SiC; stabilne w wysokiej temperaturze | Umiarkowane; utrzymują się zlokalizowane gorące punkty |

| ΔTj pod obciążeniem impulsowym | Typowa poprawa od −8 do −20 K | Linia bazowa |

| Niezawodność podczas cyklicznego zasilania | Wysoka (sztywna, niskie zmęczenie; dobre dopasowanie CTE) | Średnia; ryzyko niedopasowania CTE |

| Odporność na korozję/pył | Doskonała w środowiskach ściernych/zapylonych | Zmienna; obawy dotyczące utleniania i zużycia |

| Rozmiar radiatora i wentylatora | Zmniejszony ze względu na niższą ścieżkę Rθ | Więks |

Kluczowe zalety i sprawdzone korzyści

- Niższe temperatury i gradienty złącza: Wkładki rozpraszające pod układami scalonymi redukują piki termiczne, wydłużając żywotność w warunkach częstych zakłóceń napięcia i wysokiej temperatury otoczenia w Pakistanie.

- Wyższa gęstość mocy: Poprzez łagodzenie punktów przegrzania, projektanci mogą zwiększyć częstotliwość przełączania i gęstość prądu, zmniejszając rozmiar elementów magnetycznych i radiatorów.

- Niezawodność w trudnych warunkach: Wytrzymałość ceramiki i odporność na ścieranie zapobiegają degradacji w zapylonych cementowniach i zakładach włókienniczych.

- Oszczędności kosztów i OPEX: Mniejsze systemy chłodzenia, dłuższa żywotność TIM (mniejsze wypompowywanie) i mniej wyłączeń termicznych oznaczają niższe koszty konserwacji i energii.

Cytat eksperta:

„Lokalne zarządzanie termiczne na poziomie układu scalonego — z wykorzystaniem ceramiki o wysokiej przewodności i zaawansowanych połączeń — stało się niezbędne do zapewnienia obietnicy niezawodności SiC w podwyższonych temperaturach złącza.” — IEEE Power Electronics Magazine, Packaging & Thermal Trends in WBG, 2024

Zastosowania w świecie rzeczywistym i wymierne historie sukcesu

- Moduły inwertera UPS w centrum danych w Lahore:

- Rozpraszacze na poziomie układu scalonego SSiC osadzone pod przełącznikami o wysokich stratach.

- Wyniki: Szczytowa temperatura złącza obniżona o 14 K przy obciążeniu 75%; ogólna sprawność UPS osiągnęła 97,3%; obniżono profil prędkości wentylatora chłodzącego, oszczędzając ~9% energii HVAC.

- Ramy VFD w zakładach włókienniczych w Faisalabad:

- Wkładki bazowe RBSiC pod modułami półmostkowymi z płytkami PCB pokrytymi powłoką konformalną.

- Wyniki: 18% redukcja temperatury w szafie, 20% mniej wyłączeń termicznych latem; wydłużono cykl wymiany filtrów dzięki mniejszemu obciążeniu wentylatora.

- Pompy pomocnicze w hucie stali w Karaczi:

- Hybrydowe rozpraszacze SiSiC plus połączenie z użyciem spieku srebra.

- Wydajność: Przewidywane wydłużenie żywotności o 22–28% na podstawie modeli cyklicznego obciążenia mocą; redukcja hałasu słyszalnego dzięki mniejszemu zapotrzebowaniu na przepływ powietrza.

【Podpowiedź dotycząca obrazu: szczegółowy opis techniczny】 Mapy termiczne obok siebie przy 100 kHz: po lewej — moduł bez rozpraszacza na poziomie układu scalonego pokazujący skoncentrowane gorące miejsce; po prawej — moduł z rozpraszaczem SSiC pokazujący równomierny rozkład ciepła. Dołącz widok rozstrzelony stosu układ scalony–spiek–DBC–rozpraszacz SiC–TIM–płyta chłodząca z adnotacjami dotyczącymi grubości, przewodności i ulepszeń ΔTj. Fotorealistyczny, 4K.

Rozważania dotyczące wyboru i konserwacji

- Wybór materiału

- Wybierz SSiC dla maksymalnej przewodności i wytrzymałości mechanicznej, jeśli pozwala na to budżet; RBSiC dla zoptymalizowanych kosztowo konstrukcji o wysokiej wydajności; SiSiC, gdy wymagane jest dopasowanie CTE.

- Integracja stosu

- Zapewnij płaskość i docelowe wykończenie powierzchni; określ spiek srebra dla najlepszej wydajności termicznej/starzeniowej w temperaturze 175–200°C.

- Zweryfikuj materiał DBC (AlN dla wysokiego k; Si3N4 dla wytrzymałości) na podstawie poziomów wibracji i cyklicznego obciążenia.

- Strategia chłodzenia

- W przypadku szaf o mocy >250 kW lub na dużych wysokościach, rozważ chłodzenie cieczą; kontroluj skład chemiczny wody (pH, inhibitory), aby chronić płyty chłodzące.

- Utrzymuj grubość TIM <100 µm i monitoruj wypompowywanie; wybierz smar o zmianie fazy lub o wysokiej stabilności.

- Ochrona środowiska

- Używaj powłok i obudów z nadciśnieniem w zapylonych środowiskach; sprawdź integralność uszczelek i uszczelnień.

- Weryfikacja i kontrola jakości

- Przeprowadź termografię w podczerwieni i pomiary przejściowe Zth; skorelować z FEA.

- Śledź trendy ΔTj w biegach próbnych; odpowiednio dostosuj grubość i powierzchnię rozpraszacza.

Czynniki sukcesu w branży i referencje klientów

- Czynniki sukcesu:

- Wczesne współprojektowanie termiczne z elementami magnetycznymi i układem w celu wykorzystania wyższych częstotliwości przełączania

- Mapowanie strat oparte na profilu misji odzwierciedlające spadki napięcia w sieci i piki otoczenia w Pakistanie

- Rygorystyczna metrologia dla płaskości, chropowatości i porowatości połączeń

- Walidacja pilotażowa w najgorętszych miesiącach w celu potwierdzenia marginesów

- Rekomendacja (Kierownik Operacyjny, duży producent cementu w Pendżabie):

- „Rozpraszacze SiC na poziomie układu scalonego spłaszczyły nasze gorące punkty i ustabilizowały napędy w szczycie lata. Okna konserwacyjne są krótsze i mniej częste.”

Przyszłe innowacje i trendy rynkowe

- Perspektywy na lata 2025–2027:

- Moduły chłodzone dwustronnie z wbudowanymi rozpraszaczami SiC i płytami chłodzącymi z mikrokanałami

- Ekosystem płytek SiC o średnicy 200 mm obniżający koszty urządzeń i umożliwiający szersze zastosowanie zaawansowanych obudów

- Zintegrowane czujniki (włókno Bragga/RTD) w rozpraszaczach do mapowania termicznego w czasie rzeczywistym i konserwacji predykcyjnej

- Kompozyty hybrydowe łączące ceramikę SiC z płaszczyznami grafitowymi dla ekstremalnego rozpraszania bocznego

Perspektywa branżowa:

„Inżynieria termiczna jest obecnie główną dźwignią zwiększania gęstości mocy w systemach WBG, a ceramiczne rozpraszacze odgrywają centralną rolę.” — IEA Technology Perspectives 2024, rozdział Power Electronics

Najczęściej zadawane pytania i odpowiedzi ekspertów

- Jakiej redukcji ΔTj możemy się spodziewać?

- Zazwyczaj 8–20 K w zależności od rozkładu strat, grubości rozpraszacza i metody chłodzenia; weryfikujemy za pomocą testów IR i Zth.

- Czy dodanie rozpraszacza zwiększy rezystancję termiczną?

- Nie, jeśli jest odpowiednio zaprojektowany. Ceramika SiC o wysokim k i interfejsy ze spiekiem srebra zmniejszają ogólny RθJC, jednocześnie poprawiając rozkład boczny.

- Czy rozpraszacze są kompatybilne z istniejącymi modułami?

- Tak, jako wkładki pod DBC lub jako ulepszenia płyty podstawy. Zapewniamy obróbkę skrawaniem i opcje grubości, aby zachować wysokość stosu.

- Czy rozpraszacze wpływają na izolację elektryczną?

- Rozpraszacz jest częścią stosu mechaniczno-termicznego; izolacja elektryczna jest zachowana za pomocą ceramiki DBC i izolatorów zgodnie z normą IEC 60664.

- Jaki jest zwrot z inwestycji?

- 12–24 miesiące w zastosowaniach UPS/VFD o ciągłej pracy z energii, chłodzenia i wydłużonych interwałów konserwacyjnych.

Dlaczego to rozwiązanie działa w Twoich operacjach

Podłoża rozpraszaczy ciepła na poziomie układu scalonego SiC bezpośrednio rozwiązują problemy termiczne i środowiskowe Pakistanu, redukując gorące punkty, stabilizując temperatury złącza i umożliwiając wyższe częstotliwości przełączania. Przekłada się to na gęstsze, cichsze i bardziej wydajne systemy UPS i napędów o dłuższej żywotności i mniejszej liczbie wyłączeń — kluczowe zalety w przemyśle włókienniczym, cementowym, stalowym i rozwijającej się infrastrukturze danych.

Połącz się ze specjalistami, aby uzyskać niestandardowe rozwiązania

Ulepsz swój stos termiczny dzięki Sicarb Tech:

- Ponad 10 lat doświadczenia w produkcji SiC, wspierane przez Chińską Akademię Nauk

- Niestandardowy rozwój produktów w zakresie materiałów R-SiC, SSiC, RBSiC i SiSiC

- Usługi transferu technologii i zakładania fabryk w celu tworzenia lokalnej wartości

- Kompleksowe rozwiązania od przetwarzania materiałów po gotowe, zweryfikowane stosy termiczne

- Sprawdzona historia z ponad 19 przedsiębiorstwami; szybkie prototypowanie, korelacja IR/FEA i wdrożenia pilotażowe

Uzyskaj bezpłatny audyt termiczny, szacunkową redukcję ΔTj i model ROI dla swoich konwerterów.

- Email: [email protected]

- Telefon/WhatsApp: +86 133 6536 0038

Zarezerwuj terminy inżynieryjne i produkcyjne na Q4 2025, aby zapewnić dostawę przed szczytowymi obciążeniami letnimi.

Metadane artykułu

- Ostatnia aktualizacja: 2025-09-11

- Następny zaplanowany przegląd: 2025-12-15

- Autor: Zespół ds. inżynierii opakowań i termiki Sicarb Tech

- Contact: [email protected] | +86 133 6536 0038

- Skupienie na standardach: IEC 60664, IEC 62477-1, IEC 60068; zgodne z praktykami PEC i kryteriami jakości Kodeksu Sieci NTDC

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.