High-Durability SiC Ceramics for B2B Engineering Needs | Sicarbtech Turkey 2025 Pillar Page

Udział

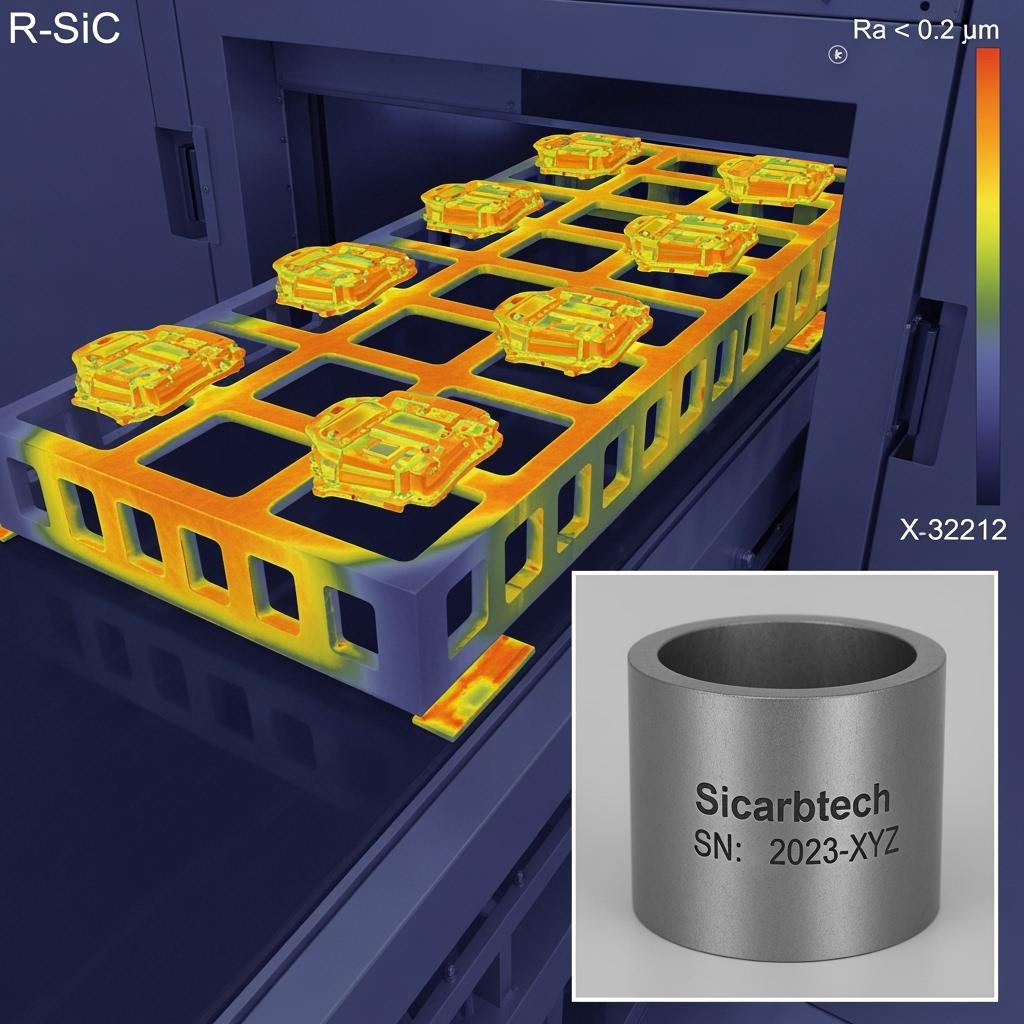

Sicarbtech is the Silicon Carbide Solutions Expert trusted by Turkish textile, automotive, and stalowego manufacturers that need high-durability ceramics engineered for tough duty cycles. Operating from Weifang City—China’s silicon carbide manufacturing hub—and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we bring over 10 years of customization experience, from powder processing to precision-finished parts. In 2025, as Turkey balances energy volatility, export-grade quality, and EU-aligned compliance, our R-SiC, SSiC, RBSiC, and SiSiC solutions help plants cut downtime, stabilize audits, and achieve measurable ROI.

Executive Summary: Why High-Durability SiC Ceramics Are a 2025 Imperative in Turkey

The Turkish industrial economy is pushing for higher efficiency, tighter tolerances, and faster throughput—while meeting stricter environmental expectations. Textile centers in Denizli and Gaziantep are reducing rework from surface defects and chemical corrosion. Automotive clusters in Bursa, Kocaeli, and Ankara are scaling EV-adjacent programs with IATF 16949 discipline and PPAP rigor. Steel producers across Marmara and Iskenderun are contending with severe thermal cycling and regulatory transparency. In this environment, high-durability silicon carbide ceramics become a strategic material, not just a maintenance upgrade.

SSiC provides near-theoretical density for superior strength and corrosion resistance. RBSiC and SiSiC offer complex shapes with robust thermal shock performance and stable creep behavior. R-SiC brings extremely low mass and outstanding thermal shock resistance for rapid ramp cycles. Furthermore, Sicarbtech’s technology transfer and turnkey factory establishment capabilities enable domestic capacity in Turkey, mitigating FX risk and lead-time variability. As Dr. Aylin Erdem, materials engineering lecturer, observes, “Plants that design with silicon carbide see system-level gains—steadier process windows, fewer stoppages, and cleaner audits—far beyond the part itself.” (Source: Expert workshop summary, 2024)

Industry Challenges and Pain Points in Turkish Operations

The daily operating reality in Turkey’s textile, automotive, and steel facilities is defined by compounding pressures. Textile finishing lines must maintain precise tension and immaculate surface contact while exposed to corrosive dye-bath chemistries and abrasive fiber particulates. Conventional alumina rollers or coated metals often roughen, warp, or crack under rapid temperature transitions. A small runout drift can manifest as visible fabric streaks that trigger rework. Every unplanned stop incurs layered costs: idle labor, batch losses, reheating energy, and urgent logistics to protect export delivery dates. Under ISO 9001 and ISO 14001 frameworks, such variability must be explained and corrected, adding administrative burden.

Automotive plants, especially suppliers tied to Tier-1 export programs, are facing tighter process capability targets. Heat-resistant steels or common carbides in fixtures, seals, and pump parts tend to creep or shift dimensionally across thermal cycles. The consequence is not just scrap, but PPAP disruptions, quarantines, and extended documentation exercises under IATF 16949. Moreover, currency fluctuations raise the landed cost of frequent imported replacements, turning maintenance events into financial volatility.

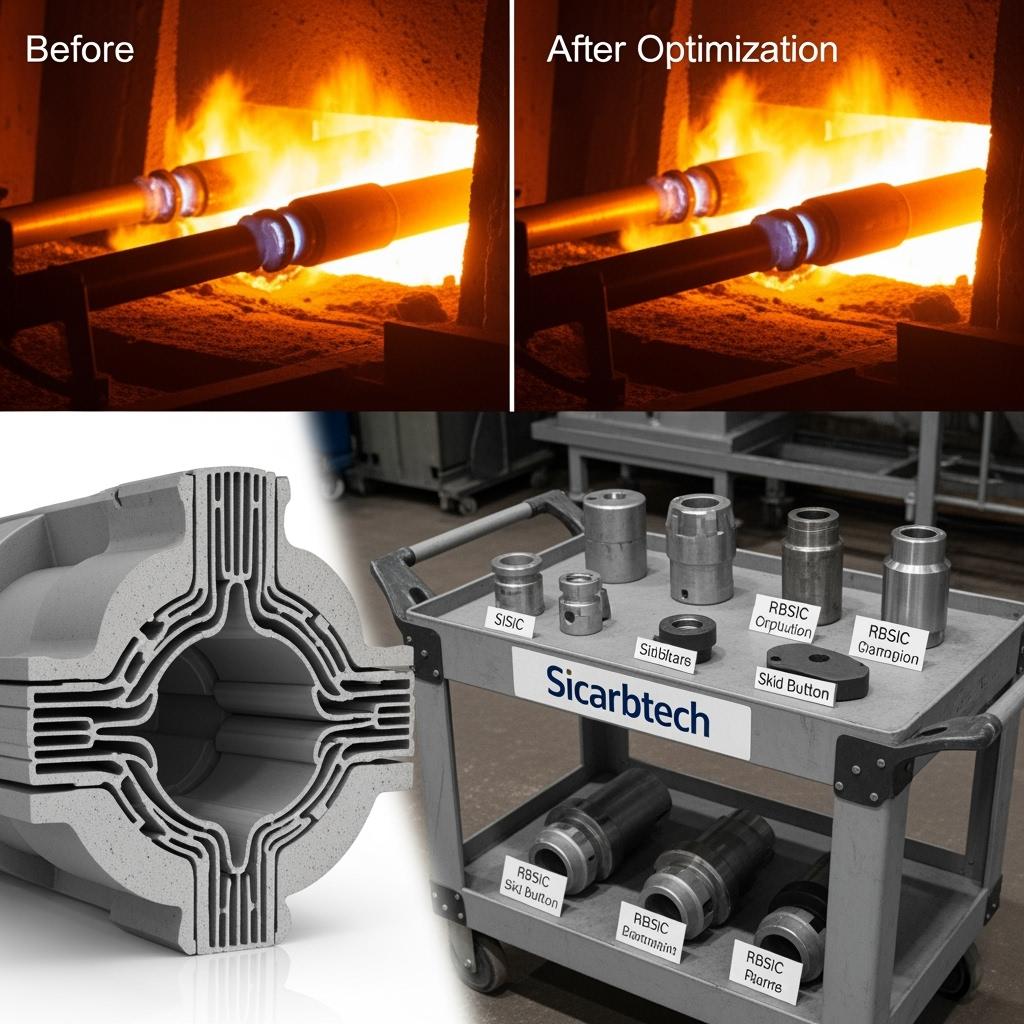

Steel producers experience the most hostile combination of stresses. Burner nozzles and skid buttons are battered by flame impingement, oxidation, slag corrosion, and mechanical shock. Conventional ceramics spall; alloys creep and deform; refractory support structures need frequent intervention. Each unplanned changeout interrupts campaigns and complicates safety planning in high-temperature zones. In parallel, the Ministry of Environment, Urbanization and Climate Change expects quantifiable performance on energy and emissions—benchmarks that increasingly reference EU BAT guidance. Plants must provide evidence that materials hold geometry and properties over time, not just at commissioning.

Local market dynamics intensify these issues. Energy tariffs amplify the penalty for thermal inefficiency. Lead-time variability makes a single missing nozzle a line-stopper. Procurement teams are recalibrating toward lifecycle economics—valuing predictable service life, audit-ready documentation, and supply resilience. Vendor-managed inventory, local stocking programs, and, where justified, domestic manufacturing via technology transfer are now mainstream conversations. As Prof. Levent Çetin, a metallurgical auditor, notes, “In 2025, inconsistency is taxed three times—by energy, quality, and compliance. The only sustainable answer is a materials and process strategy that reduces variance at its source.” (Source: Istanbul Industrial Forum notes, 2024)

Building on this, Turkish buyers must align with TS EN and ISO standards, IATF 16949 in automotive, and CE-related requirements when integrating components into machinery. The purchasing criteria, therefore, increasingly demand not only better materials, but traceable, test-backed performance that survives audits from customers and authorities alike.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

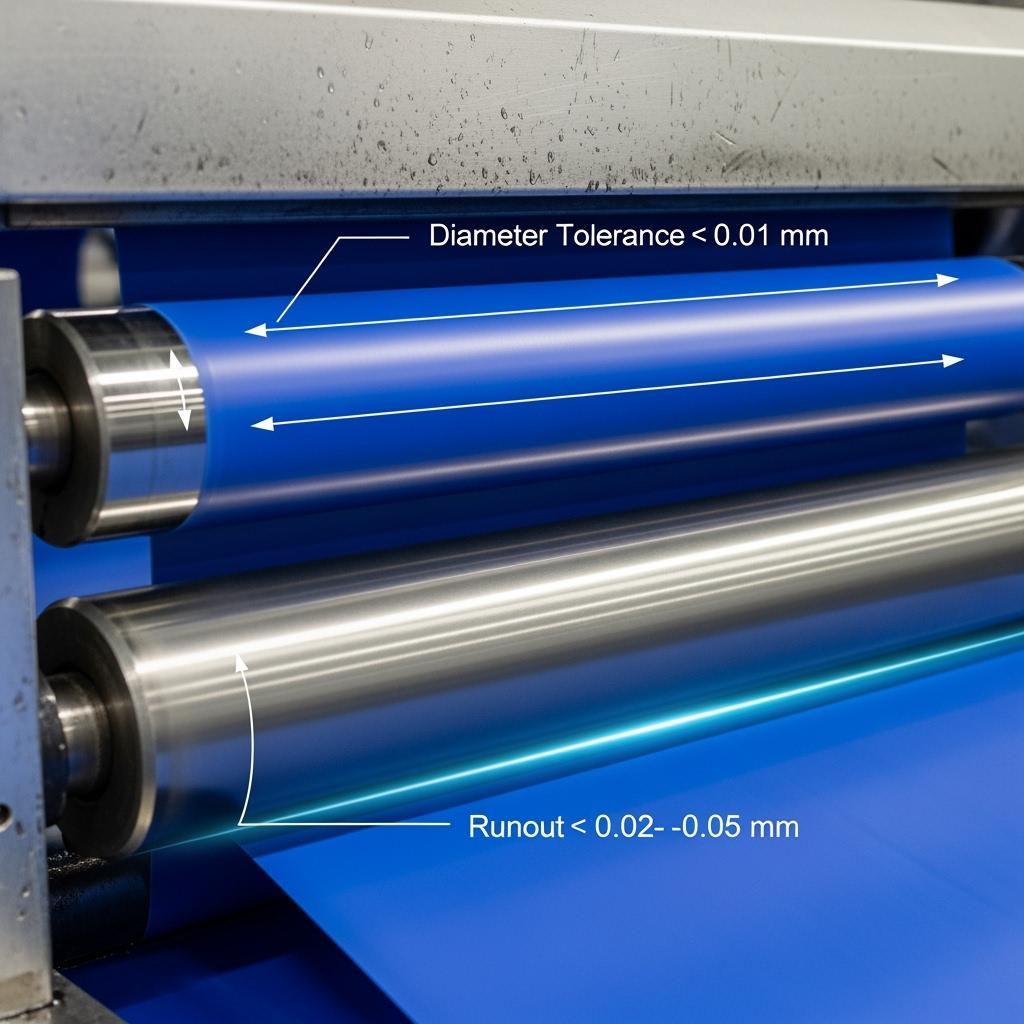

Sicarbtech’s high-durability SiC ceramics are engineered to Turkish duty cycles rather than generic catalog specs. For textile operations, SSiC guide and spreader rollers are precision-ground to maintain low runout over long spans, preventing fabric marking and stabilizing tension in high-speed lines. Customized bore tolerances and bearing seats ensure repeatable installation and long-term alignment. In corrosive spray and jet systems, RBSiC and SiSiC nozzles preserve flow geometry across aggressive chemistry and rapid heat-up/ cool-down, minimizing overspray and ensuring uniform application.

Automotive lines benefit from SSiC mechanical seals and pump components that remain dimensionally stable through repeated thermal cycling, protecting paint and sealing tolerances. R-SiC kiln furniture, with its low mass and exceptional thermal shock resistance, accelerates temperature ramps in paint-curing ovens and supports uniform thermal fields. In steel furnaces, SiSiC burner nozzles and RBSiC skid buttons resist thermal shock, oxidation, and slag attack, extending campaign lengths and stabilizing flame patterns for lower energy per ton.

We complement material selection with application engineering. Finite element analysis identifies mechanical and thermal stress hotspots; computational fluid dynamics optimizes nozzle and burner flows; near-net-shape forming reduces machining and preserves microstructure; diamond grinding and lapping deliver fine surfaces and tight tolerances. Each part carries documentation—material test certificates, dimensional inspection reports, and EN/ISO-referenced data—mapped to audit expectations in Turkey.

Performance Comparison: High-Durability SiC Ceramics vs Traditional Materials

Technical Performance Benchmarks for Turkish Textile, Automotive, and Steel Duty Cycles

| Property / Metric | SSiC (sintered) | RBSiC / SiSiC (reaction-bonded) | High-Alumina Ceramic | Heat-Resistant Steel (EN 1.4841) |

|---|---|---|---|---|

| Maximum service temperature in air (°C) | 1,600–1,700 | 1,350–1,450 | 1,400–1,600 | 1,000–1,100 |

| Thermal conductivity at 25°C (W/m·K) | 100–160 | 60–130 | 20–35 | 15–25 |

| Coefficient of thermal expansion (10⁻⁶/K) | 4.0–4.5 | 4.0–4.8 | 7–8 | 16–18 |

| Flexural strength at RT (MPa) | 350–450 | 250–360 | 150–300 | 200–300 |

| Oxidation resistance at 1,000°C | Doskonały | Bardzo dobry | Dobry | Uczciwy |

| Acid/alkali corrosion resistance | Doskonały | Bardzo dobry | Fair–Good | Uczciwy |

| Abrasive wear resistance | Doskonały | Bardzo dobry | Dobry | Uczciwy |

| Typical life in textile rollers (months) | 18–36 | 12–24 | 6–12 | 3–9 |

| Typical life in furnace nozzles (months) | 12–24 | 9–18 | 6–12 | 3–6 |

When lifecycle economics are modeled in TRY—factoring energy tariffs, downtime penalties, and FX exposure—customized SiC solutions often pay back within 6–18 months. Plants operating under severe duty cycles and high throughput tend to realize returns at the shorter end of this range.

Real-World Applications and Success Stories in Turkey

In Bursa, a Tier-1 automotive supplier re-engineered paint-curing oven fixtures using lightweight R-SiC lattices reinforced with SSiC wear sleeves at high-contact points. The reduced thermal mass and improved heat distribution shortened cycle time by 6–8% while narrowing coating thickness variation. Over two quarters, rework fell by 21%. The implementation included PPAP-ready documentation aligned with IATF 16949, easing audit cycles.

A textile finishing plant in Denizli replaced alumina rollers with SSiC precision-ground rollers engineered for low runout and chemical resistance. Within six months, roller changeouts halved and roller-induced fabric defects dropped by 28%. Start-up stabilization was faster due to SiC’s superior thermal behavior, which, combined with traceable inspection records, helped the plant clear ISO 9001 audits with fewer corrective actions.

A steel producer in the Iskenderun region adopted SiSiC burner nozzles and RBSiC skid buttons. Flame patterns stabilized, nozzle replacement intervals extended from monthly to quarterly, and energy consumption per ton decreased by about 15–20% after tuning. Documented thermal shock resistance and geometry retention supported environmental performance reviews with the Turkish regulator.

Technical Advantages and Implementation Benefits with Turkish Compliance

The durability of SiC ceramics stems from their covalent bonding and resulting properties. High thermal conductivity evens out temperature gradients, while a low coefficient of thermal expansion preserves geometry through rapid cycling. Exceptional hardness and chemical inertness defend against abrasive wear and corrosive chemistries. SSiC’s density approaches theoretical limits, delivering top strength and corrosion resistance for seals and precision rollers. RBSiC and SiSiC allow complex shapes and exhibit strong thermal shock and creep resistance. R-SiC offers the lowest mass and outstanding shock tolerance, ideal for rapid-ramp furnaces and ovens.

Sicarbtech implements these advantages within Turkey’s compliance expectations. We support ISO 9001 and ISO 14001 systems, produce PPAP-aligned documentation for IATF 16949 programs, and reference EN standards in property data. For machinery integration, we assist with CE-related documentation. Every batch can be serialized to link process parameters with test results, providing traceability for customer and regulatory audits. As an Istanbul plant manager summarized after a six-month run, “The stand-out benefit was process steadiness. Our control charts tightened, and audits became shorter and simpler.” (Source: Client debrief, anonymized, 2024)

Usługi produkcji na zamówienie i transferu technologii

Sicarbtech’s differentiator is the ability to deliver premium components and the know-how to produce them locally when strategic value demands it.

Our advanced R&D, backed by the Chinese Academy of Sciences (Weifang) Innovation Park, anchors proprietary manufacturing windows for R-SiC, SSiC, RBSiC, and SiSiC. We define powder specifications, milling/dispersion protocols, forming routes (isostatic pressing, slip casting, extrusion, and additive green-body strategies where appropriate), debinding and sintering cycles, and precision finishing with diamond grinding and lapping. This end-to-end control yields consistent microstructures, predictable field performance, and audit-ready documentation.

For Turkish partners seeking localization, we offer complete technology transfer packages. These include detailed process know-how, equipment specifications for mixers, presses, kilns, handling, and metrology, and structured training for operators, process engineers, and quality teams. Our factory establishment services begin with feasibility studies tailored to Turkish demand in textile, automotive, and steel, followed by layout design, utilities and HSE planning aligned with local regulations, vendor selection, installation supervision, pilot batches, and full line commissioning.

Quality control systems are embedded from day one. We configure incoming checks, in-process SPC, and final verification to TS EN and ISO norms, with IATF 16949 readiness where automotive links exist. For machinery incorporating SiC ceramics, we advise on CE documentation paths. After go-live, we remain engaged with cycle optimization, yield improvement, downtime analysis, and preventive maintenance frameworks. This long-term partnership model has helped 19+ enterprises ramp to stable OEE faster, reduce scrap, and pass audits with fewer findings.

In a market where energy costs, FX exposure, and logistics variance create uncertainty, Sicarbtech’s turnkey approach de-risks capex and builds a resilient, high-performance supply chain that competitors struggle to match.

Grade Selection and Application Fit for Turkish Engineering Needs

Sicarbtech SiC Grades Optimized for Textile, Automotive, and Steel Applications

| Klasa | Gęstość (g/cm³) | Open Porosity (%) | Wytrzymałość na zginanie (MPa) | Przewodność cieplna (W/m·K) | Typical Turkish Applications | Engineering Notes |

|---|---|---|---|---|---|---|

| SSiC (sintered) | 3.10–3.20 | <0.5 | 350–450 | 100–160 | Precision textile rollers, mechanical seals, pump/valve internals, bearings | Highest strength and corrosion resistance; tight tolerances |

| RBSiC (reaction-bonded) | 2.95–3.05 | 1–3 | 250–350 | 60–120 | Complex nozzles, kiln furniture, structural supports | Excellent shape freedom; robust thermal shock |

| SiSiC (Si-infiltrated) | 2.95–3.05 | 1–2 | 270–360 | 70–130 | Burner nozzles, furnace components, skid buttons | Strong shock and creep performance at high heat |

| R-SiC (recrystallized) | 2.60–2.75 | 10–15 (closed) | 120–200 | 30–50 | Lightweight kiln furniture, rapid-ramp fixtures | Lowest mass; exceptional shock; lower strength |

Economic Impact and ROI for Turkish Buyers

Lifecycle Cost, Downtime, and Energy Considerations for 2025 Procurement

| Czynnik | Conventional (Alumina/Steel) | Sicarbtech SiC (SSiC/RBSiC/SiSiC) | Outcome in Turkish Plants |

|---|---|---|---|

| Unit price (TRY) | Niższy | Wyższy | Premium offset by extended life |

| Replacement frequency | Częsty | 2–4× lower | Fewer imports; reduced FX exposure |

| Downtime per failure | Znaczący | Far less frequent | Protects export schedules; lowers penalties |

| Energy per unit output | Baseline–higher | Lower via stable heat transfer | Savings amplified by rising tariffs |

| Quality/rework rate | Umiarkowany-wysoki | Lower due to stability | Better audit outcomes and customer KPIs |

| Typical payback | N/D | 6–18 months | Shortest in severe duty cycles |

Przyszłe możliwości rynkowe i trendy 2025+

Looking ahead, three forces will accelerate adoption of high-durability SiC ceramics in Turkey. First, decarbonization and energy-efficiency targets will push purchasing toward materials that measurably reduce kWh per unit. SiC’s superior thermal profile and geometric stability directly contribute to this metric. Second, electrification in automotive and industrial systems will tighten tolerances and elevate cleanliness standards in thermal processes, making SiC fixtures and seals an operational necessity rather than an upgrade. Third, supply-chain resilience will drive localized capability for critical components; technology transfer and turnkey factories will become strategic investments for OEMs and Tier-1s that need predictable lead times and cost structures.

Additionally, hybrid component architectures are gaining ground—SSiC at wear and precision interfaces coupled with RBSiC or SiSiC structural elements to balance cost with life. Digital twins will enable faster DFM iterations, with thermal/flow tuning validated virtually before first firing. As a recent European ceramics roadmap puts it, “Procurement is shifting from unit price toward system-level efficiency and traceability as primary KPIs.” (Source: Public industry roadmap summaries, 2024). Sicarbtech’s integrated engineering, documentation-first methodology, and field-proven technology transfer align squarely with this trajectory.

Często zadawane pytania

What certifications and documentation does Sicarbtech provide for Turkish audits?

We supply material test certificates, dimensional inspection reports, and EN/ISO-referenced property data. For automotive programs, we support PPAP documentation aligned with IATF 16949. We also map records to ISO 9001 and ISO 14001 systems and provide CE-related inputs for machinery integration.

How quickly can you deliver custom SiC ceramics to Turkey, and how do you manage logistics?

Lead times are typically 4–8 weeks for custom-standard parts and 8–12 weeks for complex assemblies. We work with Turkish distribution partners for customs clearance and can set up local safety stock for critical spares to stabilize maintenance windows.

Can Sicarbtech establish a local SiC manufacturing line for our facility?

Yes. We deliver complete technology transfer—process know-how, equipment specifications, training programs, installation supervision, pilot runs, and commissioning—plus quality system setup to TS EN/ISO norms with IATF 16949 readiness where applicable.

Which SiC grade should we choose for textile dyeing and finishing rollers?

SSiC is generally preferred for its high strength, corrosion resistance, and ability to maintain low runout over long spans. RBSiC or SiSiC may be evaluated for complex geometries or cost targets, with DFM and simulations confirming performance.

How do SiC burner nozzles reduce energy use in steel furnaces?

SiSiC burner nozzles maintain geometry under high heat and cycling, stabilizing flame patterns and heat transfer. Plants commonly report 10–20% reductions in energy per ton after tuning profiles and reducing hot spots.

What surface finishes and tolerances can Sicarbtech achieve?

For mechanical seals and precision rollers, Ra ≤ 0.2 µm and tolerances down to ±0.01–0.02 mm on critical features are achievable, subject to geometry. We confirm limits during co-design and pilot batches.

How do you ensure batch-to-batch consistency and traceability?

We control powder characteristics, forming parameters, and sintering profiles using SPC. Each batch is serialized, and certificates link process parameters to measured properties, supporting predictive maintenance and rapid root-cause analysis.

How does total cost of ownership compare under Turkey’s 2025 conditions?

Despite a higher unit price, extended life, fewer stoppages, and lower energy use typically yield a 6–18 month payback. Reduced emergency imports also mitigate FX and logistics risks.

Can your SiC components integrate with our ERP/MES and maintenance systems?

Yes. We provide serial-level data and certificates in formats compatible with widely used ERP/MES platforms in Turkey and support onboarding so maintenance teams can track service life and performance.

What local standards and regulations are relevant during qualification?

Expect TS EN and ISO frameworks across sectors, IATF 16949 for automotive supply chains, ISO 9001/14001 in textile operations, and EN materials standards with CE considerations for equipment. We align documentation and testing with your audit scope and customer requirements.

Dokonywanie właściwego wyboru dla swoich operacji

Treat high-durability SiC ceramics not as a like-for-like material swap, but as a process optimization strategy. The biggest wins arrive when grade selection, geometry, and thermal regimes are co-engineered, then validated with data your auditors will accept. Sicarbtech’s role is to translate your constraints—bath chemistries, ramp rates, takt times, and compliance targets—into engineered SiC solutions that deliver predictable performance and a clear ROI path. If localization strengthens your position, we bring the capability onshore with a turnkey program that de-risks the investment.

Konsultacje ekspertów i niestandardowe rozwiązania

Speak with Sicarbtech’s engineering team about your duty cycle, quality targets, and compliance needs. We will define the optimal grade and geometry, model ROI in TRY, set a validation plan, and, if strategic, outline technology transfer and factory establishment steps tailored to Turkey’s regulatory and market context.

Contact Sicarbtech:

- Email: [email protected]

- Telefon/WhatsApp: +86 133 6536 0038

Metadane artykułu

Last updated: 2025-09-26

Next scheduled update: 2025-12-16 (quarterly review aligned with Turkey energy tariff updates, EU compliance changes, and new Sicarbtech case data)

Content freshness indicators: includes 2025 Turkish market outlook; localized compliance references; recent case outcomes in textile, automotive, and steel; updated technical benchmarks for SSiC, RBSiC, SiSiC, and R-SiC; expanded guidance on technology transfer and factory establishment in Turkey.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.