Tailored SiC Coatings and Linings for Harsh Environments | Sicarbtech Turkey 2025 Pillar Page

Udział

Sicarbtech is the Silicon Carbide Solutions Expert trusted by Turkish textile, automotive, and stalowego manufacturers to protect critical assets with tailored silicon carbide coatings and linings. From Weifang City—China’s silicon carbide manufacturing hub—and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we deliver end-to-end solutions spanning R-SiC, SSiC, RBSiC, and SiSiC. With more than 10 years of customization experience and support for 19+ local enterprises, we combine materials science, process engineering, and on-site execution to extend equipment life, cut energy use, and streamline audits across Turkey’s most demanding plants.

Executive Summary: Why Silicon Carbide Coatings and Linings Matter in Turkey’s 2025 Operations

Turkey’s industrial base is operating under tighter energy tariffs, rising export scrutiny, and stricter environmental oversight. Steel producers in Marmara and Iskenderun are chasing stable heat profiles and longer campaigns despite corrosive off-gases and slag-laden atmospheres. Automotive clusters around Bursa and Kocaeli are combating fouling and heat-driven distortion in ovens and thermal equipment while maintaining IATF 16949 discipline. Textile processors in Denizli and Gaziantep must protect spray booths, ducts, and heat exchangers from aggressive chemistries that degrade metal and conventional ceramics. Against this backdrop, tailored silicon carbide coatings and linings bring a rare combination of high thermal conductivity, low thermal expansion, and chemical inertness that directly address premature failure modes.

Moreover, the business case is strengthening. Coatings and linings engineered to real duty cycles reduce unplanned stoppages and extend maintenance intervals, while low-mass SiC structures and high-conductivity interfaces shorten ramps and flatten temperature gradients—both of which reduce kWh per unit. Sicarbtech’s approach is not a one-size overlay; it is a co-engineered system that matches substrate, surface preparation, SiC layer architecture, and installation method to the environment and audit requirements. As Dr. Eren Kılıç, a materials reliability consultant, notes, “In harsh industrial environments, geometry control and chemistry resistance are the two levers that buy back uptime. SiC lets you pull both, without paying a thermal penalty.” (Source: Industrial Reliability Forum, 2024)

Industry Challenges and Pain Points in Turkish Plants

Harsh environments tax equipment in ways that traditional claddings and refractories struggle to manage. In steel operations, off-gas ducts, burner blocks, and furnace throats face high-velocity particulates, fluctuating oxygen levels, sulfur-bearing gases, and thermal shocks during starts and skids. Unprotected metals oxidize rapidly; standard ceramics crack along thermal gradients. A small spall can cascade into hot spots, distorted flame patterns, and unplanned outages. Each hour of unscheduled downtime is amplified by energy lost to reheating and campaign disruptions. Furthermore, plant KPIs reported to the Ministry of Environment, Urbanization and Climate Change place a premium on stable performance and documented maintenance.

Automotive ovens and heat-treatment systems present a different but related challenge. Coating lines need clean, stable surfaces that do not shed particles or deform under cycling. Build-up from volatiles and overspray increases thermal resistance, forcing higher setpoints and longer ramps. Standard protective layers may insulate rather than conduct, causing localized overheating that affects coating uniformity and complicates PPAP upkeep. When a lining fails or a coating delaminates, corrective actions multiply—containment plans, retests, and delayed shipments.

In textile chemical finishing, corrosive media and fine particulates degrade ducts, hoods, and heat exchangers. Conventional stainless steels pit or scale, and polymeric coatings soften or blister under heat, prompting frequent patching. The cost of repeated interventions is not limited to the spare itself—every intervention bleeds throughput, increases energy per batch, and triggers ISO 9001 documentation overhead.

Local market conditions sharpen the edges of these problems. Energy tariffs magnify the cost of thermal inefficiency; TRY volatility makes emergency imports painful; and EU-aligned expectations raise the bar for EN-referenced materials and CE-related documentation in integrated equipment. Plants cannot tolerate coatings that simply “look good on day one.” They need engineered SiC solutions that maintain geometry, resist chemical attack, and come with traceable evidence. As Prof. Leyla Aksoy, a metallurgical auditor, puts it, “In 2025, the gap between datasheet claims and audit-ready evidence decides supplier selection. Repeatable thickness, adhesion, and property data matter more than brochure adjectives.” (Source: Istanbul Industry Audit Roundtable, 2024)

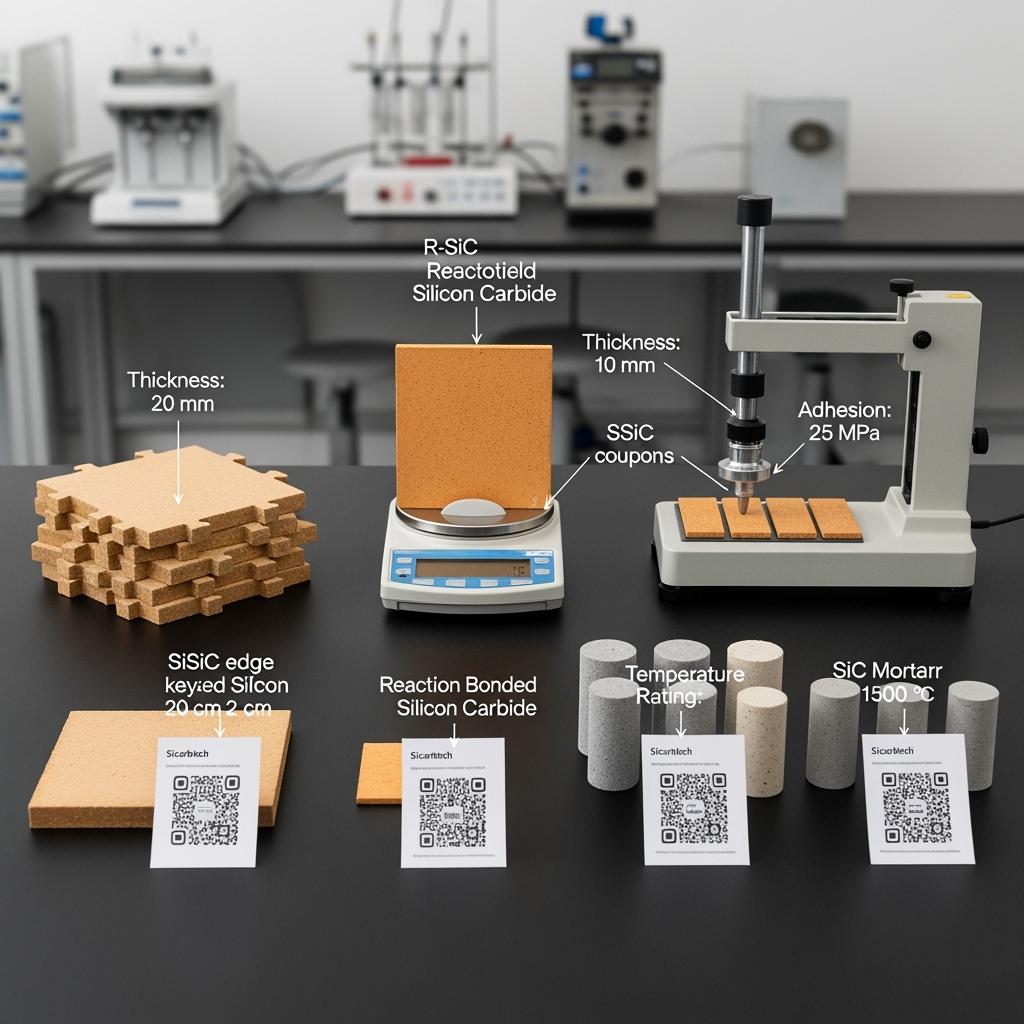

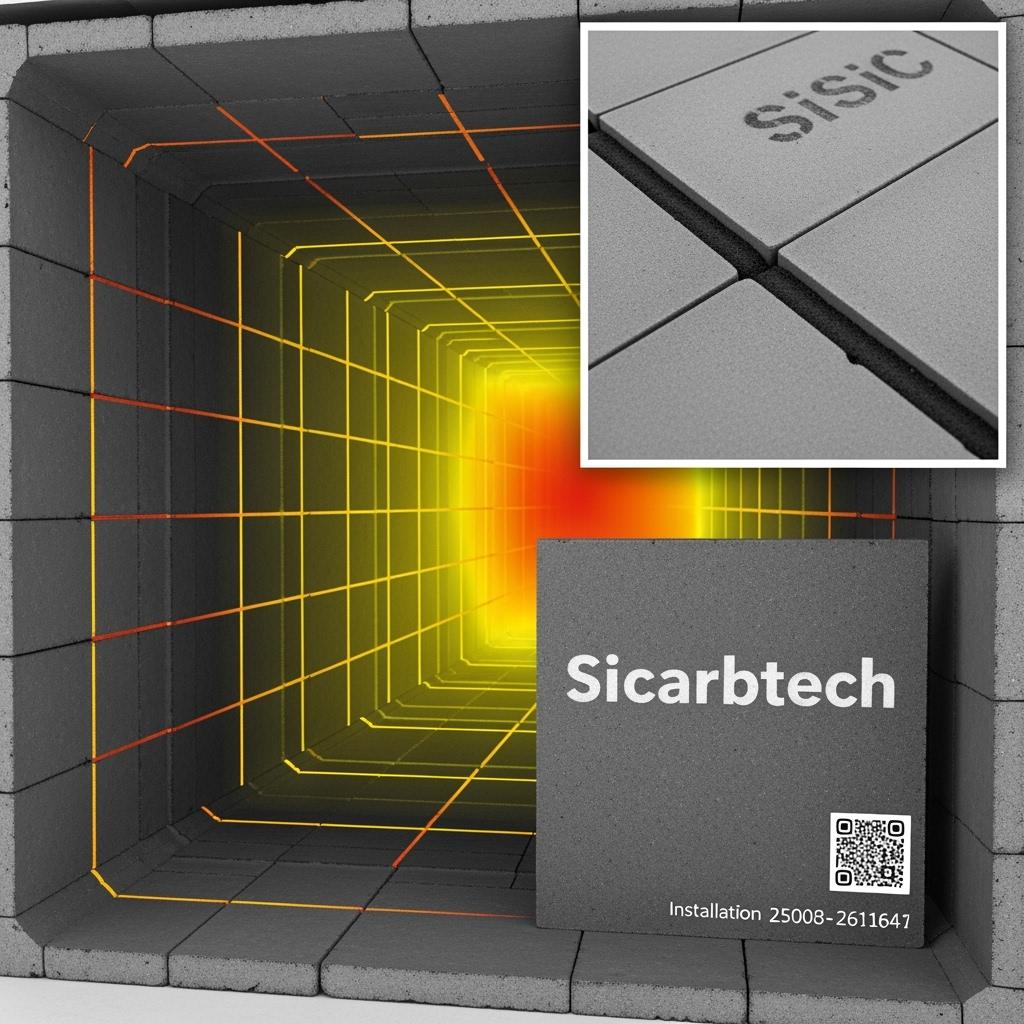

Advanced Silicon Carbide Solutions Portfolio for Coatings and Linings

Sicarbtech’s portfolio integrates SiC materials science with installation know-how to deliver coatings and linings that survive heat, shock, and chemistry without compromising thermal performance. For steel furnaces and off-gas lines, SiSiC and RBSiC tile systems with SiC-rich mortars maintain geometry under flame impingement and particulate erosion. Where low mass and thermal shock dominate, R-SiC panels and liners minimize thermal inertia, reducing lag and lowering thermal strain. For automotive ovens, thin SSiC-based coating architectures combine high thermal conductivity with low CTE, enabling quick ramps and uniform temperature fields without flaking or particle generation. In textile environments, dense SiC layers over treated substrates resist acids, alkalis, and oxidizers, protecting metal components while easing clean-in-place routines.

We start with your failure modes. Our engineers examine temperature maps, chemistry analyses, velocity and particulate profiles, and maintenance logs. Based on these inputs, we select layer architectures—primer chemistries, SiC particle distributions, binder systems, and seal coats—and specify surface preparation protocols that maximize adhesion without compromising substrate integrity. Where required, we supply preformed SiSiC/RBSiC tiles and R-SiC panels tailored to geometry, then supervise on-site installation, curing, and commissioning to ensure results match models.

Performance Comparison: SiC Coatings and Linings vs Traditional Materials

Thermal, Mechanical, and Chemical Benchmarks for Harsh Industrial Environments

| Property / Metric | SSiC (coating/layer) | SiSiC / RBSiC (tiles/linings) | R-SiC (lightweight panels) | High-Alumina Ceramic | Stainless Steel (e.g., 1.4841) |

|---|---|---|---|---|---|

| Max service temperature in air (°C) | 1,600–1,700 | 1,350–1,450 | 1,400–1,600 | 1,400–1,600 | 1,000–1,100 |

| Thermal conductivity (W/m·K, 25°C) | 100–160 | 60–130 | 30–50 | 20–35 | 15–25 |

| Coefficient of thermal expansion (10⁻⁶/K) | 4.0–4.5 | 4.0–4.8 | 4.5–5.0 | 7–8 | 16–18 |

| Oxidation/corrosion resistance | Doskonały | Bardzo dobry | Bardzo dobry | Dobry | Uczciwy |

| Odporność na szok termiczny | Doskonały | Bardzo dobry | Doskonały | Umiarkowany | Umiarkowany |

| Typical maintenance interval (relative) | 2–4× longer | 1.5–3× longer | 2–3× longer | Linia bazowa | Krótsza |

In practice, SiC’s low CTE and high conductivity limit thermal strain and hot spots, supporting both structural integrity and energy efficiency. Plants report steadier temperature fields, fewer delaminations, and lower kWh per unit when SiC replaces insulating or creep-prone alternatives.

Real-World Applications and Success Stories from Turkish Plants

A Marmara steel producer lined critical off-gas duct sections with SiSiC tiles bedded in SiC-rich mortar after repeated scale formation and hot spots. The new lining stabilized surface temperatures, reducing cold-end corrosion and unplanned outages. After optimization, fuel per ton fell by 10–14%, and maintenance windows shifted from monthly patching to quarterly inspections.

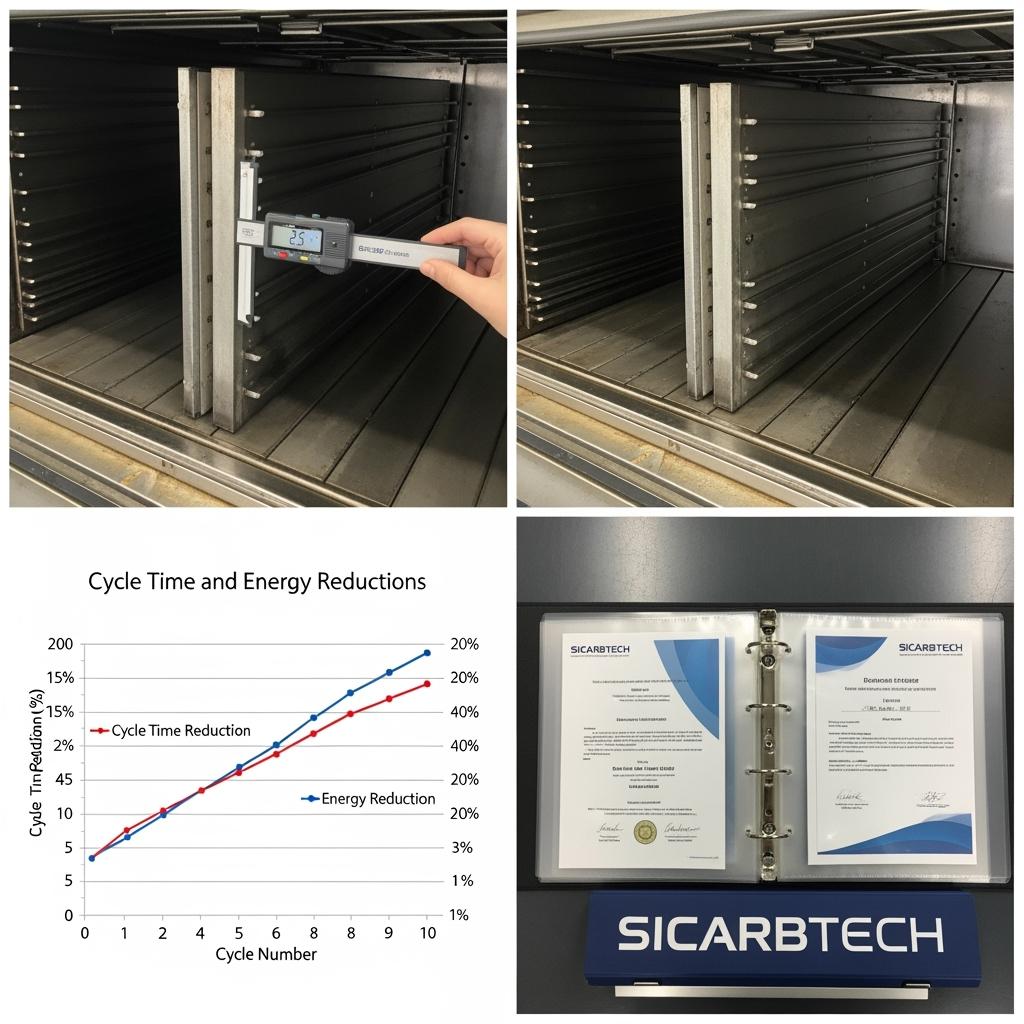

In Bursa, an automotive paint-curing line adopted an SSiC-based thin coating over prepared stainless panels in zones prone to fouling and thermal distortion. The higher conductivity and low CTE allowed lower setpoints with faster ramp-up, while the dense surface shed overspray more readily. Over two quarters, cycle time shortened by 5–7%, and coating uniformity improved, reducing rework. PPAP documentation integrated smoothly thanks to serialized thickness and adhesion reports.

A Denizli textile finisher protected ducts and heat-exchanger headers with SiC linings designed for acid and alkali resistance. Fouling decreased, CIP intervals lengthened, and post-clean restart times were shorter due to retained thermal performance. Energy per batch improved, and ISO 9001 audits flagged fewer corrective actions owing to stable SPC charts.

Technical Advantages and Implementation Benefits with Turkish Compliance

Silicon carbide does three things exceptionally well in harsh environments. First, it spreads heat rather than trapping it, allowing equipment to reach steady-state faster and at lower setpoints. Second, it resists thermal shock via low CTE and robust bonding, minimizing crack initiation during rapid transitions. Third, it withstands corrosive chemistries—from sulfur-bearing gases to acidic/alkaline sprays—without losing geometry or shedding particles.

Implementation matters as much as material selection. Sicarbtech specifies surface prep windows, anchor profiles, and interlayer choices that secure adhesion under cyclic stress. We validate with in-situ pull-off tests and hardness mapping and provide EN-referenced property data aligned with Turkey’s audit expectations. For automotive-linked programs, we package evidence in PPAP-friendly formats aligned with IATF 16949. As Nilay Demir, a quality systems auditor, notes, “Adhesion data attached to a serial number shortens the auditor’s checklist. It turns a subjective inspection into an evidence-backed sign-off.” (Source: Quality Systems Notes, 2024)

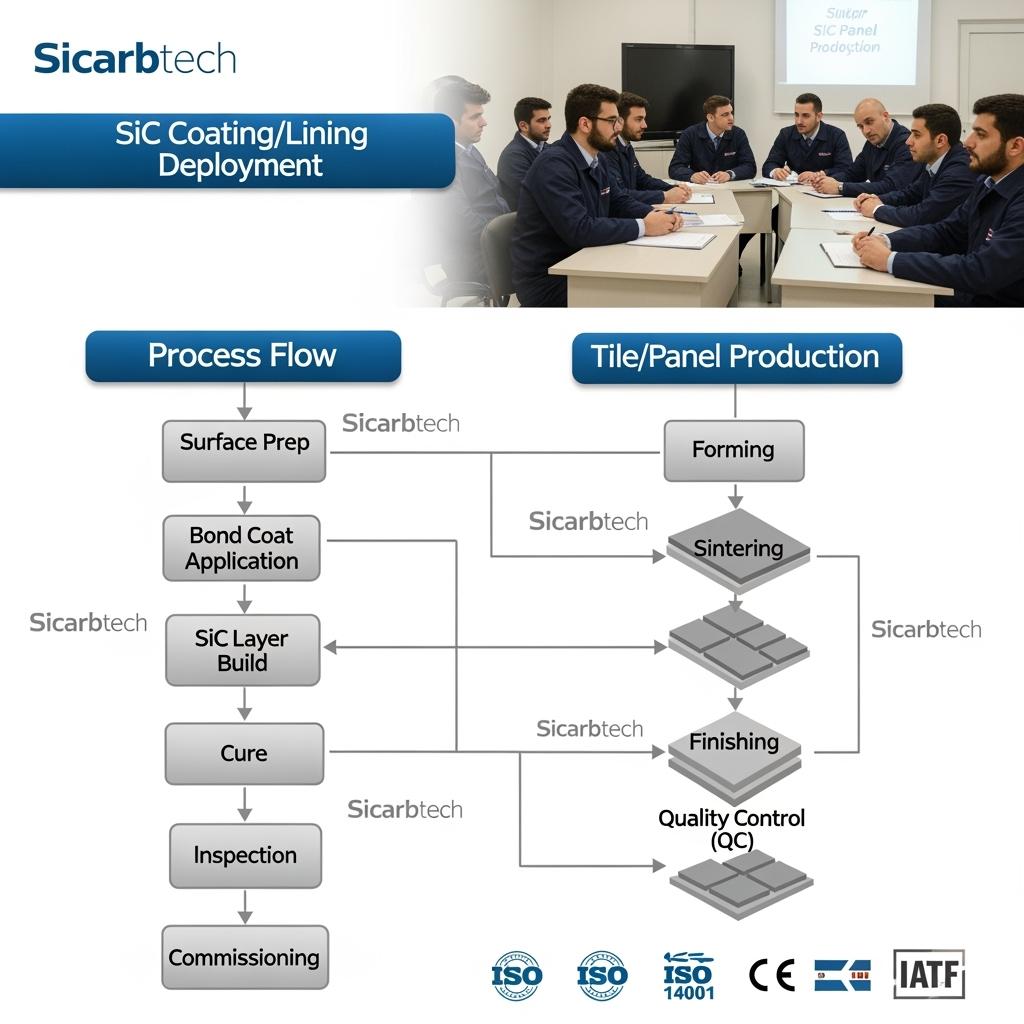

Usługi produkcji na zamówienie i transferu technologii

Sicarbtech’s competitive advantage is comprehensive: premium SiC chemistries and preforms, controlled coating processes, and the ability to localize capability in Turkey when justified by volume and risk.

Our advanced R&D—backed by the Chinese Academy of Sciences (Weifang) Innovation Park—supports proprietary processes for R-SiC, SSiC, RBSiC, and SiSiC. We tailor powder chemistries and particle-size distributions for coating feeds and mortars; enforce contamination-safe dispersion and mixing; and define layer architectures—from bond coats to wear or barrier layers—optimized for your temperatures, chemistries, and velocity profiles. For preformed linings, we select forming routes (cold isostatic pressing, slip casting, extrusion, additive green-body strategies) based on geometry complexity and shock demands, then tune debinding and sintering to hit density, porosity, and residual silicon targets. Finishing includes diamond grinding and lapping to mate tiles and panels with minimal stress concentrators.

For Turkish partners, we provide complete technology transfer packages. These include detailed process know-how, equipment specifications (grit blasting cabinets with calibrated profiles, spray or slurry application skids, curing ovens, isostatic presses, clean kilns, handling fixtures), and metrology suites for thickness (magnetic/eddy current and cross-section), adhesion (pull-off), hardness, density, and porosity. Structured training programs cover operators, process engineers, maintenance, and QA. Our factory establishment services move from feasibility studies grounded in Turkish textile, automotive, and steel demand through layout and utilities design, HSE planning per local regulation, vendor selection, installation supervision, pilot runs, MSA, and commissioning.

Quality systems are built in from day one. We align control plans with TS EN and ISO frameworks, implement SPC on critical variables (substrate roughness Ra/Rz, layer thickness, adhesion MPa, porosity), and structure documentation for CE-related machinery integration and ISO 14001 environmental reporting. Post-launch, our engineers support cycle optimization, failure analysis, repair procedures, and preventive maintenance planning. This turnkey approach—validated in engagements with 19+ enterprises—compresses time-to-quality, de-risks capex, and creates durable local supply for critical SiC coatings and linings.

Engineering Data and Architecture Selection for Coatings and Linings

Coating and Lining Architecture Options with Typical Performance Windows

| Architecture | Typowa grubość | Target Adhesion (pull-off, MPa) | Thermal Range (°C) | Typical Turkish Use Cases | Uwagi |

|---|---|---|---|---|---|

| SSiC thin-film coating on prepped steel | 100–500 µm | 8–15 | Up to 600–800 (surface) | Automotive ovens, warm ducts, splash zones | High conductivity; low mass; smooth, cleanable surface |

| SiC composite coating with graded interlayers | 0.5–2.0 mm | 10–20 | Up to 1,000+ (localized) | Textile chem handling, hot ducts, HX headers | Graded layers mitigate CTE mismatch under cycling |

| SiSiC/RBSiC tile system with SiC mortar | 10–40 mm | N/A (mechanical anchoring + mortar shear) | Up to 1,350–1,450 | Steel off-gas, burner blocks, throats | High shock and erosion resistance; serviceable sections |

| R-SiC lightweight panels mechanically fixed | 6–20 mm | N/A (mechanical + gasket) | Up to 1,400–1,600 | Rapid-ramp zones, heat shields | Low thermal inertia; fast ramps and cool-downs |

Cost and Energy Impact for Turkish Buyers

Lifecycle Economics of SiC Coatings and Linings Under 2025 Tariffs

| Czynnik | Conventional Solutions (Stainless/Alumina/Polymer) | Sicarbtech SiC Coatings and Linings | Outcome in Turkey |

|---|---|---|---|

| Upfront price (TRY) | Niższy | Wyższy | Premium offset by energy and uptime gains |

| Replacement frequency | Wysoki | 2–4× lower | Fewer imports; reduced FX exposure |

| Energy per unit output | Baseline–higher | Lower via uniform heat and low mass | Tariff-sensitive savings |

| Downtime for repair | Frequent/unplanned | Planned and less frequent | Protects export schedules |

| Cleanliness and fouling | Zmienna | Improved (dense SiC surfaces) | Fewer quality incidents and rework |

| Typical payback | N/D | 6–18 months | Faster in heat-intensive or corrosive zones |

Przyszłe możliwości rynkowe i trendy 2025+

Three structural shifts will elevate tailored SiC coatings and linings in Turkey. First, decarbonization pressure and rising energy costs will favor materials that lower setpoints and shorten ramps; SiC’s thermal conductivity and low mass directly support this. Second, audit intensity—especially for export-linked plants—will prioritize suppliers who deliver serial-level thickness and adhesion data tied to EN-referenced properties; this accelerates approvals and reduces findings. Third, supply resilience will push capability closer to the line; Sicarbtech’s technology transfer and local stocking can convert strategic intent into onshore execution.

Beyond these, hybrid protection strategies will grow—thin SSiC layers in zones where cleanliness and ramp speed matter, SiSiC/RBSiC tiles in hot, erosive sections, and R-SiC panels where shock and low inertia dominate. Digital twins for ducts and furnaces will become routine, enabling plants to simulate heat flow, particulate impingement, and stress before committing to tooling. As an EU industrial materials brief observed, “System efficiency and evidence-backed reliability are overtaking piece price as the decisive KPIs.” (Source: Public industry roadmap summaries, 2024). Sicarbtech’s documentation-first engineering and turnkey localization align directly with this procurement reality.

Często zadawane pytania

How does Sicarbtech verify adhesion and thickness for audit purposes?

We conduct pull-off adhesion tests, non-destructive thickness checks (magnetic/eddy current where applicable), and destructive cross-sections on witness coupons. Results are serialized and tied to EN-referenced material data for audit trails.

Can SiC coatings be applied on existing stainless steel equipment in our ovens and ducts?

Yes, provided surface preparation achieves the specified anchor profile and cleanliness. We may use graded interlayers to mitigate CTE mismatch and thermal cycling stress.

How do SiC linings affect energy consumption in steel furnaces?

High thermal conductivity smooths gradients and reduces hot spots, allowing lower setpoints. R-SiC’s low mass shortens ramps. Plants commonly report 10–20% energy reduction after tuning.

What is the typical maintenance interval for SiSiC tile linings in off-gas ducts?

Intervals vary by particulate load and chemistry, but plants often shift from monthly patching to quarterly inspections, with sectional replacements planned during scheduled stops.

Are SiC coatings suitable for corrosive textile chemical streams?

Yes. Dense SiC layers resist acids and alkalis and maintain smooth, cleanable surfaces. We tailor layer architecture for your chemistry and temperature profile.

Can Sicarbtech localize coating or tile manufacturing in Turkey?

Yes. We provide complete technology transfer, equipment specifications, operator and QA training, pilot runs, and commissioning, plus quality systems aligned with TS EN/ISO and CE-related requirements.

How do you ensure consistency from batch to batch?

We implement SPC on powder PSD, binder ratios, application parameters, and curing cycles. Each lot ships with serialized certificates covering thickness, adhesion, density/porosity (for tiles), and referenced properties.

Will your documentation integrate with our ERP/MES and IATF workflows?

Yes. Certificates and serial/batch data are delivered in digital formats compatible with common ERP/MES platforms used in Turkey, supporting PPAP-style records where needed.

What local regulations and standards should we plan for?

Expect TS EN and ISO frameworks, CE considerations for integrated equipment, and environmental reporting aligned with national rules informed by EU guidance. We map documentation to your audit scope.

How do Sicarbtech’s SiC solutions compare with traditional refractory or polymer coatings?

SiC provides higher thermal conductivity, lower CTE, and superior oxidation/corrosion resistance, translating into longer life, lower energy, and cleaner audits—benefits documented in Turkish deployments with 19+ enterprises.

Dokonywanie właściwego wyboru dla swoich operacji

The central question is not whether a coating can survive a single cycle, but whether it can stabilize your process week after week, with evidence auditors accept. SiC coatings and linings do this when the architecture, substrate prep, and installation method are co-engineered to your environment. Sicarbtech’s role is to convert your temperature maps, chemistries, and maintenance constraints into a protection system that lowers energy per unit, extends maintenance intervals, and compresses audit timelines—delivering ROI in both TRY and time.

Konsultacje ekspertów i niestandardowe rozwiązania

Bring us your failure modes and operating windows—thermal profiles, gas compositions, fouling data, and maintenance logs. Sicarbtech will recommend the optimal SiC architecture—SSiC thin layers, SiSiC/RBSiC tiles, or R-SiC panels—model energy and uptime benefits, define validation and inspection plans, and, if strategic, outline a technology transfer roadmap to localize capability in Turkey.

Contact Sicarbtech:

- Email: [email protected]

- Telefon/WhatsApp: +86 133 6536 0038

Metadane artykułu

Last updated: 2025-09-26

Next scheduled update: 2025-12-16 (quarterly review aligned with Turkey energy tariff changes, EU compliance updates, and new Sicarbtech case studies)

Content freshness indicators: includes 2025 Turkish market outlook; localized EN/ISO/CE references; new case outcomes for SiSiC tile linings, SSiC thin coatings, and R-SiC panels; expanded guidance on technology transfer and on-site installation support.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.