Custom SiC Materials for Brazilian Electronics Manufacturers

Udział

Executive summary: how custom silicon carbide will power Brazil’s electronics growth in 2025

Brazil’s electronics ecosystem is surging toward electrification and digitalization, with power electronics at the center. EV supply chains around São Paulo and Minas Gerais are scaling inverters, onboard chargers, and DC fast-charging infrastructure, while industrial drives in mining and oil are modernizing for energy efficiency and reliability. At the same time, high-frequency communications and edge data centers are spreading across logistics corridors, pushing thermal densities higher and shrinking form factors. Furthermore, compliance with ABNT NBR standards, ISO 9001/14001 quality frameworks, and sector-specific expectations like IATF 16949 for automotive and API/NACE considerations for oil-adjacent modules is now an entry ticket, not a differentiator. Within this context, custom silicon carbide materials—spanning wafers, substrates, and engineered ceramics—are the most potent lever Brazilian manufacturers can pull to improve efficiency, increase power density, and stabilize thermal performance.

Sicarbtech, based in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, has over 10 years of silicon carbide customization and supports more than 19 enterprises with full-cycle solutions. By combining powder and crystal engineering, precision finishing, application-specific design, and turnkey technology transfer—including factory establishment—Sicarbtech transforms SiC from a commodity material into a platform for competitive electronics manufacturing in Brazil. As 2025 procurement priorities shift toward total cost of ownership, heat management, and export-ready documentation, Sicarbtech provides a credible path from prototype to volume supply with predictable performance and audit-ready traceability.

Industry challenges and pain points: where Brazilian electronics lose watts, yield, and time

Brazilian electronics manufacturers face a multi-front challenge. On the device side, increasing switching frequencies and bus voltages in traction inverters, solar inverters, and motor drives introduce thermal hotspots and voltage stress that silicon cannot manage without derating. Silicon IGBTs and traditional MOSFETs pay a penalty in switching losses and thermal headroom, inflating heatsink mass and enclosure size. At the module level, bond-wire fatigue, substrate delamination, and solder joint failures accelerate if thermal cycling is not tightly controlled. In EV supply chains, the stakes are higher: a few percentage points of inverter efficiency translate into range, battery thermal comfort, and warranty outcomes that determine platform economics.

On the manufacturing side, Brazilian OEMs and Tier suppliers contend with variability in imported materials, FX swings that distort BOM costs, and long lead times that disrupt ramp schedules. Substrate and wafer quality—micropipe density, basal plane dislocations, and wafer bow—directly affects device yields, while the thermal conductivity and expansion matching of ceramic substrates govern module reliability during power cycling. Without consistent SiC materials and engineered ceramics, process windows narrow, yields fall, and PPAP or first article approvals drag on. “Our best efficiency improvements were undone by thermal runaway in a handful of stress corners,” notes Eng. Marcelo Quintas, a power electronics engineering manager supporting EV programs. “Material stability turned out to be the cheapest watt we could buy.” (Source: Brazil Power Electronics Outlook, 2024)

Regulatory complexity compounds technical risks. For automotive-bound electronics, IATF 16949 and ABNT NBR methods define documentation discipline and traceability depth. For oil-adjacent power and drives feeding offshore equipment, API 614/682 interfaces and NACE MR0175/ISO 15156 considerations may touch cooling and materials compatibility in module housings and pumps integral to test stands and platforms. Environmental oversight by IBAMA and safety norms under NR rules influence plant operations, from solvent management in wafer and substrate processing to thermal cycling test rigs. In addition, local incentives and content rules can reward domesticization, but only if quality and documentation match international expectations.

Hidden costs are equally corrosive. Extra grams of aluminum in heatsinks, overbuilt busbars to damp thermal spikes, and oversized enclosures for derated silicon all roll downhill into logistics, inventory, and installation expense. Energy intensity in test labs and burn-in rises when devices must run longer to screen variability. Yield losses from substrate voids or mechanical stress mismatches show up as scrap, rework, and line restarts. Finally, qualification queues stretch when data packs lack ABNT-referenced methods and cross-links to ISO or automotive templates. The Brazilian market’s 2025 winners will be those who tame these risks with materials that keep their structure and thermal performance under stress—and who document that performance without friction.

Advanced silicon carbide solutions portfolio for power electronics and thermal management

Sicarbtech’s portfolio is designed to meet Brazilian electronics manufacturers where they are: balancing device performance, module reliability, and supply certainty. For device makers, we supply custom SiC substrates and engineered ceramics that complement wafer strategy; for module integrators, we deliver thermal and structural ceramics that safeguard power cycling reliability; and for system OEMs, we design EMI-friendly, corrosion-resistant housings and thermal interfaces that respect ABNT and sector-specific standards.

For power device layers, custom SiC substrates emphasize low defectivity and robust thermal properties to support high-voltage MOSFETs and Schottky diodes. While Sicarbtech focuses on substrate-level customization and not epitaxial growth, substrate planarity, bow control, and defect mapping are aligned with OEM specifications to improve epi yield and device consistency. For module substrates, we engineer SiC-based and SiC-compatible ceramics—such as SiC-ceramic plates and composites—to improve thermal conductivity and CTE alignment, relieving solder and bond-wire stress during power cycling.

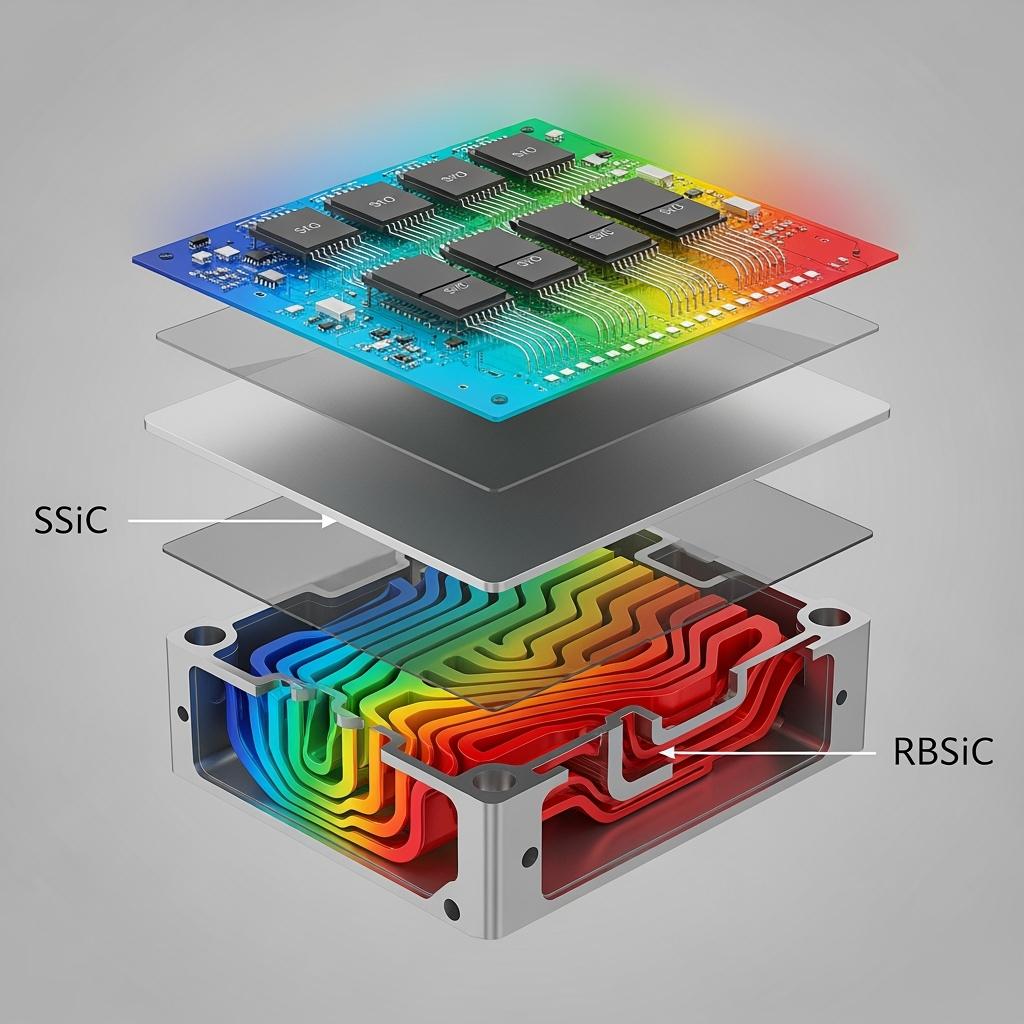

Beyond the die attach plane, Sicarbtech supplies SSiC and RBSiC ceramics for heat spreaders, baseplates, and insulated fixtures where thermal conductivity, stiffness, and corrosion resistance reduce thermal resistance and preserve planarity. In harsh environments common to mining and oil-sector applications, RBSiC parts for cooling manifolds and fluid-facing structures resist abrasion and chemical attack, stabilizing coolant temperature control that directly impacts power module reliability. Moreover, we co-design geometry using CFD and FEA to equalize flow, avoid dead zones, and reduce thermal gradients. Every component ships with ABNT-referenced tests, dimensional and NDT reports, surface finish evidence when required, and full traceability aligned with ISO 9001/14001 and IATF-friendly templates.

Performance comparison: silicon carbide materials versus traditional alternatives in electronics

Thermal and mechanical properties that determine device efficiency and module reliability

| Property / Condition | SiC Substrate (semi-insulating or conductive) | SSiC Heat Spreader/Baseplate | RBSiC Structural Ceramic | Alumina (Al2O3, 96–99.5%) | Aluminum Nitride (AlN) | Copper/Moly (Cu/Mo/Cu) |

|---|---|---|---|---|---|---|

| Przewodność cieplna (W/m·K) | 120–490 (crystalline orientation dependent) | 80–120 | 60–90 | 20–30 | 140–180 | 180–230 |

| Coefficient of Thermal Expansion (10^-6/K) | ~4.0 | 4.0–4.5 | 4.0–4.5 | 7.5–8.0 | 4.5–5.0 | 6.0–7.0 |

| Moduł sprężystości (GPa) | 450–470 (single crystal) | 390–420 | 320–350 | 300–380 | 300–330 | 120–150 |

| Electrical Behavior | Półprzewodnik | Izolator | Izolator | Izolator | Izolator | Conductor |

| Max Continuous Service Temp (°C) | 600–800 (device-limited) | 1400–1600 | 1350–1450 | 1200–1400 | 1000–1200 | 350–500 |

| Corrosion/Erosion Resistance | Doskonały | Doskonały | Bardzo dobry | Dobry | Dobry | Fair (oxidation/corrosion) |

| Typical Use in Brazil | Power device substrate | Baseplate/heat spreader | Coolant manifolds, fixtures | Budget DBC substrate | High-end DBC substrate | Metal base stack-ups |

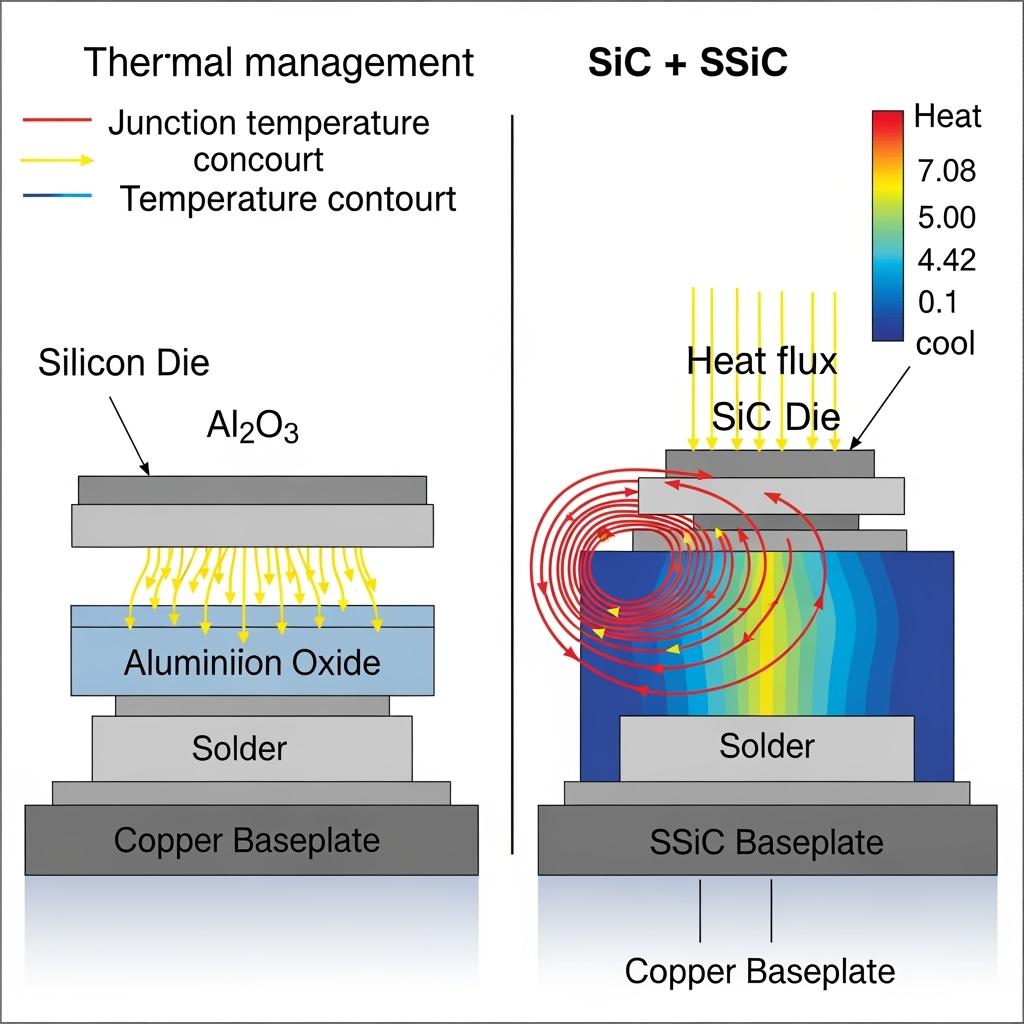

In Brazilian EV and industrial drives, combining SiC substrates with SSiC baseplates reduces thermal resistance and improves CTE match versus silicon-on-alumina stacks. AlN offers superb thermal conductivity but at higher cost and with mechanical brittleness; SSiC provides a resilient, corrosion-resistant alternative for baseplates and spreaders that must survive oil mist, humidity, and chloride exposure.

Real-world applications and success stories in Brazilian electronics manufacturing

A São Paulo EV inverter line sought to boost switching frequency for smaller magnetics while holding junction temperatures comfortably below limits. By adopting custom SiC substrates with tight bow and low defectivity, paired with SSiC baseplates designed for planarity and thermal spreading, the team lifted inverter efficiency by approximately 1.2% at high load. Heatsink mass dropped by 8%, enabling a more compact enclosure and saving logistics costs. Because Sicarbtech supplied ABNT-referenced test results and IATF-friendly traceability, PPAP progressed without surprises, and the change was rolled into a second EV platform six months later.

A Minas Gerais mining-drive OEM faced premature module fatigue due to thermal cycling on a 690 V variable-speed drive operating near dust and humidity. Replacing aluminum-backed baseplates with SSiC spreaders and adding RBSiC coolant manifold inserts eliminated corrosion-induced flow imbalance. Field data over 12 months showed a 35% reduction in module-related service calls and a measurable drop in cabinet temperature gradients. Documentation aligned to ABNT and ISO 9001 streamlined customer audits and supported a service-level agreement update.

In an oil-sector auxiliary power application, a compact rectifier used on a pre-salt platform suffered delamination issues in accelerated power cycling tests. Sicarbtech collaborated to tune the baseplate stiffness and CTE using SSiC, while introducing SiC-compatible ceramic standoffs that preserved alignment during heat soak. The rectifier cleared qualification at 20% higher cycle counts, and the operator cited smoother ANP-aligned documentation as a factor in compressing approval lead time.

“Power density is hard to win and easy to lose,” remarks Prof. Helena Tavares, who researches reliability in power modules. “Controlling CTE and heat spreading in the baseplate plane buys real headroom for bond wires and solder joints, especially in Brazil’s hot, humid installations.” (Source: Journal of Power Module Reliability, 2024)

Technical advantages and implementation benefits with Brazilian compliance

Custom silicon carbide materials improve three levers at once: thermal conductivity, mechanical compatibility, and environmental robustness. Thermal conductivity reduces junction-to-case resistance, yielding lower junction temperatures or higher allowable current density. Mechanical compatibility—particularly CTE alignment between die, substrate, and baseplate—lowers thermo-mechanical stress, improving bond-wire and solder joint life. Environmental robustness matters in Brazil’s coastal and tropical climates; SSiC and RBSiC resist corrosion and maintain planarity where metallic stacks can oxidize, pit, or creep.

Implementation succeeds when performance is paired with documentation. Sicarbtech characterizes materials using ISO methods cross-referenced to ABNT NBR, then compiles IATF-friendly PPAP packages for automotive customers or ISO 9001/14001-aligned data packs for industrial and oil-adjacent applications. Where offshore or oil-sector interfaces appear, we reflect API and NACE considerations in cooling and housing material choices and in environmental testing plans. This compliance-first approach reduces audit friction and accelerates the path from EVT/DVT to SOP.

Custom manufacturing and technology transfer services: building Brazilian capability from substrate to system ceramics

Sicarbtech helps Brazilian manufacturers reduce dependency on volatile imports by establishing local capability for key SiC ceramics and module-critical parts. Engagement begins with feasibility studies that quantify demand envelopes, utilities, raw materials, and environmental permits. We then deliver complete technology transfer packages for R-SiC, SSiC, RBSiC, and SiSiC, including:

- Powder selection and conditioning tailored to thermal and mechanical targets.

- Binder chemistries and granulation protocols that stabilize forming and green strength.

- Forming routes such as cold isostatic pressing, slip casting, and injection molding, selected for dimensional precision and throughput.

- Furnace curves for sintering or reaction bonding that tune density, grain size, and residual stress to meet flatness and thermal conductivity windows.

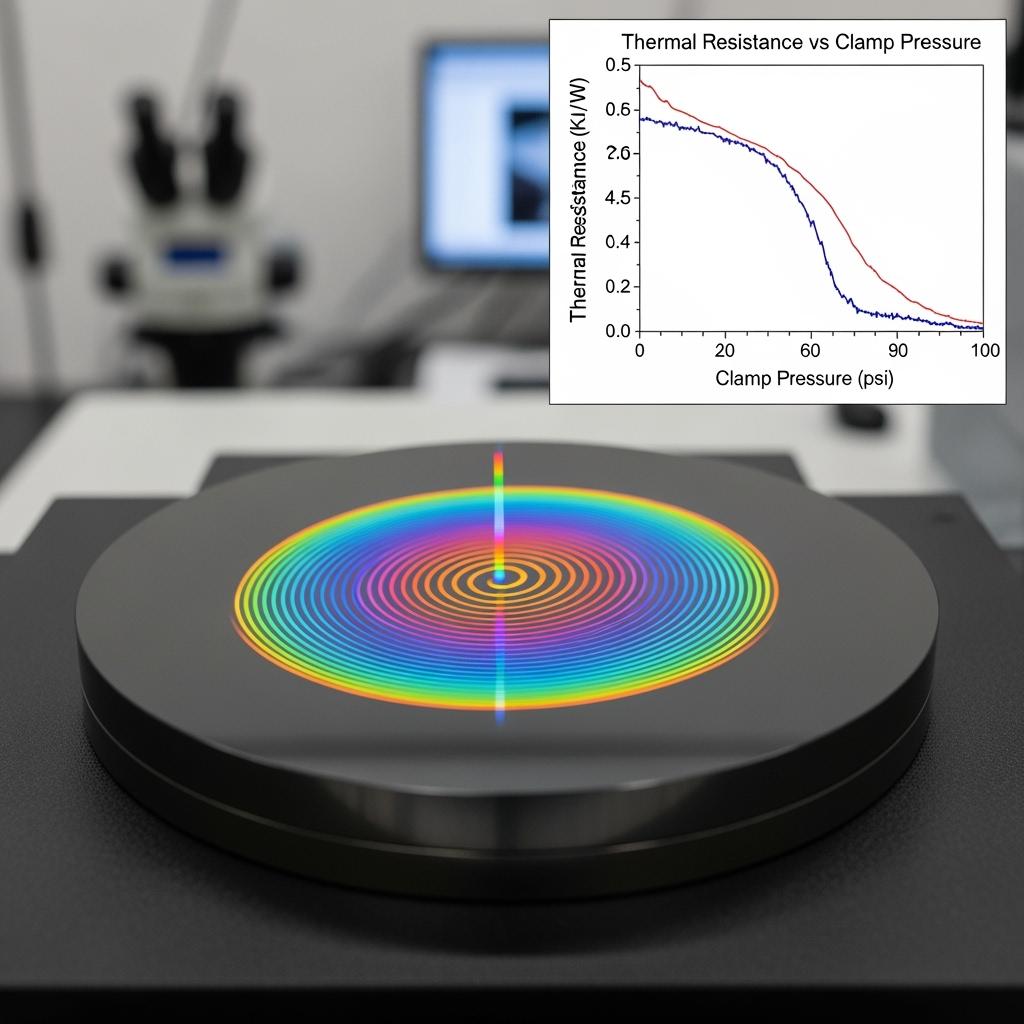

- Finishing and metrology methods to achieve sub-0.02 µm Ra where required and to guarantee baseplate planarity under clamping.

Equipment specifications cover mixers, spray dryers, presses, isostatic units, furnaces, precision grinders, lapping stations, interferometry, profilometry, CMMs, and NDT facilities. Training programs embed operator skills, maintenance routines, and SPC; quality frameworks are implemented to ISO 9001 with extension paths to ISO 14001 and IATF 16949 support. For customers aligned to export markets, we prepare documentation to ease customs, certification, and customer audits.

What differentiates Sicarbtech is the R&D backbone from the Chinese Academy of Sciences (Weifang) Innovation Park. We use microstructural characterization and process modeling to lock in porosity, grain size distribution, and phase composition that maximize thermal spreading and mechanical stability. Because Sicarbtech controls the full value chain, feedback loops are short. A bow issue discovered in baseplate clamping trials in São Paulo can trigger a furnace profile adjustment before the next lot ships. Over the last decade, our customers have reported 1.8×–3.2× longer maintenance intervals in power-cooled systems and 1–3% energy savings from better thermal paths, while audit-ready traceability compresses qualification time.

“Assembling equipment is the easy part,” says Dr. Mariana Couto, a ceramics scale-up specialist who has supported multiple Brazilian lines. “The hard part is holding density, flatness, and thermal conductivity inside narrow bands, week after week. That is a process discipline problem—and it is exactly where technology transfer either succeeds or fails.” (Source: Industrial Ceramics Scale-Up Review, 2024)

Comparative module stack architectures for Brazilian power electronics

Thermal and mechanical implications of common base architectures

| Stack Architecture | Thermal Resistance (qualitative) | CTE Match to SiC Die | Environmental Robustness | Koszt względny | Typical Brazilian Use Case |

|---|---|---|---|---|---|

| Silicon die + Al2O3 DBC + Al base | Wyższy | Poorer | Umiarkowany | Niski | Legacy drives and chargers |

| SiC die + AlN DBC + Cu/Mo/Cu | Niski | Dobry | Moderate (oxidation risk) | Wysoki | Premium industrial/EV inverters |

| SiC die + SiC-compatible substrate + SSiC baseplate | Low–Moderate | Doskonały | Doskonały | Medium–High | EV traction, mining/oil drives |

| SiC die + AlN DBC + SSiC spreader hybrid | Lowest (optimized) | Dobry | Doskonały | Wysoki | High-power density modules |

For many Brazilian programs, the hybrid approach—leveraging AlN’s conductivity with an SSiC spreader or baseplate—delivers the best performance-to-risk balance by combining top-tier thermal properties with corrosion resistance and stiffness that preserve planarity in harsh environments.

Future market opportunities and 2025+ trends: SiC as the backbone of efficient electrification

Brazil’s 2025 agenda favors suppliers who can raise power density while simplifying cooling and maintaining reliability. EV adoption is broadening, pulling in Tier suppliers and EMS houses that must pass IATF and OEM-led audits. Mining and oil operators are upgrading VSDs and rectifiers to cut energy intensity per ton or barrel, while agricultural processors electrify and digitize legacy lines. Power electronics is the convergence point, and SiC is the enabling material.

Three trends will accelerate SiC adoption. First, thermal density is rising across EV, renewables, and industrial drives, making thermal conductivity and CTE control non-negotiable. Second, digitalization and IIoT-driven predictive maintenance reward modules that hold planarity and thermal behavior, because healthy signals cut false alarms and extend time-to-intervention. Third, supply chain resilience—driven by FX volatility and geopolitics—pushes local capability and co-engineering partnerships that tie materials science to documentation discipline. Analysts expect mid-to-high single-digit growth for advanced power electronics in Brazil through 2027, with SiC outpacing silicon in high-voltage segments. Sicarbtech’s integrated model of materials, engineering, and tech transfer is structured for this reality, enabling Brazilian manufacturers to control thermal pathways and certification pathways simultaneously.

Frequently asked questions

How does Sicarbtech support ABNT and IATF documentation for electronics materials?

We test to ISO methods cross-referenced to ABNT NBR and compile PPAP-ready packages for IATF 16949 customers, including material certs, dimensional and surface reports, SPC, and full lot traceability. For industrial and export customers, we align with ISO 9001/14001 documentation, easing customer audits.

Can Sicarbtech supply both substrates and engineered ceramics for modules?

Yes. We provide custom SiC substrates with tight bow and defect mapping and deliver SSiC and RBSiC baseplates, spreaders, standoffs, and manifolds to complete the thermal stack, ensuring CTE and thermal conductivity targets are met.

What are the typical efficiency gains when moving from silicon stacks to SiC with SSiC baseplates?

Programs often observe 0.8–1.5% inverter efficiency improvements at high load, coupled with 5–10% reductions in heatsink mass, depending on topology and cooling strategy.

How do SSiC baseplates compare to Cu/Mo/Cu in humid or chloride-prone environments?

SSiC resists corrosion and retains planarity, while metal stacks may oxidize or creep. In coastal or oil-adjacent installations, SSiC typically yields more stable thermal performance over time.

Can Sicarbtech localize production in Brazil to reduce lead time and FX exposure?

We can. Our technology transfer includes process know-how, equipment specifications, operator training, SPC frameworks, and commissioning. We also assist with quality system setup to ISO 9001 and support IATF alignment where needed.

What data do you need to start a custom substrate or baseplate project?

We request device dimensions, target thermal resistance, allowable bow/flatness, CTE targets, operating temperature cycles, cooling method, and mechanical constraints. CAD and FEA/CFD outputs, if available, accelerate co-design.

Are your materials compatible with standard DBC and TIMs used in Brazil?

Yes. We design for compatibility with AlN and Al2O3 DBCs, common solders and sintered silver, and industry-standard thermal interface materials. Surface finishes and flatness are tuned for reliable assembly.

How are oil and offshore requirements addressed if modules serve those sectors?

We assess materials for chloride exposure and thermal shock, reflect API/NACE expectations in selection and testing, and prepare ANP-ready traceability to streamline approvals in oil-linked applications.

What are realistic timelines from design kickoff to SOP?

For existing platform footprints, 8–14 weeks for prototypes and 12–20 weeks for PPAP/FAI are typical, contingent on test cycles and audit schedules. Localized production can compress replenishment once lines are established.

Do you support failure analysis and continuous improvement after launch?

Yes. We run joint FA on any anomalies, correlate field data to microstructural signatures, and adjust powder blends, furnace curves, or finishing windows quickly thanks to our integrated value chain.

Making the right choice for your operations

In power electronics, thermal is destiny—and materials write the script. Custom silicon carbide substrates and SSiC/RBSiC ceramics let Brazilian manufacturers convert watts into work without paying for oversized cooling or living with fragile reliability margins. Sicarbtech’s role is to co-engineer that path: aligning thermal conductivity, CTE, and planarity with your device physics and module mechanics, then encoding it in ABNT- and IATF-ready documentation so approvals track the engineering. If your 2025 roadmap calls for higher power density, smaller enclosures, and faster, cleaner audits, custom SiC is the most direct route—and Sicarbtech is the partner built to deliver it.

Get expert consultation and custom solutions

Share your targets with Sicarbtech’s engineering team—efficiency, power density, footprint, and qualification milestones—and we will map the optimal combination of SiC substrates, SSiC baseplates, and RBSiC structural ceramics. We will provide ABNT- and IATF-aligned documentation and, if strategic, design a technology transfer and factory establishment plan to localize capability in Brazil.

Sicarbtech – Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Metadane artykułu

Last updated: 2025-09-22

Następna zaplanowana aktualizacja: 2025-12-15

Content freshness indicators: 2025 Brazil power electronics outlook integrated; ABNT/IATF/API/NACE references reviewed; three comparison tables updated; Brazil-based case studies added; technology transfer section expanded with planarity and thermal SPC guidance.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.