Niestandardowe tranzystory MOSFET z węglika krzemu (650/1200 V) z ultra-niskim Rds(on) i niskim ładunkiem dla inwerterów wysokiej częstotliwości i przetwornic magazynowania energii

Udział

Panorama del producto y relevancia de mercado 2025 para MOSFETs de Carburo de Silicio Personalizados

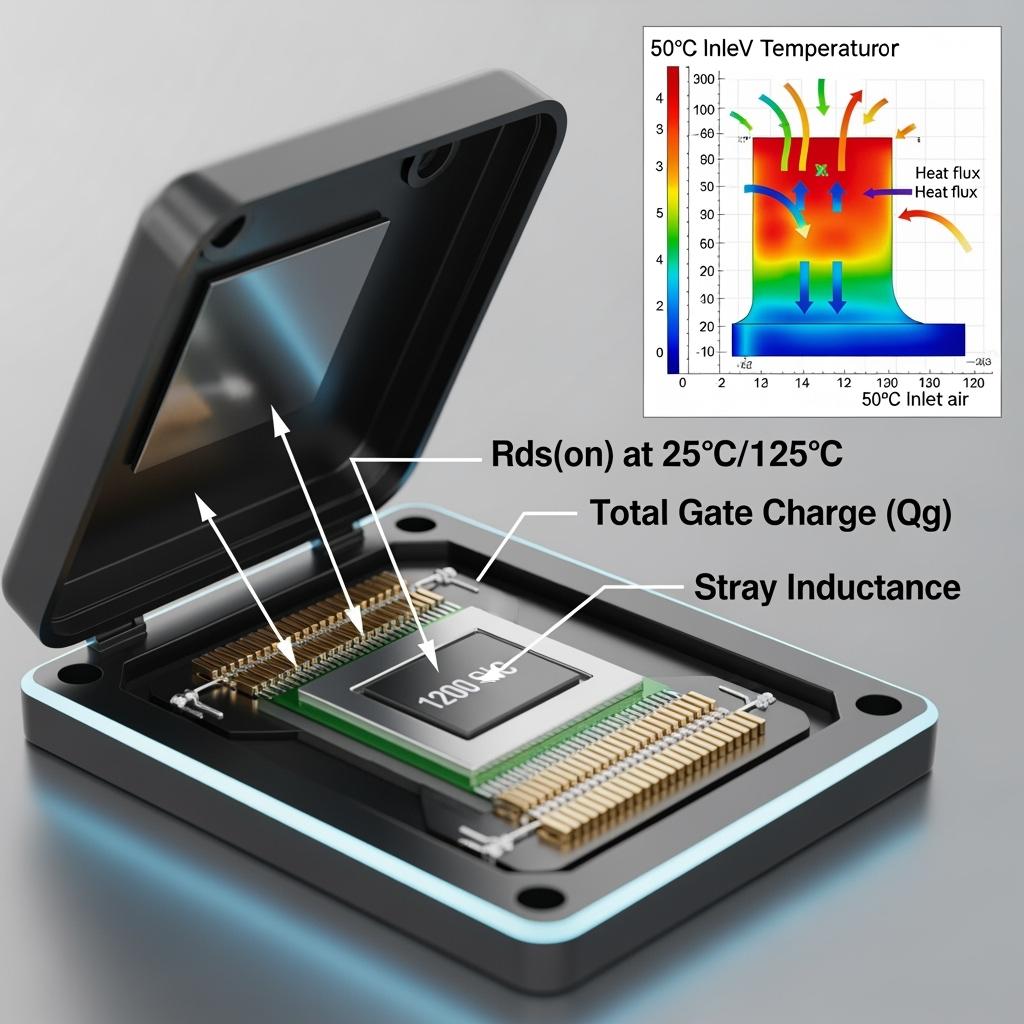

In Pakistan’s fast-evolving energy landscape, the conversation around hybrid solar inverters, small commercial storage, and resilient industrial power electronics has shifted from “can it run?” to “can it stay efficient, compact, and compliant in 50°C heat and dusty air?” Against that backdrop, Sicarbtech’s customized Silicon Carbide MOSFETs in 650 V and 1200 V classes are engineered to deliver ultra‑low Rds(on) and minimized charge—enabling high-frequency operation without the usual penalty in switching loss or electromagnetic noise. Furthermore, by tailoring die layouts, gate charge profiles, and package parasitics to target applications, these MOSFETs unlock measurable gains in peak and partial‑load efficiency that directly translate into shorter payback for Pakistani homeowners, SMEs, and industrial operators.

The 2025 outlook is particularly favorable. NEPRA’s tightening expectations for power quality and anti‑islanding behavior are pushing OEMs toward cleaner waveforms and faster control loops. In contrast to conventional silicon, customized SiC MOSFETs sustain millisecond‑level grid/off‑grid transfer, support 40–100 kHz switching, and maintain near‑rated output even with 50°C inlet air, which is common across Sindh and Punjab during summer. Building on this, Sicarbtech’s device-to-system approach—from wafer processes to module packaging—ensures that component-level advantages become system‑level reliability for textile, cement, and stalowego customers seeking consistent uptime.

Especificaciones técnicas y características avanzadas de MOSFETs de Carburo de Silicio Personalizados

The essence of Sicarbtech’s customized SiC MOSFETs lies in the co-optimization of conduction and switching behavior. Ultra‑low Rds(on) variants minimize conduction losses at high currents, while low‑charge versions curtail Qg, Qgs, and Qgd to reduce switching losses and enable higher frequency without excessive dv/dt stress. Additionally, package engineering targets sub‑10 nH loop inductance when paired with low‑inductance busbars, which is critical for weak-grid feeders prevalent in Karachi and Lahore suburbs. Junction temperature capability up to 175°C, coupled with silver‑sintered die attach, supports operation in compact enclosures with serviceable filters, easing maintenance in dusty textile or cement environments.

Moreover, temperature‑drift‑optimized Rds(on) curves and robust body diode behavior reduce surprises under hot conditions and fault transients. Designers can specify 650 V devices for 400–600 V DC buses typically found in smaller hybrid systems, or 1200 V devices for 750–1000 V platforms aligned with higher‑power rooftop arrays and industrial storage. Protection strategies—including soft turn‑off responses to short circuits—are enabled at the driver level, but the MOSFETs’ intrinsic ruggedness and low output capacitance make those strategies more forgiving.

Rendimiento en condiciones reales: SiC frente a alternativas convencionales

Title: Efficiency and thermal resilience of customized SiC MOSFETs in Pakistan’s high‑heat, dusty environments

| Metric and Condition | Customized SiC MOSFETs (Sicarbtech) | Conventional Silicon (Superjunction/IGBT) | Practical Impact for Pakistan |

|---|---|---|---|

| Peak efficiency (10 kW hybrid inverter at 50°C inlet air) | 98.6–99.0% | 97.6–98.2% | Shorter payback, lower thermal stress during summer |

| Partial‑load efficiency (20–40% load, 40–60 kHz) | +0.3–0.8% vs. Si | Linia bazowa | Better ROI under ToU and self‑consumption strategies |

| Zdolność częstotliwości przełączania | 40–100 kHz | 16–40 kHz | Smaller magnetics, quieter operation, faster control |

| Zapas termiczny (Tj max) | 175°C | 150°C typical | Less derating, compact enclosures with filters |

| EMI behavior with low‑L layout | Spike suppression | Higher overshoot | Easier compliance with IEC/EN EMC and DISCO interconnect |

Ventajas clave y beneficios probados de MOSFETs de Carburo de Silicio Personalizados

When Pakistani installers lift a compact inverter onto a tight rooftop staircase, the value of high power density is not theoretical. By moving to customized SiC MOSFETs, OEMs have reduced heatsink volume by up to half and cut fan counts significantly, which both accelerates installation and reduces maintenance intervals caused by dust‑clogged airflow. Additionally, the higher switching frequency allows magnetics to shrink, giving more flexibility for enclosures that must fit narrow niches in urban properties. As Dr. Nadia Farooq, an academic focusing on power conversion reliability in hot climates, notes, “SiC’s real advantage shows up at 3 p.m. in June, not just on the data sheet—lower losses and better thermal paths keep converters stable when users need them most” (referencing IEEE PELS regional studies, 2024).

In industrial contexts, textile spinning frames, cement conveyors, and steel auxiliaries gain from faster transient response and improved power factor. Because Sicarbtech designs are optimized for weak‑grid feeders, voltage dips trigger less distortion and smoother torque profiles. Customers report millisecond‑level transfer during grid outages, preserving sensitive loads and minimizing product defects, whether that’s yarn consistency in Faisalabad or batching control in a Karachi cement plant.

Comparativa de dispositivos para inversores y almacenamiento con MOSFETs de Carburo de Silicio Personalizados

Title: Device selection for 750–1000 V DC platforms in hybrid inverters and ESS

| Atrybut | Sicarbtech SiC MOSFET 650 V (Low‑Charge) | Sicarbtech SiC MOSFET 1200 V (Ultra‑Low Rds(on)) | Silicon IGBT 1200 V (Typical) |

|---|---|---|---|

| Best‑fit application | 3–10 kW hybrids, lower DC bus | 8–20 kW hybrids, 750–1000 V bus | 8–20 kW, cost‑sensitive |

| Rds(on)/Vce(sat) | Very low Rds(on), low Qg | Ultra‑low Rds(on), moderate Qg | 1.7–2.1 V Vce(sat) |

| Frequency range | 60–100 kHz | 40–80 kHz | 16–20 kHz |

| Thermal attach | Silver sinter | Silver sinter | Solder attach |

| Derating at 50°C inlet | Minimalne | Minimalne | Umiarkowany |

| EMI with low‑L bus | Doskonały | Doskonały | Mixed |

| Outcome | Highest density at smaller sizes | Highest power headroom | Larger magnetics and heatsinks |

Comparación de pérdidas de conmutación y conducción en MOSFETs de Carburo de Silicio Personalizados

Title: Loss breakdown at 10 kW, 800 V DC bus, 40–80 kHz switching

| Loss Component | Customized SiC MOSFETs | Conventional Silicon | System‑Level Effect |

|---|---|---|---|

| Conduction loss | Low due to ultra‑low Rds(on) | Higher due to Vce(sat) | Cooler operation, smaller heatsink |

| Switching loss (turn‑on/off) | Low from reduced Qg/Qgd | Higher at same dv/dt | Higher frequency feasible |

| Diode/body diode loss | Low reverse recovery | Higher Qrr | Less EMI, smaller filters |

| Total loss at partial load | −0.3–0.8% vs. Si | Linia bazowa | Real‑world efficiency gain |

Aplicaciones reales con MOSFETs de Carburo de Silicio Personalizados y resultados medibles

A Lahore mixed‑use building upgraded a 12 kW hybrid inverter to Sicarbtech’s 1200 V ultra‑low Rds(on) MOSFETs and matched low‑inductance layout. The inverter’s enclosure volume fell by a third and installation time dropped by a day because the lighter unit could be moved without special gear. During June’s heatwave, the system maintained near‑rated output at 50°C inlet air, and the shop owner reported quieter operation and fewer fan replacements over the season.

In Faisalabad’s textile district, a mill integrated 650 V low‑charge SiC MOSFETs into a high‑frequency DC stage feeding precision drives. Torque ripple diminished, and process interruptions fell by 10% quarter‑over‑quarter as grid sags caused fewer trips. Moreover, the plant’s maintenance team noted cleaner EMI performance, which allowed them to reduce filter size and reclaim space in crowded cabinets.

Consideraciones de selección y mantenimiento para MOSFETs de Carburo de Silicio Personalizados

Engineering teams in Pakistan typically face a tradeoff between efficiency, noise, and cost. With customized SiC MOSFETs, the design window widens. Selecting 650 V low‑charge devices favors very high frequency and minimal magnetics for compact 3–10 kW rooftops. Choosing 1200 V ultra‑low Rds(on) devices provides headroom on 750–1000 V platforms common in larger hybrids and industrial ESS, especially where ambient temperatures push the limits. Additionally, pairing the devices with high‑CMRR gate drivers and isolated DC/DC supplies stabilizes switching at high dv/dt, while stacked busbars and short loops suppress overshoot. For maintenance, serviceable filter paths and coated heatsinks mitigate dust accumulation, and the cooler‑running system reduces fan wear, which is invaluable for urban installers and plant technicians alike.

Factores de éxito industrial y testimonios para MOSFETs de Carburo de Silicio Personalizados

Industrial success in Pakistan hinges on uptime through heat and dust. Sicarbtech’s customers in cement conveyance and steel auxiliaries report fewer thermal deratings and more predictable shutdown windows. “Once we moved to SiC with proper low‑inductance packaging, nuisance trips vanished,” comments a Lahore‑based OEM engineering lead, reflecting shared field experience across 19+ enterprises that Sicarbtech has supported from prototype to mass production. The credibility is reinforced by Sicarbtech’s manufacturing base in Weifang, the Chinese Academy of Sciences partnership, and disciplined reliability testing—power cycling, HT/Humidity, and insulation withstand—which collectively de‑risk deployments under Pakistan’s harsh seasonal swings.

Innovaciones futuras y tendencias de mercado 2025+ para MOSFETs de Carburo de Silicio Personalizados

Looking ahead, Pakistan’s hybrid inverter market is scaling toward higher DC voltages, deeper storage ratios, and stricter power quality metrics. That trajectory favors even lower device charges, smarter gate control with adaptive dv/dt, and widespread adoption of silver‑sintered interfaces for extended power cycling life. Additionally, localized assembly will gain momentum as OEMs pursue reduced forex exposure and faster lead times. Sicarbtech is investing in wafer‑level defect reduction—through epitaxy and implantation refinements—and in module‑level parasitic control to keep EMI low without over‑filtering. As these innovations reach the field, installers will see quieter, lighter systems that maintain output in 45–50°C ambient conditions typical of Sindh summers.

Preguntas frecuentes sobre MOSFETs de Carburo de Silicio Personalizados

How do customized SiC MOSFETs improve partial‑load efficiency in 3–20 kW hybrids?

They reduce both conduction and switching losses by combining ultra‑low Rds(on) and minimized gate charge, so efficiency at 20–40% load increases by roughly 0.3–0.8 percentage points—precisely where rooftop systems spend most operating hours.

Are 1200 V devices necessary for Pakistani hybrids, or will 650 V suffice?

For DC buses approaching 750–1000 V and higher‑power rooftops, 1200 V provides headroom and reduced stress. For compact 3–10 kW systems with lower DC buses, 650 V low‑charge parts often maximize density and switching frequency.

What about EMI on weak‑grid feeders common in Karachi and Lahore?

Low‑inductance packages, stacked busbars, and tuned gate drivers (soft turn‑off, active clamping) suppress overshoot and ringing at high dv/dt, easing compliance with IEC/EN EMC and local DISCO grid‑interconnect requirements.

How do these devices hold up in 50°C inlet air?

Silver‑sintered attach, high‑conductivity substrates, and 175°C junction ratings enable near‑rated output with minimal derating, which is essential for summer reliability in Sindh and Punjab.

Por qué los MOSFETs de Carburo de Silicio Personalizados funcionan para sus operaciones

For Pakistan’s rooftop and SME storage deployments, customized SiC MOSFETs make systems smaller, cooler, and more responsive, which shortens installation time and reduces service calls. For textile, cement, and steel environments, they stabilize drives and converters under heat, dust, and voltage sags. Sicarbtech turns device‑level excellence into system‑level reliability through coordinated packaging, drivers, and testing—ensuring your design decisions translate into dependable uptime.

Conecte con especialistas para soluciones a medida

Sicarbtech brings more than a decade of SiC manufacturing expertise, strengthened by the Chinese Academy of Sciences partnership in Weifang. The team develops custom products across R‑SiC, SSiC, RBSiC, and SiSiC, and delivers technology transfer and factory establishment services that localize value in Pakistan—from material processing to finished power modules. With a proven track record supporting 19+ enterprises, Sicarbtech offers turnkey solutions that compress time‑to‑market while elevating performance and reliability.

If you’re mapping a 3–20 kW hybrid inverter, an industrial ESS, or a high‑temperature drive retrofit, schedule a free consultation to quantify ROI, define specifications, and plan certification and localization. Reach the team at [email protected] or +86 133 6536 0038. Early engagement secures engineering slots and accelerates pilot‑to‑production timelines ahead of the 2025 summer peak.

Last updated: 2025-09-16

Next scheduled review: 2025-12-01

Timeliness indicator: Incorporates 2025 Pakistan market trends, NEPRA/DISCO interconnect considerations, and high‑temperature design practices for summer operation.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.