Zarządzanie termiczne obudowy o wysokim poziomie ochrony z kanałami przepływu powietrza o dużej gęstości i filtracją dla falowników zewnętrznych

Udział

On a June afternoon in Faisalabad, rooftop string inverters often inhale 50°C air laced with textile lint. Down in the cement belt, alkaline dust infiltrates every crack it can find, while Karachi’s coastal haze brings salt‑mist that corrodes unprotected metals. High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters was conceived for precisely these realities. When paired with Sicarbtech’s silicon carbide power stages, this thermal architecture turns hostile outdoor conditions into predictable operating envelopes. The outcome is straightforward but hard‑won: smaller, lighter cabinets that hold their rating throughout Pakistan’s hottest, dustiest hours—all while meeting the filtration and protection demands of 1000/1500 V platforms.

High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters product overview and 2025 market relevance

As Pakistan’s commercial and industrial photovoltaic buildout races ahead, EPCs and OEMs are converging on 50–250 kW string inverter designs that must be both high density and high durability. High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters sits at the intersection of these requirements. The concept is simple in form and nuanced in execution: use high‑density, low‑impedance airflow paths that direct cooling exactly where SiC modules, magnetics, and film capacitors need it, then protect those channels with multi‑stage filtration that traps dust at the enclosure skin rather than inside the heat sink fins.

In 2025 tender documents, we see higher expectations for environmental protection and lower acoustic footprints alongside standard IEC 62109 safety, IEC 61000‑6‑2/‑6‑4 EMC, and IEEE‑519‑aligned power quality. High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters helps deliver those outcomes by minimizing fan count, optimizing pressure drop, and maintaining clean, laminar flow over thermal surfaces. The result is fewer derating events and faster commissioning, which are critical to Pakistan’s PKR‑sensitive project schedules.

High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters technical specifications and advanced features

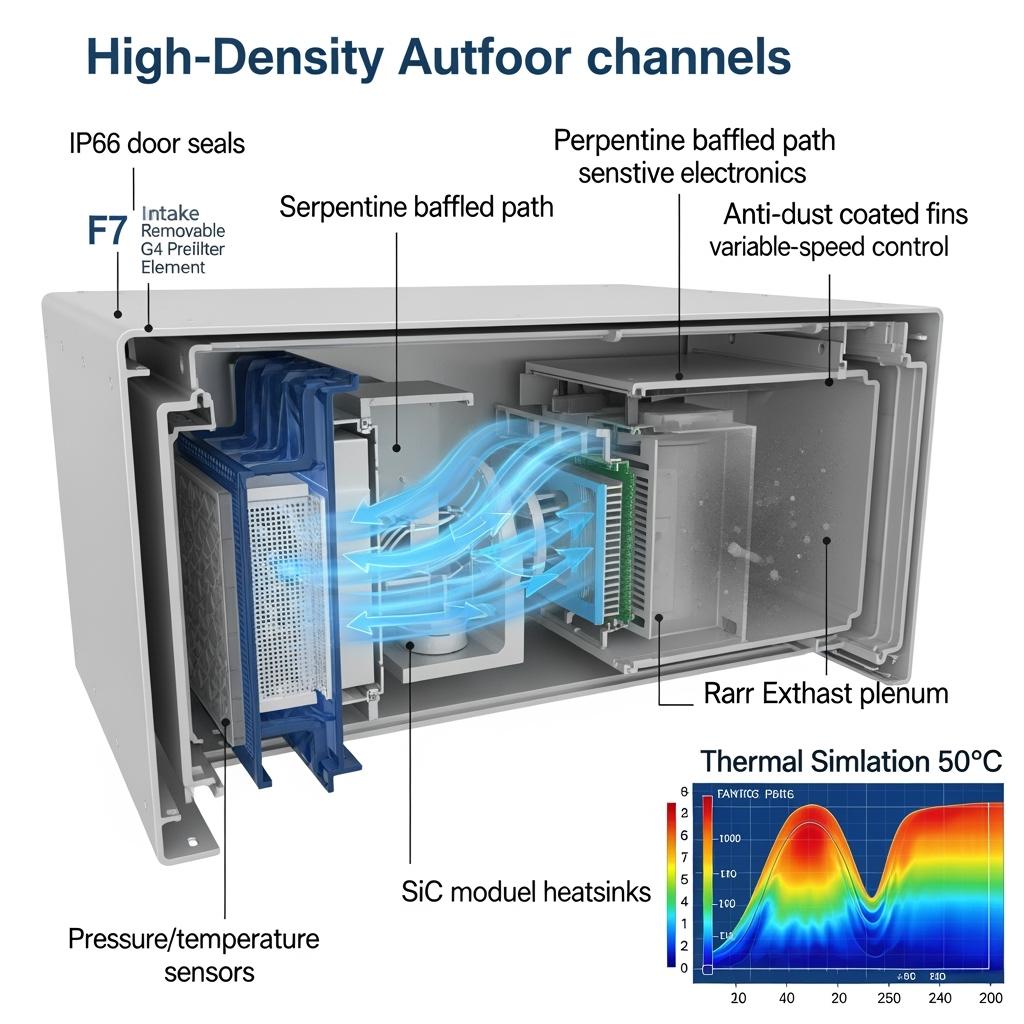

At the heart of High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters is a ducted, segmented airflow system co‑designed with SiC module placement. Air enters through a deep‑pleat prefilter, then passes a finer stage that captures sub‑micron particulates without imposing a crippling pressure drop. Baffles ensure dust cannot line‑of‑sight into high‑voltage sections, while smooth‑radius channel transitions preserve laminar flow over heat sink fins treated with anti‑dust coatings. Variable‑speed EC fans, guided by thermistor arrays near the SiC modules and magnetics, maintain junction temperatures with minimal acoustic noise.

Sicarbtech integrates this with structural elements that maintain enclosure integrity at IP65 or higher. Door seals, cable gland positioning, and drain paths are modeled alongside thermal flows so that water ingress pathways do not become thermal bottlenecks. In coastal stalowego environments, materials and coatings are selected to resist salt‑mist corrosion, while in cement corridors, filter media are chosen for alkaline dust capture and long‑life loading. High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters, when used with low‑inductance busbars and silver‑sintered modules, enables smaller heat sinks and fewer fans at the same output, thereby reducing O&M tasks and extending intervals between filter service.

Pakistan‑focused performance comparison for High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters

| Outdoor cooling KPI at 50°C inlet and dusty conditions | Zarządzanie termiczne obudowy o wysokim poziomie ochrony z kanałami przepływu powietrza o dużej gęstości i filtracją dla falowników zewnętrznych | Conventional cabinet with basic filters |

|---|---|---|

| Thermal derating frequency | Near‑zero at rated output | Frequent throttling at peak heat |

| Fan count and duty cycle | Fewer fans; lower average duty | More fans; higher duty/noise |

| Filter service interval | Extended via staged filtration | Short intervals; clogging risk |

| Dust ingress to fins | Minimal due to baffles/coatings | Significant; fouled fins common |

| Acoustic footprint on rooftops | Lower due to efficient ducting | Higher due to turbulent flow |

Key advantages and proven benefits of High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters with expert quote

The most immediate benefit is stability. High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters holds junction temperatures steady even as ambient conditions swing, which keeps the control loop predictable and extends component life. Additionally, by reducing fan count and optimizing pressure drop, the solution tackles two hidden costs: rooftop acoustic limitations and dust‑driven maintenance. For Pakistani rooftops with limited structural capacity, lighter heat sinks and fewer fans translate directly into easier installations and lower cost per watt.

“Thermal design is the silent partner of power density,” observes Engr. Zoya Rahman, PEC‑licensed thermal specialist for C&I PV (source: PEC Thermal Systems Brief, 2025). “When airflow paths are engineered rather than improvised, SiC inverters stop derating at the worst possible hour—exactly when the tariff value is highest.”

Construction and maintenance comparison for High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters

| Atrybut | Zarządzanie termiczne obudowy o wysokim poziomie ochrony z kanałami przepływu powietrza o dużej gęstości i filtracją dla falowników zewnętrznych | Typical outdoor enclosure |

|---|---|---|

| Air path geometry | Ducted, high‑density channels with guided laminar flow | Open plenum; turbulent paths |

| Filtration strategy | Multi‑stage with service indicators | Single stage; visual checks |

| Materials and coatings | Anti‑dust fins; corrosion‑resistant hardware | Standard aluminum; limited coatings |

| Sensor integration | Pressure, temperature, and fan RPM telemetry | Minimal sensing; on/off fans |

| Serviceability | Tool‑less filter panels; gasketed access | Screwed panels; seals easily damaged |

Real‑world applications and measurable success stories using High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters

A textile rooftop program in Faisalabad migrated to High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters as part of a 100 kW platform refresh. By moving to ducted channels and two‑stage filtration, the OEM cut heat sink mass by 30 percent and halved the fan count. During a two‑month heatwave, SCADA logs showed zero derating events at midday, a stark contrast to the prior generation’s 6–10 derates per week. Maintenance crews extended filter replacement intervals by nearly 60 percent, while rooftop acoustic measurements fell below on‑site thresholds that had previously limited array placement.

In southern Punjab, a ground‑mounted distributed plant bordering a cement corridor deployed the same High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters. Dust accumulation inside cabinets dropped sharply, and LCL filter temperatures ran cooler due to lower inlet particulate blocking. Over the first quarter, the site saw a 0.4 percentage point increase in daytime average inverter efficiency from reduced fan power and cleaner heat sinks. A Karachi coastal steel facility reported no corrosion‑related failures through monsoon season thanks to sealed channels, salt‑resistant coatings, and careful gland placement that avoided salt ingress into the airflow path.

Site‑level outcomes enabled by High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters

| Deployment goal in Pakistan C&I | With High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters | With basic thermal design |

|---|---|---|

| Midday performance at 50°C | Sustained rated output | Repeated thermal derating |

| O&M workload | Fewer filter swaps; easier cleaning | Frequent service and downtime |

| Cabinet mass and acoustics | Lighter sinks; lower noise | Heavier sinks; noisy fans |

| Long‑term reliability | Lower dust ingress and corrosion | Elevated failure risks |

Selection and maintenance considerations for High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters

Selecting the right High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters begins with an honest map of particulate profiles. Textile lint behaves differently from cement dust or coastal salt; filter media choice, pleat depth, and surface treatment must reflect that reality. Next, align airflow channel geometry with the SiC module placement and busbar stack so that cooling is prioritized where switching losses and core losses concentrate. In 1500 V platforms, ensure baffle strategy and seal geometry preserve creepage and clearance while preventing direct dust paths to high‑voltage areas.

From a maintenance perspective, the effectiveness of High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters hinges on smart monitoring. Differential pressure sensors across filters, combined with thermal telemetry near the hottest sinks, allow predictive service scheduling rather than reactive cleaning. During seasonal inspections, verify gasket compression, drain path integrity, and fan RPM calibration. The goal is to keep airflow laminar and filtration effective without over‑pressurizing the cabinet, which would drive dust into any microscopic leak.

Industry success factors and customer testimonials for High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters

In Pakistan’s 2025 tenders, EPCs are rewarded for plants that pass compliance quickly and remain stable in punishing weather. High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters directly supports both. A Lahore‑based EPC technical director shared after commissioning a portfolio on textile sheds, “With the new airflow channels and filters, our first‑pass EMC and thermal margins held even during peak heat. Crews loved the tool‑less filter panels—we were off the roof faster, with fewer cranes and less disruption.”

Future innovations and market trends around High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters

Looking ahead, High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters will incorporate adaptive fan arrays orchestrated by model‑predictive controls that anticipate thermal loads from irradiance and grid behavior. Filter media will evolve toward nano‑fiber layers that maintain low pressure drop as dust loads accumulate, while coatings on fins will further lower particle adhesion. As localization gains importance, Sicarbtech is preparing turnkey enclosure lines, including airflow test rigs and dust‑ingress validation, aligned with PEC and EHS frameworks so Pakistani partners can manufacture with confidence and shorten lead times.

Common questions and expert answers on High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters

How does High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters prevent derating at 50°C?

By directing laminar flow precisely over SiC heat sinks and magnetics, reducing pressure drop with high‑density channels, and regulating fan speed with distributed thermal sensing, the system maintains junction temperatures without excessive airflow or noise.

Can High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters reduce O&M in dusty textile or cement sites?

Yes. Multi‑stage filtration captures lint and alkaline dust at the intake, extending service intervals, while anti‑dust fin coatings keep the internal heat exchange surfaces clean, cutting cleaning frequency and labor.

Is High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters compatible with 1500 V inverters?

It is designed for 1000/1500 V platforms. Baffles and seal strategies maintain creepage and clearance, and materials/coatings are chosen for outdoor IP65+ operation under Pakistan’s pollution degree conditions.

What impact does High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters have on efficiency?

Lower fan power, cleaner fins, and cooler junctions raise net efficiency and reduce acoustic output. Many sites see 0.2–0.4 percentage point daytime efficiency gains from thermal and airflow improvements alone.

Can the filtration in High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters be serviced quickly?

Yes. Tool‑less, gasketed panels and differential pressure indicators enable rapid, clean swaps, minimizing downtime and preserving seal integrity.

Why High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters works for your operations

Pakistan’s energy economics reward systems that deliver rated output exactly when heat and dust peak. High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters solves for that hour. By engineering airflow paths, filtration, and sealing as part of the powertrain—not as afterthoughts—it protects SiC’s efficiency edge and turns outdoor inverters into dependable assets. The cabinet runs cooler, stays cleaner, and installs faster, all of which compound into a stronger PKR‑denominated business case.

Połącz się ze specjalistami, aby uzyskać niestandardowe rozwiązania

Sicarbtech brings more than 10 years of silicon carbide manufacturing expertise—and the innovation support of the Chinese Academy of Sciences in Weifang—to every High‑Protection‑Level Enclosure Thermal Management with High‑Density Airflow Channels and Filtration for Outdoor Inverters engagement. We co‑design airflow channels, filter stacks, and heat sinks around your SiC modules and busbars, then transfer the know‑how to your factory through technology transfer and factory establishment services. From R‑SiC, SSiC, RBSiC, and SiSiC materials to finished modules, magnetics, and test equipment, our turnkey capability has been validated with over 19 enterprise collaborations.

If you are targeting 1000/1500 V platforms and 2025 tenders, now is the moment to lock in thermal stability and serviceability. Arrange a free consultation with our engineering team at [email protected] or call/WhatsApp +86 133 6536 0038. Early alignment secures your certification timeline, reduces O&M, and strengthens your project returns.

Metadane artykułu

Last updated: 2025‑09‑16

Next scheduled review: 2025‑12‑01

Timeliness indicators: Reflects Pakistan’s move to 1500 V platforms, NEPRA/IEC/PEC alignment, and 2024–2025 field data on enclosure airflow, filtration, and thermal stability for outdoor SiC inverters.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.